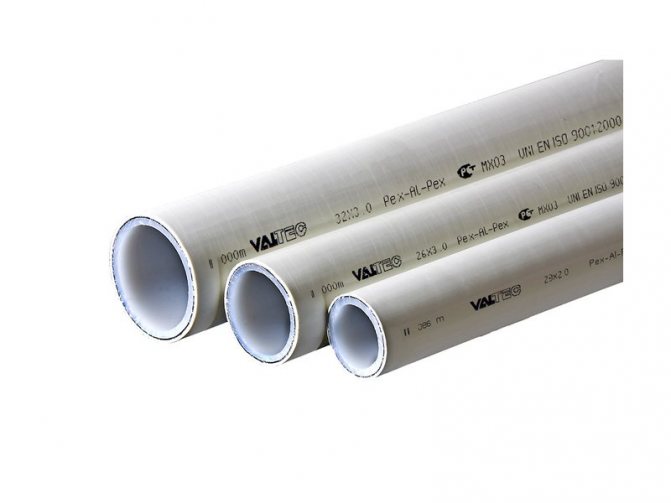

In order to conduct a hot water supply and heating system in the house, many use metal-plastic pipes. This equipment, which demonstrates a high level of efficiency, has the necessary hydraulic and thermal characteristics necessary for efficient operation. therefore metal-plastic pipes for heating, reviews of which are presented in this article, are so common

.

Advantages of pipes made of metal-plastic

Advantages of pipes made of metal-plastic

- they are resistant to corrosion;

- they can be easily bent, therefore, metal-plastic is often used in rooms with complex geometry;

- resistant to temperature extremes;

- pipes have a low noise level when water moves;

- metal-plastic is characterized by a small linear elongation when heated;

- pipes are easy to install, they can be laid both on the wall and on the floor;

- they have a low specific weight and large footage in bays (up to 500 m), which allows laying a pipeline in areas without the use of connections;

- the surface of the pipes is chemically inert, so the risk of mold growth is minimized;

- long service life (more than 20 years);

- acceptable price.

Disadvantages of a metal-plastic pipeline

In addition to a large number of advantages, this material also has its disadvantages:

- polymer pipes are afraid of open fire and mechanical stress;

- metal-plastic is not recommended to be kept in direct sunlight, ultraviolet light has a detrimental effect on the surface of the pipes;

- during installation, there may be some problems with the connection, the inner diameter of the thread of the fitting is smaller than that of the pipe, so the holes can overgrow over time;

- during the installation of the threaded fitting, there is a possibility of the pipe being pinched by the nut, which can lead to rupture;

- metal-plastic is afraid of kinks, crushing, chemically active substances.

Which is better - metal-plastic or polypropylene

The choice between polypropylene and metal-plastic depends on many factors. For example, on how the installation is carried out. If the owner of the house performs such work on his own, it is better to dwell on metal-plastic. Fittings for pipes made of this material are easier to install yourself using only a spanner wrench.

If specialists are engaged in the device of autonomous water supply, they will recommend polypropylene products. This will be a good choice, since such fittings are cheaper than metal-plastic ones, and professionals have the equipment necessary for installation.

With a closed gasket (for example, in grooves or inside walls), it is better to use reinforced polypropylene products, mainly because of the one-piece joints. Threaded fittings, such as those used for reinforced plastic products, weaken over time, resulting in a loss of tightness.

Press fittings for hot water partially solve the problem. At high temperatures, it is initially better to use metal-plastic, since it can withstand temperatures up to + 110 ° С, while polypropylene has a limit of possibilities - 95 ° С.

Reinforced-plastic products should be used where the most important criterion is the durability of the system, since the service life is longer. They will definitely serve for several decades. For pipelines with pressures above 10 atm, reinforced polypropylene products are chosen, trying to use the minimum number of detachable connections.

Features of the structure of pipes. Specifications

Water supply and heating metal-plastic pipes are composed of 5 layers:

- inner polyethylene makes the product smooth, and also prevents the growth of bacteria and the accumulation of harmful substances;

- 2 adhesive layers connect aluminum and polymer;

- aluminum foil, which gives the pipeline hydraulic resistance and oxygen impermeability;

- the outer layer of polyethylene endows the pipeline with high temperature resistance, and also protects against mechanical stress.

Reinforced-plastic pipes do not contain substances harmful to the human body, therefore, such a pipeline is used in drinking water supply systems.

In order to install heat channels in accordance with all the rules, you need to comply with technical standards and take into account the features of metal-plastic pipes. Main settings:

- the pipeline can function effectively at a coolant temperature of no more than + 95 ° С;

- the maximum pressure value that must be created at temperatures from 0 to 25 ° C is 25 bar, at 95 ° C - 10 bar.

Compliance with these technical parameters guarantees the service life of pipes from 40-50 years.

Marking

Marking

- pipeline diameter;

- polymer type: polypropylene (PP-R); polyethylene (PE-R); heat-resistant polyethylene (PE-RT); high-strength cross-linked polyethylene (PE-X);

- nominal pressure (PN);

- type of pressure stitching (a, b, c, d);

- batch number;

- production date, etc.

Before purchasing metal-plastic pipes, each buyer has the right to request a quality certificate for the goods sold.

Characteristics and properties

Reinforced-plastic pipes are bent and cut without much effort. They are transported and stored in bays. Pieces of the required length are cut from the bay. Due to the low weight density of plastic and aluminum, a low weight of the finished product is ensured. At the same time, its transportation is facilitated.

Such pipes have a fairly long service life. In practice, it exceeds the periods between planned capital repairs of premises. If water freezes in a metal-plastic pipe, then an accident will not occur. The pipe will swell locally and retain its functionality.

The flexibility of this type of pipes allows them to be used for underfloor heating.

Before proceeding with the installation of the heating system, you need to determine which pipelines are best suited for a particular room. To do this, you need to take into account not only the technical characteristics, but also the positive and negative aspects of the selected material.

Main advantages

- reliability and durability;

- pronounced resistance to salt deposition, aggressive environments;

- resistance to silting and overgrowing;

- high throughput rate;

- light weight and high ductility;

- easy to do it yourself;

- good maintainability;

- high coefficient of noise absorption capacity;

- low thermal conductivity.

Negative sides

- it is forbidden to use in fire safety systems;

- cannot be installed near heat sources, the temperature of which is more than 1500 ° С;

- unreliability of fittings;

- high sensitivity to defrosting.

It is not recommended to use metal-plastic products outdoors. They can burst if you start defrosting the heating system. As a result, an emergency shutdown of the boiler from electricity will occur, which leads to the replacement of all pipes and dismantling of the system.

Taking into account all the characteristic features, it can be noted that the use of metal-plastic pipes for heating residential buildings is most justified.

Pipeline connection methods

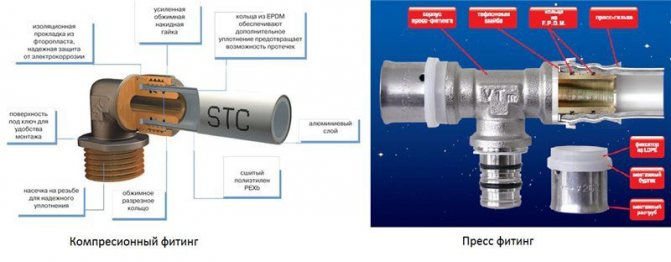

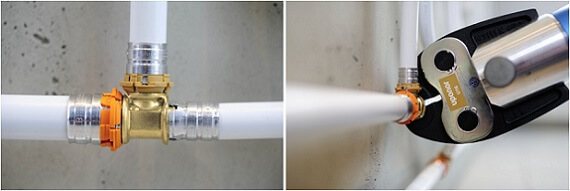

Installation of metal heating pipes involves the use of one or another installation method. To connect the pipeline, you will need a welding machine and special parts: couplings, fittings, elbows, tees, etc. There are three main connection methods: press fittings, crimp fittings and detachable elements.

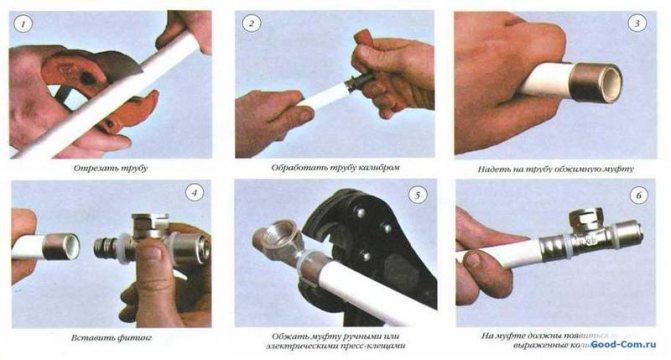

The first method assumes that the master has a hand or electric pistol, which will come in handy during installation. The press fitting is a sleeve inserted into the body. With the help of a special device, spinning is performed. These fittings look quite attractive on the outside, so pipes do not need to be laid under walls or floors. The disadvantages of this connection method is that the fittings have a high cost in comparison with their counterparts. Plus, it is impossible to dismantle the part without violating the integrity of the structure.

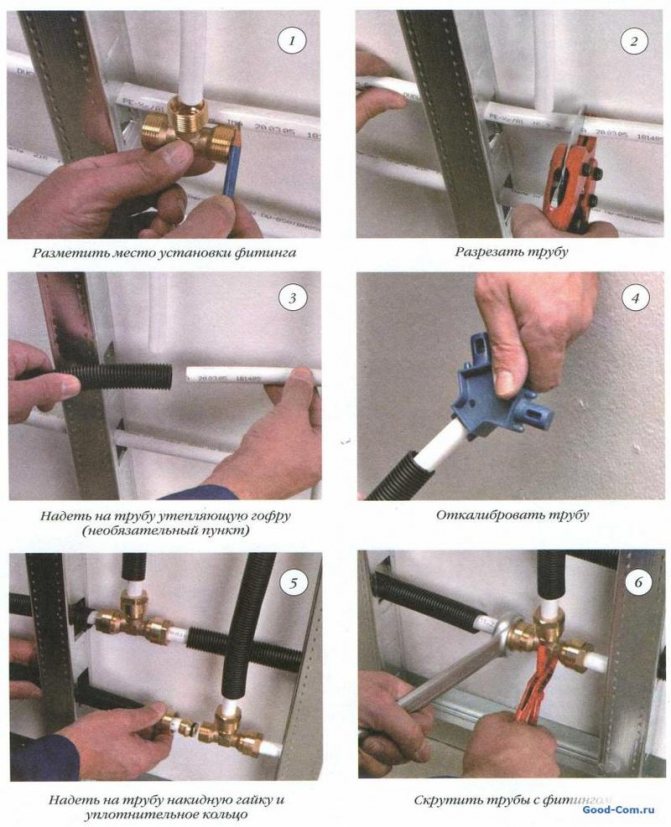

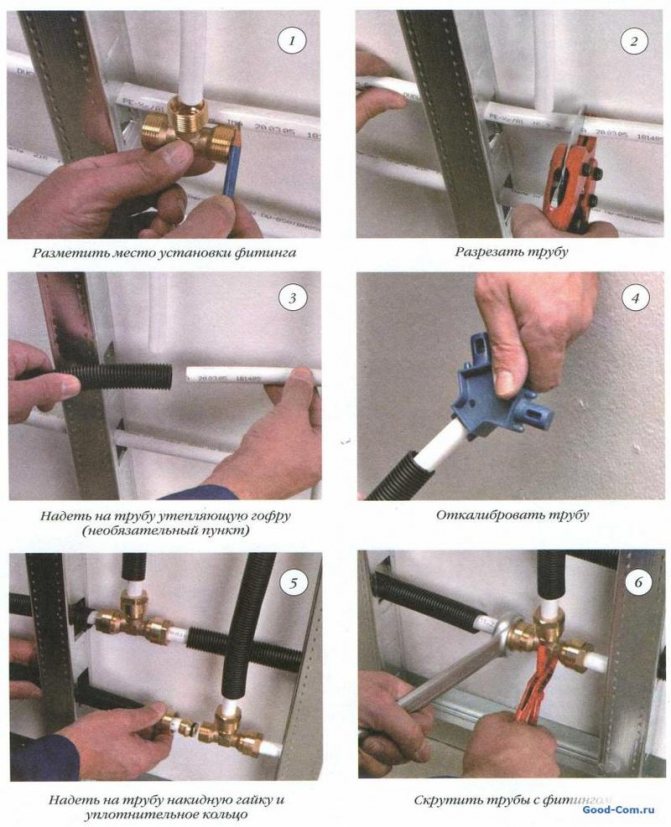

The essence of the installation of compression fittings is that at the place of the pipe joint, the ring is attached and tightened with a nut. For installation in this way, you may need the following tools:

- to clean the ends of the pipes, you must use a beveller;

- to fix the fitting - wrenches;

- to change the direction of the heating channel, a pipe bender is useful;

- pipe cutter.

Crimp (compression) fittings provide a detachable connection, they can be reused after dismantling old pipes. And the cost of such parts is much lower than press fittings. On the negative side, it can be noted that the crimping elements need to be constantly tightened. For prevention purposes, this should be done 3-5 times a year, if the joints of the pipes are leaking more often. Another significant disadvantage is that the pipes must be constantly accessible. Therefore, it will not work to mount them in a hidden way.

The most expensive are threaded or collet fittings. Thanks to the detachable part, they can be repeatedly undocked from different parts of the pipeline and devices. Compression and detachable fittings are used for open pipe laying, used for installing a radiator system, for connecting to manifolds and when docking with valves.

The above parts are available in different metals: bronze, brass and plastic. Usually, they use cheaper options made of plastic. But they all connect the ends of the pipeline equally well.

The process of installing a polypropylene pipeline

Installation of polypropylene pipes is carried out using fittings in two ways: threading and welding. A special soldering iron is required for welding. The principle of operation of which is to heat and soften the edge of the fitting and pipe. The heated joints join and weld together as they cool.

Installation of polypropylene pipes

For reinforced profiles, special joint preparation is required. To form a monolithic joint, the edges are cleaned from the metal and the second layer of plastic.

Threaded joints are used to create detachable joints, connect polypropylene pipes to metal networks, and supply connections to mixers and meters. Threaded fittings on both sides end with a socket and a squeeze. The thread can be internal or external.

Angles, tees and couplings are used for turns and branches. All joints are welded by welding to achieve a monolithic joint.

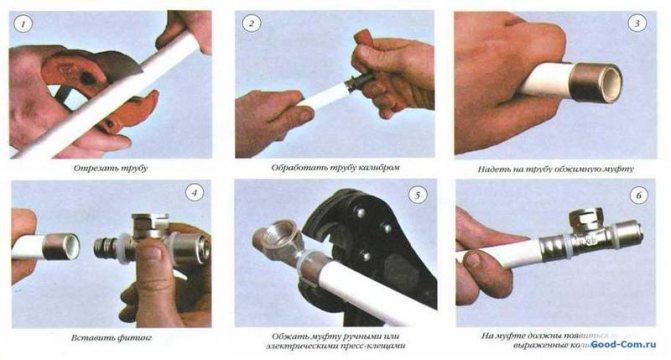

Installation of metal-plastic pipes

Installation of metal-plastic pipes

- press tool;

- round file;

- pipe cutter or scissors for cutting metal;

- spanners;

- pipe bender or spring;

- calibrator.

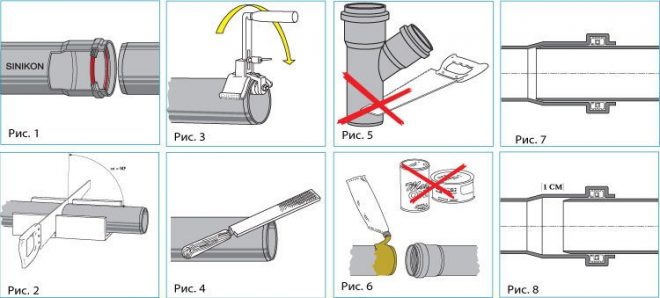

Installation of heating from metal-plastic pipes takes place in several stages.

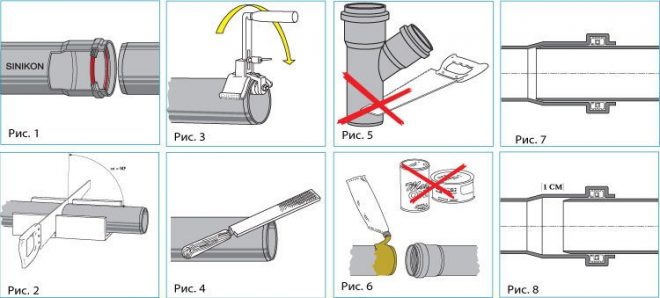

- First, using special scissors, the pipeline is cut into sections of a certain length. Do not use other tools, as the edges can be sharp and uneven, which can subsequently lead to leakage.

- Further, with the help of improvised means (drill, round file), a sharp edge is removed, which is located inside and outside the pipeline. If this is not done, the metal bends can damage the rubber O-ring of the fitting, leading to a leakage of the connection.To get perfectly straight pipe edge shapes, you can use a calibrator.

- A rubber band is installed on the fitting nipple, with which a seal is made. In order not to damage the rings, it is recommended to flare the pipe during calibration.

- Next, a nut and a clamping clamp are put on the pipe.

- The end of the pipeline is flared and pushed onto the nipple of the fitting.

- Next, the fitting squeegee is leveled and the clamping collar is returned.

- At the end of the installation, tighten the nut. This should not be done in full force, when the crackling sound appears, you can release the key.

After all the manipulations, it is necessary to check the heating system for leaks.

... It is necessary to fill the pipes with water and create a pressure that exceeds the operating pressure by 1.5–2 times. Air vents must be open. It is recommended to run water into the system slowly and evenly.

Recommendations for the installation of metal-plastic pipes

Installation recommendations

- you need to work with gloves, observing safety precautions;

- installation should be done only with serviceable tools;

- metal-plastic is a combustible material. Extinguishing media can include sand, foam and water spray;

- in no case should the pipes be thrown from a height and dragged;

- it is necessary to store the metal-plastic pipeline on a flat surface in a horizontal position, preferably in a closed room.

- installation can be started only after a complete inspection of the heating system and checking the components for flaws and deformations. The parts must be compatible with each other, it is advisable to study the regulatory documents and product quality certificates in advance.

Instructions for installing metal-plastic piping indoors

- Read the product labeling carefully before purchasing. The pipes must operate at a coolant temperature of no more than 95 ° C and a pressure of no less than 6.6 atm.

- Fasteners must be installed at a distance of 0.5 m from each other, otherwise the pipes may sag, which will lead to a violation of the circulation of the coolant.

- The reinforced-plastic pipeline is not recommended to be installed outside the premises. When the heating system defrosts, pipes can burst. Accordingly, the pipeline will have to be changed completely, which is very costly.

- The air temperature in the room should not be less than + 10 ° C. If the pipes were in frost, then before installation, the bay should stay at room temperature for at least a day.

- Open laying of metal-plastic is possible only in those places that are protected from direct exposure to ultraviolet rays, and the pipeline must also run away from open flames.

- Finishing work near the installation of the reinforced-plastic pipeline must be completed prior to installation.

- The rest of the fittings must be fastened separately without placing any stress on the pipes.

- In no case should you use sharp objects when marking.

- A broken pipe can be repaired with a wooden or rubber mallet.

- Twisting of the pipeline, deformations and lateral stresses must be avoided.

- In the longitudinal direction, the pipes require freedom, in the rest - fixation.

- The intersection of building objects is possible when using sleeves, the gap must be treated with a non-combustible material.

- It is important to ensure open access to screw connections and fittings.

Compliance with the above rules will ensure the efficiency of the heating system, and most importantly - safety.

Preparation and assembly of connections on fittings

First of all, we should mention calibration - a procedure that is sometimes neglected even by professionals. Meanwhile, metal-plastic pipes come from the factory in coils, and therefore, without calibration, they retain some ovality, which can then come out sideways. After all, when a fitting is inserted into a curved pipe, its O-rings are simply pulled out of the grooves, shifting towards the fitting body.

We recommend: How to install a heat meter for a house with central heating?

All this leads to a decrease in the tightness of the connection, since the polyethylene sheath must be pressed with rings directly to the fitting. Moreover, polyethylene will inevitably soften when heated and partially displaced from the area under the split ring. This means that if the O-rings are not in place, leaks can occur. The latter is usually easy to remove by tightening the nut, but sometimes it is not.

Installation of metal-plastic pipes

We add that with mandatory calibration, pipes with compression fittings can be laid openly. However, when such pipes are walled up in a screed or grooves, it is better to use press fittings.

If we talk about the assembly of heating systems, then, of course, there are few subtleties in this matter. When installing steel pipes, threads are usually used, which are wound with plumbing flax. Such products are cut with a grinder or a hacksaw for metal. The need for calibration and deburring and chamfering is not canceled. In addition, a jumper is required directly in front of the ball valves that cut off the radiator. Otherwise, the throttle or valve will regulate the passage of the entire riser.

When tightening the nut on the compression fitting, hold its body with another wrench, otherwise you can accidentally break the tightness of the previously made connections. Do not forget that the turns of the heating line are made using special corner fittings, and not by pipe bends. With a small radius, you can simply break the aluminum core, and too large a radius will look sloppy. When connecting the eyeliner to the radiator, it is better to use special nuts - American. This connection allows, if necessary, to quickly disconnect the heater.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- How to install a heat meter for a house with central heating?

- How to choose a microprocessor controller for two central heating pump pumps?

Applications of metal-plastic pipes

Most often, this pipeline is used in the private sector for laying a heating system. In addition, it is used:

- in air conditioning installations;

- in engineering systems inside buildings under construction;

- when transporting liquid and gaseous media in industry and agriculture;

- in compressed air supply systems;

- to protect and shield other cables;

- when replacing old pipelines in buildings that are undergoing reconstruction.

Manufacturers of reinforced plastic pipes

Manufacturers of reinforced plastic pipes

The Henco product line includes not only heating ducts, but also the necessary connecting elements. The company has established itself as a reliable manufacturer; it has been on the market for over 10 years. Designers develop their own technologies for the production of pipes and fittings. The manufacturer produces the Henco RIX and Henco Standart pipelines. The main difference between them is the thickness of the aluminum foil in the structure. For a home heating system, the Henco RIX is suitable. The pipes will do a great job with the pressure, plus they are inexpensive.

The German brand Oventrop is considered the most reliable sanitary fittings of all. Despite the rather high cost, most homeowners choose it. Oventrop's main competitor is the REHAU pipe. The high-quality execution of the pipeline in conjunction with durable connecting fittings puts this manufacturer in the first place.

The cost of metal-plastic pipes is different, it depends on the size of the coil and the structure. Prices range from 30 to 300 rubles per running meter.