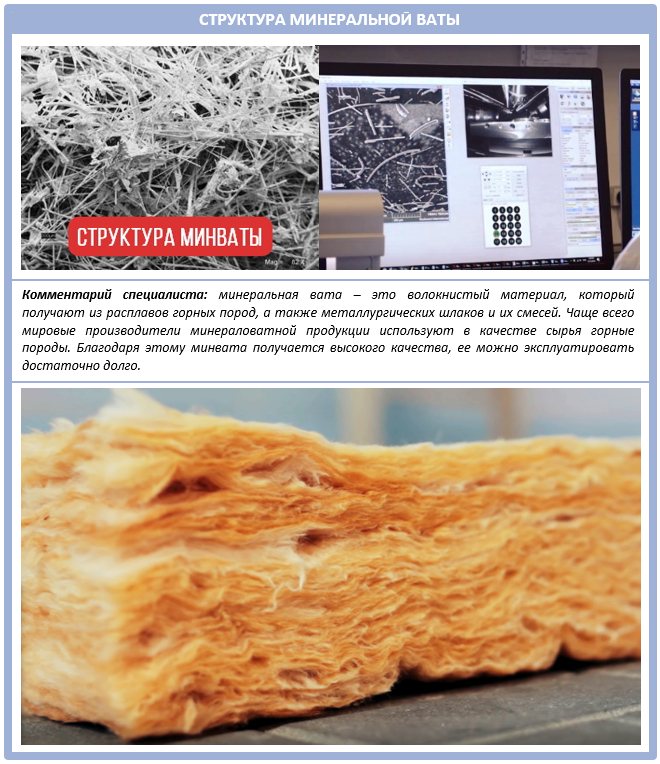

Among the huge amount of insulation materials, there are varieties of cotton filler produced on the basis of waste products from glass, metallurgical or mining industries. At the same time, it is not entirely correct to raise the question of which is better - mineral wool or basalt wool. Since all types of insulation in the form of cotton wool and cotton slabs are considered mineral. To be clear, we note that mineral wool is called:

- Glass wool;

- Basalt insulation;

- Slag.

All types of heaters can be used to insulate the perimeter of a house, roof, heating mains, industrial facilities, etc. In our material we will try to figure out which is better and better quality - basalt-based mineral wool or fiberglass-based mineral wool.

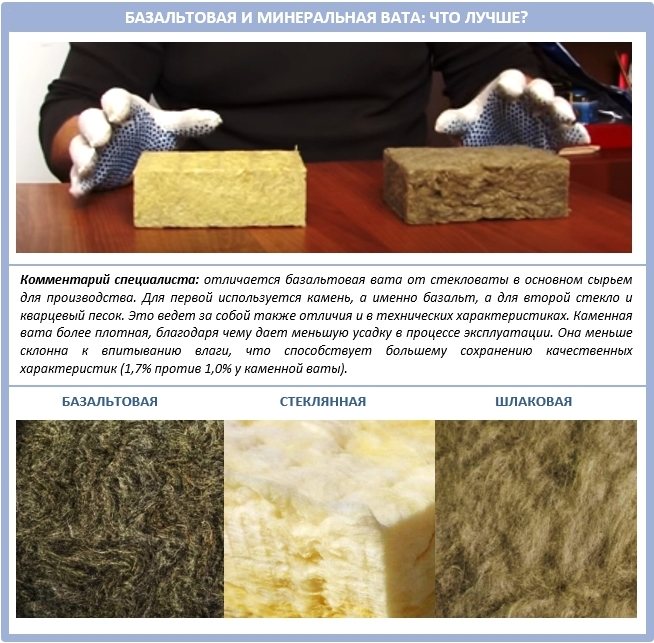

The difference between basalt and mineral wool

It is important to understand that in the modern construction industry, the concept of mineral wool has a wide meaning. This material is a special type of insulation that has a characteristic fibrous structure on an artificial basis. Various mineral raw materials are used for its production: glass, blast-furnace slags, rock basalt rocks. That is, mineral wool is the general name for all types of heaters of this class, which include:

- fiberglass;

- slag fiber;

- stone (basalt) fiber.

Thus, basalt wool is one of the types of mineral wool, so the question of which one is best to use is not entirely correct. More correctly, you should choose between fiberglass, cinder fiber or basalt fiber. Most often, the consumer's choice is between mineral fiberglass and mineral stone fiber, that is, between glass wool and stone wool. To figure out which of these materials is better, you need to compare their properties and characteristics.

Requirements for high-quality fibrous mineral insulation

High-quality insulating fibrous material must meet many characteristics

In order to choose the right mineral wool insulation in rolls or slabs, it is worthwhile to understand exactly what requirements are imposed on the material according to building technologies and standards. So, a high-quality insulating fibrous material must meet the following characteristics:

- Environmentally friendly insulation. Especially if the material will be used to insulate the interior. In addition, this factor, if standards are not met, can often cause allergic reactions in households.

- Insulation fire resistance. Any mineral wool material must have a high degree of fire safety. In addition, it is desirable that the insulation could self-extinguish when ignited and not emit a large amount of harmful compounds during combustion. The degree of fire resistance can be determined by the markings on the packaging. It looks like the symbols G1, G2, G3, G4, which is interpreted by the increasing ability of the insulation to burn. That is, the G1 marking indicates that the cotton wool is non-combustible. Accordingly, G4 speaks of the ability of the insulation to burn. The NG marking indicates that the cotton wool does not burn at all due to the flame retardant impregnation. By the way, here we also pay attention to the marking "D". The higher the numerical value next to it, the more smoke the cotton wool gives when smoldering. And the marking "RP" with a numerical value indicates the speed of flame propagation through the room if the insulation is located next to combustible materials and devices / objects.

- Moisture resistance. This criterion affects the durability of the insulation. Because the tendency of cotton wool to accumulate and absorb water will cause it to rot. This means that not only the effect of heat protection will be reduced, but also the risk of fungus spreading along the walls of the room will increase.

- Thermal conductivity. This figure should be low. And the lower the better. This means that the mineral insulation will keep warm well.

- Density of cotton wool. The lower it is, the easier the material is to work with and the more it contributes to the preservation of heat in the house.

The soundproofing characteristics of cotton wool will also be useful.

- The soundproofing characteristics of cotton wool will also be useful. Especially if the insulated cottage is located close to busy streets and avenues.

Important: you should also pay attention to the installation technology of one or another mineral insulation. That is why we will analyze below: basalt wool or mineral wool, which is better and easier to install and behave in operation.

Advice: some manufacturers of mineral wool insulation deviate somewhat from GOSTs in the production of the material, which is permissible. In this case, instead of the usual GOST marking, the packaging will have the TU marking. In this case, it is advisable to additionally familiarize yourself with the technical characteristics of the material from the corresponding certificates. Otherwise, you run the risk of running into a very substandard product.

Basalt insulation - its main features

Basalt, aka stone wool, is made on the basis of fibers, which are obtained in the process of melting volcanic mountain gabbaro-basalt rocks. During production, this material is mixed with special binders, which are subsequently important for the operation of the material.

For example, they provide water-repellent, heat-insulating, fireproof, sound-proof properties. Today, mountain minerals are used in many industries, as well as in domestic construction, for example, when laying roads, producing commemorative sculptures, stone products, etc.

Due to its loose and fibrous structure, basalt mineral stone wool maintains temperature conditions much better than mineral fiberglass. This is achieved due to the interfibrous air layers, which are formed due to the structure of the material itself. So, in winter it will always be warm in the room, since the temperature will be reliably kept inside the building, and in summer, on the contrary, it will be cool in the house, despite the hot weather. In the case of using fiberglass, this important advantage will be missing.

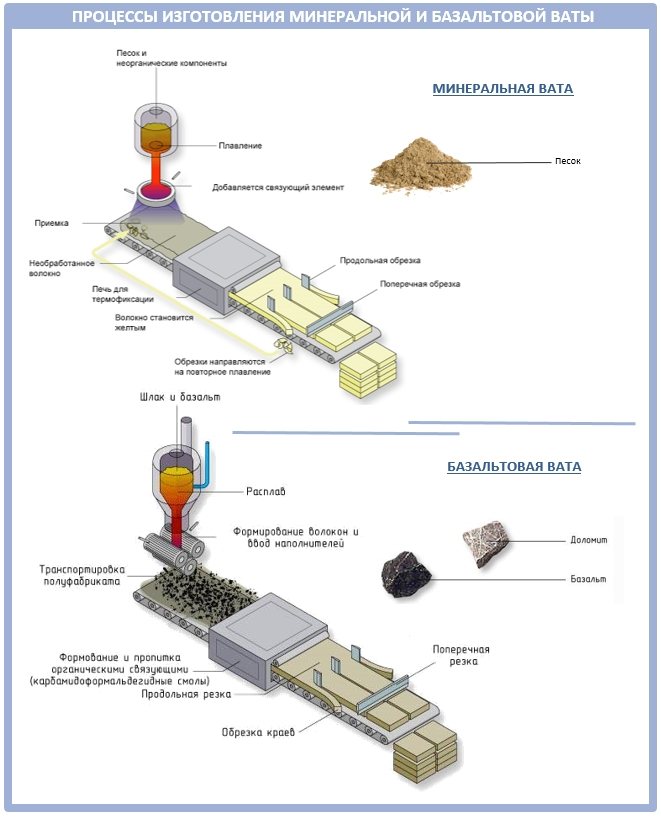

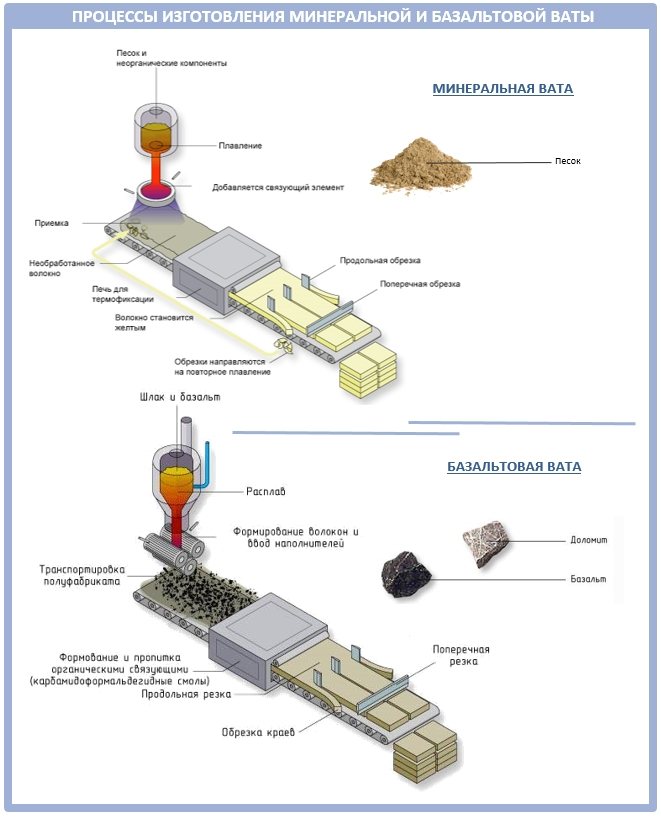

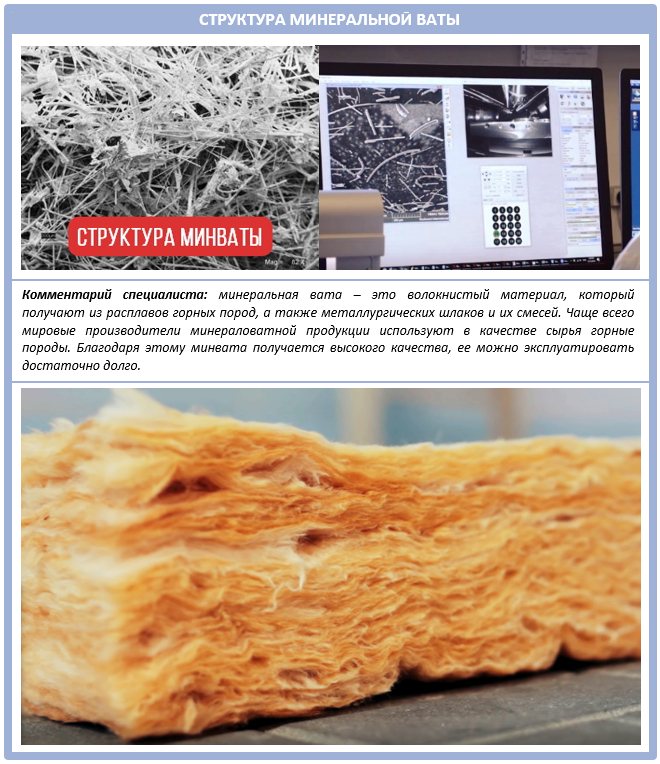

Mineral fiber manufacturing technology

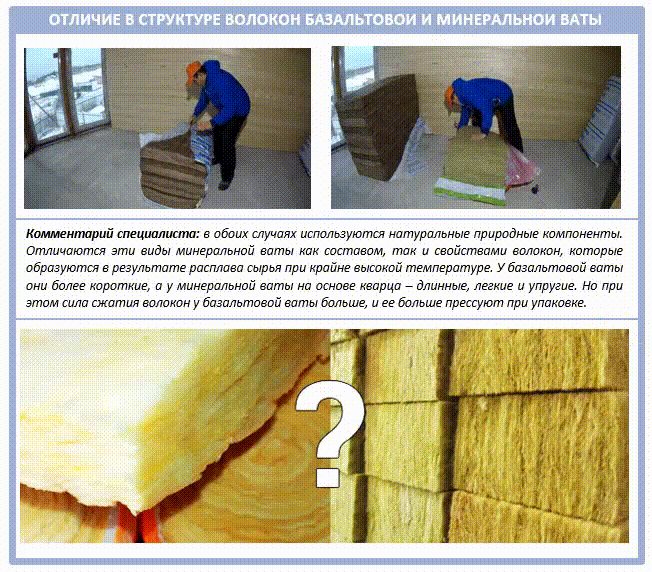

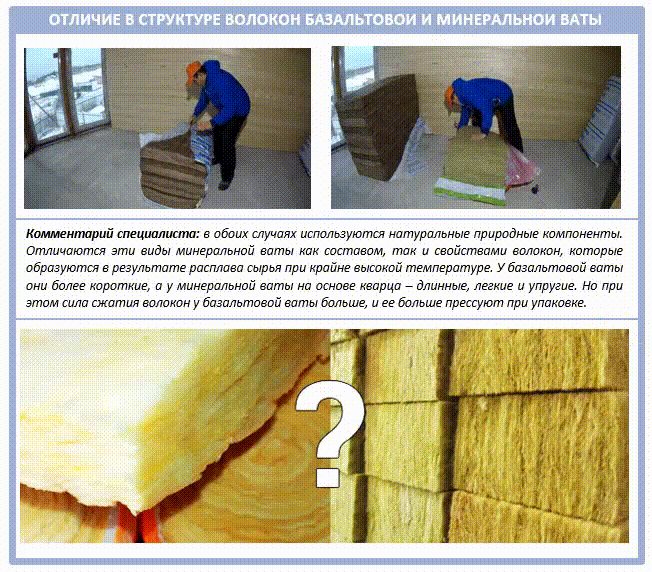

As we have already said, depending on the raw material itself and the technology used, each insulation will differ in the thickness and orientation of the fibers. In this case, the fibers can be arranged spatially, corrugated, horizontal or vertical layers, depending on what equipment they were melted on.

But the general principle is this:

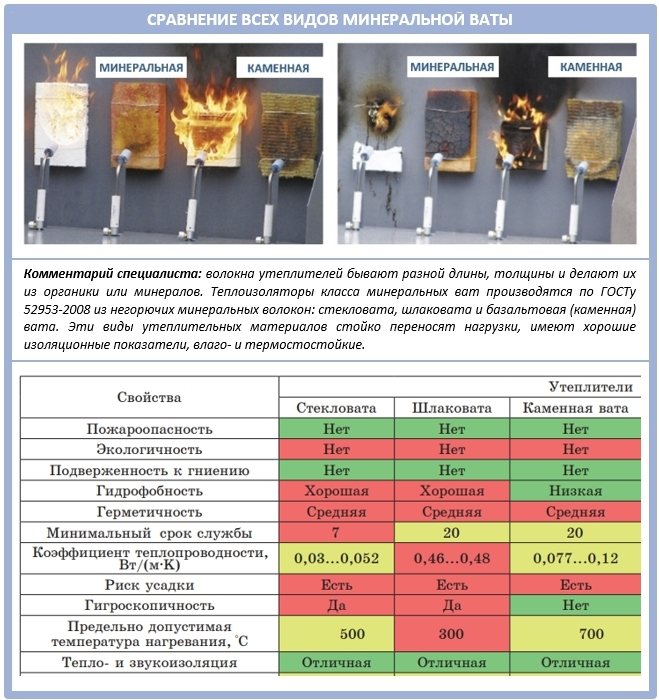

As a result of production, mineral wool of different colors, thicknesses and fiber lengths is obtained, which directly affects its properties. In the Russian market, all three types have the following sectional view:

Spiky ubiquitous glass wool

Cylindrical glass wool is actively used today for thermal insulation of pipelines, and in the form of slabs for ventilated facades. This material is even used in aviation! They are used to trim cabins to achieve the desired protection against heat loss and muffle sounds. Also, glass wool always insulates parts that are too hot.

Another good thing about glass wool is that it perfectly tolerates vibration loads. It is made from dolomite, sand, limestone or cullet. Usually it is yellow, very light or more saturated (abroad - more often pink).

The process itself is simple: a glass break or its analogue is heated and almost one and a half thousand degrees until the glass begins to melt. Then thin fibers are easily drawn from them, with a thickness of 5 to 15 microns and a length of 15 to 50 mm. The threads dry up and twist into cotton wool:

The material turns out to be quite strong and elastic, but it is not easy to work with it. The fact is that all these glass fibers are quite fragile, and when they break, they fall on the skin and eyes in the form of thousands of small sharp needles, causing redness and irritation.

And if you also inhale glass dust, then it will be bad for your lungs. That is why they work with such material only in a protective suit and a respirator, although there are many extreme people.

Reliable and fireproof stone wool

Stone wool is produced by alloying rocks and a mixture of metallurgical slags. Basalt, diabase, or gabbro with the addition of limestone or dolomite rocks are used as raw materials. Water vapor permeability - within 0.25-0.35 mg / m2 * h * pa. Such insulation is much more expensive compared to glass wool, but it also has completely different characteristics. But in terms of heat and sound insulation, both materials are similar.

By the way, only basalt wool, which is strong enough to break, is suitable for some roof structures. Neither glass wool nor slag wool can boast of this quality.

Affordable and soft slag wool

Another common mineral wool insulation is slag wool produced from waste from the metallurgical industry. Such raw materials are obtained in the process of melting in coke oven cupolas. The so-called cupola method, due to which the physical and mechanical properties of cotton wool are improved and the process becomes cheaper.

The only negative is that acidity remains unstable in the process of blast furnace slag production. After all, the blast-furnace slag for slag wool itself is obtained in the process of metallurgy production, namely pig iron smelting. Because of this, mineral wool may differ slightly in its properties and reactions to environmental influences in different packages.

Those. it may turn out that a neighbor's attic insulated with the same brand of slabs can last longer than yours. In short, it is difficult to predict the final result here. And the filaments themselves are obtained from molten blast furnace slags, with a thickness of 4 to 12 microns and a length of 16 mm. It turns out quite elastic and heat-insulating wool. Its thermal conductivity coefficient is 0, 46 ... 0, 48 W / (m ∙ k).

Also, residual acidity in a damp room can negatively affect metal surfaces. Slag wool also absorbs moisture rather quickly, and therefore it cannot be used for insulation in the bathroom. Because of these features, plastic and metal pipes are never insulated with it. And for finishing the facade, it is not suitable at all.

But slag wool does not prick like glass wool, although its dust often hovers in the air and creates unpleasant sensations when inhaled. Also, unfortunately, the slag wool contains formaldehyde resin, which releases phenol.

This is unsafe for human health, therefore, during the installation process, special safety precautions must be observed. And it is important during the installation process to cover such insulation with a vapor barrier film without gaps. Although this also applies to the previous two types.

Pros and cons of basalt heat insulator

Mineral wool on a stone basis has a number of decent characteristics compared to other thermal insulation materials. Among the most important are:

- resistance to high temperatures;

- when heated, toxic substances are not released from the material;

- resistance to pollution;

- easily transported;

- long service life. High-quality brands of such insulation from reliable manufacturers can last up to 50 years without losing their qualities at all;

- has low sound conductivity;

- has good vibration resistance, unlike fiberglass;

- is not explosive material;

- not affected by rodents or other pests;

- with a low specific gravity, high insulation is observed;

- has good resistance to a number of mechanical influences, due to the chaotic arrangement of the fibers;

- possesses good water-repellent qualities, easily passes moisture without accumulating it.

With all the variety of advantages, mineral basalt wool also has its disadvantages:

- high cost of heat-insulating material;

- on tiled basalt insulation, the connecting sections have many seams, which subsequently cause a decrease in thermal insulation properties;

- low indicators of strength characteristics;

- Some brands of basalt wool are harmful to health, since an unsafe phenolic binder can evaporate and enter the human body with air.

When insulating walls with basalt insulation, precautions must be taken, since crumbling dust can get into the eyes and lungs. To protect yourself from this, it is enough to wear glasses, a respirator or a gauze bandage.

Basalt wool - what you need to know about?

Insulation based on basalt wool is characterized by fiberglass, which is combined with special components to maintain the bond and improve the hydrophobicity of the material.

An important advantage of thermal insulation based on basalt wool is its resistance to high temperatures, which is especially noticeable when compared with mineral wool insulation. In addition, the insulator is characterized by:

- lack of ability to release toxins when the temperature rises;

- resistance to dirt and fungi;

- high melting point;

- easy transportation and installation.

The manufacturer of basalt wool insulation claims fifty years of operational life in compliance with the basic rules of use. In addition, the characteristics of the material indicate a high level of sound absorption, which allows it to be used for insulation and noise reduction in rooms for various purposes.

Heaters made of basalt wool are much better than mineral wool and in terms of vibration resistance, they do not belong to the explosive group, they are suitable for isolating an environment with an elevated temperature and an aggressive type.

Analyzing how much better insulation based on basalt wool is really better than mineral wool, it is worth noting the special chemical composition of the material. It does not include dolomite and limestone elements, which are necessarily included in the adhesive required for the installation of mineral wool.

Basalt heaters, with all their positive qualities, weigh little and show increased resistance to mechanical damage. This is important, because at the stage of destruction, heaters pose a real danger to human health, inhaling microparticles of fibers floating in the air.

Perhaps there is no better insulation than basalt wool when it comes to the ability to cope with the effects of moisture. The material has a high level of water repellency, and when moisture gets inside, it does not allow it to accumulate.

The material also has some disadvantages. Stone wool is sold at a fairly high price, which is different from the cost of mineral wool - rather a budget option.

The peculiarities of the structure of the insulation can also be considered a minus. The material in the form of a plate, most often used for thermal insulation, has many seams in the joints, which can cause poor quality thermal insulation, especially if mistakes in installation are made.

In terms of safety, basalt wool insulation is considered more environmentally friendly than conventional mineral wool, despite minor inclusions in the composition of phenolic binders.

So, summing up the differences between basalt thermal insulation from other types of insulators based on mineral wool, it is worth noting the following important factors:

- the material is resistant to chemical and biological attacks, which distinguishes it from the same glass wool;

- the plasticity of the material in terms of indicators exceeds the same parameter for mineral insulation, including glass wool;

- the material provides a high level of thermal insulation, significantly exceeding the level of glass wool counterparts.

How much the advantages overlap the above disadvantages - everyone decides for himself after analyzing the features of alternative types of insulation, including those based on mineral wool.

The difference between stone wool compared to other mineral insulation

When considering the features and characteristics of basalt wool, its advantages become noticeable in comparison with existing similar heat-insulating materials. The most important factor of this heat insulator is its high level of biological and chemical activity. Based on this fact, stone wool has advantageous differences compared to other insulation materials, for example, with glass wool.

The types of heat insulators to which basalt is added have a unique structure consisting of short and thick fibers. Due to this, the plasticity of the material increases significantly, and the risk is reduced that when laying the insulation, it will crumble and crumble.

Characteristics of materials

To say which is better: mineral wool or basalt wool, - impossible without studying the composition... It is he who has a direct impact on the operational and installation qualities of the product.

Basalt wool

Stone wool is endowed with high density. This quality is due to short, tightly fitting fibers. Cotton wool absorbs little moisture, which helps to maintain good thermal insulation properties.

It will be possible to say how basalt wool differs from mineral wool during installation. Stone wool slabs are very fragile and require careful handling. Due to the dense structure of the product, it is allowed to be used for external decoration.

Indoors, rigid slabs may be mounted to the ceiling. It is allowed to apply plaster on top of the slabs. Special slabs can be purchased for embossed and curved surfaces.

Mineral fiber

Speaking about which is better: mineral wool or stone wool, one should not forget about the characteristics inherent in the material. It is customary to denote fiberglass with mineral wool. By its characteristics, it is more airy and has a relatively low density.

These qualities make it vulnerable to moisture. To protect against excess moisture, some manufacturers use special formulations that process raw materials. They can reduce the hygroscopic properties up to three times and improve the heat-insulating qualities.

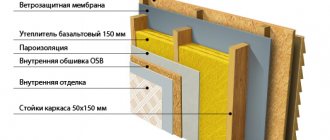

In other cases it is recommended to use a vapor-proof polyvinyl chloride film... A variety of production methods make it possible to fix products on surfaces of various shapes. For the preservation of heat-saving qualities, it is not recommended to press the raw material strongly against the wall during installation.

The fibers are highly volatile and, when cutting the material, can enter the respiratory tract of the worker. For protection, a work suit, rubber gloves, goggles and a respirator or mask should be worn.

If small particles get on the skin, rinse it with cold running water. Hot water will open the pores of the skin and the fibers will get inside, causing burning and redness.

Features of mineral insulation (glass wool)

Compared to basalt insulation, the cost of fiberglass insulation is much lower. The difference in material prices depends on the availability and low cost of the manufacturing process. Mineral wool is produced in special packages that do not require special transport for their transportation. In comparison with basalt analogs, this is its main advantage. In addition, fiberglass is lightweight and easy to transport, which is a very important aspect of the pricing of the product. The advantages of mineral fiberglass include the following qualities:

- low weight of the material;

- has a low degree of density;

- does not create large loads when used;

- has excellent chemical passivity, that is, it does not emit harmful substances;

- has high biological endurance;

- does not tend to ignite;

- due to the long fiber length it has excellent elasticity;

- does not cause corrosive processes on metal structures;

- applicable for uneven surfaces with different geometries;

- has better sound insulation than stone wool.

When choosing a mineral insulation, special attention should be paid to its thickness, the location of the fibers and its density.

What to give preference to?

There is no universal answer to this question, since the choice is largely determined by the specific situation. The owner must independently figure out what and how he will insulate. And only after that go to the store for a heat insulator.

Important indicators are:

- Features of installation or installation. For example, soft material cannot be fixed vertically. It will still lose its shape and deform.

- Duration, safety and ease of use.

All mineral insulators, obtained not from basalt rocks, are highly deformed due to their relatively loose structure. For example, glass wool absorbs moisture and is compressed - it must be protected with a vapor barrier film on both sides.

But on the other hand, it perfectly helps in insulating the attic and pipelines - the material bends easily. And the most modern brands are very similar in quality to cotton - the insulation does not prick at all, and is perfect for interior work.

Thermal insulation with cotton wool

Stone wool is resistant to deformation, absorbs excess moisture poorly and retains heat well even when wet. But at the same time it is quite fragile. It is extremely difficult to install it in a confined space requiring cutting of individual slabs. Basalt dust quickly penetrates the lungs, causing irritation of the respiratory tract. Therefore, such insulation requires reliable insulation - particles of basalt slabs should not get into living quarters!

It can be concluded that thornless glass wool is more suitable for indoor use, and stone wool for outdoor use (installation on facades) and insulation of the space between walls.

What is the best choice?

Based on the considered features of the materials, it is difficult to say which of them is better - basalt insulation or fiberglass. Both materials have their own positive characteristics and disadvantages. But before making a final decision, it is worth considering the heaters presented in a more detailed comparison.

The difference between mineral wool and stone is in the density of materials. Fiberglass is much softer, it often shrinks and is highly exposed to moisture. Water in the insulation lingers for a long time and is poorly removed, therefore, during installation, it is necessary to cover the material with a film. In addition, not all types of mineral wool can be used under screeds and plastering. Fiberglass is best used for horizontal surfaces as it will loose its shape and sag on vertical surfaces.

Speaking about transportation, it can be noted that fiberglass benefits significantly due to its low weight and small dimensions. Presumably, during transportation and unloading, glass wool can lose its original shape, but then it quickly returns to its natural position, since it has high elasticity. It is flexible, so it can be easily used for insulating any type of surface - pipes, crevices, attics and various irregularities.

At the same time, the service life of mineral glass wool is significantly inferior to the service life of stone. Therefore, for a long period it is more profitable to use basalt heaters. In addition, stone wool is excellent for installation in all areas of the house, it is easy to install it to the ceiling, walls, under the floor or sub-floor.

The basalt fiber heat insulator is suitable for use in any conditions, therefore it can also be used for external insulation of houses. Whereas fiberglass is several times inferior in these characteristics.

That is why most people from the private housing sector give their preference to basalt insulation. The final price of a basalt heat insulator is quite high and not every consumer can buy it, but still it is worth it. This material will allow you to perform the task of warming as efficiently as possible and get the most acceptable result, forgetting for many years about the problem of home insulation.

In general, studying the question of which insulation is better, we can conclude that everything depends on individual needs and construction work for which a heat insulator is needed. Before purchasing, it is necessary to consider in what conditions the thermal insulation material will be used. And only on this basis, make a decision on the purchase of glass or basalt fiber.

Comparison of technical characteristics: which raw materials are still better?

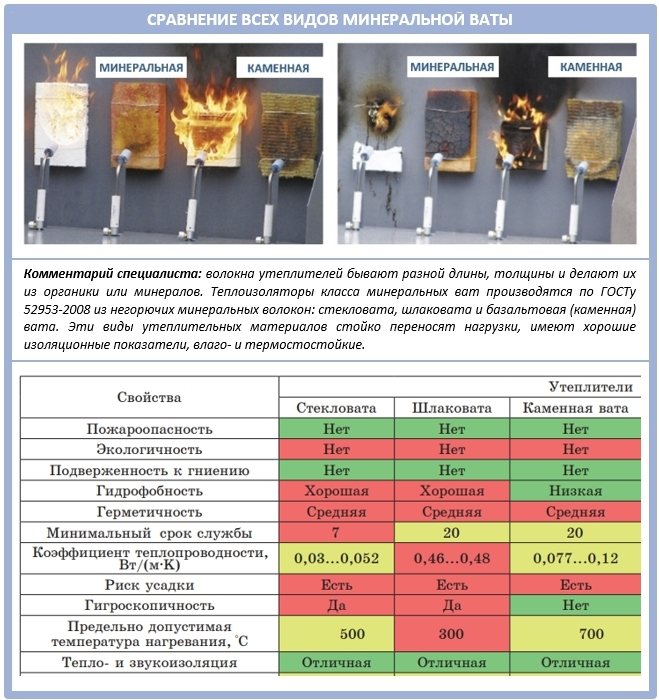

Any insulation is always subject to the most important requirements, such as heat retention and durability. In this, mineral wool significantly benefits from other types of heat-insulating materials (despite the fact that glass wool has a service life of only 7 years).

At the same time, all manufacturers are actively working on improving their products, constantly conducting some interesting research in their laboratories and making sure that their products are convenient and safe to insulate ordinary residential buildings. This is good news!

As for the raw materials, we can say that there are no bad heaters, just each of the options is better suited for a specific construction task. That is why it is so important to know the technical characteristics of all three types of mineral wool and their differences from each other.

Thermal conductivity and elasticity

So, let's start with thermal conductivity, i.e. the ability to retain heat by the material itself. For glass wool and basalt slabs, it is at the same level. These are, respectively, 0.041 W / m * k and 0.038 W / m * k.

For your own interest, you can search for popular videos on Youtube, where craftsmen are actively testing different types of mineral wool. For example, sticking thermometers into sections of insulation directly on the street, and observing which of the insulation does its job better. The difference turns out to be literally one 2 degrees, which cannot be called significant.

Further - the density and elasticity, which affect the installation process and the weight of the structure. For some roofs, thermal insulation also performs load-bearing functions, for example, in the case of inverted roofs. Therefore, strength characteristics are more important here.

For example, fiberglass has a low density and high strength characteristics. Such wool is compressive strength within the range of 40-45 KPa with a density of about 115 kg per m3. Thanks to all this, the weight of such products is much lower, but it should not be used for insulating the interfloor overlap.

By the way, the ability to compress and recover without deformation is clearly visible to the naked eye when packages with insulation are opened:

The density of mineral wool also directly affects its final strength. The better the density, the stronger the insulation. These are important technical parameters that determine for what load a particular type of mineral wool can be taken.

Fire safety and fire resistance

As for fire safety, both mineral and basalt wool do not burn in a fire. The maximum of their fibers can be baked with each other at a certain temperature. For example, glass wool melts already at 300 degrees Celsius, slag fibers do not lose their properties even when heated to 700 degrees Celsius, and basalt wool can withstand even at 1000 degrees.

But keep in mind that if you choose stone wool based only on such considerations, then this is not entirely true. The fact is that cotton wool may not ignite at a temperature of 1000 degrees Celsius, but waterproofing films and attic sheathing are unambiguous.

Here, rather, the advantage of all types of mineral wool is that they themselves do not support the burning of fire. Indeed, if we compare them with foam and expanded polystyrene products, then this is a valuable moment.

The fact is that in the process of the spread of fire, polystyrene or expanded polystyrene not only actively burns, but also help the fire spread quickly and efficiently. They say about such houses "flared up like a match":

Cotton wool sting and skin irritation

Another important point that concerns mineral wool. One of its main drawbacks is harmful dust and tartness of the material itself. But not everyone knows that this is a typical sign of the presence of short and thin fibers in the insulation.

For barbed slabs, the fiber is usually 0.02 mm thick and less than 3 mm long. Those. the thinner and shorter the fibers, the more they look like small needles. Even cutting such a plate is not very pleasant: it resembles touching dried bread, a lot of effort and a lot of crumbs everywhere. But the longer the fibers, the easier it is to work with them: they are easy to cut, almost do not dust and do not irritate the skin of the hands.

Basalt wool has an order of magnitude less problems with this, and most modern products of this series do not require the use of special protective equipment at all, except for gloves. Although in fact, glass wool is not such a bad material, if you follow the installation instructions and take care of your own safety.

Unfortunately, even with all the information, many home craftsmen still have a certain daring, due to which they calmly take glass wool with their bare hands, and do not care too much about tightly isolating it from the living space. And then these same people write negative reviews on manufacturers' websites that their cotton wool is environmentally unsafe and generally unbearable for the human body.

Important environmental issues

Let's consider such an important point. Almost all manufacturers of stone wool produce an environmentally friendly product, without toxic substances, which does not emit any unpleasant odors into the room. Such insulation is really safe for human health. In addition, such plants even use waste-free production, which is also important for the environment.

And as for the environmental safety of other types of mineral wool, like glass or slag, there are several points in contrast to stone. So, indeed, mineral wool may contain a small amount of phenol-formaldehyde resin. But in fact, even during the production process at high temperatures, it polemizes and turns into an inactive solid state. It no longer remains in its free form, and it does not in any way affect people living in an insulated house.Although formaldehyde is still used to make glass wool.

In fact, stone wool, especially the previous editions, sometimes contains this substance. The whole problem is in the layered structure of cotton wool: the fibers are arranged randomly, due to which a large number of air pores are formed. And derivatives of phenol-formaldehyde resin as a binder just transform individual fibers into a strong and elastic web that does not crumble or sag. Those. it is a really important component for production.

And cotton wool with such a composition is more durable and stable. Therefore, until now, some manufacturers also contain formaldehyde resin in stone wool, although much less - only from 2.5 to 10%. But the less formaldehyde, the less moisture-resistant insulation itself, although this is how the threat of benzene evaporation is reduced.

Of course, all of these additives are usually kept within the normal range, which is relatively safe for humans and the environment. Today, special laboratories even test mineral wool insulation for all these parameters. Moreover, the tests take place in several stages - this is a radiation assessment, a washout for general toxicity and an assessment of the release of harmful substances into the atmosphere.

To assess the level of organic matter content in mineral wool, it is placed in a climatic chamber for a day, and kept at the desired temperature and humidity for some time. This is how they check whether the mineral wool meets the sanitary and hygienic requirements recognized in Russia.

That is why, if you are concerned about the sustainability of the material, ask for a quality certificate. Indeed, today in the construction market there is a rather tough struggle and sometimes myths about the insecurity of such a heater are spread. As the saying goes, in marketing, all methods are good.

Durability and shrinkage resistance

Another significant disadvantage of glass wool is its ability to shrink. It is because of this that it has a short lifespan, while stone wool is much more durable and retains its shape well for many years.

And if we talk about the price, then of course the most affordable is glass wool. For all its shortcomings, it is great for rooms that first of all need sound insulation, and only then everything else.

Which material is better

Fiberglass insulation crumbles heavily and causes allergies

Which variety to choose depends on the specific task assigned to the insulation. Glass wool is cheap, but crumbles strongly, causes allergies, so it is not used in residential premises. During the construction of business centers in Moscow and other cities, mineral wool is used to insulate facades, walls and other structural elements. Builders choose basalt insulation as it is more resistant to weather conditions.

The main difference between basalt mineral wool is short and thick fibers in its structure, which makes the material more resistant to stress. Due to its low moisture absorption, it is suitable for rooms with high humidity - showers, saunas, baths. Despite the presence of phenol in the composition, it is considered environmentally friendly, therefore it is used in residential premises and offices for wall insulation, sound insulation of partitions, roof insulation.

Basalt wool has a higher mechanical strength, does not crumble. It is preferable to use it for doors as the most durable, resistant to dynamic loads. For the rest of the characteristics of fire safety, sound and thermal insulation, other types of mineral wool are similar.

Outcomes

Both materials withstand high temperatures, belong to the NG flammability group (non-combustible). The cost is approximately the same. According to the assurances of manufacturers, mice do not start in these heaters, but this is not true. Rodents take root almost everywhere.

Today we figured out what is better than mineral wool or stone wool.By mineral wool, we (like everyone who asks such questions) mean glass wool. Comparing the characteristics, we determined that glass wool is environmentally cleaner, does not generate dust during installation and does not prick. For interior work, it is better. If we are talking about laying thermal insulation under a screed or plaster in places with high humidity, then basalt thermal insulation is preferable. It does not absorb moisture so much and retains its insulating properties, even when wet.