Circulation pump device Grundfos

Glandless circulation pump for home heating system

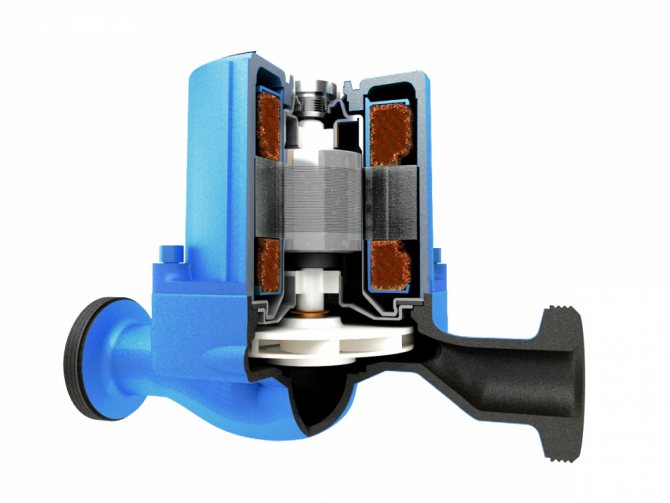

According to their design, circulation pumps for heating Grundfos are divided into two types: with a "wet" and with a "dry" rotor. The first of the constructions historically appeared before the second version. It is based on a body made of cast iron, steel, bronze or aluminum, inside which a movable rotor is located in an aqueous medium. An impeller is installed on the shaft, which sets the working fluid in motion.

Pumps with a "dry" rotor began to be produced a little later, the engine and the liquid in them are separated from each other. First class pumps are highly reliable thanks to liquid lubrication. But at the same time, the efficiency of such devices is very small (no more than 50 percent).

For units with a "dry" rotor, the efficiency is slightly higher (it reaches 70%). These models are most often used for industrial purposes, where operating conditions involve pumping large volumes of water. For domestic needs, circulating pumps operating on a "wet" circuit are usually used.

Features of the pump design

- The pump of the Danish company Grundfos differs from analog products in that it allows you to adjust the power and independently create the necessary pressure in the system.

- Inside the housing there is a wet rotor and a starter that is reliably protected from moisture. The complete set does not include stuffing box seals, which eliminates the need for maintenance of such a product.

- The pump is connected by a threaded or flanged method. It all depends on the specific model. If it is a flanged version, the required adapters are included. So Grundfos pumps can be connected to any kind of pipes.

- The Danish pump is a single technical unit, which has an electric motor, a pumping unit and an electronic control unit. All these elements are clearly matched to each other. There is a reliable partition between the rotor and the starter, which protects the important element from moisture penetration.

- Some models come with one very important attachment. It removes unnecessary air from the heating system to the outside, which is known to create dangerous traffic jams. The air valve always reacts promptly, bringing out even a tiny portion of air on time.

Special technical features make Danish Grundfos pumps versatile. They can not only be installed in closed pipelines, but also used in refrigeration units. To increase the service life of such devices, manufacturers advise observing the installation features and creating the most favorable conditions for their operation.

What are they? Let's take a closer look.

Specifications

The main technical indicators to which attention is paid when choosing a suitable equipment model are:

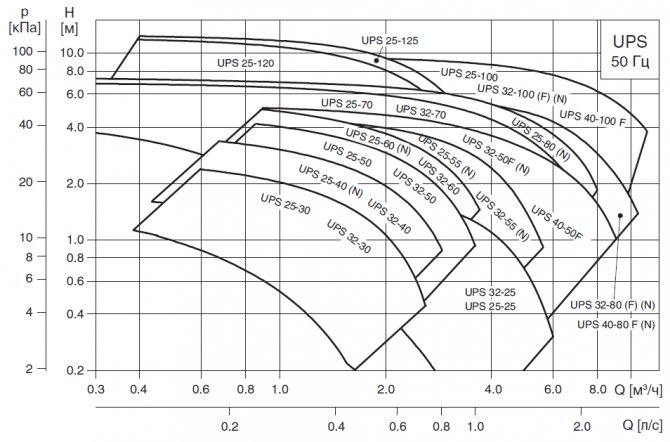

- a graph of the dependence of the fluid pressure on the amount of its supply to the system;

- power consumed by the engine of the unit from the network;

- coolant performance;

- permissible temperature of the pumped medium;

- dimensions and weight of the device.

Devices are selected according to power depending on the volume of pumped water

The first of the characteristics makes it possible to understand what volumes of water are pumped by the pump, depending on the pressure developed in the system. The higher this indicator, the less water resource must be passed through the unit to obtain the required pressure. To correctly select a sample of equipment, the operating point must be located under the curve of the graph.When choosing this indicator, it is desirable to provide a supply margin of at least 20%. Another parameter is directly related to it - pump performance.

The power taken from the network is determined by the amount of current in the load and the supply voltage (220 or 380 volts). This parameter is taken into account when selecting protection devices for current supply circuits and when calculating the cross-section of wires that are part of the supply lines of power supply. The specified value depends on the performance of the pumping equipment, which increases with its increase.

The dimensions of the purchased sample and its weight are also taken into account when choosing a suitable model. This also applies to the operating conditions of the pump - the minimum and maximum permissible temperature of the pumped medium. The reliability and durability of the purchased sample depends on the correct selection of this indicator.

Main characteristics of the model

The Grundfos UPS circulation pump has a power of 45 watts. You, like many professionals, may be interested in the lift height, which is 4 m. The maximum possible liquid temperature is equivalent to 110 ° C. The permissible water temperature varies from +2 to +10 ° C. The device complies with the protection class ip44. The construction weighs 2.6 kg. It provides for the possibility of adjustment.

The pressure is 10 atmospheres. The installation length is 180 m and the capacity reaches 48 liters per minute. Before purchasing this Grundfos UPS circulation pump, please note that it does not have dry running protection. This surface unit has a number of advantages, which you can find out about from the reviews below.

Advantages and disadvantages

The pump in the underfloor heating circuit system works silently - it can be located in the house next to the living rooms

The advantages of pumps from a Danish manufacturer include:

- high work efficiency;

- reliability of all units and parts;

- low level of intrinsic noise;

- versatility of application.

Grundfos pumps are used as part of heating systems and are in demand for organizing hot water supply (DHW) circuits. In addition, they can be installed in floor heating systems or in climatic equipment.

The versatility of Grundfos units is also manifested in the fact that after purchasing them, the user will be able to work with the following types of coolants:

- water heated to a certain temperature;

- antifreeze that does not contain solid components;

- heat carrier with the addition of ethylene glycol in a volume of not more than 40 percent.

The advantages of equipment samples of this class include the operation of the rotor in direct contact with the coolant; it is separated from the rest of the units by a metal glass made of stainless steel. In addition, in these models, the inlet and outlet pipes are located at the same level, which determines the quiet operation of the entire unit. The significant advantages of products from a Danish manufacturer include:

- optimal ratio of the declared price and quality;

- high rates of energy efficiency;

- a large selection of models that can satisfy the most demanding customer;

- long service life and advanced technical support system.

The characteristic disadvantages of Grundfos pumps are considered to be a relatively high price per unit of goods (from 6500 rubles) and the absence of a cable for connecting to the mains in the kit.

teplomex.ru

was founded in Denmark over 70 years ago. Over the years, she managed to become one of the world leaders in the production of household pumping equipment. Customer reviews for these pumps testify, first of all, to the high quality of the products manufactured by the Danish company. Pumps from this company are installed in gas boilers of such well-known manufacturers as Viessmann, Protherm, Baxi, Immergas and others.

Today we will take a closer look at circulation pumps for heating brands Grundfos, reviews, specifications and model range.We will analyze the internal structure of the pump for circulating the coolant of this brand, make a selection and summarize, comparing the advantages and disadvantages of Grundfos pumps for heating a private house.

Grundfos UPS series pumps: model range, technical characteristics

Models of circulation pumps "Grundfos UPS" are the most popular among consumers, both in the Russian and European markets. They are used for open and closed heating systems of a private house or other residential and small industrial premises.

They can also be used for underfloor heating and for cooling and air conditioning systems. They gained their popularity among buyers due to their relatively affordable prices and, of course, European build quality and materials.

Grundfos UPS 25-40 and 32-60

Recently pumps Grundfos UPS produced in several countries: Denmark, Germany, Serbia or China. When online selection of a Grundfos pump for heating, on the official website or in the online store, you can find models with different technical characteristics:

- Grundfos UPS 25-40; - Grundfos UPS 25-60; - Grundfos UPS 25-80; - Grundfos UPS 32-40; - Grundfos UPS 32-60; - Grundfos UPS 32-80.

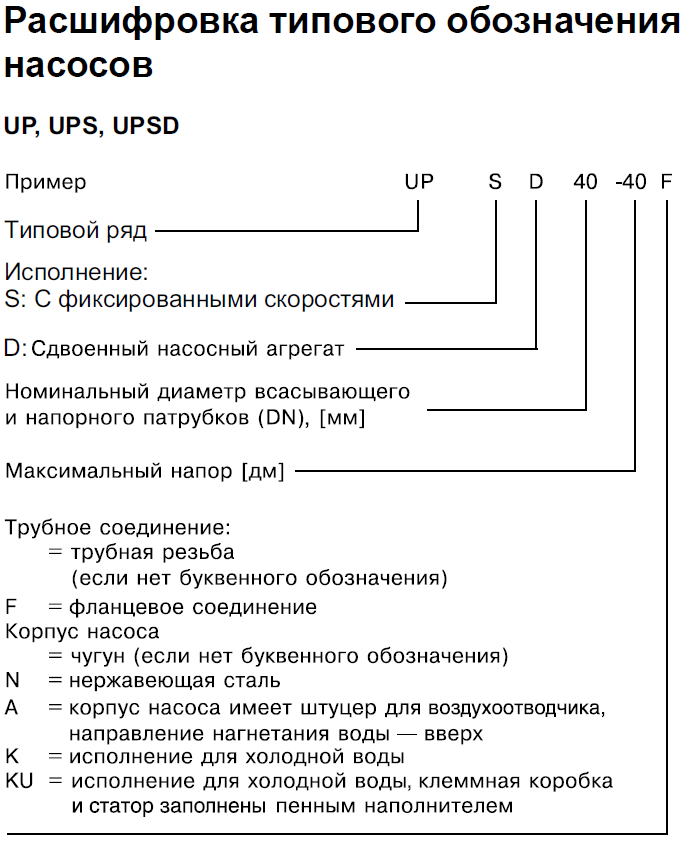

What do these numbers tell us? And it stands for the following.

The first number in the abbreviation indicates to us what internal diameter the cast-iron union nuts of the pump (American) have when connected to the heating system. In this case, they can be 25 mm, 32 mm, and sometimes 40 mm in diameter.

The second figure (40, 60, 80, 120) shows the maximum height to which this pump model is capable of raising a water column, which is 4, 6, 8 and more meters, respectively.

How to choose the right circulation pump Grundfos

The diameter of the union nuts for the pump is selected depending on the diameter of the pipe that is planned to be used for the heating system. If it is a polypropylene pipe with a diameter of 20, 25 or 32 mm, then a pump with a diameter of 25 mm nuts is sufficient.

If the system is made with a polypropylene pipe of a larger diameter, or steel from 25 mm and more, then it will be advisable to buy a Grundfos pump with an inner diameter of 32 mm union nuts and with a standard installation length of 180 mm.

As for the height of the water rise by the pump, for a one-story or two-story private house with a total area of up to 100 m2, where there is no underfloor heating system, the Grundfos UPS 25/40 or 32/40 model is quite enough, the technical characteristics of which meet these requirements.

If you have a two-story house with a small area of 100-150 m2, and an additional circuit for a warm floor without a pump-mixing unit is also planned, it is recommended to buy a UPS 25/60 or UPS 32/60 pump. For a house with a large area from 300 m2 or three-story buildings, workshops, it is necessary to install a circulation pump with parameters 25/80 or 32/80 in the heating system.

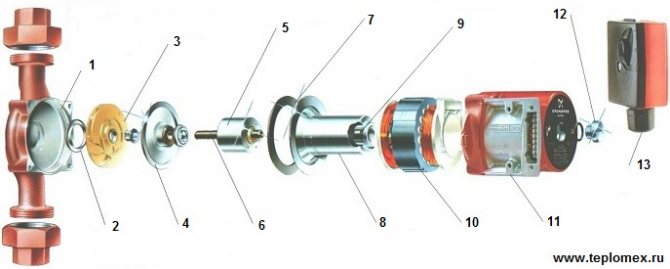

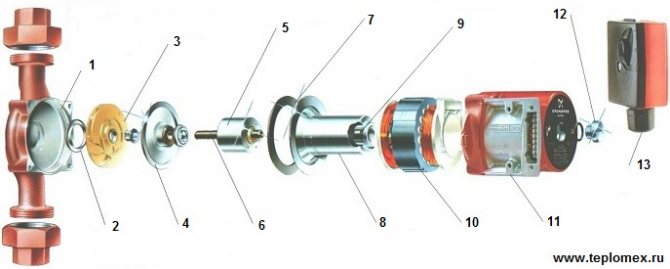

Circulation pump device Grundfos UPS

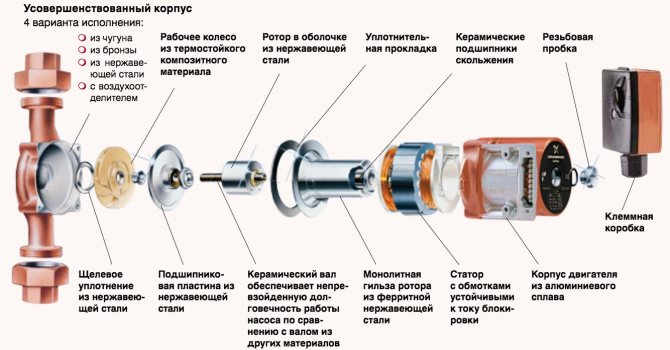

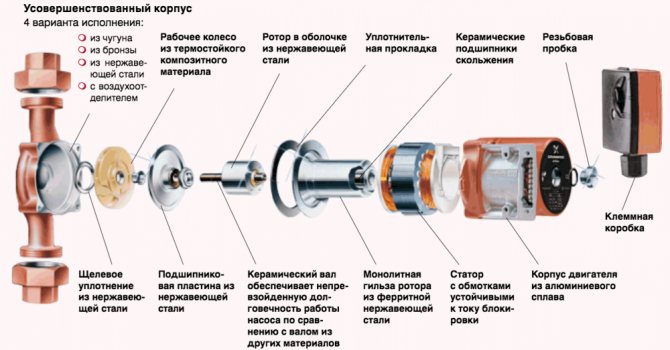

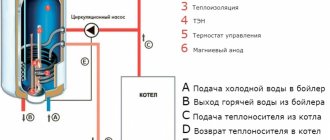

The pump body for heating the Grundfos brand is cast iron or stainless steel. It can also be equipped with an air separator. The pumps of the Grundfos UPS series have 3 speeds, manually adjustable using a special switch on the terminal box. We look at the diagram of its internal structure.

Grundfos UPS: device, materials

1 - pump casing 2 - stainless steel gasket 3 - plastic pump impeller 4 - bearing plate 5 - durable ceramic shaft 6 - rotor protected by a stainless sheath 7 - paranite gasket 8 - solid ferrite stainless steel rotor sleeve 9 - sleeve bearing with ceramic shaft 10 - stator and windings 11 - aluminum motor housing 12 - threaded plug 13 - box with terminals

Features of the Grundfos Alpha2 and 2L pumps

Like the "circulators" of the UPS series, the Alpha2 pump operates almost silently and economically, consumes no more than 45-60 watts. But, unlike the previous series, it has a display with a digital indicator showing the current energy consumption and power consumption.

In addition, the pumps Grundfos Alpha2 equipped with a sensor for protection against "dry" running, protection against overheating, summer mode to protect against blocking of the pump (jamming) in case of prolonged downtime and economical night operation.

And the main distinguishing feature of the Grundfos Alpha2 pump is the AUTO ADAPT function.In addition to three speeds, proportional and constant pressure modes, AUTO ADAPT helps the pump to work automatically, determining independently what the heating system needs at the moment. It is not for nothing that the Alpha series pumps are recognized as the most economical circulating pumps in the world.

Alpha series Grundfos pumps

The pump casing is thermally insulated and made of either cast iron or Alpha2 (N) stainless steel. This series is equipped with a special Alpha plug for easy and quick installation. The model is also available with an air separator - Grundfos Alpha2 (A).

Grundfos Alpha2L - This is a cheaper version of the pump for heating systems of the Alpha2 series. It lacks some additional functions and a thermal insulation jacket. But this pump has more compact dimensions, and it is itself a little cheaper than its "big brother".

Why Grundfos Alpha3 pumps are good

Circulation pumps in this series have the same technical characteristics as the Alpha2 model. Their main feature is the ability to quickly and professionally balance your entire heating system.

This became possible thanks to a special device "Alpha Reader", which transfers data from the pump to a cell phone (smartphone). To do this, you need to install the free mobile application "Grundfos GO Balance" on your phone, and you can monitor the state of the entire heating system at home.

Transferring Information Through the Alpha Reader

How is the heating system balanced?

1. Download a dedicated mobile application. 2. In the application, enter the data: the area of each room, the number of radiator sections, temperature. 3. Install the Alpha Reader (sold separately) on the Alpha3 Series pump. 4. Using the valves, adjust each radiator in the house according to the indications in the appendix. 5. After a while, you will receive a report on the balancing of your heating system.

Advantages of Grundfos circulation pumps:

- good reviews from buyers and specialists; - quality of materials and reliability in work; - noiselessness; - efficiency; - a wide range of models; - many useful functions in the models of the Alpha series; - a network of service centers across the country; - round-the-clock technical support by telephone "hot" line.

Disadvantages of Grundfos pumps:

- high price for the pump (from 6500 rubles for the most budget model UPS 25-40); - lack of wires for connection to the electrical network in the complete set.

We have disassembled the device and the lineup circulation pumps Grundfos for heating and their technical characteristics. We identified the features of each model, their advantages and disadvantages. The main motto of the company is reliability and modern technology, which we can be convinced of by purchasing a pump from this world famous Danish company. Watching the video.

Selection features

The size of the union nut depends on the diameter of the pipes to be connected.

When choosing the right sample of pumping equipment from Grundfos, much attention is paid to the diameter of the union nuts. It is selected depending on the size of the pipe being prepared for installation in the heating system:

- if a polypropylene pipe with a standard size of 20, 25 mm is used - nuts with a diameter of 25 mm are suitable for installation;

- when using pipes with a larger diameter (or steel billets from 25 mm and above), it makes sense to purchase equipment designed to use union nuts with an inner diameter of 32 mm.

If the listed requirements are met, the installation of the equipment will not cause serious problems if you follow the instructions in the instructions.

How to choose the right pump

When choosing pumping equipment, it is necessary to take into account the parameters of both the equipment itself and the heating circuit. If you make a mistake, then the efficiency of the device will noticeably decrease, that is, the money will be "thrown into the wind."

When choosing, the following parameters should be taken into account:

- the size of the heated area;

- indoor temperature;

- functionality;

- temperature difference between supply and return;

- pressure;

- network characteristics;

- the quality of the coolant.

If the choice is made correctly, taking into account all the requirements, the room will always have a comfortable temperature. When choosing a power, you need to take into account the volume of the room and the indicators to which the coolant in the system should be heated. There are many formulas for calculating the required pump performance.

Calculations taking into account averaged indicators:

- In order to find out how efficient the unit is, temperature differences are taken into account - from +30 to +35 ° C. The boiler power must be divided by the resulting figure, and the result will show the flow rate, that is, the productivity.

- 0.6 m of head is enough for a pipe with a length of 10 m. For each model, this indicator is regulated and indicated in the passport.

- Heating pipes must have the same diameter as the pipes of the connected equipment. With the help of one pump, pumping of up to 80 meters of the circuit is provided.

The temperature of the pumped heat carrier must be taken into account. Pumps installed in heating systems operate with a liquid that heats up to +110 ° C.

If the circulation circuit is long and the pipes have a large cross-section, then a more powerful installation will be needed. Again, increased power is required if not water is used as a heat carrier, but another, more viscous liquid.

Modern pumps have a protection class of IP44. This indicates that the ingress of foreign objects larger than 1 mm into the device and water spray is excluded.

Pump energy efficiency

Renowned European pumping equipment manufacturers have made great strides in optimizing energy consumption by introducing several wet rotor models to the market. This was achieved through the use of modern DC motors, controlled by a controller. Such models belong to the equipment of class "A", which is considered the most efficient in terms of minimizing energy losses - their consumption does not exceed 0.09-1.3 kW).

Grundfos specialists have developed a whole series of energy-saving pumps under the names ALPHA2 and MAGNA3. The first ones are distinguished by simple functionality and are intended for use in heating and hot water supply systems in private houses. Models of the second type have the AUTOAdapt function, which allows you to automatically set the optimal power consumption mode. Their capabilities correspond to modern requirements for indicators of efficiency and productivity of equipment of this class. They are designed for use in heating systems of private houses and industrial enterprises.

Model overview

There are different pump models in our catalog. When choosing the right equipment, be guided by the characteristics. You can also use a formula to calculate performance. To do this, you need to multiply the volume of the coolant by 3. The performance of the device must be higher than the result obtained.

Let's consider the most popular models:

Grundfos UPA 15-90 is a compact wet rotor device. Its maximum head is 9 m. With this device, you can pump no more than 1.6 m3 of coolant per hour. The unit is configured in manual or automatic mode. It is protected against corrosion and is installed directly on the pipeline. The model works silently and is suitable for installation in a country house.

The Grundfos UPS 25-60 is another example of equipment designed for domestic use. This device produces a maximum head of 6 m. It can pump up to 3.4 m3 of heat carrier per hour. The device is equipped with a wet rotor and has three speeds. It is installed not only in heating networks, but also in air conditioning systems.

Grundfos Alpha1 is a series of PWM-controlled units.In the models of this line, the maximum rate of the pumped heat carrier is 3.8 m3 at a head of 6.5 m. All devices of the series are very energy efficient. They have the function of automatically adjusting the rotation speed.

Grundfos Alpha2 is another line of pumps from this manufacturer. Models belonging to it can pump up to 3 m3 of coolant per hour at a head of up to 6 m. They have functions for setting night and summer modes, automatic speed control and other capabilities. The current performance of the device can be viewed on its control panel.

Modes of operation

The modern recirculation pump for heating belongs to multifunctional devices. Various samples of this equipment are capable of operating in the modes indicated in the passport, including “fixed speed”. All of them are equipped with a synchronous motor, the operation of which is controlled by an integrated processor. During the operation of the unit, the control unit registers the following basic parameters:

- current strength;

- rotor speed;

- temperature in the working area and others.

Its presence allows you to adapt to a specific heating network with an optimal energy consumption mode.

Features of Grundfus equipment

Compliance with the rules of operation and installation will allow you to use Grundfus pumps as efficiently as possible for a long time:

Double-rotor circulation pump Grundfos

- When installing the pump yourself, it is impossible to confuse the direction of the nozzles, since an arrow is drawn on the body of the product, indicating the direction of rotation of the rotor, that is, the movement of the coolant.

- The device does not include fasteners, so you will need to take care of their purchase in advance.

- The circulation pump should only work at positive temperatures in the room. If the device was stored or transported at temperatures below 00C, then it is recommended to start it after installation not earlier than in a day.

- Optimal mains connection - separate cable from the switchboard.

Parsing the pump with your own hands

If repair is necessary, the equipment must be taken to the service, if the device is under warranty

Any user who has studied the design well can disassemble the purchased sample of pumping equipment, if desired. The need for this often arises when it is necessary to repair it or overhaul with the replacement of worn parts. After complete disassembly, the main working units of the mechanism are inspected, and then checked for wear.

The main focus is on examining the condition of the "wet" rotor. It should be removed and replaced with a new part in the presence of a repair specialist who can control this difficult operation.