Purpose and range of valves

For heat supply systems, these fittings are used to control the supply of hot coolant and open the heating circuit. As a rule, a shut-off valve on a heating device is mounted in areas where radiators are piped.

In addition to functional advantages, such a solution has practical benefits. After closing the shut-off valve of the battery, the home craftsman will have the opportunity to repair it without stopping the functioning of the entire heating structure.

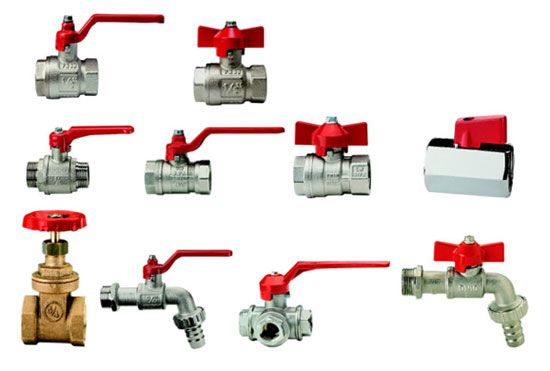

Today, shut-off valves for heating in the domestic market are offered in a large assortment, and among the most frequently used products are the following devices:

- shut-off valves;

- gate valves;

- needle valves;

- Ball Valves.

All of them are made from durable metals that are resistant to corrosive processes and high temperatures. Shut-off type fittings protect the heating circuit from the possibility of an emergency, increase the reliability of the heat supply system, thereby helping to minimize the negative consequences as a result of a breakdown of a separate heating device.

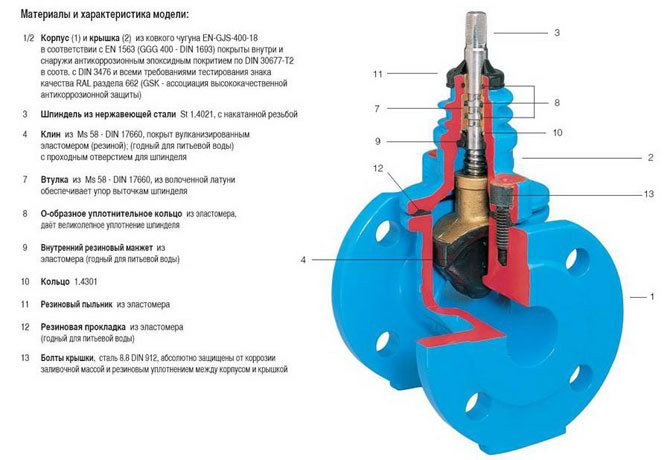

Gate valves

The design and operation of this type of pipeline shut-off valves differs from taps in that the shut-off element has the form of a disk that rotates around its axis. The axis of the disk is located perpendicularly or at a certain angle to the direction of flow of the working medium. Gate valves have found their application on pipelines of large diameters at low medium pressures. To control the dampers, the following can be used:

- hydraulic drive;

- electric drive;

- handmade.

The material of the damper body is usually cast iron, and the rotary disc is made of steel. The devices are mounted on the pipeline by means of a tie-in using welding or a flange connection.

The device of the gas pipeline shut-off valves must comply with the conditions of use and the characteristics of the working medium, such as:

- the amount of pressure loss in the open state;

- features of the operation of low pressure lines;

- ergonomics, ease of use and repair;

- speed of opening / closing.

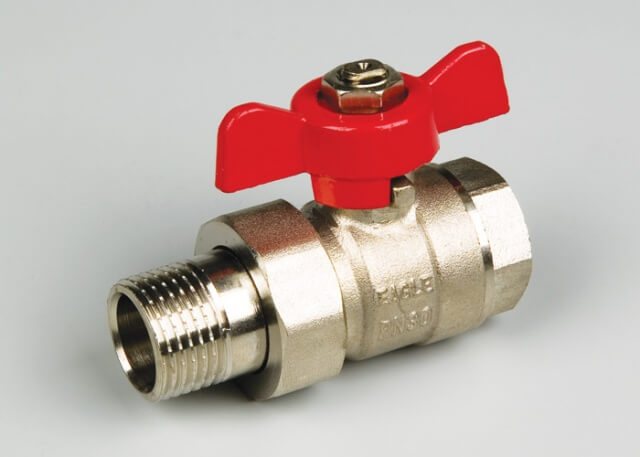

Ball Valves

This product belongs to shut-off valves for heaters. It is designed to regulate the flow of liquid, which is used as a heat carrier. The ball valve consists of a union nut, an air outlet device that is designed to drain air from the system, and a plug. The product has an internal thread.

When purchasing this type of fittings, you should pay attention to the material of manufacture, to the presence of O-rings that increase the service life of this element in the circuit. As practice shows, it is brass taps that stand out for their increased wear resistance and anti-corrosion resistance.

Installation of shut-off valves

Most often used in distribution systems of various kinds of process liquids and gases, shut-off and adjustable valves are arranged in the form of a ball valve. Due to their properties, they are necessary for the correct functioning of installations in private houses, industrial premises, industrial enterprises and wherever water and gas supply is required. Ball valves shut off the water supply using a lever that moves a steel ball in the valve seat.However, they do not properly regulate the flow rate; they only close or open the stream. Thanks to their characteristic structure, they are very robust and reliable. Their resistance to mechanical damage and minimal risk of contamination makes them durable and guarantees their functionality for many years after installation.

By its design, the ball valve is assembled in a body that has a groove for a seat, a locking ball, and a valve opening lever. Process fluid or gas flows through the orifice in the ball when the valve is open. When it is closed, the ball moves in the socket with the sides without a hole and blocks the flow. To overlap, a quarter turn of the lever is sufficient. This function is extremely important in the event of a breakdown, such as a burst of a pipe, where the flow of water must be closed quickly to prevent leakage.

The most popular types of ball valves:

- half-inch ball valve - such a ball valve is used in hydraulic systems to connect hydraulic systems in houses, apartments, water supply distribution inside buildings, and is also used for heating systems;

- two-inch ball valve - installed as the main valve in residential buildings, at the input in industrial buildings and other facilities on central pipelines;

- flanged ball valve - mounted in switchgears, on large pipes to strengthen mechanical connections;

- ball valve with filter - in addition to its normal function, it also filters impurities.

When performing installation work, shut-off and control valves can be installed in almost any position - you just need to pay attention to the correct direction of movement of the main medium, which must correspond to the mark on the body.

Shut-off valves

This type of shut-off valves is used to create the possibility of replacing the heating device without draining the working fluid from the heat supply system. Taking into account the design features, direct and angular modifications of such valves are distinguished.

Some products are equipped with a drain device designed to smoothly lower the pressure in the heating circuit. The shut-off valves are characterized by the presence of a hose nozzle, which makes it possible to install it as quickly and easily as possible.

Range

Among the large number of various fittings for debugging heating radiators, the leading positions have been held for many years. valves and taps BUGATTI and LUXOR

.

In the Gulfstream online store you can find a wide range of different valves from Luxor:

- thermostatic corner

;

- shut-off straight and corner

;

- regulating straight and angular

;

- thermostatic straight

;

- thermostatic regulators - heads

.

Regulating devices from Luxor company will work properly for a long time. You can order flanged or coupling units in just one click. Also, most valves have built-in electrical actuators, which keeps operating costs to a minimum.

If personal control over the heating system is of paramount importance to you, then the units from the company Bugati

will be the best option for purchasing.

Radiator valves from the manufacturer Bugatti

have the possibility of manual adjustment, which simplifies access to the mechanism and allows you to more accurately adjust the parameters of the heat exchange unit.

Needle valves

The functions that the needle valve must perform are varied. In accordance with the design device, this product can have a shut-off, regulating and balancing purpose.

The needle valve in heating systems is used for radiators.Thanks to its presence, a smooth flow shut-off is ensured and it is possible to avoid the consequences of water hammer, which have a negative impact on the entire heat supply structure.

Unlike a ball valve, which has two positions, the needle valve can function in three modes:

- "open";

- "closed";

- Partially closed.

Gate valves

These reinforcement products perform exclusively a shut-off function. Due to the design features, the valves can only be in two positions, since the mechanism has a locking element located perpendicular to the coolant flow. If the valve element has an open position, the heated liquid enters the circuit, and when it is closed, it does not allow it to circulate.

The valve has a number of features:

- Provides low hydraulic resistance in the circuit.

- It has the optimal size of the inner diameter, which coincides with the cross-section of the pipeline.

- It's easy to mount.

- It is highly reliable.

Shut-off and control valves

In addition to the locking function, which helps to prevent emergency situations in the circuit, the fittings can perform the task of regulating the flow of the coolant. Control valves for heating radiators and systems are used to smoothly adjust the temperature of the heated liquid, in order to stabilize the pressure, and also to control the direction of movement of the working medium.

These devices are represented by the following types of valves: balancing; reverse; make-up; thermo-; waste; bypass.

Shut-off valves for heating

Shut-off valves

Heating fittings for regulating the volume of fluid flow in pipes are one of the main elements of any heating system. It is installed at those points of the line where it is necessary to partially or completely restrict the flow of water.

Almost every manufacturer provides a catalog of fittings for heating. It is necessary for the correct choice of a particular model. The main parameters are.

- The diameter of the inlet and outlet pipes. Required for connection to the trunk. It is important that in a fully open state the valve or valve does not limit the speed of movement and the volume of the coolant;

- The degree of regulation. The accuracy of reducing or increasing water pressure depends on this. Ball valves are used to quickly shut off the flow, and with the help of wedge valves, you can smoothly regulate the flow of the coolant in the pipes;

- Possibility of installing an automatic regulator of the degree of opening of valves for heating.

Often, taps and valves are used to complete the heating system. In addition to the correct installation and selection of a specific model in terms of performance, it is necessary to know the device of these elements of the heating system.

Heating taps

Heating taps

The use of taps as fittings for heating radiators or for creating pipeline shut-off points is due to their relatively simple design and the ability to choose from several model options. Depending on the method of regulating the flow of water, the following types of taps are distinguished.

- Ball... A ball with a through hole is located inside the structure. As the handle is turned, the bore increases or decreases. This shut-off valve for heating radiators is characterized by the ability to quickly shut off - for this, it is enough to turn the lever 90 degrees. However, with the help of such a crane, it is difficult to perform smooth adjustment;

- Rod... A rod with a rubber or ceramic gasket is used as a locking mechanism. To close and open completely, you need to make several full turns of the handle.Such shut-off valves for heating are used to accurately control the volume of the heat carrier flow.

Installation and selection of valves should be carried out only in agreement with the operating parameters of the system.

Care should be taken to select the gaskets for installation. In systems with antifreeze, it is recommended to install paronite, as they are least susceptible to deformation.

Heating valves

Structurally, they are similar to the above-described rod valves. The main difference is that their size is much larger. The shape of the internal channels has also been changed - the wave structure provides protection against significant pressure drops. This ensures stem integrity and complete sealing of heating valves when closed. Such mechanisms are installed in central heating pipelines, where the pipe diameter exceeds 100 mm.

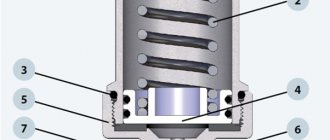

Balancing valve

When installing heat supply systems, it is used to regulate the operation of several hydraulic circuits. Installing a balancing valve allows you to increase the efficiency of the heating structure, as it helps to control the permissible volume of consumed heat carrier.

Correctly mounted, this type of fittings, in which the principle of operation is to evenly distribute the heated liquid over all segments of the heat supply system, can function in the most difficult conditions. This device is capable of withstanding significant pressure drops in the circuits and high speed of movement of the coolant through pipelines.

The balancing valve, the cost of which for direct-acting modifications is not small, consists of the following main elements:

- a body made of steel, silumin or brass;

- branch pipe;

- position lock;

- membrane septum;

- measuring diaphragm;

- shutter indicator.

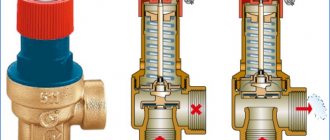

Check valve

The use of this type of control valve prevents water hammering and thereby improves the reliability of the entire heating structure. The valve prevents the heated liquid from circulating back through the system. In order for the device to be optimally combined with the contour, it must be selected taking into account the size of the inner diameter.

The main element of the check valve is the spring, which serves to hold the stem and, in the event of an emergency in the circuit, closes it.

Make-up valve

To ensure effective circulation of the working medium in the system, there must be an optimal volume of coolant in the circuit - water, antifreeze, etc. Therefore, the make-up device belongs to the mandatory elements of every heating structure.

This type of valves allows you to compensate for fluid losses as a result of leakage in heating devices and the use of drain valves and Mayevsky taps.

The main purpose of this make-up element is to control the amount of coolant in the circuit, and if necessary, it must replenish its losses. It is best to opt for an automatic device equipped with a reduction mechanism and a diaphragm, which is under the pressure of the working medium.

If the pressure in the circuit is reduced, the liquid does not affect the diaphragm, the spring-pushed stem falls, opening a gap in the seat. As a result, the circuit begins to recharge from the water pipe until the pressure in the system returns to normal.

How often do you need to service?

The average service life and maintenance schedule of one or another shut-off valve depends on the type, place of use, standard terms, which are determined by the manufacturer and the operating organization. On average, for apartment shut-off and control valves, the inspection period is one year. The shut-off valves must be checked for leaks and serviceability at least once a year.It is advisable to inspect the shut-off valves in the apartment at least once every six months. Pipe fittings on trunk networks, at distribution points and at other technological units are serviced at least once a year, most often during technological breaks in work or during scheduled repair work.

Components of water supply networks, including elements of shut-off and shut-off and control valves used in the water supply system, should be selected taking into account the corrosiveness of the water in order to ensure the standard service life. Water supply installations can only be made of materials with a valid hygiene certificate. Approval is required not only for pipes, fittings or fittings, but also for other materials in contact with water, such as seals, adhesives, paints. This should be borne in mind when choosing one or another valve for the water supply network.

Stagnant water in the installation can affect the operation of shut-off and control valves due to an increase in the concentration of various kinds of active dissolved substances, suspended solids and the growth of bacteria, which can have a negative effect on the operation of the system components. The degree of wear depends on the materials from which the installation is made, and on its technical condition, the composition of water from the water supply network. The deterioration in quality will be the greater, the higher the temperature and, the longer the immobility of the water in the system, therefore, if the operation of a particular system is not performed, the frequency of inspections and maintenance can be carried out more often.

For hygiene reasons, it is necessary to flush the system after periods of inactivity. Fragments of installations that are rarely used or for a short period of time should be isolated after use and flushed before restarting. Also, before starting the system, maintenance of the shut-off and control valves should be performed to remove oxides, rust, flush from mechanical deposits and accumulations of sand, and other suspensions that may appear as a result of prolonged downtime of the system.

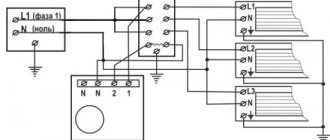

Thermal valve

It is considered the most efficient control valve for heating radiators. This device increases the functionality of the circuit and makes the heating process simple, convenient, and most importantly - rational. The thermal valve can be mechanical or automatic. Products of the first type consist of a thermal head and a valve.

Automatic models have a more complex design, they consist of the following elements:

- thermal sensor - built-in or remote;

- programmer;

- automatic control system.

The automatic mechanism is designed to adjust the temperature regime in the circuit in accordance with the settings that are preset by the consumers of thermal energy. This device is sold at a high price, but it fully justifies itself, since it can be used to optimize the functioning of the heat supply system as much as possible.

Relief valve

Exceeding the normal value of the pressure in the system leads to emergencies, damage to the integrity of the circuit and, in some cases, to the explosion of the heating boiler. For this reason, when arranging heating systems, a pressure relief valve is installed.

When choosing a place for placing this device, it must be borne in mind that most often an increase in pressure when the liquid overheats occurs in the boiler. Even the most modern units equipped with a gas valve are not 100% insured against accidents.

Experts recommend placing the relief valve as close to the heating boiler and on the supply pipeline as possible.When choosing a model of this device, you should pay attention to additional options such as the presence of a pressure gauge and an air vent. Valves with them are more reliable and practical.

Bypass valve

This type of control device is used to normalize the pressure difference between the return and supply pipes. The use of a bypass valve in heat supply systems in which thermal valves are connected in the circuits is mandatory, since they create pressure drops in certain areas and thereby reduce the heating efficiency.

Shut-off and control valves for radiators and heating circuits on the modern market are represented by a wide selection of valves of the most different designs. It is necessary to purchase specific devices in accordance with the heating system arrangement project, which is calculated and developed for a specific residential building or building, depending on its purpose.

This approach is explained by the fact that different types of pipes and heating devices are mounted in each building. Taking them into account, the selection of fittings is carried out.

Characteristics and purpose

Shut-off and control valves are devices that are designed to shut off, change and control the parameters of the internal environment of the pipeline. Such fittings are installed in water supply, heating, sewerage and gas supply systems.

Devices are used at all levels: from large highways to individual pipelines located inside a house or apartment.

Each system has several parameters that can be adjusted. These include volume and flow rate, pressure, temperature. Shut-off and control valves are used in order to be able to change these parameters without shutting down the system.

The purpose of such parts is to redirect the flow of liquid or gas to other branches of the system. For this, the device is installed in a place where there are branches. As necessary, some branches are closed, while others are opened.

Other types of shut-off and control valves are capable of reducing the pressure inside the system if it rises or decreases the temperature. Some of them work automatically according to the laws of physics.

For example, the vent valve only lets gas through when the pressure inside the system rises. This allows this parameter to be kept at the same level. Other devices are manually controlled, for example using valves.

The main characteristic of shut-off and control valves is their throughput. For optimal use, the relative, actual, maximum, initial and conditional throughput are calculated.

Note! The throughput is a physical quantity that reflects the volume of a medium of constant density passing per unit of time through a section of the cross-section of a pipe at a pressure of 1 bar. Simply put, it is the amount of liquid or gas that can pass through a pipe in a given amount of time.

In addition, shut-off and control valves are characterized by a range and range of regulation, as well as a regulator setting. These parameters reflect the difference between the maximum and minimum bandwidth data: the range of values that can be adjusted.

We recommend that you familiarize yourself with: Types of chimneys for stoves with a long burning system and which one is better to choose

Another important characteristic is relative leakage. It reflects the theoretical ability of parts to deviate from the specified tightness parameters. Simply put, this is a quantitative reflection of the leakage of the product.