Kitchen sewers often suffer from blockages. The most unpleasant of these are associated with the accumulation of fat in the pipes. Traditional chemistry like "Mole" in advanced cases can be powerless. But such an ingenious device as a grease trap will help to avoid blockages. How to build it, we'll talk in this article.

- 2 How to make a grease trap yourself

2.1 Material selection and calculation

- 2.2 DIY making

Purpose and design of the device

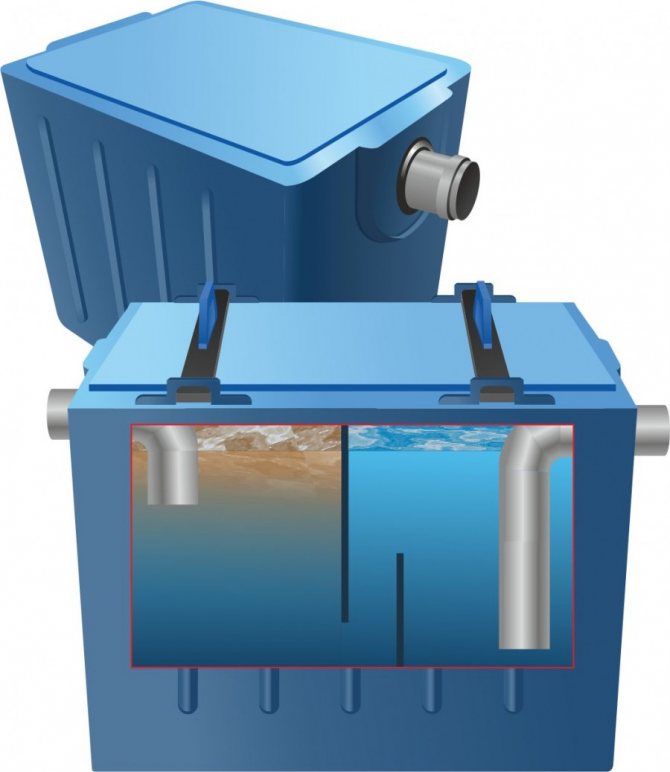

The grease trap is designed to prevent the penetration of fats and other oily substances into the sewage system or cleaning devices. Its action is based on the separation of water and fat. This is possible due to the differences in the specific gravity of these components.

Since fats and oily compounds are lighter than water, they end up on its surface. From there, they are redirected to a sump, which is regularly cleaned.

A household grease trap for a sink consists of the following components:

- compartment where heavier elements accumulate;

- compartment for fat and oil components;

- inlet tube;

- outlet tube for connection to the sewer system;

- cap.

Additionally, you can install a controller that monitors the level of accumulation of fat particles. If the compartment is overfilled, it must be cleaned mechanically.

To ensure the long-term operation of the device, fat-dissolving substances should be added to it.

Preparation for making a fixture

Having learned what the dimensions of the grease trap body should be, it is supposed to draw up a drawing and find all the necessary tools for assembling the product.

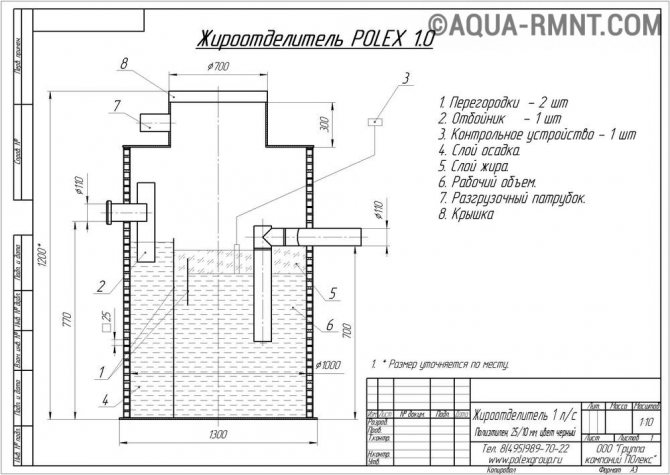

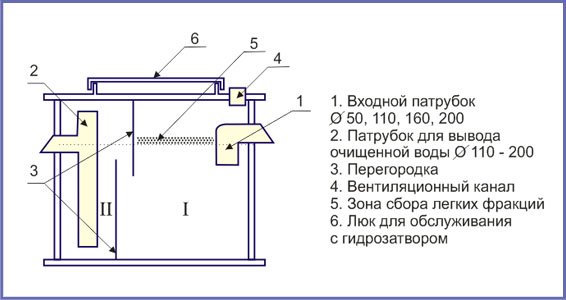

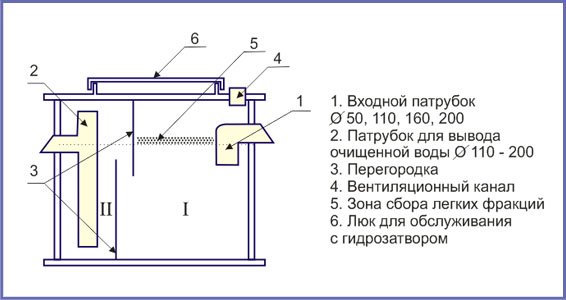

Grease trap drawing

At the stage of drawing up the drawing, it is required to indicate the location of the inlet and outlet.

The lower edge of the pipe for redirecting water from the grease trap to the sewer pipe should be located 3-5 cm below the middle of the inlet. The slot where the water supply pipe will be installed should be next to the housing cover.

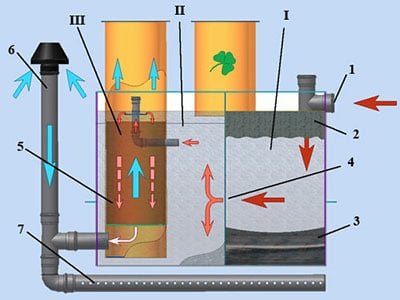

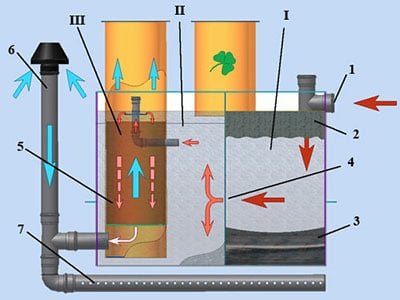

Grease trap can be composed of 6 elements, including a vent

Required tools

The manufacture of a grease trap is carried out using tools such as:

- electric jigsaw or saw;

- sanitary hermetic means;

- a piece of sandpaper;

- glue-treated rubber sealing strip.

Advantages of grease trapping equipment

Such equipment has long been used at catering establishments. There it stably demonstrates its effectiveness.

Therefore, household models also began to be popularized, possessing the following advantages:

- simplicity of design and ease of installation;

- minimal maintenance with cleaning every 2 weeks;

- high efficiency, as a result of which the sewage system is almost completely freed from the ingress of fats into it, causing deposits on the walls;

- protection of the room from unpleasant odors;

- the tightness of the apparatus;

- long period of operation;

- no need for electricity and the use of chemical compounds for cleaning pipes;

- savings on the maintenance of the sewer infrastructure.

If you have a large home with many occupants, then more powerful protection may be required. You don't need to buy an industrial device. It is enough to place one more additional device under the sink. All the advantages of using can be seen in the photo of grease traps under the sink.

Making your own fat trap

Manufacturing do-it-yourself grease trap for sewage starts with calculating its parameters. The performance of the device P is calculated by the formula:

P = n x Ps, where n is the number of washes in the house, Ps is the water flow rate in the system - the average is 0.1 l / s. If there is only one sink in the kitchen, n = 1. Then P = 0.1 l / s.

To determine the volume of the device, use the formula V = 60 x P x t, where t is the fat settling time, on average 6 minutes. We get 36 liters or 0.036 m³. Now it is easy to find out the parameters of containers for the grease trap - 0.3 m, 0.3 m and 0.4 m.

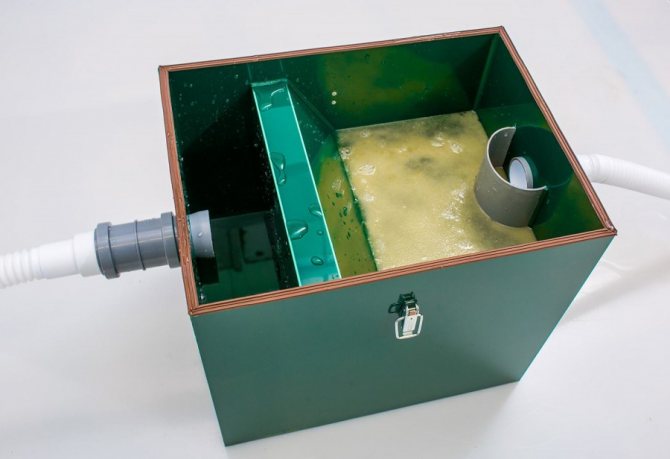

In order to construct do-it-yourself grease trap, you need to study the following step-by-step instructions:

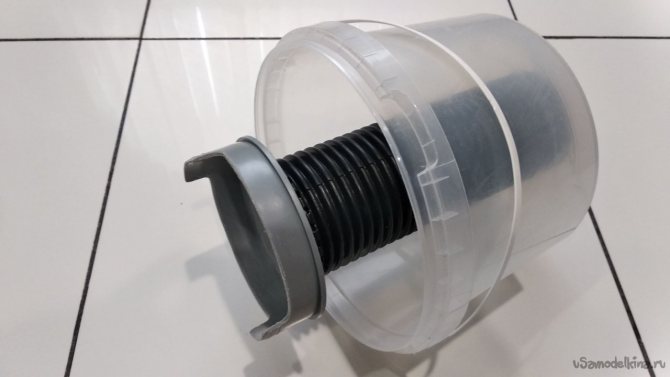

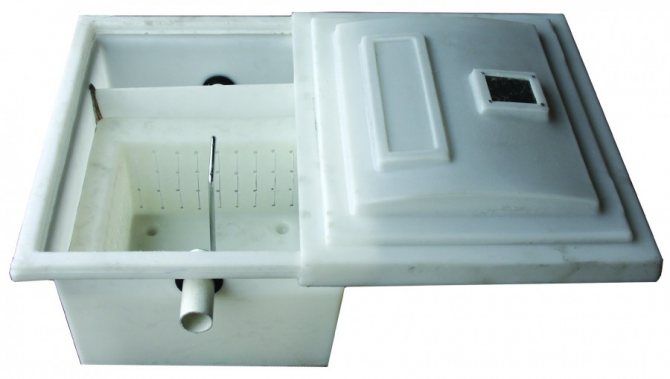

- We find a suitable container (rectangular parallelepiped shape) made of food-grade plastic, polypropylene, fiberglass, galvanized steel or stainless steel. The container must have a tight lid. You can use a plastic toy box. A duralumin corner from an old aquarium, where the glass is cracked, will do. It is removed, and a box is made of 6 mm thick fiberglass sheets on the frame. Cutting them is not easy, but the structure will turn out to be durable and waterproof.

- We make holes on the side walls of the box for water input-output Ø 50 mm (with a jigsaw, or better with a wood burner). We clean the edge of the holes with sandpaper. We place them opposite. The distance from these holes to the upper edge of the box is 5 cm.

- Under the hole we install (end) a pipe Ø 100 mm, with a length equal to 2/3 of the height of the box. We glue it so that the lower edge rises above the bottom of the box by 30-40 mm. Then we put a pipe Ø 50 mm inside the pipe. Its lower edge is 50 mm higher than the lower edge of the pipe.

- We connect a tee (elbow Ø 50 mm) to the upper end of the pipe. Of the two free ends, one will enter the hole, and the other, directed upward, will act as a ventilation duct.

- We fix the pipes on the holes using seals, epoxy resin.

- We insert 2 partitions into the box. We fix one barrier with hot glue in the upper part, at least 10 cm above the bottom. And we will attach the second partition (its length is 2/3 of the height of the box) at the bottom. Thus, the grease trap will have three sections.

- We mount the lead-in elbow, and smear all joints with silicone sealant. Where the lid connects to the box, you need to glue the sealing tape. Having closed the lid, we expect the sealant to solidify. The device for trapping fat before entering the sewer is ready.

- In order for the partitions to withstand the pressure of water, it is better to take epoxy resin instead of hot glue, and it is better to wrap the partitions themselves with rubber bands.

- The connections from the sink to the grease trap and then from it to the sewer are made of corrugated plastic pipes with rubber seals.

Plastic Models

These are the most popular and demanded models on the market. They are affordable and easy to use.

They are usually placed under the sink at home. The benefits include:

- long period of use, subject to the operating mode - up to 25-30 years;

- environmental friendliness of the material and harmlessness to humans;

- the possibility of individual selection of the size and shape of the separator;

- ease of maintenance.

With a wide variety of models in terms of power and throughput, plastic products are sensitive to mechanical damage.

Top 5 manufacturers

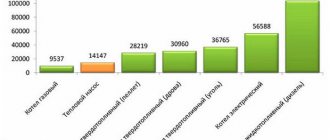

By choosing grease trap for kitchen, some prefer cheap and popular models, others buy more expensive, functional, durable - with a 30-year service life. When evaluating grease traps, one should pay attention to their performance.

The Top 5 by popularity includes several well-known manufacturers:

- Evo Stok - offers inexpensive devices made of durable reinforced plastic.

- FloTenk - is engaged in the production of high-performance GRP grease traps, mostly round in shape. The products of this brand have a high price, but a longer service life.

- The Fifth Element is a brand specializing in the production of steel and plastic devices with a removable water flow restrictor, its products are adjusted to the individual parameters of kitchen sinks.

- Wavin Labko - offers automated fiberglass models that capture grease with high performance. There is a sensor that informs about the level of accumulated fat in the container.

- Vortex - manufactures devices with a durable reinforced plastic case, including models for non-standard sewer systems. Special ribs on the body give the cage better resistance to mechanical deformation.

Stainless steel separators from the ACO Group are in demand, as well as sewer grease traps from polypropylene "Termit", which are used in small-scale catering enterprises. Grease Guardian automatic products are installed in all McDonald's.

Attention! Up to 10 washing tubs can be connected to high-quality, energy-saving and efficient HYDRIG grease traps for effluents from cafes and restaurants.

Fiberglass aggregates

This option is suitable for private houses where a high throughput of the grease purifier is important. This model can be installed both inside the house and outside.

Differs in higher strength, low weight, resistance to external influences and the influence of chemically active compounds. No effort required for installation or cleaning. At the same time, it is a more expensive model.

Installation procedure

Installing a grease trap is a simple procedure that does not require special skills. Basically, you just connect it to the pipeline, just like any other plumbing item. It is important to pay attention to the following details:

- Under the sink, it is necessary to allocate a reserve of space so that in the future it will be possible to service the grease separator;

- In the case of large objects located on the floor, it is necessary to pick up a level place, without slopes, eliminating the possibility of waste overflow;

- Use sealant and FUM tape to prevent future leaks;

- The grease trap should be installed away from stoves and heaters that can ignite accumulated waste;

- After completing the steps, it is recommended to test the product for several days before sheathing with cabinets.

Install a shredder on the sink - it will reduce the likelihood of blockages, eliminating the need for frequent opening of grease traps.

Photo of grease traps under the sink

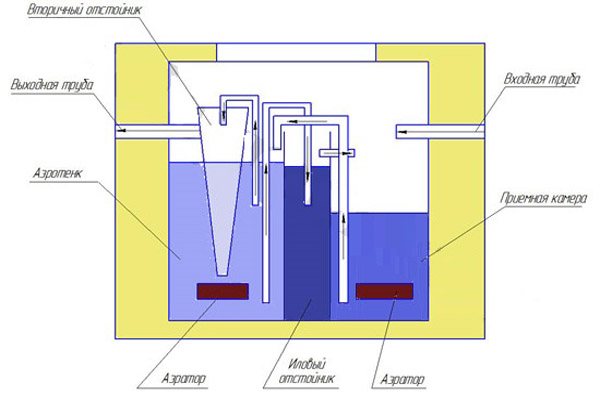

How does a sewer grease trap work?

Grease trap for sewage is similar to the operation of a household appliance. Due to the durable materials from which the device is made, it is placed underground, where the sewer pipes pass. After installation, the unit performs water purification in an autonomous mode without outside interference in the process.

It is important that the grease catcher is installed correctly immediately. Otherwise, you will have to dig up the earth and get into the structure of the pipes.

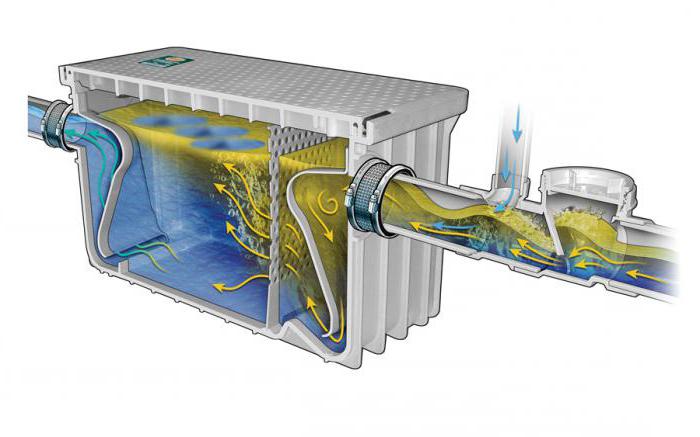

Grease trap for sewerage produces the first stage of cleaning. At this time, the separation of dirty waste water into fats, oils and other substances that pollute the sewer takes place. That is, the work is carried out on the principle of a separator, when oil is separated from water.

The device is divided into two chambers:

- The first contains a container for heavy substances;

- In the second, oil is removed from the water, where it floats to the surface.

When the oil level reaches a certain value, the sensor will be triggered. It signals that the oil layer has reached the size when it is necessary to clean the tank.

It should be borne in mind that during prolonged operation of the grease trap, oils can accumulate in it, which will eventually become solid. After that, the unit will need to be cleaned.

After passing through two chambers, the water in the sewer becomes clean, odorless, impurities, and especially without fats and oils.

Grease trap for sewage is not a complex design. But it is important to remember that it must be initially correctly integrated into the sewer system. Clean your unit periodically and then it will work as efficiently as possible.