General principles of substrate organization ↑

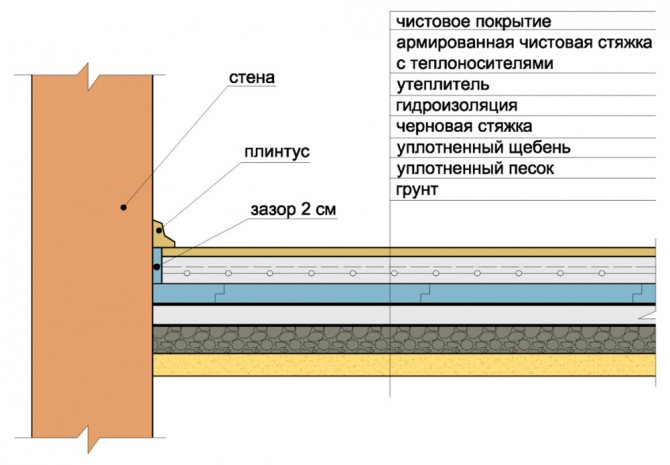

Regardless of whether a strip recessed foundation with a basement will be used or the rough floor screed will rest on the ground, it is necessary to organize a substrate or backfill, i.e. a layer that will serve as a barrier to moisture rising from the ground, as well as perform the function of thermal insulation.

Water tends to spread in a vertical direction through the smallest capillaries existing in the soil. If the cross-sectional dimensions of these capillaries are increased to sizes exceeding 0.5 mm, then such propagation becomes difficult. Thus, in order to organize an effective barrier, we need to create a layer with significant air pockets and gaps, which moisture in the soil layer cannot overcome. Also, this layer will prevent the floor from freezing, which can occur with direct contact with the soil.

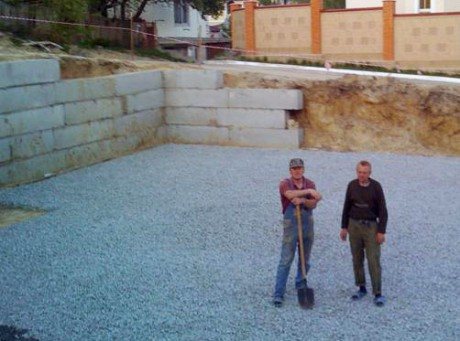

For the substrate, coarse crushed stone is used, sometimes the bottom layer is sprinkled with cobblestones. The crushed stone should be at least 30 - 50 mm, and its layer should be at least 10 cm. After filling, the crushed stone is thoroughly rammed using rollers or vibrating equipment.

First add rubble

Then, river or quarry sand is poured onto a layer of crushed stone in a layer of 7 - 10 cm, which is also rammed using a special tool. From how well the backfill layers are laid and tamped, their water repellency and bearing qualities will depend, which will affect the integrity of the subsequent concrete screed.

Sometimes a layer of fine gravel is poured onto the sand and closed with a liquid cement mortar. This is done in places where the water table is too high.

Crushed stone is covered with sand

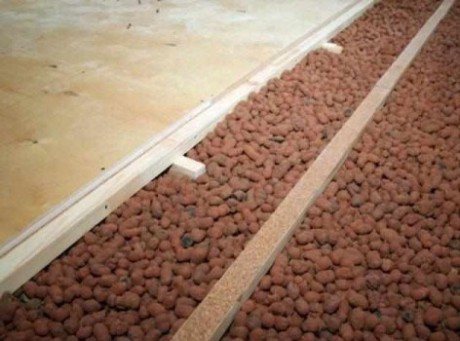

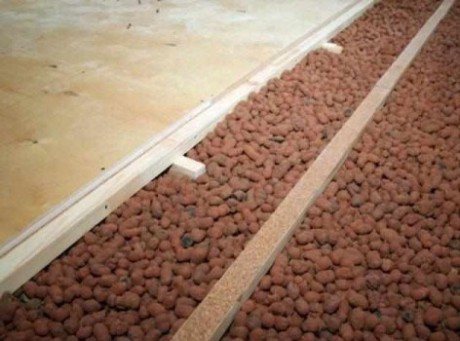

The substrate of large rubble or cobblestone creates a layer in which there are no small capillaries, instead of them there is a large number of volumetric air gaps or pockets, which water cannot overcome by capillary propagation. If the groundwater does not rise high, the composition of the substrate may include a layer of expanded clay, which will play the role of an excellent insulation.

Sometimes expanded clay is used as insulation

Sometimes measures are required to improve the waterproofing properties of the substrate. If, on the basis of measurements of the groundwater level and soil analysis, it is decided to carry out additional waterproofing measures, then the layers of sand and crushed stone are impregnated with bitumen or special polymer compounds, a rough screed must be performed and treated with mastics or penetrating waterproofing. Also, various materials are often combined.

Correct waterproofing of the foundation ↑

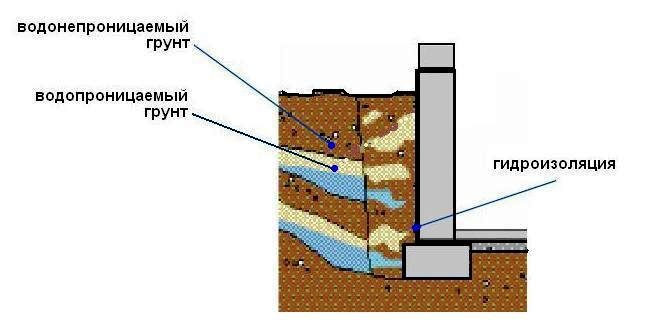

Another source of moisture penetrating the walls and floor of the first floor of a private house is a foundation that is poorly insulated from moisture. No matter how high-quality the waterproofing of the floor in the house is, if the foundation is not processed according to building codes and regulations, dampness cannot be avoided. This is especially true of basements, which can even be heated in the off-season and moisturize partitions and walls of the house. We will not list all the negative consequences of the lack of waterproofing of the foundation structures, but will dwell only on how this affects the moisture content of the ground floor floor.

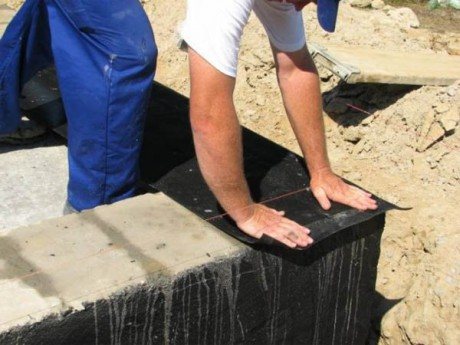

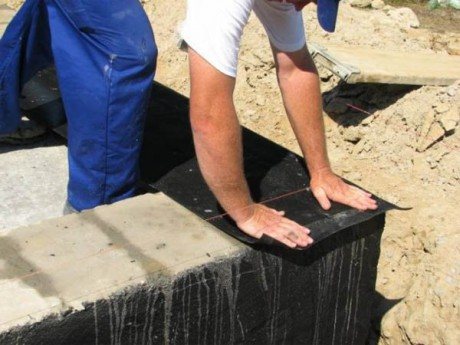

If the foundation is strip, then its structures smoothly pass into the load-bearing walls of the building, which means that the capillary movement of water can reach the rooms of your house.Waterproofing of strip foundations should be carried out using roll, bituminous, and in the case of a monolithic foundation - penetrating insulating materials.

Correct waterproofing of the foundation is a prerequisite

The choice of one or another method of isolation depends on the geodetic and climatic conditions of the area and should be made by an experienced specialist. Also, between the walls of the house and the foundation, there must be an effective vertical cut-off using roofing material or PVC membranes, which, in the event of soaking underground structures, will not allow moisture to penetrate the walls of the building.

Vertical clipping is done with roll material

If such a cutoff was made poorly or deteriorated over time, you can restore it using injection isolation. Insulation of the vertical ends is also required.

If a columnar or pile foundation is used in the construction of a house, then its structures must also be carefully processed with mastics, pasting insulation or penetrating compounds. In addition, it is necessary to insulate the upper surfaces of the ends of the posts, on which the wooden logs will lie. Wood reacts extremely negatively to constant moisture, therefore, roll materials must be laid between the wooden elements and the foundation structures: roofing material, roofing felt, PVC or polyethylene. The logs themselves can also be treated with mastics based on bitumen-latex compositions or impregnated with special solutions that prevent decay.

Roofing material is placed under the lags

Waterproofing of the ground floor floor ↑

Now we will consider the activities that precede the construction of the screed. In the case of a basement structure, this will be waterproofing of the floor of the living quarters, in the case when a basement is built in the house - insulation of the basement floor.

After completing the appropriate damper filling or substrate, we proceed to the main work on waterproofing the floor in front of the screed.

For this, various materials are used:

- construction polyethylene films;

- PVC membranes;

- roofing material;

- bitumen-polymer roll products;

- polyisobutylene;

- waterproofing, etc.

From the choice of a specific material, the principle of work does not change. Let's just say that traditional polyethylene films are the cheapest and easiest method of waterproofing, however, membranes and bitumen-polymer materials, as well as other modern insulating carpets and coverings, have the best characteristics and performance, but far exceed polyethylene in terms of cost and installation complexity.

Roll materials are carefully glued

Roll material is laid on the sand. Separate strips are carefully welded or glued, in the case of polyethylene, tape is used. The polyethylene film should be 200 - 300 microns thick, it is better to use two layers with overlapping seams. The overlap of the strips should be at least 10 - 15 centimeters. In the case of using various modern diffusion membranes or other coatings, installation should be carried out in accordance with the manufacturer's instructions, since installation conditions can vary greatly for different materials.

If a rough screed or "skinny concrete" is not used, then when installing a reinforcing frame on the film, care should be taken to provide linings that will not allow the reinforcing elements to pierce the coating. However, a more practical solution would be to build a layer of "skinny" concrete 6 - 7 cm thick from a conventional cement-sand mixture with fine crushed stone, which is also covered with roofing material or membrane on top.

The rough screed is also covered with waterproofing

Next, a reinforcement cage is laid on the rough layer and a finishing screed is performed.A rough screed can be treated with bitumen or bitumen-polymer mastic, and a layer of extruded polystyrene foam or dense foam can be laid on top for insulation.

Types of vapor barrier materials

Several basic types of materials can be used to create a vapor barrier layer. This is a polyethylene or polypropylene film, the so-called diffuse membrane or liquid rubber. Previously, only roofing felt, roofing felt and other similar materials were used.

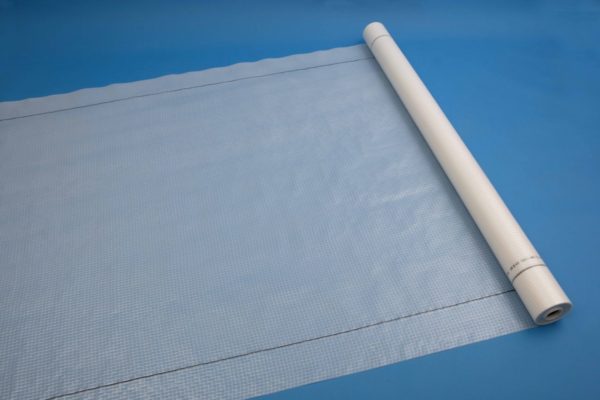

Polyethylene film

Plastic wrap is the cheapest and simplest material used to create a vapor barrier layer. It is quite thin, and therefore it is important to be careful during installation so as not to tear it. The film may or may not have fine perforations.

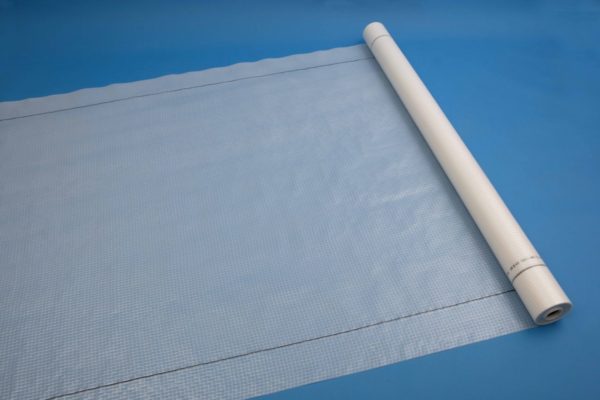

Vapor barrier film "Yutafol N 110"

However, in any case, whatever the film, when using it, you will have to equip the ventilation gap. And since you still have to do it, many do not think about the presence of perforation and just buy the material that is cheaper.

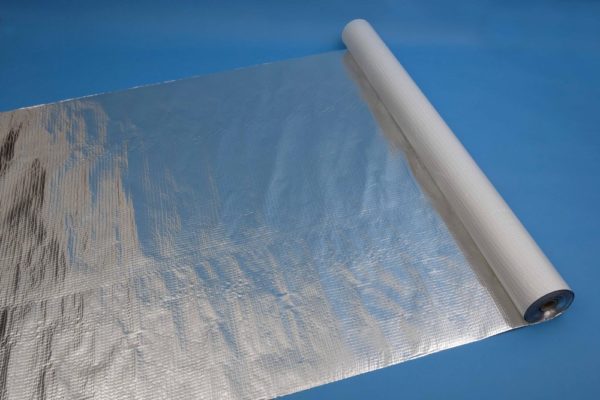

Now there is another subspecies of films made of polyethylene - it has a reflective layer coated with aluminum. Such material has a higher vapor barrier and is usually used in rooms where high levels of humidity and air temperature are noted.

Foil-coated vapor barrier film

Polypropylene film is characterized by high quality and strength. It is easy to install and can serve for many years. Polypropylene film is made not only from polypropylene - it also has an additional cellulose-viscose layer, which is able to absorb a lot of moisture and retain it. At the same time, during the decrease in the moisture level, the layer dries up and is ready to absorb it again.

Polypropylene vapor barrier

When laying this type of film, it is worth remembering that the anti-condensation absorbent layer must be turned away from the insulation. And between the layer of vapor barrier itself and the insulating material, a small gap is left for ventilation.

Diffuse membranes are perhaps the most expensive vapor barrier option. They are considered the highest quality, are called "breathable" and are able not only to protect building materials from excess moisture, but also to regulate the moisture index. Membranes are divided into one- and two-sided, and the materials are mounted in different ways - if, when laying a one-sided version of the membrane, it is important to observe which side it will be turned to the insulation, then the two-sided one can be laid as you like.

We offer you to familiarize yourself with Do-it-yourself foundation waterproofing - All about the bath

Such membranes are distinguished by significant vapor permeability indicators. They are made from a special non-woven artificial material and can have several layers. There is no need to leave a ventilation gap during installation.

Diffuse membrane

When creating a cake for a wooden floor, liquid rubber is rarely used for vapor barrier; it is more suitable for concrete substrates. However, it is still a common enough option to talk about it. Such rubber is a polymer-bitumen composition prepared on the basis of water.

Liquid rubber

Liquid rubber can be applied automatically and used to treat large structures, or manually - this option is suitable for small rooms.

Today, the building materials market boasts a huge assortment of various building materials and accessories. Every year, new chemical compositions and a new type of quality are introduced for different materials. It is worth mentioning the following types of vapor barrier materials, their pros and cons.

Creation of a hydro-barrier for a wooden floor ↑

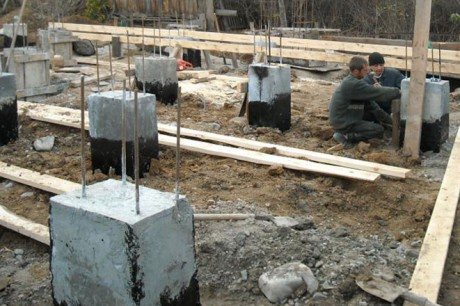

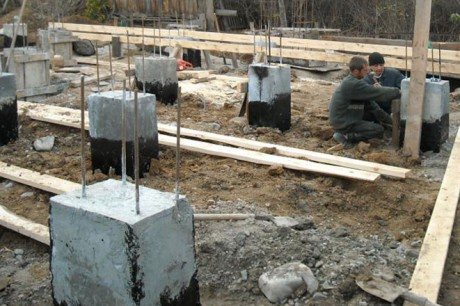

In the case of frame-panel construction, the construction of a wooden house or a house from a bar, a concrete screed is not made. Typically, the floor is raised on columnar supports, which are built of brick or concrete poured into the formwork. These supports are treated with coating waterproofing from all sides, and the upper ends are covered with roofing material or other roll material, preferably in several layers.

Poles can be coated with bitumen mastic

Further, logs are laid on the pillars, and the installation of the subfloor begins. To do this, you can use moisture-resistant plywood, impregnated with special water-repellent compounds. Often, plywood is nailed under the logs, then covered with a layer of polyethylene or a rubber membrane.

Plywood is covered with a membrane

The coating must be airtight, the strips are glued with an overlap of 10 - 15 cm. Insulation is placed on top, which is covered with a vapor barrier (in the case of mineral wool). Next, a rough plank floor is mounted on the logs, which is also covered with plastic wrap or a membrane with a 15 - 20 cm outlet on the walls.

A plank rough floor is mounted on top

Such waterproofing is quite enough, and you can start finishing the floor. In places with high humidity - kitchens, bathrooms and toilets - moisture-resistant coatings or lightweight self-leveling floors treated with waterproofing materials should be used. Self-leveling floors can be used for bathrooms and kitchens.

Where to order materials, how much do they cost?

All the necessary materials for insulation and insulation from steam can be purchased at hardware stores. A very large assortment opens in hypermarkets that have a narrow focus.

Of course, they also sell materials in online stores. But this option will not allow you to immediately verify the quality of the purchased. Therefore, it is still better to make purchases in regular stores.

You can purchase the necessary materials both in hardware stores and online.

So, it is most often necessary to equip the vapor barrier of the floor in wooden houses so that the building "lived" for a long time, and frequent repairs could be avoided.