In today's article, we will consider in detail the acts of testing the system of pipelines, sewerage, stairs and stepladders, roof fencing and fire tests.

Examples of drawing up acts can be downloaded for free at the end of the article.

The act of hydraulic testing of the heating and water supply pipelines system

Heating and water supply systems are checked:

- when entering a new engineering communications;

- during a routine check of the system's functioning.

when reconstructing an existing one;

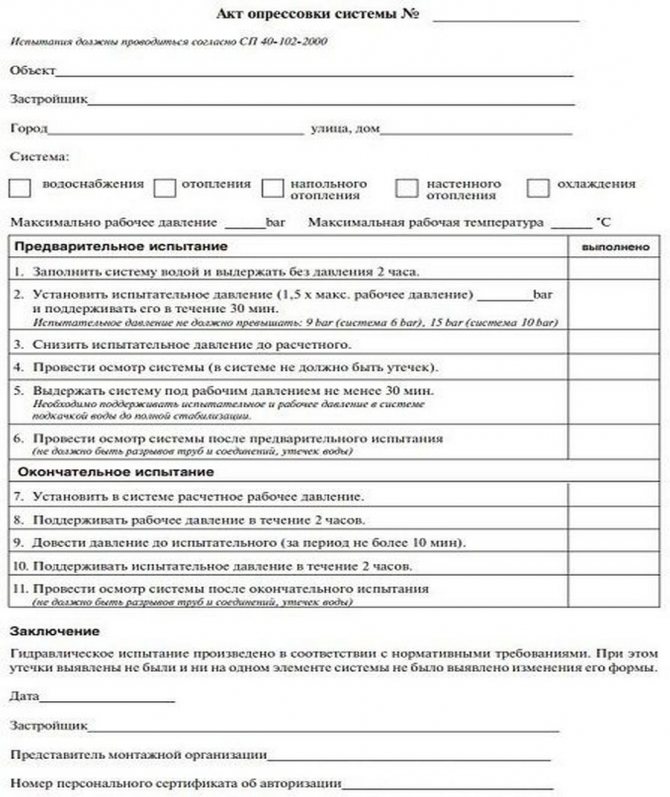

A step-by-step check and its results are recorded in the test report. The system is tested for tightness and strength in two ways, one of which is the hydraulic method: testing by using water with increased load. This method is suitable for indoor and outdoor systems (at temperatures not lower than + 5C). The second method is pneumatic.

Both acceptance testing methods are called pipe pressure testing.

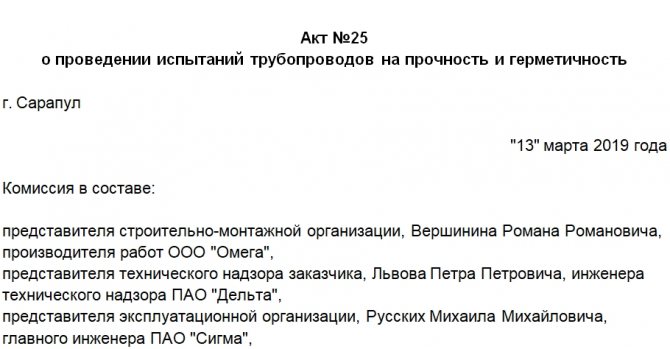

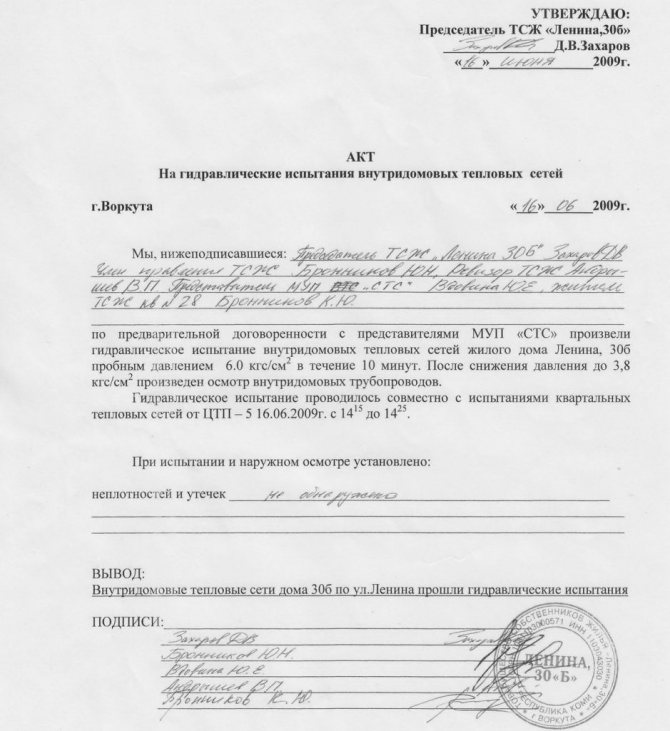

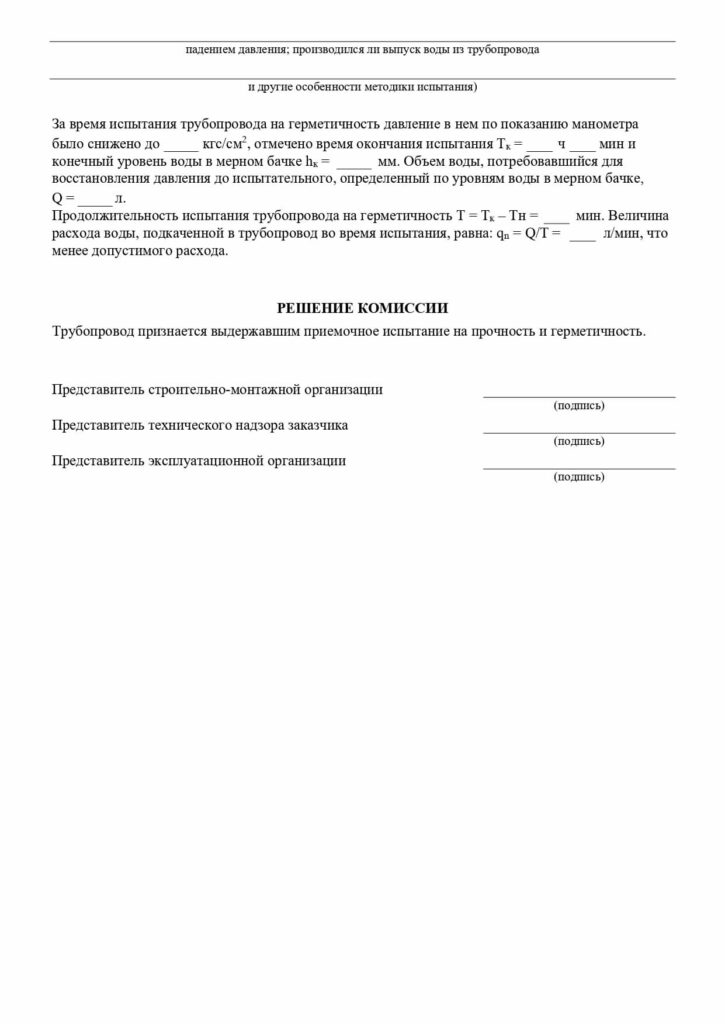

The results of the inspections are entered into an act, the form of which is established by the Code of Rules for building codes and regulations. The template is presented in Appendix 1 to SANPin "External networks and water supply and sewerage facilities". The presented form of the act is mandatory.

The procedure for drawing up an act:

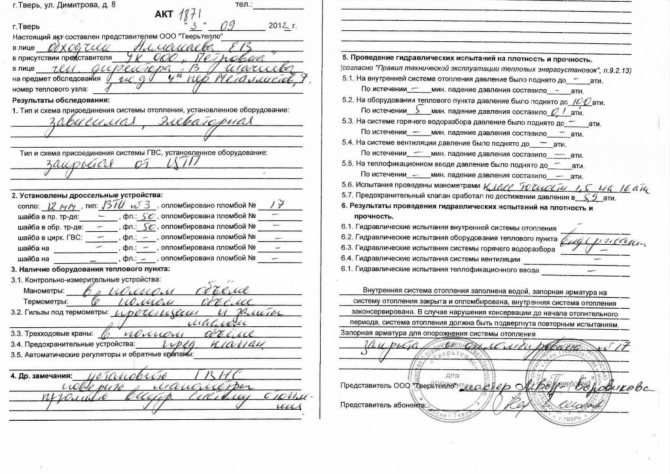

1. Indication of corporate information: city of compilation and date.

2. Representation of the members of the commission, which carried out pressure testing and acceptance of the pressure pipeline. Three parties become members:

The company that installed the pipeline

Technical supervision representative from the customer

Operating company representative

3. Below is information about the tested object and a description of the pipeline (length, diameter, material of pipes and joints), the information specified in the working documentation, provides information about the pressure gauge used.

4. The section on the test and its results is completed.

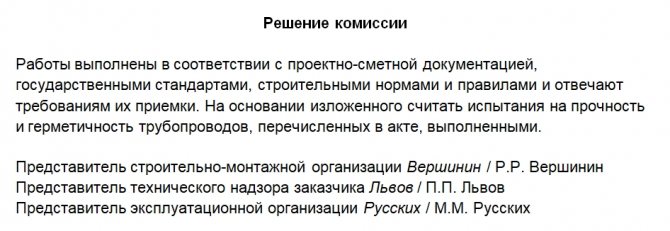

5. In the "Commission Decision" section, a statement is made that the system is considered strong and sealed and is signed by the members of the commission.

You can download the form for free at the end of the article.

Heating system flushing certificate: sample documents, form and form

Replacing pipelines is an expensive option to improve your heating system. High-quality flushing of the system allows you to eliminate various contamination of pipes, which lead to a significant decrease in the heating temperature of heating equipment.

Pipes before and after flushing.

High fuel consumption and low heating temperature of the heating system are the most important indicators of the need to clean the system.

The procedure for organizing cleaning works

The coolant in the pipes is water, which has various contaminants that settle and condense on the walls of the pipelines. They interfere with the normal circulation and functioning of the coolant, cause blockage of pipes and radiators.

The flushing organization should:

- pre-inspect the equipment;

- issue an act for hidden operations;

- select a cleaning technology;

- draw up an estimate for flushing the heating system and a contract;

- perform work;

- to carry out secondary pressure testing of the equipment;

- fill out the form of the act.

The act of flushing the heating system is an important document certifying the completion of work for specialized organizations engaged in such services.

The process of crimping heating pipes.

The equipment is pressurized with water or air. She must certify the correctness of the work.

One of the methods for assessing the technical condition of equipment is pressure testing, which identifies all faults before starting work. The pressure should be higher than the standard, but not less than 2 atmospheres.

To check with air, use a pump and a special pressure gauge that measures the pressure in the system. If the pressure does not change, then the equipment is sealed, and if it decreases, you need to look for the place where the leak occurs and eliminate the malfunction.

An act is drawn up for various hidden operations: dismantling of radiators, disconnection of flanges, preparatory work. Further, the cleaning technology is selected, but in most cases the hydropneumatic method is used.

The estimate for flushing the heating system includes the price of fuel, depreciation of equipment, reagents.

Then an agreement is drawn up, which specifies the main points of cooperation:

- service cost;

- calculation procedure;

- deadlines;

- the amount of fines in case of default on obligations;

- obligations and responsibilities of the parties;

- the procedure for terminating the contract.

After the end of cleaning, a secondary pressure test is carried out and the equipment operability is checked. The flushing certificate form is filled in, where the customer assesses the quality of the service.

Registration of the document is carried out immediately after the end of the work. If the terms of the contract are not met and the quality of the service does not suit the customer, the document is not signed until all defects and malfunctions are eliminated.

Methods for flushing heating systems

There are 3 main methods used to clean equipment:

- hydropneumatic;

- dynamic;

- chemical.

The hydropneumatic method consists in using hot or cold water, into which a stream of compressed air is mixed from the compressor, creating a wave and air bubbles. Pressurized liquid removes all deposits and scale on the walls of the pipelines. Then they draw up an equipment flushing act.

Heating system flushing equipment.

Chemical flushing is carried out using various chemicals and a container, which is equipped with a pump. Used reagents must be disposed of by a specialist.

The chemical method is often used for cleaning work, because tap water used in heating systems does not have good characteristics.

The dynamic method is the removal of scale, rust, chemical deposits, sodium and calcium salts using special nozzles that create high pressure (water hammer).

The modern method is the Typhoon pneumatic gun, which allows for spot cleaning of radiators and eliminates blockages in water pipes.

Sometimes a complex flushing of the equipment is carried out, which has several advantages:

- democratic price;

- the ability to clean pipes with small cross-sectional diameters and complex structures;

- bulk cleaning;

- execution of works in a short time.

Watch the video and study the sequence of work when cleaning equipment from contamination.

Features of registration of the flushing certificate

To control the quality of work, water is taken in different parts of the heating system.

Sample documents.

The easiest way to check is as follows: in the entrances or apartments, unscrew the deaf radiator plugs and assess the quality of the work. There may be water or silt on the radiator cap, but there should be no solid particles.

Then a flushing certificate is drawn up, which should contain the following information:

- method of cleaning the heating system;

- water consumption, if there are metering devices;

- water temperature (if rinsing was performed with hot water);

- service quality assessment: satisfactory or unsatisfactory;

- signatures of persons responsible for the work;

- the date of the service.

If the act has a unified form, then a special form is drawn up. For a sample of a flushing act, various organizations use documents that may differ in details, but the content of the document must necessarily comply with the state quality standard.

A sample sample of the act is attached.

Heating systems cleared of dirt work better. The heating of heating radiators is improved. Cleaning is carried out depending on the performance of the equipment. It is better to use purified water as a heat carrier, which will contribute to less pollution of pipelines.

Flushing is an effective measure of increasing the productivity and quality of the system, which is well combined with preventive maintenance.

If done in a timely manner, you can avoid additional costs and save money.

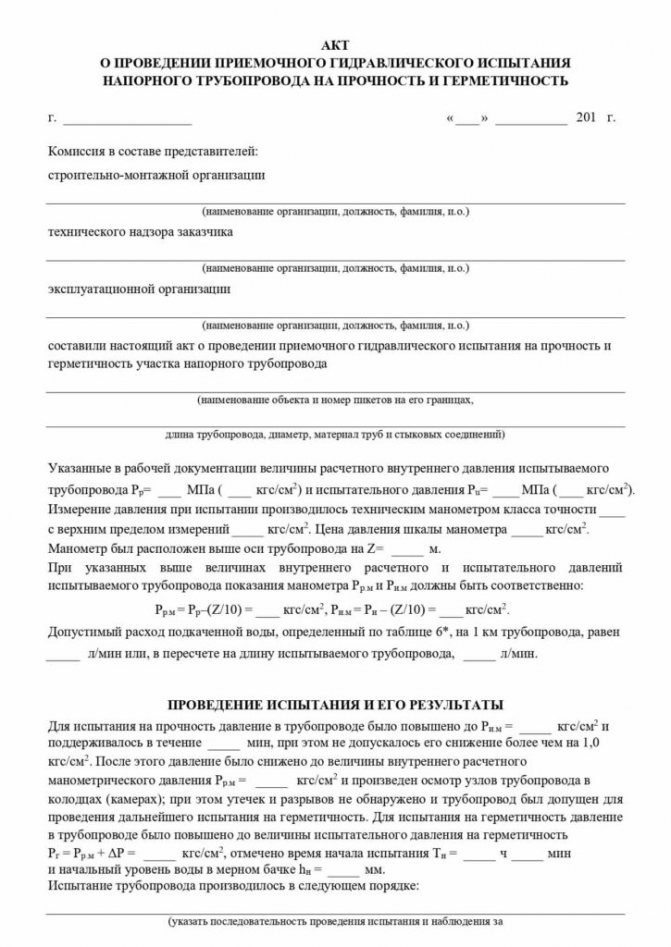

Pneumatic pipeline test certificate

Pneumatic method: diagnostics by inflating the system with high pressure air. The method is often used for outdoor systems if the temperature on the thermometer is less than +5 Celsius.

The procedure for crimping pipes by pneumatic testing is given in the same SanPin, the test report is drawn up in a mandatory form, which is given in Appendix No. 3.

Requirements for the preparation of test documentation:

- Filling in the city name and compilation date.

- The indication of the members of the commission (as well as in the hydraulic test, three parties are involved).

- Description of the pipeline: length, diameter, material of pipes and joints.

- Information about the pressure value: calculated, to what value the pressure in the pipes was increased, the final pressure, the amount of reduction. The crimping time is indicated.

- In the section "Decision of the Commission", each of its members puts a signature with a decoding, if the pipeline has passed pneumatic diagnostics, and is hermetically sealed and durable.

Sewer cleaning certificate sample. Heating system flushing act

Heating systems are flushed by specialized organizations after the preliminary conclusion of an appropriate contract. At the end of the heating system flushing work. The sample and appearance of this document depend on the complex of activities carried out by specialists.

Mandatory procedure

Heating systems are a collection of equipment (pumps, boilers, pipelines and radiators) designed to heat rooms.

Due to the fact that heated water is usually used as a coolant, all parts from the inside are covered with a dense layer of dirt. Sometimes in pipes, such deposits reach more than fifty percent of the cross section.

This reduces heat dissipation and lowers the temperature inside the room itself. There are two ways to deal with this phenomenon:

- replacement of individual parts of the heating circuit;

- flushing the system.

The second option is considered more preferable, since it does not require serious constructive intervention. After carrying out the necessary set of measures, an act of flushing heating systems should be drawn up, a sample of which is available to specialists in the form of prepared forms.

They do not have to be ordered from the printing house. To do this, you can use any printing device. How to fill out the certificate for flushing heating systems? The sample is usually a standard text in which certain mandatory fields are specially omitted.

It is usually drawn up by a representative of the cleaning organization.What does the act of flushing heating systems look like? The sample form begins with its title and date. Further, the following information is presented sequentially:

- Address of the object.

- Information about the three obligatory participants, in the presence of whom this procedure takes place (customer, representative of the service company, specialist from the cleaning organization).

- Date of work.

- The method by which the system was cleaned is selected from four options.

- water before and after work. The consumed amount and temperature are indicated separately.

- The quality of the work done.

All data specified in the act ends with the signatures of three parties.

Additional work

After other equipment, it is advisable to make a pressure test. This additional procedure will allow you to check the tightness of the entire system and identify places where air or water can escape to the outside. Such actions are optional, but highly desirable.

They correspond to the interests of both the customer and the contractor. Upon completion, both will be able to verify the quality of the previous stage.

The execution of work fixes the flushing act and its sample will look like a table that contains a list of all the activities carried out during such a procedure.

Against each of the points, the specialist must make a note of completion. At the end, as usual, the customer and the contractor put their signatures, confirming the fact of the work.

Experts sometimes call this procedure because most often a similar test is carried out using water. It is believed that air can be more hazardous when serious malfunctions are detected.

Therefore, many people prefer to take the easier path.

Reliability check

In the spring, after the end of the heating season, the system is usually preserved for the summer period. Before that, it should be checked.

This measure is quite often used as a preventive measure by specialists of a service organization in apartment buildings. It is called hydro-pneumatic testing.

Of the equipment for the procedure, only a pump with a measuring device (pressure gauge) is required. The work is carried out in the following sequence:

- First, the system under test must be filled with water.

- Then you need to connect the press.

- Check the reading on the pressure gauge.

The check is usually carried out within thirty minutes. If during this time the readings do not change, then the system is considered sealed. Otherwise, it will be possible to assert that there is a leak in it.

Therefore, it is necessary to take measures to eliminate it. At the end of the work, a pre-prepared act of hydropneumatic flushing of the heating system is drawn up.

Its sample is similar to everything described earlier.

This form also describes the entire procedure, indicating the specific value of the measurements to be taken. The act is signed by representatives of the parties and saved until the next test.

Why and how is the water supply system flushed? Are there any instructions for its implementation? Is it possible to somehow clean the water supply system if its permeability has drastically decreased after several years of operation? Let's figure it out.

The operation of a new water supply line begins ... with its flushing.

Objectives

Let's immediately separate, so to speak, flies from cutlets.

- Testing and flushing of the courtyard water supply network are carried out as part of the transfer of the object from the construction company to the balance of the operating organization. , is checked for leaks, cleaned of debris, foreign objects and disinfected.

Important: cold water supply is positioned as drinking water, which implies strict requirements for the composition of water.

- If the throughput of the water supply system is significantly lower than the norm for a pipe of a given diameter, it needs mechanical cleaning or chemical washing with reagents that dissolve lime deposits and rust. The use of hydropneumatic flushing in this case, as a rule, does not bring any result.

Testing

The procedure for hydraulic tests is exhaustively set out in SNiP 3.05.04-85, which regulates, in particular, the construction of external water supply networks.

According to SNiP, the test should be carried out hydraulically or, if it is impossible to fill the water supply before it is put into operation, by air. The test pressure should be:

Disinfection and rinsing

A guide for disinfection of a water supply system can be found in the same SNiP.

According to the doc, you can use for it:

Bleach is the most common disinfectant.

- Sodium hypochlorite solution.

- Liquid chlorine.

Flushing (cleaning) of the pipeline can be performed:

- Elastic piston. As a rule, this role is played by a foam cylinder with a diameter of 1.3 times the inner diameter of the water supply and a length of 1.5 - 2 diameters.

In the photo - foam pistons for cleaning water supply pipes.

- Water distilled through the section of the water supply system for discharge.

- Pulp (water-air mixture). Hydropneumatic flushing is organized by air supply with a compressor; the optimal ratio of water and air in the pulp is 1: 1.

The foam piston can be used in areas with smooth turns at an angle of no more than 15 degrees with fully open valves and in the absence of structures protruding inward.

The speed of movement of the piston at a pressure in the pipeline of 1 kgf / cm2 should be in the range of 0.3 - 1 m / s.

In this case, the diameter of the discharge through which the contaminants leave the water supply system can only be one step less than the diameter of the flushed pipe.

In hydropneumatic flushing, air should be supplied to the pipeline at a pressure 0.5-1.5 atmospheres higher than the water pressure. The speed of the pulp should be within 2 - 3 m / s.

Disinfection of pipelines is carried out in sections no more than 1-2 km long at a time. At the same time, temporary control valves are installed every 500 meters to take samples for chlorine concentration.

Based on the results of the work, an act of flushing the internal water supply systems and its disinfection is drawn up.

Its text must indicate:

- The composition of the commission (SES, construction and installation organization and operators).

- Description of the object (type, length, diameter, volume).

- Reagent type and concentration of active chlorine.

- Duration of processing.

- Results of biological and physicochemical analyzes of water after treatment.

Clearing blockages

Dealing with cold water supplies is very different from flushing a heating system or flushing a drain. The key difference is that the blockage cannot be destroyed by a stream of water or weak mechanical action: pipes are overgrown with strong lime deposits and rust.

However: sometimes the initial cause of the blockage is sand or a piece of scale. If it is not removed immediately, after a while the blockage is cemented and amenable to destruction with great difficulty.

Is it possible to do something with your own hands if the water pressure has dropped dramatically in a house with an old steel plumbing?

- Try plugging the gander of the faucet with your finger while opening the cold and hot water taps completely at the same time. DHW pressure is noticeably higher for most of the year; backflow can destroy a fresh blockage, after which its fragments will be carried out by water into the sewer.

- If this does not help, repeat the operation by dropping the cold water riser. The pressure difference between DHW and empty riser will be much greater.

- Is the water still not running at normal flow? Open the valve (of course, when the riser is dropped). Debris deposits under the valve seat are a common problem with cast iron and, to a lesser extent, brass screw valves.

- Finally, if all else fails, try to disassemble all available threaded connections and use a steel string to clean the pipe from the curtain rod by bending a pinhead-sized hook at the end of the pipe. On the second side of the string, a handle is formed that resembles the collar of a well. The string is fed into the pipe with continuous rotation; after it passes the blockage, its residues are washed with water.

Advice: lime deposits dissolve well with acid solutions. It is enough to plug the pipe near the valve and fill it with reagent for a couple of hours.

As an active substance, you can use imported Cillit or, which is much better, a solution of dry oxalic acid: its price is several times lower with much higher chemical activity.

Conclusion

We hope that we managed to satisfy the curiosity of the reader, and at the same time help him in solving some everyday problems. Additional useful information will be offered to his attention by the video in this article. Good luck!

When providing services for flushing the heat supply system by specialized companies, documentary registration of the work performed is required. First of all, an estimate is drawn up and an agreement is concluded.

Then the act of flushing the heating system is filled in and signed. Pipelines, radiators and piping to them need preventive work.

The technical side of flushing, as well as its documentary component, have some peculiarities.

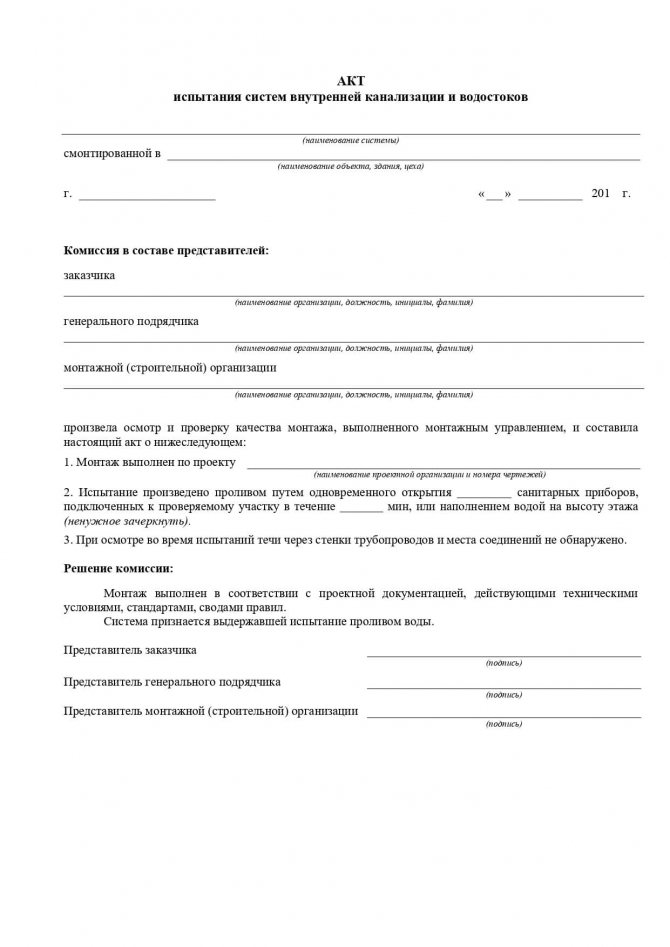

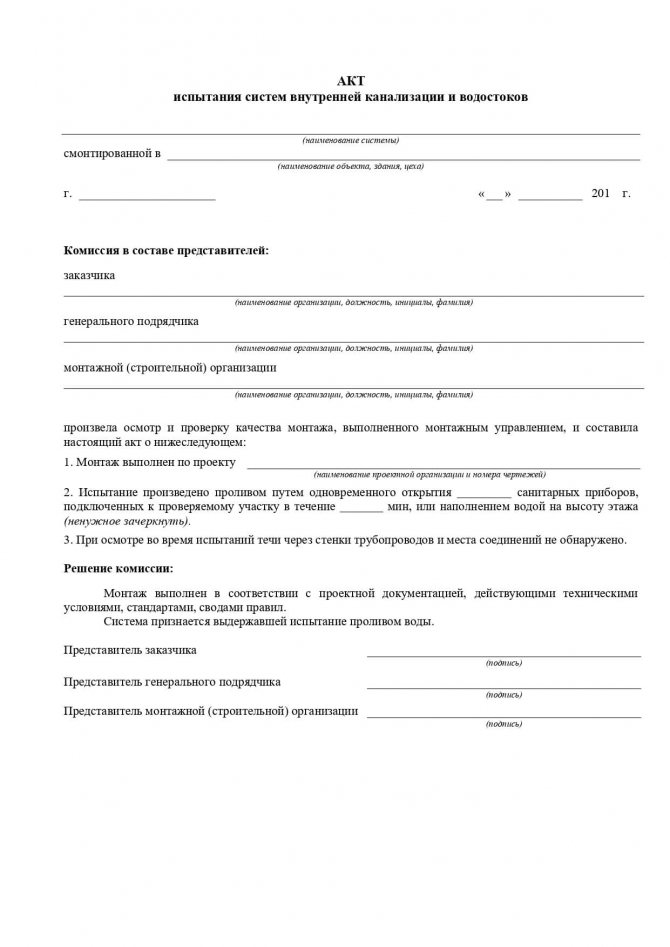

The act of testing the external and internal sewerage system for the strait

The test report for internal and external sewerage is drawn up as a result of checking the system's performance. It fixes the position of the commission that the system has passed the water spill test, and the design complies with the design documentation, GOSTs and standards.

Diagnostics of the normal functionality of the sewer system is necessary when installing a new facility or after carrying out repairs to an existing system. The health check information is entered into the act. The form is drawn up in the form specified in Appendix "D" to the Code of Rules 73.13330.2012.

The act specifies:

- the name of the system and the object in which it is installed;

- information about the members of the commission. We need representatives of three organizations: the general contractor, the customer and the installation company;

- information about the name of the project is registered;

- the results are entered: the number of simultaneously connected devices, as well as the connection time or water filling per floor (the unnecessary is crossed out);

- in the third paragraph, it is prescribed that no leaks were found at the joints and through the walls. This means the system is usable.

Members of the commission sign for the decision.

Hydro-pneumatic tests

Pressure testing and hydrotesting of the heating system

Flushing and pressure testing of the heating network are processes that are carried out after the end of the heating season. Hydro-pneumatic tests are organized to confirm that the system is ready for start-up during the heating season. The procedure is easiest to postpone in the fall after the downtime of the line in the summer.

Step by step preparation and verification is carried out as follows:

- at the end of the heating season, check the condition of nodes, valves, pipelines and heating devices;

- preventive flushing of the network;

- elimination of leaks, depressurization of joints, replacement of worn out equipment;

- visual assessment of the quality of insulation in open sections of the pipeline;

- hydro-pneumatic tests.

After checking, fill the system with coolant and leave until starting. If all checks are passed, the network is ready for operation, it will wait for the start of the heating season without losing quality indicators. The tests are organized under a pressure higher than the working pressure, therefore, the tightness due to the presence of the coolant during the waiting period for start-up will not be violated.

Hydropneumatic tests are carried out as follows:

- The master will fill the network with a coolant. Then he will connect a manual or electric pump. It will raise the pressure level to a certain standard - the limit values are prescribed in the SNiP. The injection is performed by equipment with built-in instrumentation.

- After test measurements, the pressure decreases.In the absence of defects, the system is considered suitable for permanent use.

Pressure control is carried out by pressure gauges of accuracy class from 1.5, graduated up to 0.1 kgf / cm2, body diameter from 160 mm. Unverified manometers without a seal of the state metrological organization are not allowed for use.

Indicators of the pressure value during the test:

| Varieties of networks, types of equipment | Test pressure |

| Water heaters for heating networks, hot water supply, elevator units, air heaters | The limit is 1.25 of the working pressure, but not less than 10 kgf / cm2 |

| Heating networks in multi-storey buildings with cast-iron radiators or registers | The limit is 1.25 of the working pressure indicator, no more than 6 kgf / cm2 |

| Heating systems with radiators made of steel, bimetal, aluminum panel / convector type | Not less than 10 kgf / cm2 |

| DHW circuits | Based on the working pressure plus 5 kgf / cm2, but not higher than 10 kgf / cm2 |

In the process of pressing the line to the house after laying, the pressure indicator rises to a standard of 16 kgf / cm2. The pressure is maintained for 5 minutes, the level must not drop. After the procedure, the parameters are reduced to workers, the master examines the nodes, joints, shut-off valves for defects. The test is passed on condition that there are no leaks or leaks.

Important! Pressure testing of a new heating network is carried out under a pressure 1.5-2 times higher than the working one. Operated systems are checked under pressure, 25-50% higher than the working one. Coolant temperature up to +45 C.

Conditions for confirming network readiness:

- in water / steam networks during 5 minutes of testing, the pressure dropped by no more than 0.0.2 MPa;

- in a network with panel devices, the load indicator did not decrease by more than 0.01 MPa during 15 minutes of testing;

- in the hot water supply network indicators of permissible decrease to 0.05 MPa within 10 minutes of testing;

- no leaks, violations of the tightness of seams, joints.

If defects are found, the master eliminates the leaks, then again conducts test tests. The process is repeated until the requirements are met, then the pressure can be reduced to working pressure and a test report can be drawn up.

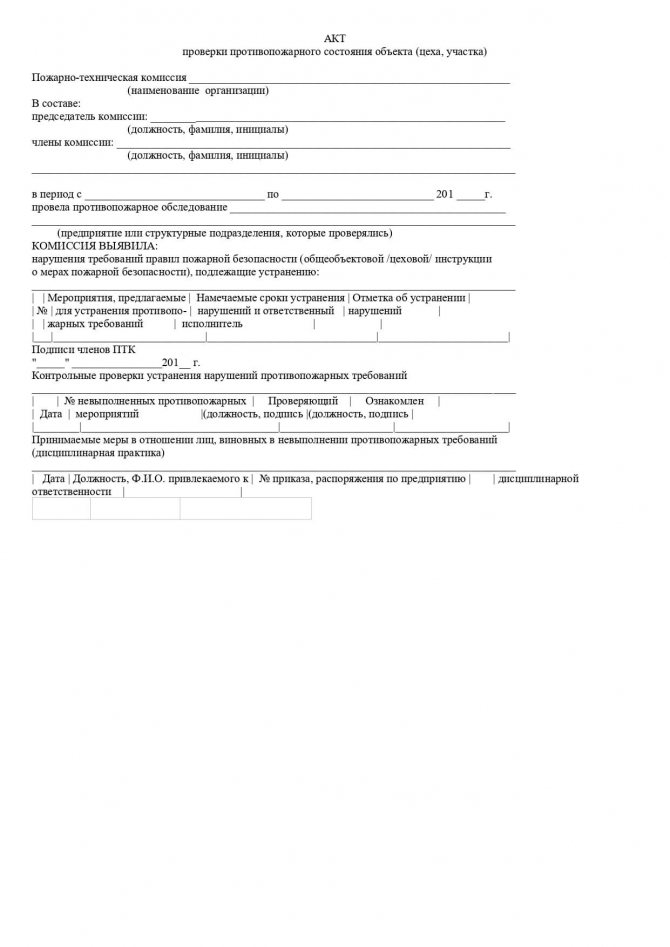

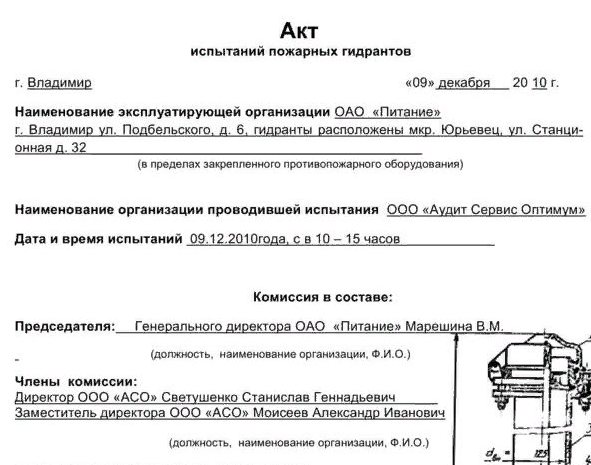

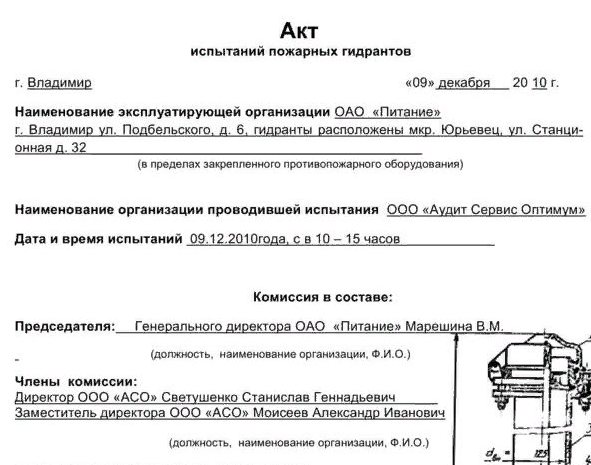

Fire test certificates

In the course of testing for the operability and safe operation of fire fighting equipment, several acts are drawn up:

- checking fire hydrants;

- internal water supply diagnostics;

- check for safety of use and compliance with the rules of labor protection of fire escapes.

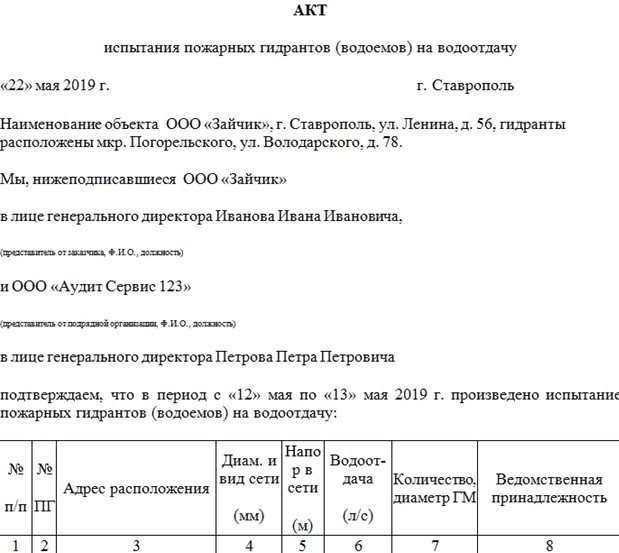

Fire hydrants

Checking the performance of hydrants for water loss is carried out twice a year and, often, is combined with checking the fire-fighting water supply system. Based on the results of the inspection, an act is drawn up, which is signed by the commission. Mandatory members: a representative of the fire inspection and a representative from the organization in which the inspection is taking place. Also, the commission may be entirely composed of company employees.

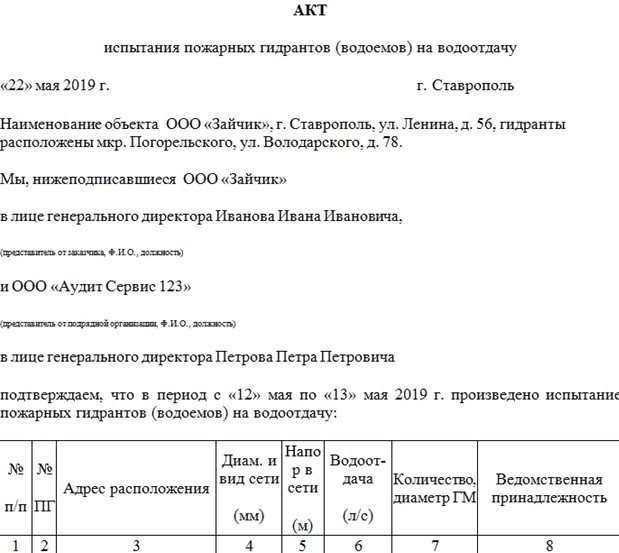

The act indicates:

- corporate information (information about the company, date and place of compilation);

- the main part describes the members of the commission and the course of the test. Information about hydrants is presented in a tabular form. Indicate the location address, diameter, head, water yield and hydrant ownership;

- in the final part, compliance (or non-compliance) with the requirements of the state of the hydrant is established.

At the end, the act is signed by the authorized members of the commission.

Internal fire-fighting water supply

The act establishes the presence or absence of defects and malfunctions in the fire-fighting water supply system. The check is carried out by the responsible employees of the enterprise. Frequency - at least twice a year, for flammable industries, inspections may be scheduled more often.

Internal fire-fighting water supply (ERW) is a complex system of pipes, sensors, switches.Therefore, it is often checked by an occupational health or fire safety specialist, as well as by persons who are trained in fire safety.

The act is drawn up on letterhead or plain paper, indicating the details. Be sure to register:

- information about the organization and participants of the audit;

- information about the checked object;

- results of inspections;

- recommendations for elimination of defects and malfunctions, if any;

- signatures of responsible persons.

If additional documents are attached to the act, their list and name are indicated.

Fire escapes

Testing of firefighting equipment, including ladders and ladders, is regulated by a special GOST. The inspection can be carried out by organizations that have received permission from the Ministry of Emergencies and have special equipment for this.

The test results are recorded in the test report. The documentation contains standard information about the organization and its details, information about the members of the commission. The main part contains information about the inspected objects (the number of stairs and stepladders, their inventory numbers and belonging to the structural unit), information on the results of inspections (absence or presence of defects). An instruction is given to eliminate the identified malfunctions.

At the end, the act is signed by the members of the commission.

Heating system flushing certificate - sample contract form

In the process of chemical cleaning of elements of heating structures, the circuit is filled with reagents (acid or alkali solution with inhibitors to prevent corrosive processes in pipelines) and ensure their long-term circulation in the system (for more details: "Flushing the heating system in a private house - instructions and rules for flushing").

The used compounds are disposed of, but since it is not allowed to drain them into the sewage system (reagents can significantly reduce its service life), they first neutralize by adding an alkaline solution to the acid reagents and vice versa.

Chemical flushing is effective in cleaning steel pipes from rust, as well as from magnet and calcium salts. As for silting up, then it is useless here (about “How and how to flush the heating system, batteries”).

Hydropneumatic flushing of heating systems

This flushing method is considered versatile and inexpensive, and therefore it is used quite often. To implement it, a large amount of water is required.

When a house is connected to a central heating main, the heat carrier coming from it is usually used. If the heating system is autonomous, then the structural elements are flushed with cold water (for more details: “Hydropneumatic flushing and flushing of heating systems”).

The sequence of actions is as follows:

- the system is started to reset - initially from the supply to the return, and then in the opposite direction;

- a stream of compressed air supplied by the compressor is mixed with the flow of the coolant through the valve. The resulting pulp cleans the inner surfaces from silt and partially from sediments;

- in the presence of risers, they are washed in turn in groups so that the pulp flow encompasses no more than 10 objects. It is better if the number of risers in the group is less. Flushing is carried out until the slurry sent for discharge becomes transparent.

When the heating system is cleaned independently, it is advisable to rinse the risers one at a time, then not only the piping will be washed, but also the radiator itself.

Personnel requirements

Important! It is allowed to independently check the heating equipment only in a private house.

All technological operations must be performed by trained personnel with established qualification tolerances, using certified equipment.

To do this, employees are required to undergo training (a special training course for six months) and certification of knowledge of the rules of operation of thermal installations and safety equipment (at least once every 3 years, and for personnel directly involved in the testing, adjustment and maintenance of equipment - 1 time per year).

After completing the training, an extract from the employee testing protocol is drawn up. It is provided for the admission of personnel of the organization performing the operation, maintenance and pressure testing of thermal installations.

Extract from the employee testing protocol.

The corresponding columns indicate:

- Full name of the employee;

- date of the previous check;

- date of the current check;

- Assessment of knowledge;

- employee signature;

- date of the next certification;

- Full name of the members of the selection committee of 3 people (including the Rostekhnadzor engineer) and their signatures.

The employee is issued a qualification certificate with stamps and marks that he has been trained.

Certificate of admission to work of increased danger.

The training results are displayed in the log of personal checks of an employee of an organization approved for performing hydrostatic or gauge tests.

Journal of personal checks of an employee of the organization.

When tests are carried out and confirmation of their results

Heating systems are pressurized:

- in the complex for the preparation of buildings before the start of the heating season;

- after replacement (repair, modernization) of a part of pipelines, radiators, other devices and equipment;

- when the object is put into operation.

The document confirming the readiness of the systems for operation is a certificate of hydrotesting or pneumatic testing (hereinafter referred to as the "Act") filled out in accordance with national requirements. It is drawn up at the final stage of technological test activities, which help to identify defects in pipelines and equipment, confirming its standard performance.

What should be in the Act

The Act displays the results of the following actions of the personnel responsible for the verification procedure:

- water or air, using special equipment, is injected into the pipelines until a certain pressure is reached;

- the system is carefully inspected, especially the joints of its elements, for the detection of leaks, as well as other defects that can cause interruptions in the operation of thermal equipment;

- measures taken to eliminate defects (if any).

The regulation of hydrotesting of thermal installations is prescribed by the standard SP 73.13330.2012 "Internal sanitary-technical systems of buildings". In accordance with it, test operations are performed as follows:

- The supply of the working fluid to the pipelines of the heating system is carried out in stages, with a stepwise increase in pressure, until it reaches the set threshold value. It is recommended to pump the coolant at intervals of 10 minutes before the release of all air locks.

- The test pressure, controlled by a manometer, is maintained for at least 10 minutes. The test pressure should be 30-50% higher than the operating pressure (depending on the wear of the system), but not higher than the minimum allowable pressure of one of the devices. For example, if cast iron radiators are installed in a building, the pressure should not exceed 6 MPa, if steel radiators are 10 MPa.

- If pressure testing is carried out in a residential building, the residents of the building are warned about the work.

- Typical indicators of leaks are a sharp drop in the pressure of the working fluid or its gradual decrease by more than 0.2 kg / cm2. As a rule, coolant losses occur at threaded or flange connections, which must be tightened, repackaged or replaced with gaskets in them. If it is impossible to eliminate the defect, the unit is discarded and replaced.

Important! Pressure testing is carried out after flushing and hydropneumatic purging of the system.Otherwise, deposits inside the pipes can hide possible leaks. Also, it is worth considering that if you do not carry out measures to clean the pipes from deposits, the heat transfer coefficient of the system will significantly decrease.

Rules for filling out the Act

The heat supply organization is responsible for filling out the pressure test certificate.

Cap

- filling in the header of the Act begins with specifying the exact name of the tested thermal system (this information is contained in its working documentation, project);

- the full name of the facility served by the thermal installation is entered. It can be found in the building permit or in its design and estimate documentation;

- information is entered about the settlement, the date of testing / approval of the Act (if no defects were identified and the documentation is drawn up on the day of test events).

The composition of the commission

The data of all members of the selection committee are indicated. It includes representatives of the general contractor, the customer and the organization that carried out the work. A representative of each of the parties must provide information about the name of his organization, the position he holds in it, as well as his surname and initials.

Inspection and Results

- The data of the design organization and the code of the project are entered according to which the structure was erected and engineering communications were installed, in particular, the heating system.

- The test method is indicated - hydrostatic or gauge (pneumatic pressure testing). Further, the data of operating parameters: pressure in the pipeline (in one of the units of measurement - MPa or kg / cm2), the time during which the system was under excess pressure.

- The value of the pressure drop during the test period is entered (in MPa or kg / cm2).

- The absence or number, as well as the location of defects identified during the test or after it, are indicated. Instructions for the elimination of defects are entered directly into the act or in addition to the cumulative statement.

What is crimping and when is it done?

Pressure testing is a set of test measures that are guaranteed to determine the tightness of the heating system. Carrying out these test works is necessary in the following cases:

- After complete completion of the initial installation - upon commissioning of the home heating system.

- Before the start of the heating season of an already installed system.

- After carrying out repair or maintenance work on the pipelines of the heating system.

- When carrying out measures for the repair of individual parts of the system, after emergencies, such as a pipe break, to identify the "front of work" and the weakest sections - for their possible replacement.

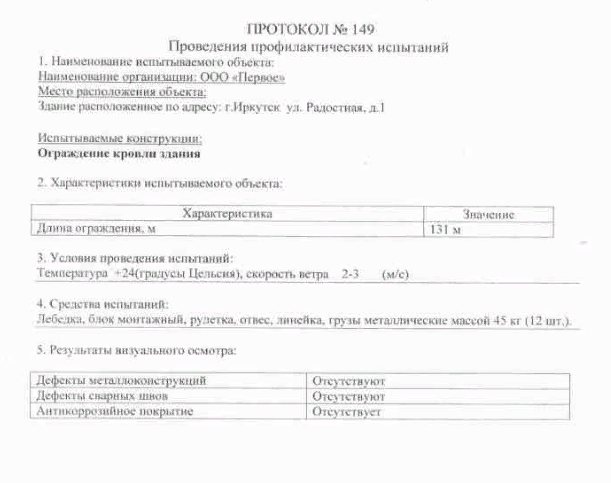

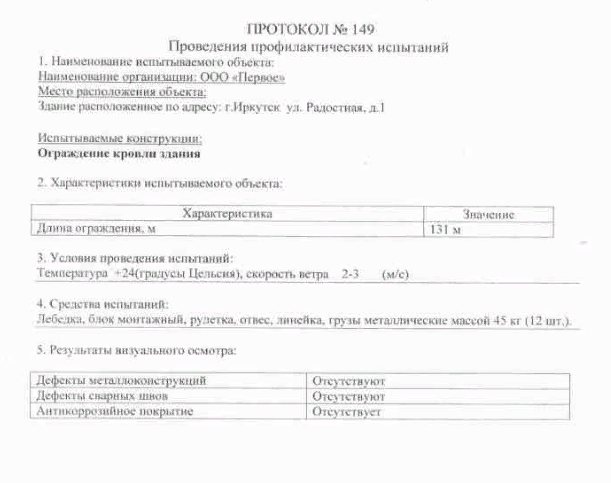

Roof fencing test report

The technical requirements and test methods for the roof are fixed in the same GOST as the standard for fire escapes and stepladders (53254-2009).

Tests are carried out at intervals of five years, integrity checks are carried out every year. The results are formalized by acts.

The conditionally completed act can be divided into three parts:

- General information. This is where information about the test object and the testing organization is entered.

- Information about the check (what manipulations were carried out, what tools were used).

- Inspection results (compliance with GOST, structural integrity and safety).

The agreement of the members of the commission during the test is confirmed by their personal signatures.

Organizations licensed from the Ministry of Emergency Situations have the right to conduct inspections and tests. Defects found must be eliminated.

Formation of estimates for the maintenance of the heating system

What is the difference between an estimate for the repair of a heating system and a document for the implementation of installation work? First of all - significantly lower costs

However, in this case, special attention must be paid to the selection of consumables. They need to be adapted to the current system.An analysis of future repair costs is performed first.

For this, the area of the heat supply problem is determined and materials are selected for its elimination. Unlike estimates for the installation of heating, consumable components cannot have a large assortment. So, for chemical cleaning of pipes, it is necessary to use a special liquid, which will be problematic to find an analogue.

In general, when forming an estimate for the repair of a heating system, one should be guided by the following rules:

- The technical and operational parameters of the replaced components must fully correspond to the old ones that are out of order. For example, when replacing a piece of plastic pipe, you should choose the same one made of a similar material and having the same geometric dimensions;

- In addition to the cost of new components, an estimate for their installation in heating is filled;

- Transport costs and the services of repair specialists must be taken into account.

Often in the repair estimate for heating a private house there are components that are purchased "in reserve". The specialist can determine the "weak" places of the heat supply and will advise you to buy the most necessary components to perform prompt repairs.

Estimates for flushing pipes and heating radiators

Cleaning the heating supply from accumulated dirt and limescale should be performed at least once every 3-4 years. It depends on the composition of the coolant and the material for the manufacture of radiator pipes. For steel models, the frequency is less, since a corrosion layer forms on their inner surface.

A correctly formed estimate for flushing heating directly depends on the selected technology. In chemical cleaning, most of the cost will be a special composition. For the hydraulic system, the cost (rent) of the device for performing this work must be indicated in the estimate for flushing the heating.

The features of filling out this type of document include the following:

- The costs of analyzing the degree of contamination of the pipeline and radiators are necessarily taken into account. Without this, the estimate for cleaning the heating will not be complete;

- After completing all preventive measures, the current state of the system is checked;

- The costs of disposal of the contaminated liquid are taken into account. If the work is performed by a specialized company, this item is most often not indicated in the flushing estimate of the heat supply of a private house.

A separate category of work is flushing the boiler heat exchanger. As well as when filling out the estimate for the installation of the heating system, in addition, the costs will include work on disassembling and assembling the heater. It is not recommended to flush the heat exchanger in a flow-through manner.

Test report for ladders, racks and stepladders

Inspection and testing of racks, ladders and stepladders is carried out at least once every six or twelve months (depending on the test object and the material from which it is made).

Tests and inspections for safe operation can be carried out by specialized organizations from the outside or by a commission specially created at the enterprise. At the same time, its members must be trained, the chairman of the commission is usually an occupational safety or fire safety engineer.

As a result of the diagnosis, the commission draws up an act, it is better to issue it with the date of the inspection. The title of the document, date and place of compilation are indicated in the header. It is also important to indicate the details of the organization, list the members of the commission: their positions and full names.

In the main part, describe the tests of ladders, ladders and racks:

- how many were checked, their inventory numbers, belonging to the workshop and department;

- what load and for how long it was used;

- presence and absence of defects;

- the presence of the affixed inventory number.

As a result of the check, the suitability (or unsuitability) for use is established: they are safe, withstand the intended load, have no defects in connections and fasteners, have no sharp edges and burrs.

The signing of the act by the members of the commission indicates agreement with the results of the audit.

By the way! If after the article you still have questions about how to fill out the forms, contact the duty lawyer of the site.

System testing

To check the tightness of the indoor or outdoor water supply (pressure test), certain rules must be followed.

- So, when checking, the water consumption from each plumbing point is taken into account. It should be at least 0.2 liters per second.

- It is worth considering the pressure of the water supply. This is especially important for the highest located water intake points. In this case, the head should be at least 2-3 meters.

- It is also worth checking the compliance of the parameters of the entire system in accordance with the project documentation. Here they check the length, diameter of the pipeline, as well as the materials from which it is made.

- Visual initial inspection of external and internal communications also helps to avoid strong gusts of the system as a result of testing.

- Pressure testing of a water supply system consists in supplying water under high pressure to the system. Testing time is at least 10 minutes. The pressure when supplying water to the system should be one and a half times higher than the maximum allowable for a particular communication.

Example: domestic water supply is able to withstand a maximum gauge pressure of 0.45 MPa or just 45 meters of water column. Therefore, for testing such a sewerage and water supply system, it is necessary to apply a gauge pressure equal to 0.675 MPa or simply 67.5 meters of a column of water.

The test is considered successful if, under the influence of water, not a single leak or rupture of the water supply (sewer) pipeline is found.

The essence and types of crimping

Nowadays, heating is most often carried out by the "water circuit" system. In this case, the heated water circulates through the labors, imparting its thermal energy to the premises. Leaks are unacceptable, the pipeline must be completely sealed for normal operation. Pressing, on the other hand, deliberately creates a volume in the pipe that is greater than normal.

When this is done with air, it is called pneumatic pressing.

When using water, then hydro-pressing. The latter method is considered safer and therefore more popular. For this reason, an example of hydraulic pressing is given as a blank.

When testing, it is recommended not to exceed the pressure inside the pipe by more than 15 MPa. When it comes to raising pressure with water, then there are limitations. The maximum possible pressure should not exceed the normal operating pressure by more than 30%.

In multi-storey buildings, they resort to pneumatic pressing if the pipes are very old and there is a possibility of flooding. But then a level of risk arises and all residents must be notified of the tests being carried out.

The work process is simple, but multi-stage. The algorithm looks like this:

- The necessary materials and equipment are being prepared.

- Draining the liquid that was in the heating system earlier.

- Uploading a new one.

- Create the highest possible test pressure.

- Taking control measurements after 10 minutes.

- Flushing, adjusting the heating system to normal pressure values inside.

- Documentary registration of the work performed, the formation of reports and acts.

But this is how the list of procedures looks only if there are no "thin spots" in the heating system and, accordingly, the tightness in it is not violated. If the pressure drops quickly, does not hold, then the system needs repair work. In such a situation, the specialist performs the necessary actions (pipe replacement, sealing of connections, cleaning, etc.), and then starts pressure testing from the very beginning.Only a heating system that has passed the test is approved for the heating season.

An important nuance! Pressure testing should be carried out after cleaning and flushing the pipes. Otherwise, salt and other deposits inside them can mask possible external damage and breakouts.

If there are deposits of the order of 1 cm on the inner surface, then this reduces the overall heat transfer and efficiency by 15 percent or more of the total indicators. For documentary confirmation of cleaning, a special act is also drawn up.