Document year: 2019

Document group: Acts

Type of document: Act

Download formats: DOC, PDF

Test reports are drawn up in the form of forms of documents, in which the result of testing the operability of mechanisms and equipment is entered.

In today's article, we will consider in detail the acts of testing the system of pipelines, sewers, stairs and stepladders, roof fencing and fire tests.

Examples of drawing up acts can be downloaded for free at the end of the article.

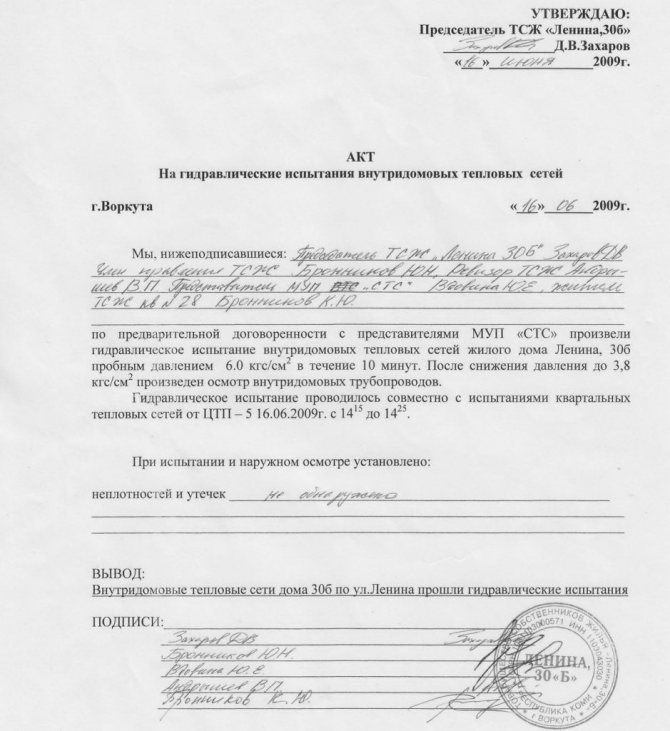

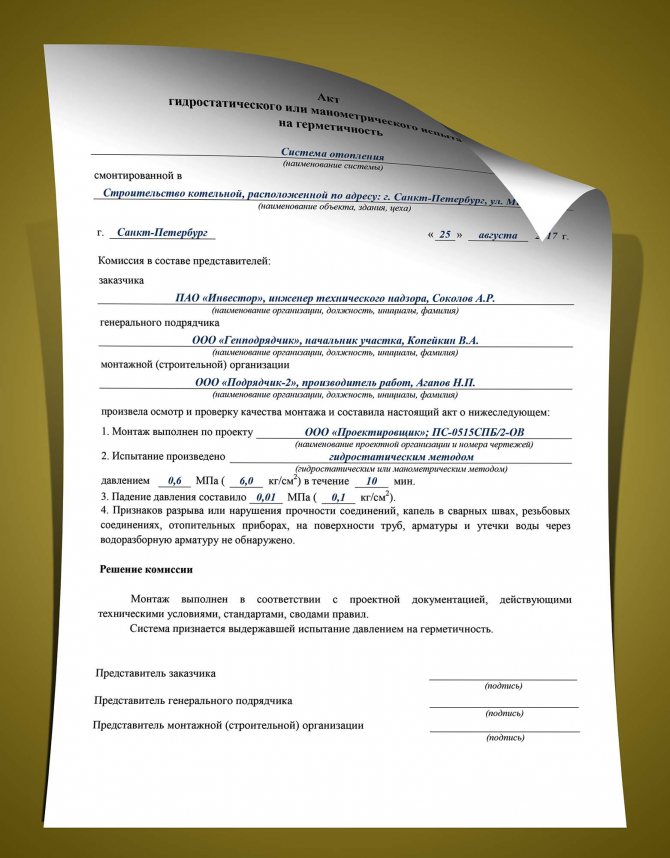

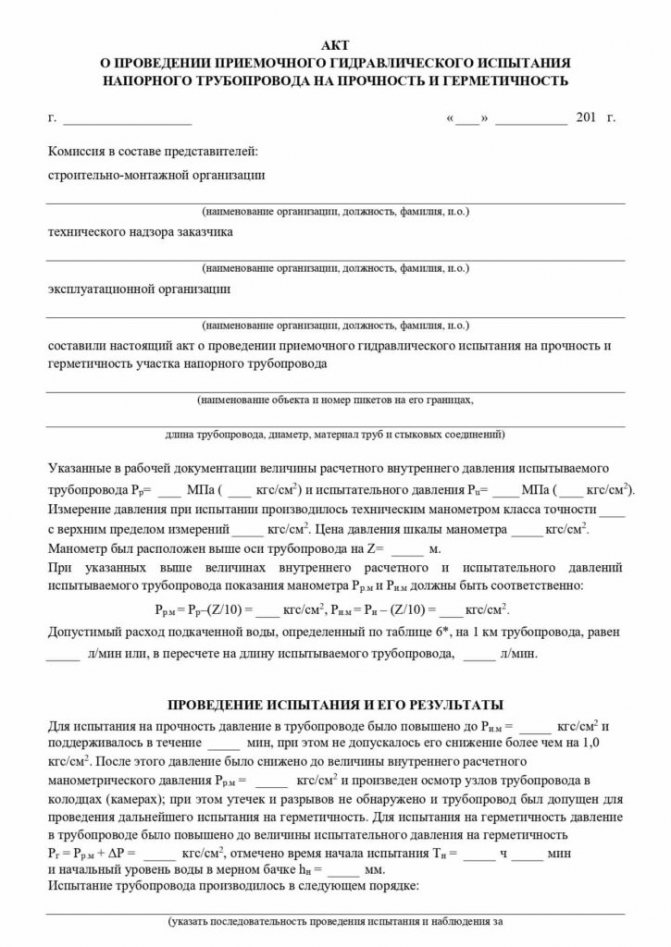

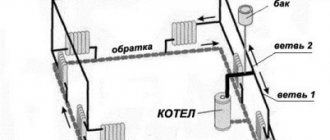

The act of hydraulic testing of the heating and water supply pipelines system

Heating and water supply systems are checked:

- when entering a new engineering communications;

- when reconstructing an existing one;

- during a routine check of the system's functioning.

A step-by-step check and its results are recorded in the test report. The system is tested for tightness and strength in two ways, one of which is the hydraulic method: testing by using water with increased load. This method is suitable for indoor and outdoor systems (at temperatures not lower than + 5C). The second method is pneumatic.

Both acceptance testing methods are referred to as pipe pressure testing.

The results of the inspections are entered into an act, the form of which is established by the Code of Rules for building codes and regulations. The template is presented in Appendix 1 to SANPin "External networks and water supply and sewerage facilities". The presented form of the act is mandatory.

The procedure for drawing up an act:

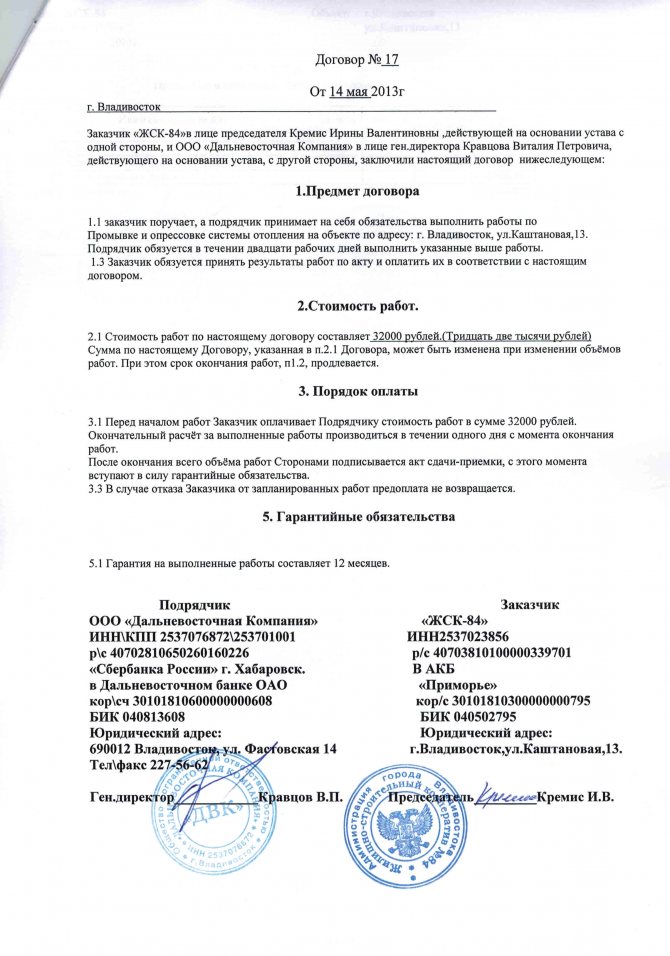

1. Indication of corporate information: city of compilation and date.

2. Representation of the members of the commission, which carried out pressure testing and acceptance of the pressure pipeline. Three parties become members:

| The company that installed the pipeline |

| Technical supervision representative from the customer |

| Operating company representative |

3. Below is information about the tested object and a description of the pipeline (length, diameter, material of pipes and joints), the information specified in the working documentation, provides information about the pressure gauge used.

4. The section on the test and its results is completed.

5. In the "Commission Decision" section, a statement is made that the system is considered strong and sealed and is signed by the members of the commission.

You can download the form for free at the end of the article.

In what cases is it compiled

The act is required for:

- Commissioning of new equipment. The act will be a confirmation that each element is in its place, the installation was carried out responsibly, the system is working.

- The onset of the heating season. After a summer break in operation, the pipes could fail. After checking their capacity, an act is drawn up.

- Already carried out repair work.

- The emergence of docked emergency situations on the pipeline. Thus, specialists identify the amount of work required, weak points of the existing heating network.

For the smooth operation of the heating system, preventive control checks are necessary, reliable information about the high-quality functioning of the system at startup.

Pneumatic pipeline test certificate

Pneumatic method: diagnostics by inflating the system with high pressure air. The method is often used for outdoor systems if the temperature on the thermometer is less than +5 Celsius.

The procedure for crimping pipes by pneumatic testing is given in the same SanPin, the test report is drawn up in a mandatory form, which is given in Appendix No. 3.

Requirements for the preparation of test documentation:

- Filling in the name of the city and the date of compilation.

- The indication of the members of the commission (as well as in the hydraulic test, three parties are involved).

- Description of the pipeline: length, diameter, material of pipes and joints.

- Information about the pressure value: calculated, to what value the pressure in the pipes was increased, the final pressure, the amount of reduction. The crimping time is indicated.

- In the section "Decision of the Commission", each of its members puts a signature with a decryption if the pipeline has passed pneumatic diagnostics, and is hermetically sealed and durable.

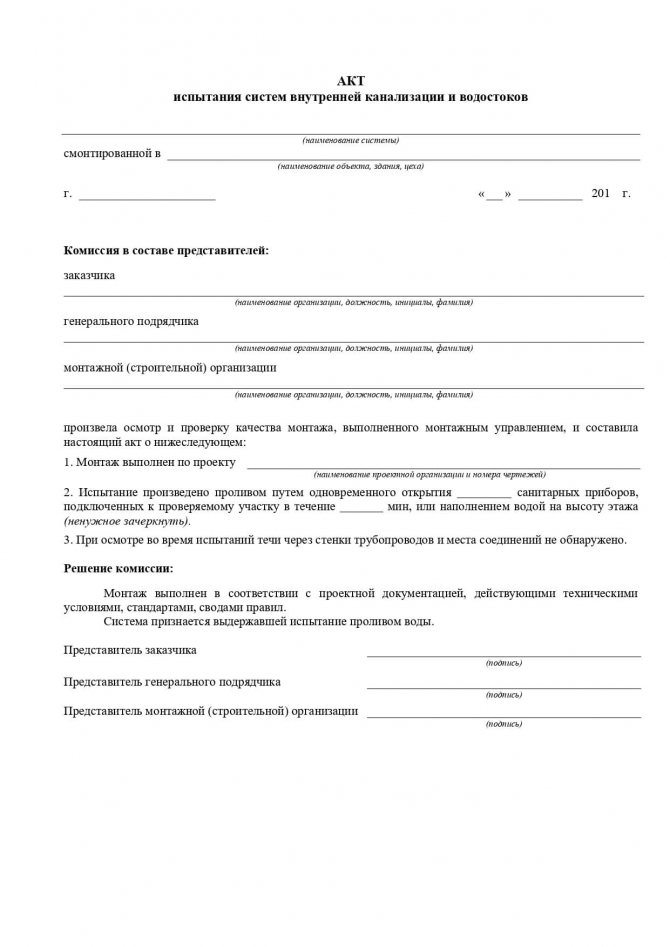

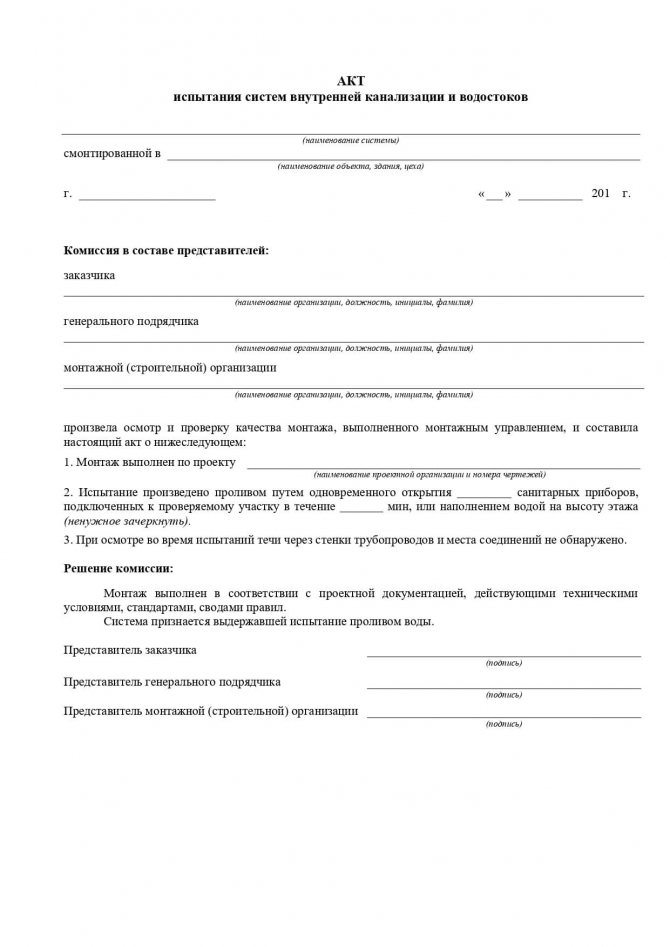

Test report of external and internal sewerage for the strait

The test report for internal and external sewerage is drawn up as a result of checking the system's performance. It fixes the position of the commission that the system has passed the water spill test, and the design complies with the design documentation, GOSTs and standards.

Diagnostics of the normal functionality of the sewer system is necessary when installing a new facility or after carrying out repairs to an existing system. The health check information is entered into the act. The form is drawn up in the form specified in Appendix "D" to the Code of Rules 73.13330.2012.

The act specifies:

- the name of the system and the object in which it is installed;

- information about the members of the commission. We need representatives of three organizations: the general contractor, the customer and the installation company;

- information about the name of the project is registered;

- the results are entered: the number of simultaneously connected devices, as well as the connection time or water filling per floor (the unnecessary is crossed out);

- in the third paragraph, it is prescribed that no leaks were found at the joints and through the walls. This means the system is usable.

Members of the commission sign for the decision.

What should be in the Act

The Act displays the results of the following actions of the personnel responsible for the verification procedure:

- water or air, using special equipment, is injected into the pipelines until a certain pressure is reached;

- the system is carefully inspected, especially the joints of its elements, for the detection of leaks, as well as other defects that can cause interruptions in the operation of thermal equipment;

- measures taken to eliminate defects (if any).

The regulation of hydrotesting of thermal installations is prescribed by the standard SP 73.13330.2012 "Internal sanitary-technical systems of buildings". In accordance with it, test operations are performed as follows:

- The supply of the working fluid to the pipelines of the heating system is carried out in stages, with a stepwise increase in pressure, until it reaches the set threshold value. It is recommended to pump the coolant at intervals of 10 minutes before the release of all air locks.

- The test pressure, controlled by a manometer, is maintained for at least 10 minutes. The test pressure should be 30-50% higher than the operating pressure (depending on the wear of the system), but not higher than the minimum allowable pressure of one of the devices. For example, if cast iron radiators are installed in a building, the pressure should not exceed 6 MPa, if steel radiators are 10 MPa.

- If pressure testing is carried out in a residential building, residents of the building are warned about the work.

- Typical indicators of leaks are a sharp drop in the pressure of the working fluid or its gradual decrease by more than 0.2 kg / cm2. As a rule, coolant losses occur at threaded or flanged joints, which must be tightened, repackaged or replaced with gaskets in them. If it is impossible to eliminate the defect, the unit is discarded and replaced.

Important! Pressure testing is carried out after flushing and hydropneumatic purging of the system. Otherwise, deposits inside the pipes can hide possible leaks. Also, it is worth considering that if you do not carry out measures to clean the pipes from deposits, the heat transfer coefficient of the system will significantly decrease.

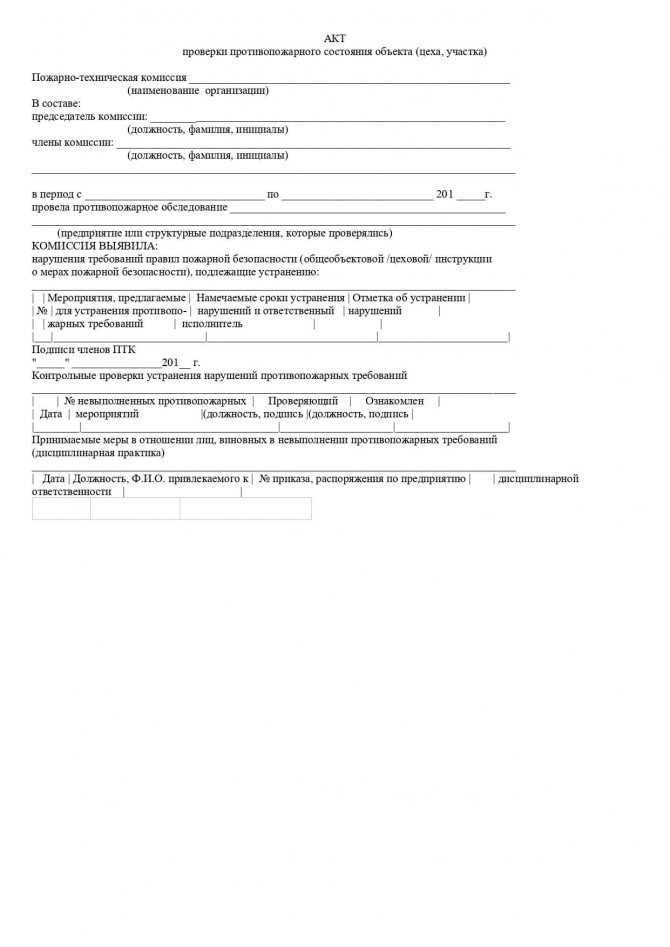

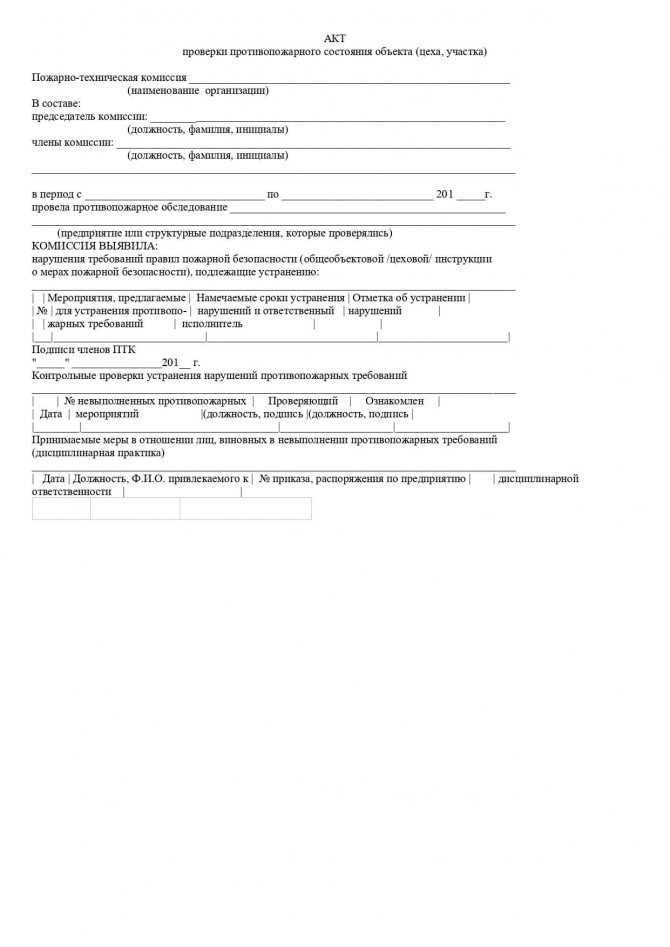

Fire test certificates

In the course of testing for the operability and safe operation of fire fighting equipment, several acts are drawn up:

- checking fire hydrants;

- internal water supply diagnostics;

- check for safety of use and compliance with the rules of labor protection of fire escapes.

Fire hydrants

Checking the performance of hydrants for water loss is carried out twice a year and, often, is combined with checking the fire-fighting water supply system. Based on the results of the inspection, an act is drawn up, which is signed by the commission. Mandatory members: a representative of the fire inspection and a representative from the organization in which the inspection is being carried out. Also, the commission may be entirely composed of company employees.

The act indicates:

- corporate information (information about the company, date and place of compilation);

- the main part describes the members of the commission and the course of the test. Information about hydrants is presented in a tabular form. Indicate the location address, diameter, head, water yield and hydrant ownership;

- in the final part, compliance (or non-compliance) with the requirements of the state of the hydrant is established.

At the end, the act is signed by the authorized members of the commission.

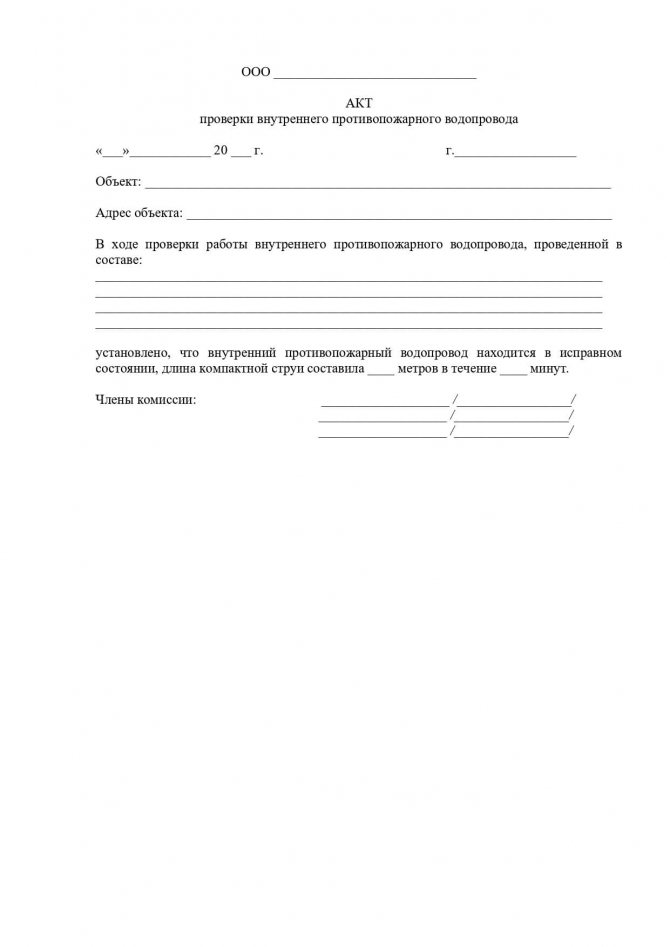

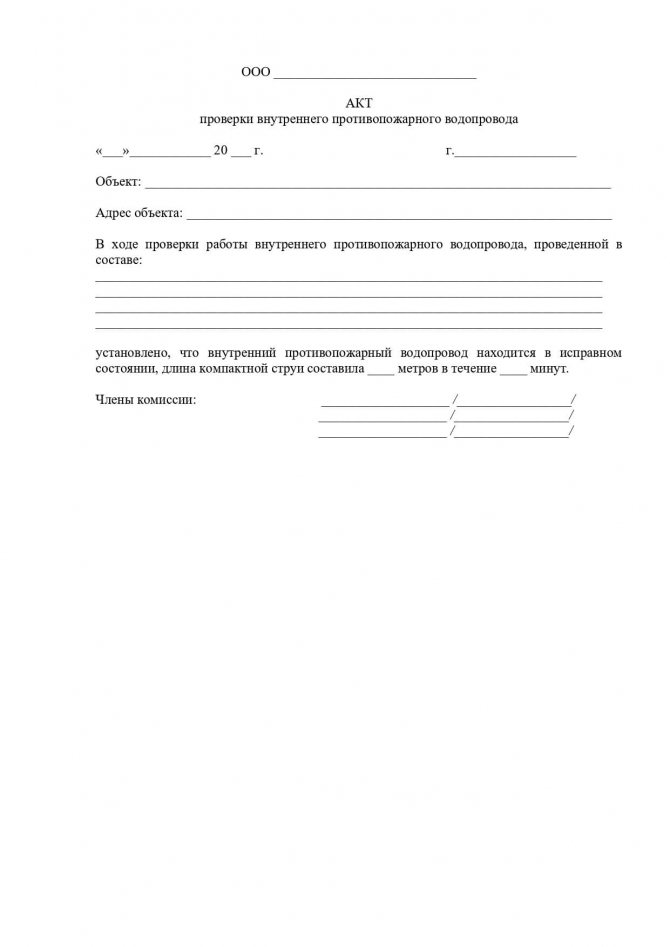

Internal fire-fighting water supply

The act establishes the presence or absence of defects and malfunctions in the fire-fighting water supply system. The check is carried out by the responsible employees of the enterprise. Frequency - at least twice a year, for flammable industries, inspections may be scheduled more often.

Internal fire-fighting water supply (ERW) is a complex system of pipes, sensors, switches. Therefore, it is often checked by an occupational health or fire safety specialist, as well as by persons who are trained in fire safety.

The act is drawn up on letterhead or plain paper, indicating the details. Be sure to register:

- information about the organization and participants of the audit;

- information about the checked object;

- results of inspections;

- recommendations for elimination of defects and malfunctions, if any;

- signatures of responsible persons.

If additional documents are attached to the act, their list and name are indicated.

Fire escapes

Testing of firefighting equipment, including ladders and ladders, is regulated by a special GOST. The inspection can be carried out by organizations that have received permission from the Ministry of Emergencies and have special equipment for this.

The test results are recorded in the test report. The documentation contains standard information about the organization and its details, information about the members of the commission. The main part contains information about the inspected objects (the number of stairs and stepladders, their inventory numbers and belonging to the structural unit), information on the results of inspections (absence or presence of defects). A prescription is given to eliminate the identified malfunctions.

At the end, the act is signed by the members of the commission.

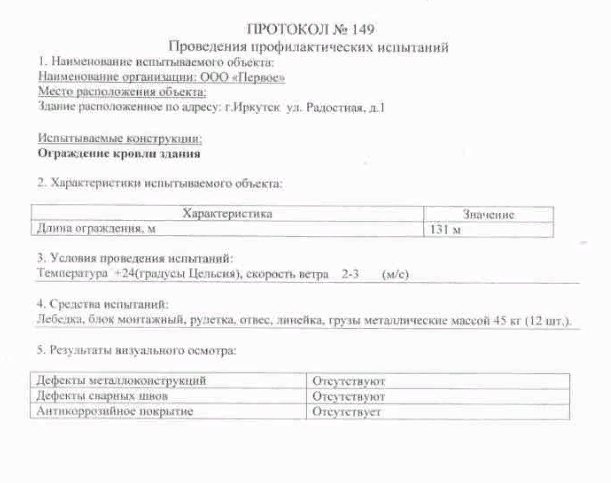

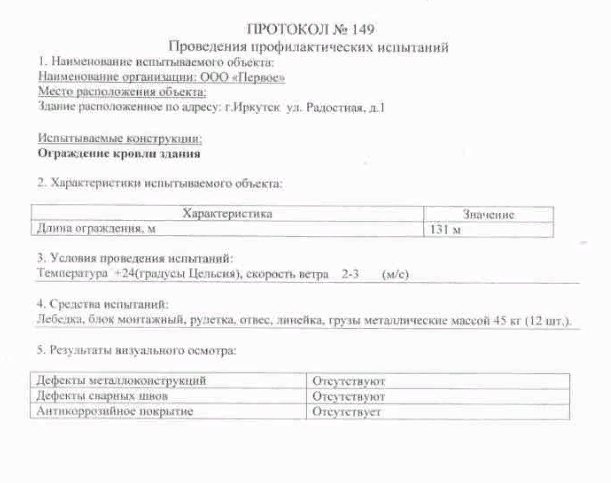

Roof fencing test report

The technical requirements and test methods for the roof are fixed in the same GOST as the standard for fire escapes and stepladders (53254-2009).

Tests are carried out at intervals of five years, integrity checks are carried out every year. The results are formalized by acts.

The conditionally completed act can be divided into three parts:

- General information.This is where information about the tested object and the testing organization is entered.

- Information about the check (what manipulations were carried out, what tools were used).

- Inspection results (compliance with GOSTs, structural integrity and safety).

The agreement of the members of the commission during the test is confirmed by their personal signatures.

Organizations licensed from the Ministry of Emergency Situations have the right to conduct inspections and tests. Defects found must be eliminated.

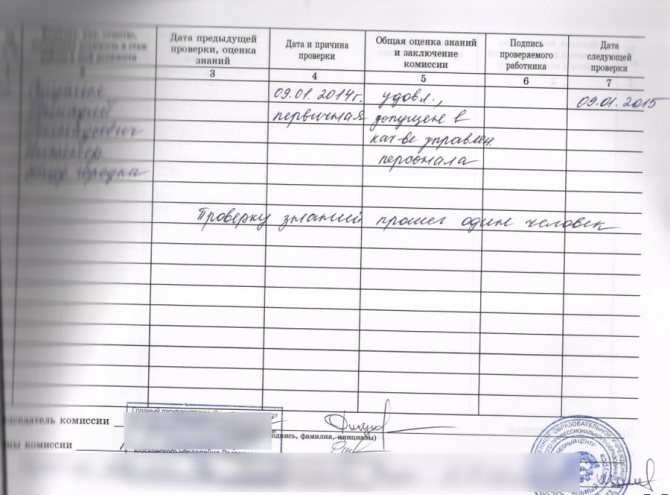

Test report for ladders, racks and ladders

Inspection and testing of racks, ladders and stepladders is carried out at least once every six or twelve months (depending on the test object and the material from which it is made).

Tests and inspections for safe operation can be carried out by specialized organizations from the outside or by a commission specially created at the enterprise. At the same time, its members must be trained, the chairman of the commission is usually an occupational safety or fire safety engineer.

As a result of the diagnostics, the commission draws up an act, it is better to issue it with the date of the inspection. The title of the document, date and place of compilation are indicated in the header. It is also important to indicate the details of the organization, list the members of the commission: their positions and full names.

In the main part, describe the tests of ladders, ladders and racks:

- how many were checked, their inventory numbers, belonging to the workshop and department;

- what load and for how long it was used;

- presence and absence of defects;

- the presence of the affixed inventory number.

As a result of the check, the suitability (or unsuitability) for use is established: they are safe, withstand the prescribed load, do not have defects in connections and fasteners, do not have sharp edges and burrs.

The signing of the act by the members of the commission indicates agreement with the results of the audit.

By the way! If after the article you still have questions on how to fill out the forms, contact the duty lawyer of the site.

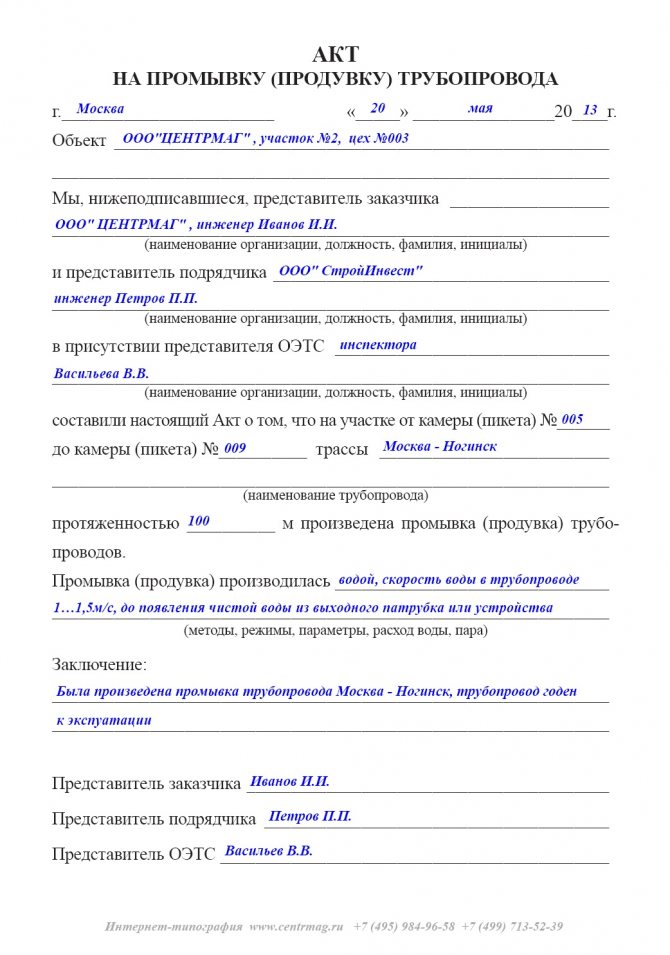

The need for preliminary flushing of the pipeline

Before carrying out all the activities, the heating networks of the house are disconnected from the heating main and the coolant is drained. If the heating circuit has been in operation for some time, then it must be flushed before pressure testing.

Flushing can be done in several ways. Its purpose is to remove scale, salt deposits and rust from pipes. The appearance of various deposits on the inner diameter of the pipeline impedes the normal circulation of the coolant, increases the hydraulic resistance in the system and reduces the heat transfer of heating radiators.

Due to various deposits and deposits, the bore diameter of the pipeline decreases, which increases the load on pumping equipment and heating boilers. All this contributes to the overconsumption of the energy carrier and adversely affects the efficiency of the heating system at home.

This is why the pipes are flushed regularly. Otherwise, this will affect the comfort of staying in the premises of the house and the heating costs for which residents pay. Even in a single room, the batteries can heat up unevenly, so the room will be noticeably colder.

Another reason why pipe flushing is so necessary is that deposits containing sulfur, magnesium, zinc, potassium and copper over time erode and thin the metal walls of the pipelines. As a result, they become vulnerable to the increased pressure of the coolant in the circuit.

A manual or electric compressor is used to flush the line. If flushing is performed for preventive purposes, then the frequency of such a procedure is once every 4-6 years.

Flushing methods

There are several ways to flush.Each of them uses different equipment:

- The pneumatic impact method consists in using the so-called "shock wave". It causes plaque delamination from the inner surface of the pipes. Following the air shock, a normal water rinse is performed to remove any loose deposits.

- Hydrochemical flushing is performed using special chemical compounds that dissolve salt deposits. However, it is not used as an independent method, because it does not allow removing silt deposits in the lower parts of the contour. As a rule, hydrochemical washing is used in combination with other measures.

- The pneumohydraulic flushing technique is also called bubbling. During the procedure, a complex effect on sediments is carried out. For this, compressed air and water are simultaneously supplied to the system under pressure. The technique is very effective because it allows you to clean the pipes from any deposits.

- The most effective is considered to be complex flushing, during which several of the methods listed above are used at once. It is usually used in pipelines with small diameters and heavy pollution.