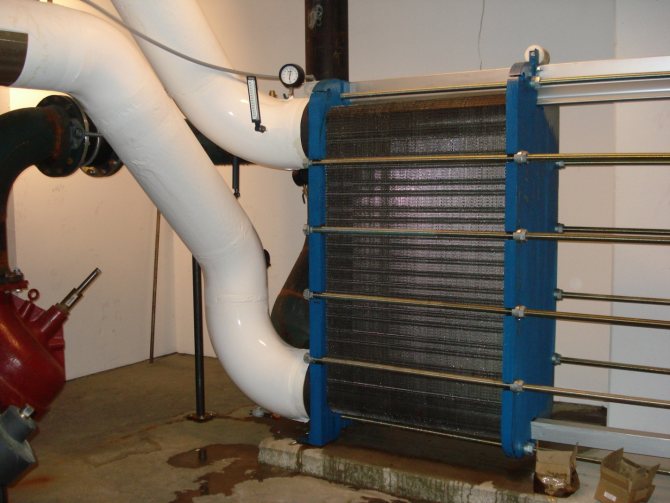

From time to time, the heating main needs to be cleaned. The fact is that during operation, rust and scale settle on the inner walls of the pipes. Lime deposits reduce the throughput of the pipeline, moreover, scale does not conduct heat well. As a result, heating costs have to be increased in order to keep the room temperature at the proper level. For flushing work, there is a set of special equipment, the main tool of which is a compressor for flushing the heating system.

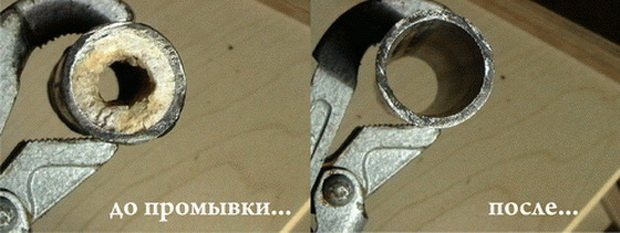

Pipe after 10 years of continuous operation

Important! Pipes that have served 10 years are 50% clogged with scale. Every millimeter of deposits increases fuel consumption by 25%. Thus, even a single flush of the system will increase its efficiency and help save energy costs.

Choosing a device for flushing the heating system

It is best to purchase an electronically controlled heating system flushing apparatus. It won't be just a pump for solution or compressed air. Such a device is able to analyze the intensity and nature of the oscillations of the working medium in the circuit. The operator's task will only be to regulate the frequency and power of the pulses.

The equipment must also be provided with pressure and fluid flow sensors, protection against accidental activation. Let's list some brands that are in high demand among the consumer:

- Rockal

- Ropulse

- Cillit-Boy

- Virax

- RIDGID

High-quality compressors can flush not only the heating system, but also water pipes, solar collectors, as well as the underfloor heating system.

Hydraulic flushing

The process itself is based on the supply of water and air under pressure to the pipeline sections at the same time. The resulting mixture cleans the heating system due to the many pulses that the compressor produces to flush the heating system.

Small bubbles are formed, which gradually break up various deposits on the walls of the pipelines.

Pipes before and after cleaning

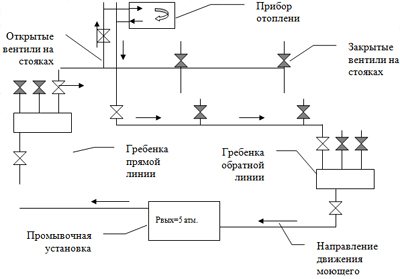

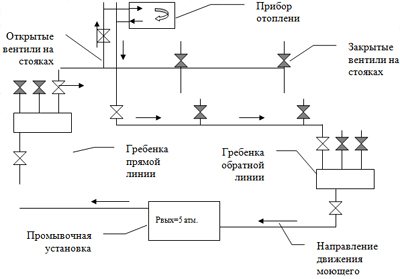

Important! In order for the flushing process to complete successfully, it is necessary to calculate the speed and flow rate of water, pressure and air flow rate by pipe diameters, and calculate the length of the pipelines. The flushing itself should be carried out in separate sections, that is, in groups of risers.

Methods of conducting

- Flowing... The return and supply pipelines are first filled with water, with the valve on the air collector open. After filling the pipelines, the valve is closed and compressed air is supplied. The air and water mixture is fed into the pipelines at the same time (see also the article on hydropneumatic flushing of the heating system). Flushing ends when clean water begins to flow through the nozzle. Then the water is drained into the drain. This method is used to flush hot water and heating systems;

- Fillings... This method has some consistency in its actions. First, the pipelines are filled with water and the valve is closed. In the second branch pipe, the supply of compressed air is organized for twenty to twenty-five minutes (depending on contamination and pipe diameters). After the cessation of the air supply, the shut-off valves are closed and the water is drained through the drain pipe. At the end, the system is rinsed a couple of times with clean water.

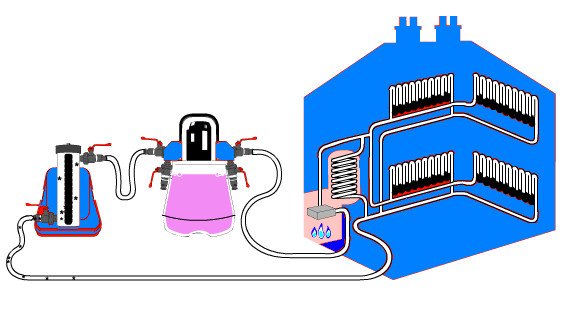

Typical scheme for work

Washing technology

Before starting work, you should diagnose the system, find out the condition of the pipeline, boilers and heat exchangers.Based on these data, the cleaning method and the operating mode of the flushing equipment are selected. Typically, one of two flushing options is used:

- Filling. The circuit is filled with water or a chemical reagent and left for half an hour. After that, the compressor is turned on and compressed air is fed into the pipes. After a certain period of time, close the valve on the supply line, open the valve and drain the dirty water. The procedure is repeated until a clear liquid appears.

- Flow-through method. Most effective. It consists in a long and continuous supply of compressed air and water (or solution) to the heating system. Not all compressors support both technologies - many of them supply either water or compressed air. When buying, you should pay attention to the technical characteristics of the equipment.

Compressor flushing methods

To do everything quickly and efficiently, it is recommended to use a compressor when flushing heating radiators, piping systems in order to restore the heat exchanger of a gas or other heating boiler. For some procedures, specialized equipment will be needed, for others, a conventional household (for example, automobile) compressor is sufficient.

Hydraulic and hydrochemical flushing

Hydraulic flushing is considered a classic of the genre. For its implementation, a water source is connected to the inlet of the heating circuit after disconnecting the corresponding pipe from the boiler or tapping in the outlet. This could be a communal water supply.

A hose is connected to the drain pipe of the heating system or a specially made cut-in to drain the dirty liquid into the sewer. In the simplest case, the procedure does not require any equipment. Water is fed into the pipeline.

Important! The minimum pumping volume for cleaning the system should be no less than five times the amount of the coolant.

The procedure can be carried out with the addition of chemicals, in the simplest case - soda ash. In this version, it is called hydrochemical. Cleaning can be carried out either manually, with preliminary preparation of a large volume of the working composition and pouring it into the system, or using a compressor. The most difficult option in the context of the equipment used looks like this.

- A special flushing compressor creates pressure of the working solution and ensures its movement in the pipeline system. A circulation pump can be used instead.

- At the outlet of the drain pipe, a filter is installed that retains impurities.

- The circulation of the working solution is carried out for at least an hour.

Advice! To make sure that cleaning is nearing completion, it is recommended to install a transparent hose on the drain pipe of the heating network. In this case, flushing lasts until the working solution comes out practically clean.

The procedure can be done with a conventional car compressor. In this case, a container is mounted, a 19 liter polyethylene tank is quite suitable, into which purified water is poured. A removable sealing block with a tube equipped with a check valve is installed on its neck. A chemical solution will be fed through it. An inlet for the compressor is mounted in the bottom or wall of the tank. This is a fairly simple device that you can assemble yourself.

The chemical solution is poured into the tank. A tee is used to enter the system. It connects to a water supply or other source of liquid, the outlet tube of the tank. The outlet from the tee will be connected to the inlet pipe of the heating system. The procedure looks like this:

- water turns on;

- after some time, after preliminary flushing, the compressor turns on;

- the chemical solution enters the system as the pressure rises.

By adjusting the compressor capacity or by carrying out a short-term start-stop, it is easy to achieve a sufficiently uniform supply of the active substance. Best results are obtained when using a compressor with a low capacity. The completion of hydrochemical cleaning should be the flushing of the pipe network with clean water to remove chemical residues.

Advice! In order to achieve a really high-quality flushing by a hydraulic or hydrochemical method, it is recommended, after processing the system as a whole, to remove the radiators and carry out the cleaning procedure for each of them separately.

Hydrodynamic cleaning

The hydrodynamic cleaning procedure removes almost all contaminants from the heating system:

- limescale residues;

- carbon deposits;

- sediment of solids;

- corrosion products;

- organic fats;

- mineral bloom;

- waste products of bacteria.

The procedure is carried out using specialized compressors equipped with nozzles that emit water with high-energy pulses. The jet has a high speed and working pressure up to 200 atm.

However, such nozzles are difficult to operate inside pipelines. Therefore, hydrodynamic cleaning is mainly used for heating radiators. Services are provided by specialized companies, since for a private person the idea of buying equipment of this class is simply irrational, its price is very high.

Bubble or hydropneumatic flushing

Hydropneumatic flushing is the most common way to restore the parameters of a heating system. It is the process of feeding an air-water mixture into pipes under significant pressure. Its effect literally tears off plaque, breaks precipitation and perfectly cleans both pipelines and heating radiators.

There are two ways to carry out this procedure.

- The system is filled with water and left for up to 1 hour. After that, an air compressor is connected to the inlet pipe and pressure is generated, which pipes and radiators can withstand. The system slugs again for half an hour. Finally, the drain pipe opens and the dirty water is discharged. Repeat the procedure if necessary. Any compressor can be used, including a car compressor.

- The system is supplied with an active air-water mixture. When carrying out this version of the procedure, you must use a special compressor. The device immediately delivers the finished mixture, allowing the washing procedure to be carried out as quickly as possible.

Hydropneumatic flushing is often referred to as purging. The procedure is carried out simply, quickly, without adding chemicals to the water, which can be immediately drained from the outlet pipe into the sewer.

Advice! It is recommended to carry out hydropneumatic cleaning before putting the heating system into operation.

Water hammer cleaning

Water supplied with a powerful impulse, at a speed of up to 1200 m per second, perfectly breaks up any deposits and dirt inside the pipelines of the heating system. This method has some danger for modern plastic pipes, non-welded joints, household heating boilers and boilers, thin heating radiators. However, water hammer is the most effective way to clean extremely clogged, old systems built on metal pipes and cast iron radiators.

For the procedure you will need:

- pneumatic gun, pressure accumulator with a pressure gauge and a valve opened by pressing the handle;

- a compressor that generates operating pressure for pulse shaping;

- source of liquid, plumbing can be used.

The mechanics of the work are quite simple.The heating system is supplied with water at a constant flow. The worker, monitoring the pressure indicator, launches the pneumatic gun.

The air pressure creates a hydraulic wave that breaks down the deposits in the pipes with an impulse. The time it takes to flush the system of a private house is an hour or a little more. For the fastest cleaning, you can use a specialized compressor, which is adjusted to certain parameters of the water hammer and the volume of fluid pumping.

Such an installation can be equipped with containers with chemical agents for automatic addition to the cleaning liquid, has a wide variety of protections, is able to combine water hammer with hydropneumatic mechanics, creating an air-water mixture.

Chemical cleaning

Cleaning with a concentrated active solution is a method that must be used with caution. Aluminum and silumin parts can be severely damaged when exposed to even relatively safe citric acid. However, for steel pipes, radiators, gas heat exchangers and other boilers, this is the most convenient way of cleaning.

The procedure looks like this:

- the volume to be cleaned is filled with a concentrated solution;

- after the lapse of time for which the maximum effect of the drug is achieved, it is removed from the system;

- the procedure is repeated for maximum thorough cleaning;

- the system is flushed with clean water to remove chemical residues.

In domestic conditions, a method with the movement of an active composition is used. For this, the liquid is pumped over. It is most convenient to use a special compressor.

However, you don't have to look for this type of equipment. You can get by with a conventional car compressor.

- For this, a container is made with two taps in the upper and lower parts. The ideal option is a plastic canister with a tightly screwed lid and a capacity of at least 5 liters.

- The compressor is connected to the upper outlet, and one of the heat exchanger pipes is connected to the lower outlet.

- A drain pipe is connected to the second pipe of the heat exchanger, the end of which is placed in an open container.

The procedure looks simple enough. 2/3 of the active solution is poured into the canister. After switching on the compressor, the delivery is started. The chemical mixture passes through a heat exchanger and is drained into a container. The fluid is pumped in portions for maximum impact.

After the canister is empty, the compressor is turned on in reverse. This provides a rarefaction, the reverse flow of the active composition occurs. The chemical mixture flows back into the canister. During the entire procedure, you need to ensure that the end of the drain tube is in the liquid. Finish the cleaning process by thoroughly flushing the heat exchanger.

The following types of active chemistry bring good results:

- alkalis;

- organic and inorganic acids;

- solvents.

Advice! If the pipes are slightly dirty, you can use citric acid and even a common toilet cleaner.

In order to flush not a separate radiator, but the system as a whole, specialized means are used. Their solution is pumped into pipelines and left for 6 to 10 hours to completely dissolve contaminants.

Heating system cleaning methods

To clean the internal channels of heating networks, several methods are used: hydrochemical, pneumohydraulic and hydropneumatic impact.

Chemical washing

This is the most common cleaning method. Its essence lies in the fact that a chemically active liquid is supplied to the system for flushing the heating system together with a corrosion inhibitor. An aggressive solution dissolves deposits layer by layer and flushes them out of the pipes, and the inhibitor additionally passivates the pipes from the inside (creates a stable anti-corrosion coating, increasing their service life).

Important! After draining the reagent, the system should be flushed with a neutralizer or water, and then filled with a coolant.

Such work is performed using a pump for flushing the heating system, pumping a chemical fluid under pressure.

Important! Flushing work can be carried out in winter without interrupting the heating process. Flushing the pipes with a reagent, carried out on their own, is fraught with a major overhaul of the entire system. Contact the specialists!

Chemical cleaning will extend the operation of the heating system for 10-15 years and significantly reduce heating costs.

Bubbling: pneumohydraulic cleaning

The procedure will require a compressor that creates high pressure in the flushing hoses. The compressor delivers a water-air mixture to the pipes, which loosens deposits and removes scale, grease, sodium, calcium, magnesium salts, chemicals and rust from the walls. This method is widely used to remove sludge from cast iron radiators.

Equipment for pneumohydraulic flushing

Battering ram: hydro-pneumatic cleaning

The method is based on the creation of a shock pulse passing through the highway at a speed of 1500 m / s. It is used on pipelines with a total length of no more than 60 m. The kinetic shock is produced by a special device. The result of the passage of the shock wave is the detachment of scale from the inner surface of the pipes.

Attention! Only a trained specialist can perform this operation!

A device for creating a shock wave in a pipeline

Do-it-yourself chemical washing

For chemical cleaning, it is important to select the correct product and carefully study the instructions before starting work. For self-cleaning of the heating system in a private house, you need:

- pump;

- container for liquid;

- cleaning agent;

- hoses.

Most chemicals are diluted with a certain volume of water before use. If desired, you can purchase ready-made liquid in stores, which is the best option for flushing a small system. For large stand-alone systems it is recommended to purchase a concentrate. The cleaning procedure is as follows:

- drainage of water from the heating network;

- filling the tank of the treatment plant with the prepared composition;

- switching on using the pump nozzles and filling the heating system elements with a chemical composition.

Usually 2-3 hours are enough for the destruction of scale. The circulation is carried out until there are no deposits in the filter tank. Flushing of the heating system with water is mandatory to completely remove the chemical reagent

Please note that the spent chemical solution must not be disposed of down the drain

When carrying out work, pay attention to the precautions with the chemical. Precautions:

- when working with a solution, it is imperative to wear gloves;

- the concentration of the reagent can be very dangerous for humans, therefore, before starting work, it is necessary to protect the mucous membranes with a respirator.

The main advantages of this method are

- High-quality removal of limescale and rust on the inner surface of pipes.

- No need to completely dismantle the heating system.

- Uniform heating of radiators after flushing.

- Reduced fuel consumption and, as a result, savings.

- Extending the life of the heating system.

Heating system flushing agents

Before buying a reagent, you need to consult with an expert about the composition of the layers in the pipes. Based on this, chemistry is selected for flushing the heating system. Acid concentrate acts faster, but alkaline is safer for the pipeline. The instructions always indicate which metals the reagent has a destructive effect on.

Attention! Do not wash aluminum radiators with acidic or alkaline solutions.Special means are provided for them.

Pipe after flushing

Stages of work

The cleansing process is divided into 2 types, namely:

- Technology that requires the disassembly of communications. It includes:

- disassembly of the heat exchange mechanism;

- removal of all plates;

- placing the plates in a chemical solution;

- manual cleaning of plates;

- pressure testing and assembly of the heat exchanger.

- The technology of the second type includes the following stages:

- parsing the heat exchanger;

- direction of the jet pressure into the radiator;

- extraction of dirt, thanks to the high pressure;

- assembly of communications.

The advantages of a collapsible flush include the fact that the master can be completely sure that the communications are really cleaned. In this way, even the most stubborn salts can be eliminated. The foreman personally supervises every stage of the process.

As disadvantages, one can single out the need to replace seals and other components that fail during operation.

Professional flushing of pipelines

Responsible homeowners rarely decide to flush the heating system themselves, especially when it comes to multi-storey buildings. The risk of being left with emergency heating is too great. The best solution would be to contact a company that specializes in such services. Engineers will assess the technical condition of the pipes and carry out preliminary pressure testing of the pipeline. Based on the results of the check, an act and an estimate for flushing the heating system will be drawn up.

After completing the work, the contractor must dispose of the used reagents. They cannot be drained into the sewer.

Quality control of flushing of the heating system is carried out in accordance with SNIP 3.05.01-85. According to the standards, water must be taken in different sections of the pipeline, as well as in the heating unit. It is assumed that a competent commission will assess the amount of suspended matter and the transparency of the coolant. In fact, representatives of the housing office use a more effective method: they open several radiators in apartments and entrances, unscrewing the blind plugs. The thickness of the scale layer in the battery is visually assessed, as well as the presence of solid particles on the cork. If the result is unsatisfactory, a period for re-flushing the system is assigned.

Let's summarize. It seems that flushing heating pipes is easy. In fact, the process is quite complicated and requires the use of special equipment and chemical reagents. Damaged pipes, numerous leaks and bursts in weak points of the system can be the result of unprofessional actions. Contacting a specialized organization will be a guarantee of competent and responsible performance of the entire range of flushing work.

Which method to choose

Chemical technology is used more often than others. You don't need to spend a lot of time on it. Its main advantage is that it does not require disassembly. For cleansing, the Russian market offers compositions based on alkalis and acids.

If the technology is violated, they can damage the system, or have no effect. In addition, it is not enough to use only one alkali, therefore its effect is unidirectional. Such chemistry is very dangerous, therefore only professionals can use it. Even if a very small part ends up in the sewer, it is fraught with massive poisoning.

The second, pneumatic method is absolutely safe, and has a number of advantages:

- Ideal for spot cleaning of heating lines.

- Affecting all hard-to-reach areas.

- The main and very significant advantage is that there is no need to disconnect devices from general communications to use it.

- To date, no one has yet succeeded in obtaining a similar effect in another way.

Most often, the first and second methods are used to flush common house and large highways.But if only one radiator is clogged, flushing is carried out using a special tap.