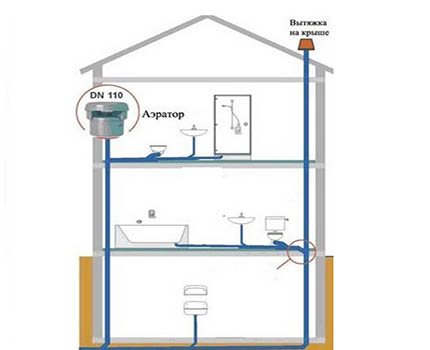

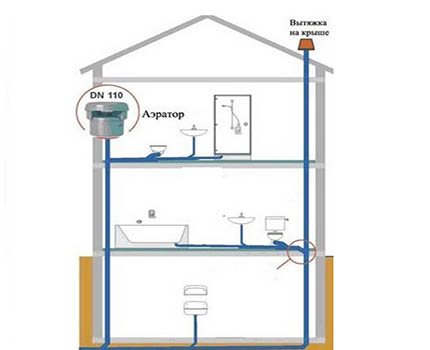

The sewer system does not always work correctly. This is especially important for multi-storey buildings with long-standing communications. The cause of these troubles is related to the pressure difference in the system. An effective way to regulate the pressure in the sewer is to install a fan valve. It is used as both an inlet and an outlet. It is taken outside the boundaries of windows, walls or roofs. Because in any pipe located vertically, a constant upward thrust is created. Unpleasant smelling effluent fumes are discharged into the surrounding atmosphere.

Attention! In windy weather, the thrust also becomes stronger when warm water is discharged into the sewer system (warm air rises).

If the drain pipe does not work well (microcracks and blockages appear, tightness is lost), in some plumbing fixtures the pressure becomes not constant. In this case, instead of the funnel system, an affordable and simple method of removing the sewer odor is used - to install a vacuum valve for the sewer. To put it correctly, you need to know some of the features, this device is able to ensure reliable operation of the device and cope with 2-3 connected devices.

When a large amount of water is discharged (discharged from the toilet bowl), a strong flow moves along the riser, partially or completely covering the diameter of the pipe. The flow squeezes all the air from the riser into the basement or sewer well. A vacuum appears at the top of the riser, compensating for the intake of air through the ventilation outlet on the roof of the building.

The principle of operation of the vacuum valve and its design

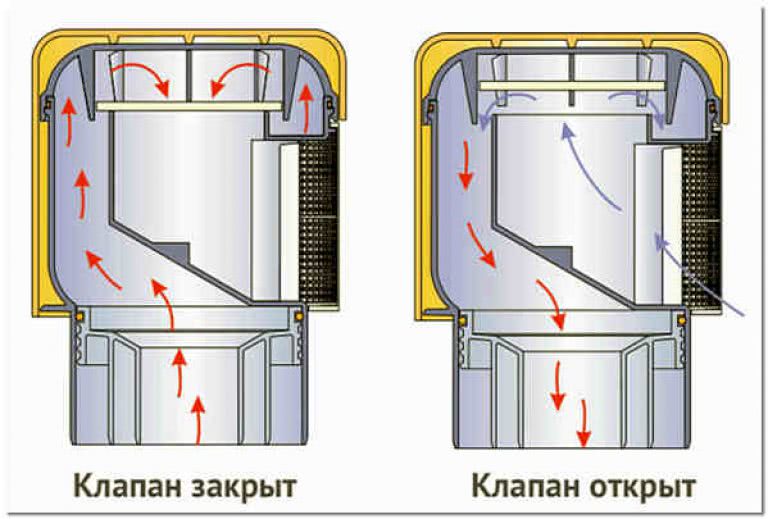

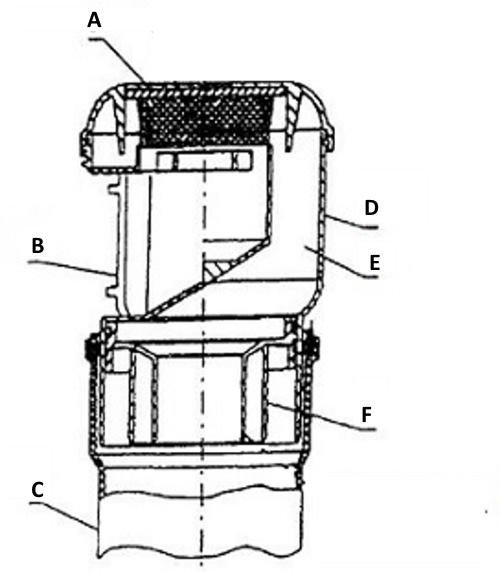

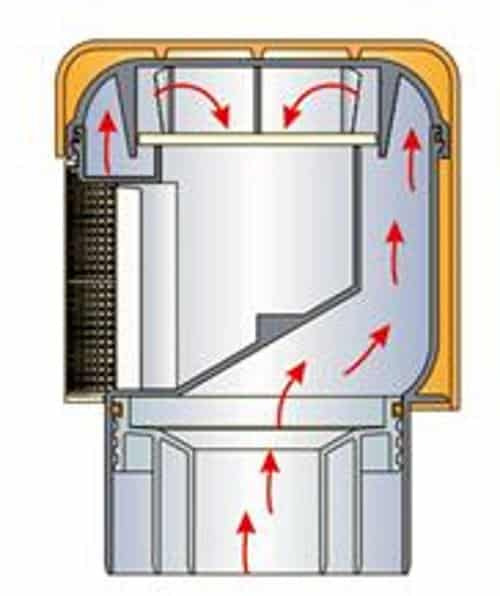

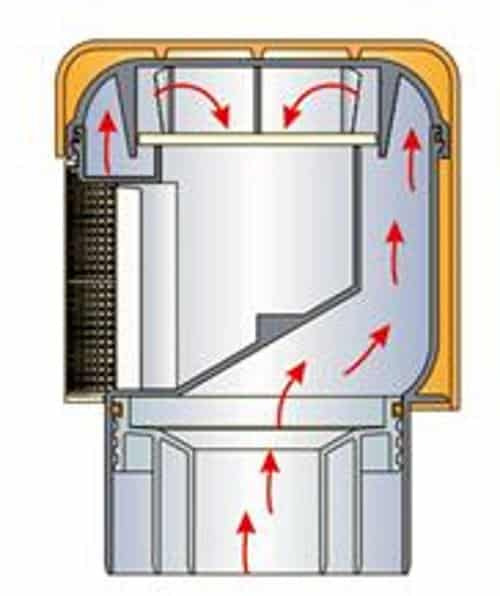

Before talking about how a vacuum type air check valve works, consider its device, it is shown in the figure.

Vacuum damper design (simplified diagram)

Designations of structural elements:

- A - damper;

- B - ventilation hole;

- C - the upper part of the riser;

- D - walls of the device case;

- E - air channel;

- F - insert.

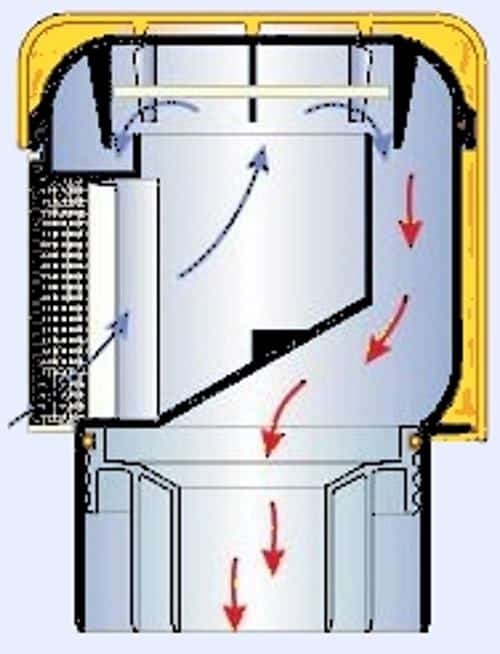

Now let's move on to the principle of the vacuum lock. When the water is drained into the system, a pressure change occurs. To stabilize it, a cover is opened in the valve through which air enters the system.

Open damper valve

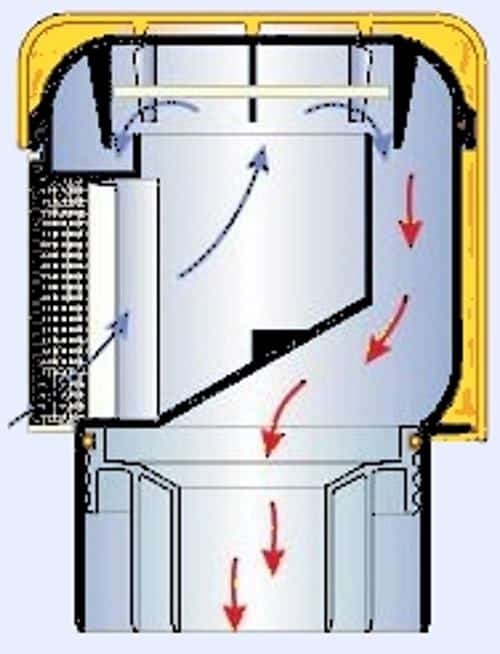

When the pressure in the system is equalized, the damper is in the locked position, so that unpleasant odors cannot enter the room.

The damper is closed, which prevents air recirculation

The aerator should be installed in the following cases:

- when the sewer systems are not equipped with drain pipes;

- if it is not possible to run the ventilation pipe through the roof.

The purpose of this type of shut-off valves is to provide the required level of ventilation inside the system. As a rule, vacuum valves are installed in low-rise buildings (no more than 5-6 floors), otherwise there is a high probability of failure of constipation.

DIY installation step by step

Considering how to properly install a sewer element, it is worth mentioning the compliance of diameters. If the cross-section of the pipeline does not match the size of the valve, use adapters. The plastic product can be installed on a cast iron pipe. To ensure the tightness of the connection, an adapter with a rubber seal is used.

The installation of a fan valve for the sewage system begins with the choice of a place. It is important to remember the rules here, where the ventilated room and the highest point of the sewer system are mentioned.The air temperature where the fan element is located should not fall below 0 ° С. The best place in the apartment is the bathroom. In a private house, it is reasonable to bring the riser to the attic, and install a valve on top. You can make a hidden installation. For the aeration element, a prefabricated ventilation shaft and a service window closed with a decorative grill are provided.

Installation work on the existing sewerage system begins with a water supply cutoff. A sewer pipe is cut at the installation site. The edges are deburred and a tee is inserted at the cut. The center hole of the shaped piece is a socket for the aerator, where it just needs to be immersed. The elements are connected using rubber cuffs. The rings provide reliable sealing of the joint.

To make connections easier, the cuffs are lubricated with silicone.

On the new sewage system, shaped inserts are provided in advance. If this is a riser in the attic, then the fan element is simply inserted into the socket of the pipe.

At the end of the work, the water supply is resumed. The sealing of the joints is checked by draining a large amount of water into the sewer.

What to look for when choosing

There are three factors to consider before purchasing a vacuum type valve:

- diameter of the vacuum lock, valves can be Ø110 mm and Ø50 mm. The first is installed on the sewer riser, the second - on the corner outlet from it. Please note that the Ø50 mm aerator is designed to equalize the pressure when draining water from two devices (no more), for example, a toilet bowl and a sink;

Photo: vacuum valve with a diameter of 50 and 110 mm

- design features. Devices can be equipped with a diaphragm or stem, the latter being preferable since their service life is longer;

- equipment manufacturer. We recommend purchasing models of well-known brands, for example: Ostendorf, TDI, Ssangyong, EGR, KVE, KVM, KVR, etc.

Ostendorf air safety valve for internal sewerage systems

Related videos:

Pros and cons of using a vent valve

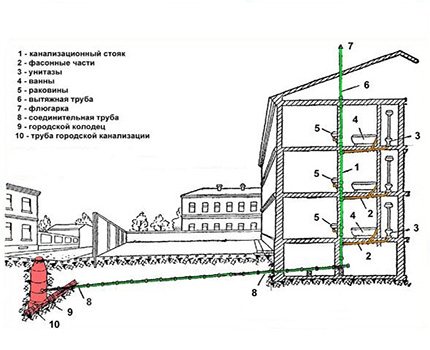

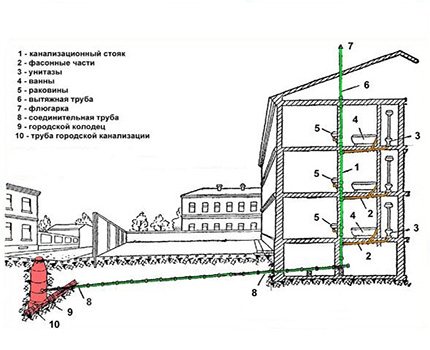

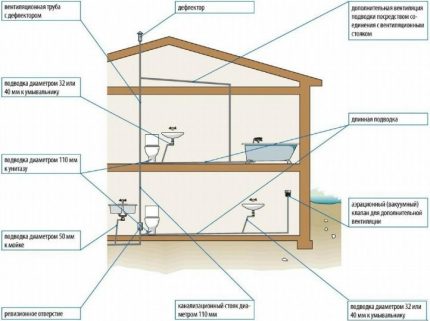

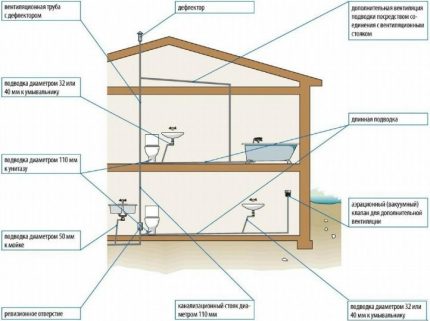

To prevent gases, vapors and odors from the piping system from entering the house, provide ventilation that will facilitate their removal from the system. The principle of ventilation is based on the flow of air from the ventilation pipe of the septic tank, the passage of air flows through the external and internal sewer networks and their exit through the ventilation duct leading to the roof.

So, the air, passing through the septic tank and the sewerage system, carries away all the odors, comes out with them through the ventilation riser in the roof and then dissipates. In the absence of a ventilation system, an unpleasant odor and volatile substances from the septic tank and pipes can enter the room through the torn off hydraulic gates.

The presence of a ventilation system in the building ensures that odors do not penetrate into the premises, even if the siphons break or dry out. But sometimes the arrangement of a fan channel is impossible or causes great difficulties.

This can occur due to the peculiarities of the roofing material, due to the operated roof, the impossibility of locating the outlet of the exhaust stack away from balconies, windows, ventilation systems. In this case, the exhaust part is taken out to the attic, and an aerator is mounted on its top.

The outlet of the fan riser is most often brought out to the roof. If ventilation is discharged into a wall, then the distance from it to windows and balconies should be at least 4 meters. When planning, the direction of the wind is also taken into account so that gases from the sewage system are scattered and do not enter through open windows and ventilation devices into the premises.

The vacuum valve cannot be a full-fledged replacement for ventilation risers, but its use can be justified by the following advantages:

- easy and quick installation;

- saving money;

- impossibility of installing a fan riser;

- minimization of heat loss through ventilation risers;

- improved work of the sewer network and greater freedom in its planning.

Simply put, the ventilation valve solves only one task - it prevents the failure of the drain valve, while the drain pipe equalizes the pressure in the network, and also ventilates the septic tank and the internal sewage system.

In multi-storey buildings, it is not recommended to replace the ventilation riser with a ventilation valve, since the latter will not be able to provide air access in the required volumes. Here the aerator can be installed as an accessory to improve the sewerage performance.

When installing a non-ventilated system or replacing a ventilation riser with an aerator, it is necessary to correctly calculate the throughput of the network in order to exclude the possible breakdown of siphons or failure of the fan valves.

It should also be borne in mind that if the building is not inhabited all year round, it may happen that the hydraulic gates will not be filled with water (dry out) and air from the sewage system will flow into the premises, which will not happen when installing a ventilated riser.

Installation Algorithm

Installation of vacuum shut-off valves is carried out according to the following algorithm:

- choose a place to connect the valve;

- it is necessary to check the tightness of the device;

- install.

Recommendations for choosing a location

When choosing an installation location, the following tips should be taken into account:

- valves should be connected at a higher height than the connected hose from the plumbing fixture. In this case, the stable and reliable operation of the vacuum seal can be guaranteed;

- the premises where the installation is carried out must have good ventilation. That is, if this is the attic of a private house, it must be ventilated. When the place of inclusion is a bathroom or toilet, they must be equipped with an extractor hood;

- the vacuum shut-off valve does not tolerate cooling, therefore, in the room where it is installed, the temperature should not fall below the freezing point of water (0 ° C). If this rule is not followed, the device is likely to lose its functionality or may completely fail;

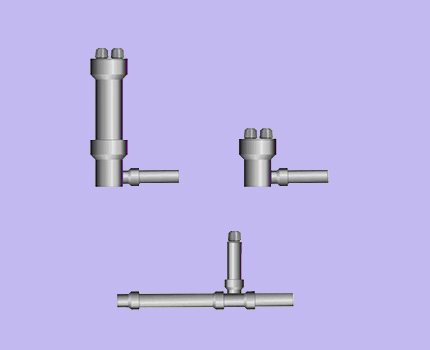

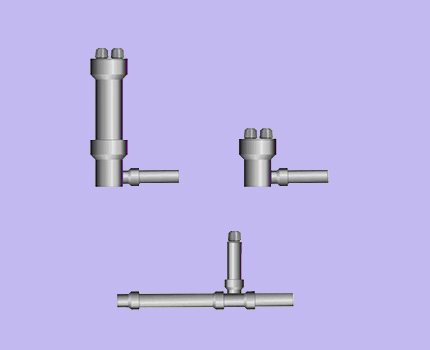

- the valve must be installed vertically. In the event that the pipe is laid horizontally in the selected place, an elbow must be cut into it. Below is a photo showing a similar solution.

Elbow embedded in the pipe for vertical installation of the vacuum seal

We consider it necessary to pay attention to the following point: the valve must be installed in such a place so that access to it is always provided in case it is necessary to make repairs or manual (forced) start of the device. It is also necessary for preventive maintenance (timely cleaning of the device).

How tightness is checked

There are several ways to check the anti-vacuum seal without using special equipment, that is, at home:

- it is necessary to fill the valve with air (you can use a bicycle pump for this), having previously treated the surface of the valve with soap. The bubbles that appear will show the place where the tightness is broken;

- a device filled with air is placed under water, the appearance of air bubbles will indicate a violation of the tightness;

- pour water into the valve, if it is sealed, then it will not flow out of the valve.

As a rule, valves are checked directly by the manufacturer, as evidenced by the entry in the device's passport.If a model of an unknown Chinese manufacturer is purchased, then it is better to carry out a tightness test using one of the methods described above.

Installation

After choosing a place and checking for leaks, proceed with installation. It depends on the design features of the shutter, it can be:

- flanged, in this case the connection is made using bolts;

- threaded, you will need to cut a thread on the pipe;

- flared, the connection is made using a special rubber cuff. This connection option, although the simplest, provides the required reliability.

For tightness at the connection point, it is recommended to use a silicone-based sealant.

The installation procedure is as follows:

- it is necessary to completely disconnect the house or apartment from the water supply;

- prepare the pipe for installation, cut threads if necessary, or install a special elbow (adapter);

- install in an appropriate way;

- check the joint for leaks.

We remind you that during operation, the vacuum valve for the sewage system must be periodically cleaned, this will significantly extend its service life.

Installation rules

There are rules for installing a fan valve that require strict adherence. If you ignore them, the work of the sewer will be disrupted. The rules consist of three main points:

- for the connection point, select a point above the connection of all plumbing fixtures;

- the aeration element is installed only in a ventilated room and provides free access to it for maintenance;

- fix the valve to the sewer only vertically.

The aerator is mounted on rubber seals. The process is simple for anyone not familiar with plumbing.

Other types of vacuum valves

Vacuum seals are used not only in sewer systems, for example, a bellows electromagnetic (electrovacuum) valve provides air release or supply in various equipment.

The throttle solenoid valve (electric) provides vacuum support in common systems.

In addition, vacuum valves are widely used in the automotive industry (brake booster, fuel pump, automatic transmission, in the hydraulic steering system of the front axle, for exhaust gas recirculation (thermal vacuum valve), turbine vacuum modulator, etc.).

The engine of a modern car cannot function without this equipment. Of course, such devices are much more complicated than vacuum valves for sewer systems, respectively, the price for a package of equipment is much higher.

General rules for installing a fan valve

Before installation, first of all, it is necessary to check the valve for leaks. The easiest way to do this is to fill it with water from the side from which air should not flow into the inside of the case and check this part for leaks.

The aerator is installed exclusively in a vertical position. When placed horizontally or tilted, the manufacturer does not guarantee its correct operation. Tees and elbows can be used to achieve the desired position when installing the valve, which will help to install it vertically. Although the device does not require regular maintenance, it must still be accessible for cleaning if necessary.

For the correct placement of the valve, choose a vertically directed pipe, or install it on a horizontal section using various adapters. There are also models with connections designed for installation in horizontal pipe runs

During installation, it is necessary to ensure the free flow of air to the aerator, since when draining, water is capable of carrying air with it, the volume of which is 25 times the amount of the waste liquid itself. It is especially important to take this feature into account when installing a hidden aerator for a sewer system.

Connect the fan valve, removing it from the drain point horizontally or taking it up above the riser. Tees, turns, adapters, reducing inserts are used for different connection options.

Installed above the connection level of the most extreme drain point (in the place farthest from the riser). To exclude the possibility of splashing and dirt getting on the sealing membrane - the main working element - the aerator is installed above 300 mm from the junction with the riser.

When installing the aeration valve, certain rules are followed. It can completely replace the fan riser only in the case of a small water consumption (+)

The device is mounted in places accessible for air intake. This can be an attic, a technical floor, or a bathroom on the top floor of the house. All rooms must be ventilated or equipped with hoods.

The operating temperature range of different device models may vary from –50 ° C to + 95 ° C. When installing the aerator in an unheated part of the house, the sewer riser (pipe) is insulated. The valve body need not be protected from negative temperatures, since there is an air cavity between its cover and the body, which can serve as a heater.

Pros and cons

Before deciding to install a vacuum valve on the sewer, it is worth learning about the advantages of this device and assessing its disadvantages. Let's start with the pros:

- The main advantage of installing an aerator before installing a fan pipe is that you do not need to make a hole in the roof. And this can significantly reduce the risk of roof leaks;

- another positive point is that the presence of an additional pipe will not spoil the appearance of the building;

- do not underestimate the economic aspect either. Installing a vacuum valve will cost significantly less than installing a fan pipe;

- another plus is the ability to install the part yourself, since the installation work is quite simple.

The disadvantages include the fact that the device will have to be periodically inspected and cleaned and repaired.

Purpose of the device

During the drainage of water, negative pressure forms in the pipes - vacuum... It is capable of breaking the water seals of toilet bowls, bathtubs or sinks, connecting the internal volume of the system with the atmosphere of the living quarters. After removing the water plug in the siphon device of plumbing fixtures, a foul smell appears in residential premises, indicating the penetration of biogas.

The only possible solution to the problem is to supply air to the system. The owner of a private house has the opportunity to make a funnel pipeline with an outlet to the roof.

In a private house or apartment

Installing a fan pipe - a simple and affordable way to eliminate odor, but it also has disadvantages. An aerator installed on the roof not only supplies air to the inside of the system, but also allows gases to escape from it, therefore it is impossible to place such systems inside living quarters.

For people living in apartment multi-storey building, the only way to resolve the issue will be the installation of an air valve on the sewer. This procedure is not very difficult, but it is best performed during the initial construction work. The insertion of such devices into a common operating pipeline is a laborious undertaking that causes inconvenience to all residents whose apartments are located on this riser.

Purpose of the vacuum sewer valve

A vacuum valve for sewage is required in the following cases:

- if there is no ventilation of the sewer riser in the building;

- if access of the riser to the roof for ventilation is difficult or impossible.

The system works like this: all toilets are connected to the central sewer system. There is always a certain volume of gases in the pipelines, and periodically water enters the system, which can be either cold or hot. Naturally, all hot couples will try to reach the highest point to which there is access.

Usually, the situation is solved by the most affordable method: a plug is mounted on the outlet of the riser, and water seals are engaged in protecting residents from sewage odors.

Sewerage ventilation device

Unpleasant "odors" from the sewer are blocked by vacuum valves in the plumbing siphons. But, if the drain was too sharp, and the amount of liquid is large, then the internal pressure may decrease, and water will begin to be sucked out of the siphon. At such a moment, unpleasant odors can enter the building, bypassing the obstacle. The stench can appear due to a long downtime of the plumbing, the water from the blocking device simply evaporates. Also, the reason is often the small size of the siphon.

The best solution would be to install a sewer air valve or drain pipe. The air passing through them regulates the pressure inside the sewage system with atmospheric. In this case, all unpleasant odors are led through the pipes to the collector system, rather than being siphoned out.

Which vacuum valve to install?

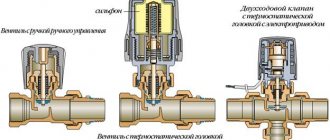

The range of vacuum valves is available in various modifications. So, according to the principle of conductivity, devices can be:

- linear (hollow);

- closing (non-passable).

The most common type of stem actuator vacuum valve is the manual ball valve. Such devices are currently used in many vacuum systems, ranging from a household washing machine to the cooling system of a nuclear power plant. Another type, a solenoid valve, uses the physical properties of an electromagnetic field in its work. Such devices justify their use in complex systems, the operation of which is controlled by computer programs.

On the other hand, valve models may differ in technical direction, and are one-way and two-way devices. In modern apartments and private houses, it is quite enough to use a one-way valve for a sewer riser.

How to install: step by step instructions

Most of the air valves are manufactured by manufacturers for connection to DN110 pipes. If the connecting size of the device does not correspond to the size of the pipe, a special adapter is used. For pipes DN50 or DN75, use aerators with the corresponding diameter of the connecting outlet or equipped with a reducing insert.

It must be remembered that a valve designed for pipes with a diameter of less than 110 mm can be installed for a maximum of two plumbing points.

In the areas of transition from a pipe of a larger diameter to a valve with a smaller diameter, reducing inserts and various adapters are used. To install the aerator on a cast-iron pipe, there are also special adapters that provide a reliable plastic-to-metal joint.

At the beginning of the work, the place of valve installation is determined, taking into account the installation rules and its availability for further maintenance. Next, perform the following actions:

- Turn off the water supply in the house.

- If the installation is carried out on a previously installed pipeline, then a tie-in is carried out and a special adapter is installed.

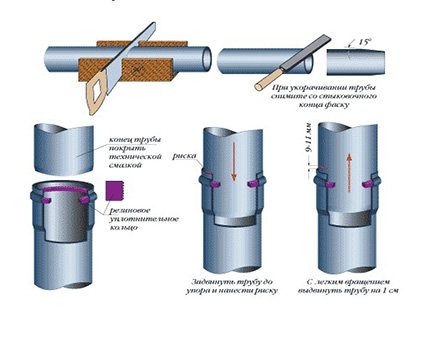

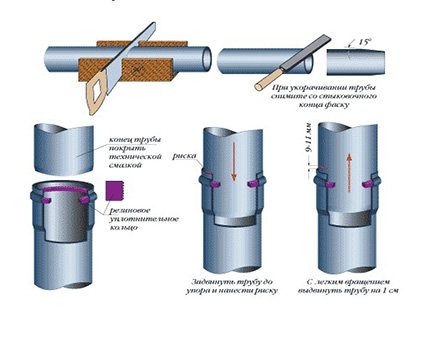

Most models of aerators have a bell-type connection. The assembly of such connections is carried out in the following sequence:

- The outer surface of the smooth part and the surface inside the socket are cleaned of dust.

- Wipe the O-ring from possible contamination and insert it into the socket groove.

- Surfaces that touch during bonding are lubricated to reduce friction. To do this, use a silicone-based sealant or soap solution, glycerin.

- The smooth end of the valve is inserted into the socket up to the mark. The quality of the connection is checked by turning the parts relative to each other, followed by returning to their original position.

If necessary, the section with the connected vacuum valve is secured with a clamp. At the end of the work, it is necessary to check the joints for tightness.

The connection of pipeline elements with a fan valve is carried out according to the same principle as pipes for sewage

For concealed installation, special models of vacuum valves are used. If the riser is hidden in a pipe or protective box, then measures must be taken to ensure the flow of air into the drain valve. For this, a ventilation hole is made according to the size of the aerator mesh.

The aerator body is recessed into the wall, the fastening element is adjusted so that its outer edge is flush with the wall surface. The only visible element is the decorative grille, which can be fastened with self-tapping screws or inserted manually. For aesthetic reasons, it is available in the most popular colors - white, gray, black and chrome.

Some models of valves can be used as openings for cleaning sewer drains. To do this, remove the decorative cover, take out the internal mechanism of the fan valve and put a cable inside.

Scope of application

Sewers not equipped with a ventilation system. If it is not possible to equip the pipeline network with ventilation, valves are installed. Suitable for protection against odors from pipes of sinks, toilets, where a large pressure of water can cause imbalance in the pressure in the pipes and the suction of liquid from the water seal.

Long sections of the sewer line, located horizontally, and having many plumbing cutouts, are more often subjected to powerful water drainage. For example, toilets in public areas. In order not to disable the operation of the hydraulic seal, valves are mounted after several points with plumbing fixtures.

In the case when the pipes are located at a distance from the riser, the angle of inclination of the central pipe exceeds the value of the height of the hydraulic seal mechanism.

The air valve facilitates the installation work during the laying of the sewer network in your own homes, saving time and effort on equipping the ventilation system.

In multi-apartment buildings, aerators are used as additional equipment for the pipeline system to ensure optimal operation.

What the aerator consists of. The aerator device consists of:

- - from a plastic case with a hole on the side.

- - from the cover, easily removable if necessary.

- - from a stem or a rubber membrane.

- - from a gasket, which serves as a joint sealant, serves to ensure tightness and prevents the stem from shifting.

Installation

Let's figure out how a vacuum sewage system is mounted, that is, a system equipped with an aerator. Here are general guidelines for work:

- before starting work, you need to make sure that the valve does not leak. To do this, it recommends opening the water supply and filling the aerator with water. If the model does not miss a drop, then this is a quality option;

- the valve can be mounted on both vertical and horizontal pipes, but the aerator itself must always be installed vertically. If you put a part with a slope, then the device will cope much worse with the functions assigned to it;

- If it is not possible to correctly install the aerator on the pipe, then it is recommended to use fittings - elbows and tees;

- it is necessary to position the device so that it can be accessed for maintenance and repair;

- it is recommended to connect the aerator higher in the level of the highest point of the network;

- the installation of the device must be carried out above the highest drain point;

- it is not recommended to install the valve close to the floor. The smallest valve height must be at least 20 cm.