What are the pros and cons of electric welding?

Welded joints have the following advantages:

- connections of large sizes can be obtained;

- for welding, you can use a material that is similar to that of the pipe. Thanks to this, all the properties of the pipeline are preserved;

- thanks to the connecting seam, the external and internal dimensions of the structure remain unchanged;

- simple and cheap way.

The disadvantages of welded joints, as a rule, are due to the low qualifications of the employee. Due to non-observance of technology, rules, inexperience, welding may be incomplete. This means that cracks and displacements can form. Therefore, the welding of radiators must be carried out competently, carefully and carefully.

Selecting and calculating the power of the radiator

When replacing heating batteries, it is not necessary to choose the same ones; you should pay attention to modern options from steel, aluminum, copper, alloys (bimetallic). But before choosing radiators, it is necessary to clarify their size by performing simple calculations. If the ceiling height does not exceed 2.65 m, the number of sections is calculated by the area of the room. It is multiplied by 100 W (this is the building rate for 1 m²). The resulting value is divided by the amount of heat transfer from one section, indicated in the passport (standard 170 W), the result is rounded to an integer.

What is needed to carry out electric welding?

To weld pipes using electric welding, you need a welding machine. Today there are two types of such devices: devices made on the basis of a step-down transformer and inverters that operate at high frequencies. The first type is used extremely rarely, since it is considered morally obsolete. The inverter is a more modern device that is simple and portable. It is possible to adjust the welding mode with high precision. True, in use, inverters are considered less reliable. Therefore, to work with such equipment, you must have a certain qualification.

In addition, heating welding presupposes the presence of other auxiliary equipment:

- special mask with a light filter. It reliably protects eyes and face from sparks and molten metal particles during welding;

- overalls for body protection;

- suede gloves. With their help, the device in the hand will be securely held;

- electrodes;

- metal brush. It is necessary for cleaning the pipe section before welding, for descaling;

- a special hammer that is used to knock down scale.

Battery replacement process for welding

If it is planned to replace old radiators with batteries of a different type or change the number of sections, this must be agreed with the management company. You also need to provide documents confirming that the work will be performed by a qualified welder. Amateur performance is punished with a large fine.

Preparatory work

First of all, the adjacent furniture is removed from the welding site, the adjacent sections of the wall and floor are covered with non-combustible material. To shut off the heating and drain water in an apartment building, a specialist from the housing office is called. In private houses and autonomous heating systems, a drain valve is provided for such cases. Then, using a grinder, the old batteries are dismantled. Pipes suitable for the radiator must be cut evenly so that there is no difficulty in installing a new one.

Assembling a new heating system

The assembly and installation of a new radiator can be done independently without calling the wizard. To do this, you need to stock up on:

- a set of nuts (for the battery);

- two ball valves;

- Mayevsky crane;

- investment paste;

- flax sealant or fum tape.

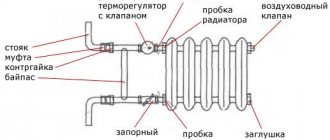

Before tightening, the nuts are processed with paste, and a seal is wound in the places of threaded connections. Ball valves are installed on the supply and return pipes. They are necessary to disconnect the radiator from the heating system in emergency situations. On the other side of the battery, a Mayevsky crane is screwed in at the top. Air locks, which are often formed in central heating systems, will descend through it.

Ball valves are installed without fail to turn off the radiator in emergency situations

Gas welding

The complete battery is put in place by hanging it on special mounts. To prevent air from accumulating inside, the installation of heating radiators is carried out according to the building level. Dirt is removed from the ends of the elements to be connected and degreased. The supply and return pipes are connected to the radiator at a slope to prevent air pockets from forming. So that the circulation of the coolant is not disturbed when the taps are closed, a jumper is welded on the radiator between the supply and return from a pipe of slightly smaller diameter.

How to choose the right electrode?

Before starting welding, you need to select an electrode. It should be noted that the electrodes for welding heating pipes may be different. They differ in the thickness of the core, the amount of coating and the method of production. Rod thickness for pipes - 2-5 mm. And the coating can be 3-20% of the total mass.

Depending on the material of manufacture, the electrode can be consumable and non-consumable.

Melting ones are made from welding wire, non-consumable ones - graphite, tungsten and electrical coal.

Advantages and disadvantages of welding

The popularity of gas welding is explained by the specifics of the functioning of heating systems. In addition to constant pressure, its surges and water hammer are possible during filling of the system. Since the gas-welded seam exceeds the strength of the base metal, such joints do not fail under extreme loads. The advantages also include:

- Long service life.

- The ability to connect parts of different shapes and sizes, if the wall thickness does not exceed 3.5 mm. It is more economical to weld thicker metal by electric welding.

- Gas welding does not require electricity, which is important for new buildings.

- A reliable connection of pipes made of cast iron, copper, brass is done only by gas welding.

The main disadvantage is that when replacing batteries during welding, the surrounding space heats up. This could cause a fire if flammable items are not removed beforehand. Decorations and heavy furniture are covered with heat-resistant material. When working with gas welding, harmful substances are emitted, therefore personal protective equipment is required.

Connection diagrams for heating radiators in apartments of multi-storey buildings.

Heating radiators Rifar Base

The RIFAR Base model is one of the most powerful bimetallic radiators, which makes it a priority when choosing radiators for heating large and poorly insulated rooms. The RIFAR radiator section consists of a steel pipe cast under high pressure with an aluminum alloy with high strength and excellent casting properties. The resulting monolithic thin finned product provides efficient heat dissipation with maximum safety margin. It is produced serially from 4 to 14 sections, color according to the RAL 9016 catalog. Confirming the high design characteristics of its radiators and strict quality control, it gives a guarantee for its products for a period of 10 years and at the same time guarantees its uninterrupted operation for 25 years from the moment of installation at compliance with the rules of transportation, installation and operation.All products manufactured are certified by the sanitary and heating equipment certification body "SANROS" and insured by OJSC "INGOSSTRAKH".

Heating radiators Rifar Monolit

The bimetallic radiator MONOLIT is a fundamentally new, patented heating device with especially high technical characteristics that meet the most severe operating conditions. Externally similar to conventional bimetallic and aluminum sectional radiators, the MONOLIT radiator differs from them in that inside it the coolant moves through steel channels connected using a unique welding technology into a single non-separable structure. Thanks to this, in the MONOLIT radiator, in principle, there are no areas potentially dangerous for the occurrence of leaks. MONOLIT radiators have exceptional reliability, as well as high heat transfer, which is achieved due to the developed geometry of the heat transfer surfaces made of aluminum alloy. The design and manufacturing technology of the MONOLIT bimetallic heating radiator provide: - Durability of operation - Manufacturer's warranty - 25 years. - Efficiency of maintaining a comfortable temperature regime. - High resistance to corrosion - The channels through which the coolant flows are made of steel with increased corrosion resistance, and their thickness corresponds to that of conventional steel water pipes. - Lack of intersection joints. - Indifference to the type of heat carrier and the quality of its preparation in individual and collective heating systems - Possibility of using various non-freezing liquids as a heat carrier. - Possibility of using the radiator at high temperature of the coolant up to 135 ° C. - High structural strength - Working pressure of the heat carrier - up to 100 atm, test pressure - 150 atm; - Possibility of use in premises for various purposes, including in medical institutions, in kindergartens, etc. due to the best ratio of the radiation and convective components of the heat flux. - Ease of installation - No need to install adapters with left and right threads. Standard threaded connections G1 / 2 "or G3 / 4" are an integral part of the radiator design.It is produced serially from 4 to 14 sections, color according to the RAL 9016 catalog.

Heating radiators Rifar Supremo

Heating radiators

RIFAR SUPReMOIs an innovative development of technology and the last word in the development of equipment for space heating. The basis of efficiency ismonolithic construction, which practically retains all the positive nuances of the previous RIFAR technology, but at the same time new positive changes were introduced into the design. The heater has a monolithic construction,two-pipe vertical ductand unique ergonomiccrash-proof design... Its design, in principle, even excludes the likelihood of leaks, allowing you to connect a radiator in all possible schemes. The radiator sections are connected using the latest flash-butt welding technology. The device has high performance in terms of breaking and working pressure, corrosion resistance.The rated power of each section for the Rifar Supremo 500 is 202 W.Water, oil or antifreeze can be used as a heat carrier.Multilayer painting of the radiator using anaphoresis primer guarantees high quality painting and durability of the decorative and protective coating. Warranty 25 years. Serially produced from 4 to 14 sections, color according to the RAL 9016 catalog.

We work officially under a contract. We provide all the necessary documents to coordinate the shutdown of heating risers.

Stages of work on replacing heating batteries

Each model range of radiators has advantages and disadvantages, depending on the place of installation and operating conditions.

Change batteries in stages:

- Preparatory activities... Before replacing gas-welding batteries, you need to prepare the room, namely, insulate pieces of furniture, cover the floor and walls, protecting them from damage. Liquid is drained from the system. Using the grinder, they dismantle the devices that have become unusable.

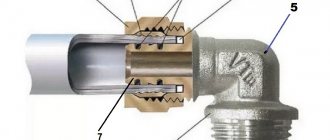

- Assembling a new radiator... At the joints, the nuts are sealed with flax, coated with investment paste and carefully tightened. A crane is placed on top, designed to discharge air, and on the side of the docking with the pipe, a crane is installed - an American with a squeegee.

- Installing a new radiator... It is placed on special brackets, after which all connections with pipes are adjusted - they are welded and then cleaned. You need to know that gas welding is performed with pipes whose diameter does not exceed 100 millimeters.

- The final stage... After the replacement of gas-welded heating radiators has been completed, the heat supply system should be checked for the strength of the connections and their tightness.

The use of gas welding, in comparison with the threaded method, is a more expensive and time-consuming process with drawbacks. But the advantage of this installation method is its durability and reliability.

Features of gas welding technology

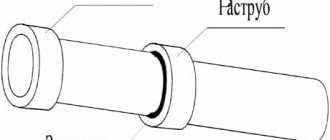

The fastening of heating pipes by gas welding is carried out according to the following principle: the end parts of the two elements are combined, and then gradually heated in the tribe of the gas-oxygen mixture to high temperatures.

It is best to replace radiators in the warm season, since during the cold season you will have to turn off the common house heating for at least a few hours, which is unlikely to please the neighbors

For extra strength of the seam, a filler material in the form of a wire or a rod is used. When the hot metal cools down, a monolithic joint is formed.

Advantages and disadvantages of welding pipes

One of the main reasons for the popularity of the gas welding method is the specificity of the operation of our heating systems.

During the circulation of the coolant, all structural elements are constantly under pressure, which deforms the joints. Therefore, a durable weld seam reliably protects against breakouts and helps prevent accidents during short pressure surges and even water hammering, which often accompany the start-up and shutdown of centralized heating.

If the gas welding is done with high quality, the pipes will have a smooth surface without abrupt transitions and visible sagging, and the black burn marks from the flame perfectly mask the paint

Advantages of the gas welding method:

- Durability and reliability of the connection (it is believed that the strength of the seams after gas welding even exceeds the strength of the radiators themselves!).

- The ability to use parts of any shape and size. The only requirement is that the elements are made of metal with a thickness of no more than 3.5 mm (in case of excess, it is more economical to use electric arc welding).

- An aesthetic moment - pipes and batteries welded by gas welding become a solid monolith, which can be easily repainted in a color suitable for the interior.

- It is possible to carry out work without connecting to the mains (especially important for new buildings).

- Many of the metals from which pipes are made, such as copper, cast iron, brass and lead, form the strongest joints with gas welding.

The main disadvantage of this installation method is the large heating area, as a result of which it is easy to damage furniture and flammable finishing materials, for example, parquet, wallpaper, wall panels made of plastic, laminated chipboard or MDF.To avoid destruction, it is recommended to remove thermally unstable elements from the working area, and to cover non-mobile ones with asbestos cloth or other protective material.

If the batteries are replaced by gas welding after finishing finishing work, be sure to use insulating gaskets between the wall and the pipes.

In addition, during gas welding, substances that are harmful to health enter the air - it is strictly forbidden to work without special protective equipment. That is why everyone who wants to master the gas welding machine in practice must study the safety rules and get a permit to work.

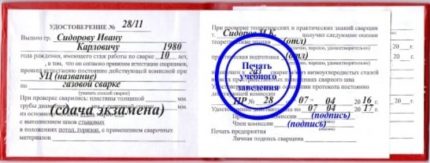

Who can work with a gas welding machine

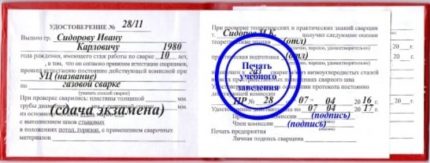

Installation of the heating system using gas welding is allowed only to professional welders who, in addition to special education, have permission to carry out work from the fire service. Please note that the document is issued only for a certain period, so when hiring a master, you should not just look at the "crust", but also study its validity period

Other mandatory requirements for welders: serviceability of the gas apparatus and mandatory protective equipment - glasses, work gloves, a shield.

It is advisable that the foreman use filler wire for seams and modern equipment working on a mixture of oxygen and acetylene. Other flammable gases, such as methane or propane, are acceptable provided their combustion temperature is twice the melting point of the filler rod.

The certificate of such a sample confirms that the specialist has the appropriate qualifications and has passed safety training. A prerequisite for authenticity is the seal

If you are not a professional gas welder, you can contact the local heating network or the organization managing the house to carry out the work. To do this, the owner of the apartment draws up a statement on the need to replace the batteries and agrees on a date to block the movement of the coolant in the common building highway.

After welding and installation of radiators, the invited foreman must carry out commissioning and make sure that the system is in good working order. It is strictly forbidden to stop and start heating in apartment buildings on your own.

Conclusions and useful video on the topic

And finally, we suggest that you study our selection of videos for a visual representation of the specifics of the upcoming work and important nuances that you should know when replacing batteries.

Tips from a professional - when you need a replacement, which radiators to choose and what to look for when installing new batteries:

In this video, you can visually study the process of welding a bypass by gas welding using filler wire:

And in conclusion, an example of a professional installation of heating pipes and batteries using gas welding and a pipe bender:

Replacing radiators using gas welding is a reliable way to protect your home from possible leaks in the heating system and the consequences of water hammer. But in order for the work to be done with high quality, it is important to entrust it to a specialist with good experience and modern equipment, because an incorrectly or inaccurately welded seam can lead to an accident in the coming heating season.

Gas welding. Replacement of batteries, heating radiators, pipes.

So, replacing heating radiators with gas welding involves the direct use of gas welding for joints. This is a process that has the following principle: the edges of the metal parts of the heating system to be joined are heated with special equipment. As a result, a hot metal is formed between them. When it cools down, a strong, inseparable connection of the parts welded together is created.

Typically, gas welding devices will work as follows:

- Preparation of parts for welding.

- Welding works - using different types of welding seam: ceiling, horizontal, vertical.

- If necessary, then the superimposed cooled seam is boiled in supposedly weak places, cracks on the parts are welded.

- The seams are cleaned.

Currently, replacing heating batteries in welding is a common method. And any professional will be able to explain why this is so - after all, the nuances that are used in the systems of multi-apartment domestic buildings matter here. Their use is due to the use of a coolant that is in a state of high pressure.

Equipment for gas welding

The fact that the heating system is constantly under pressure on each element, as well as the possibility of water hammer, can have a somewhat detrimental effect on other types of connections. If an accident suddenly happens, then replacing the heating battery in another way will be more costly - in addition, you will also have to pay for the repair of neighbors if it comes to an apartment building.

However, it is still impossible to underestimate the reliability of such a structure and its durability. After all, the strength of the seam after welding will be even greater than the strength of the batteries themselves! Therefore, it cannot be such that a breakthrough in the system is formed at the seam site. In addition, replacing heating radiators with welding is also aesthetically beautiful. That is why such a method as gas welding is the most effective.

Regardless of how much it costs to replace a heating radiator with gas welding, this method will have several significant advantages over the threaded method:

- The joints have a more aesthetic appearance - there will be no nuts, fittings and other connecting structures.

- The strength of the connection is incredible - so the tightness of the system will not be compromised even if the nominal pressure rises.

- There are no different seals that are used for threaded connections. Therefore, there will be no breakthroughs due to the fact that these components will wear out at the most inopportune moment.

- Welded joints can be used in circuits that have high pressure - in this case, threaded joints will simply not withstand the pressure.

Welded pipes look aesthetically pleasing

I would like to highlight the following features of these works:

- When making threaded connections, fittings, nuts and other bulky structures are used that do not look very aesthetically pleasing. Carefully welded seams become invisible after painting.

- The strength of the welded joint is high, which eliminates the likelihood of a leakage of the system.

- The welded fastener is indispensable in high-pressure heating circuits, since the threaded connection simply cannot withstand the load.

- The absence of seals, which are a mandatory element of the threaded connection, eliminates the likelihood of pipeline rupture due to wear.

- The final cost of work, including the purchase of materials necessary for replacing the batteries, when using gas welding will be lower than with a threaded connection method.

Gas welding is inferior to the threaded fastening method in terms of the time of dismantling and installation work. Considering all the pros and cons, it can be concluded that the threaded mount when replacing batteries is most suitable for private homes.

Due to all the advantages of welding, many consumers prefer this option when replacing batteries. Welding heating batteries has the following advantages:

- Neat appearance, after painting the weld seam remains practically invisible.

- A high degree of reliability, provided that the welding work is performed by a specialist, the seam is characterized by high strength and durability.It is important to note that the weld can provide the system with much greater reliability than any other modern connection, such as a fitting.

Read more: Retractable worktop sockets how and where to install

The specialists working in our company are able, thanks to the availability of modern welding equipment, to carry out the installation of batteries as soon as possible.

The appearance of new proposals on the heating equipment market prompts the population to think about replacing old batteries with new heating radiators.

In order to perform a replacement, it is important to correctly determine how the installation of heating radiators will be performed. There are many options with which the job can be done, but the most effective is to use gas welding.

This is due to the fact that replacing batteries with gas welding has many advantages, such as:

- Increased reliability. Provided that the work is done, there will be a highly qualified craftsman, the resulting seam will be distinguished by reliability, thanks to which it will be able to ideally serve for many years. In addition, the weld seam will not require additional attention to itself, as is observed when performing installation using assembled joints. This is due to the fact that the junction does not have an additional seal, which, as a rule, is fragile in operation.

- Neat appearance. After the welding work is completely finished, the seam remains practically invisible, so that it does not spoil the external design of the room and can remain in an open place.

Only an experienced master should be trusted to install heating radiators, since the efficiency and economy of the heating system will depend on the quality of the work performed. The craftsmen of our company are able to perform the installation of radiators using gas welding efficiently and accurately.

| 1 | Departure for replacement | PC | is free |

| 2 | Consultation and estimate | PC | is free |

| 3 | Purchase and delivery of material | PC | is free |

| 4 | Replacement of batteries by gas welding from 20 pcs. | PC | 2500 |

| 5 | Replacement of batteries by gas welding from 10 pcs. | PC | 3000 |

| 6 | Replacement of gas welding batteries from 4 pcs | PC | 3500 |

| 7 | Replacement of gas welding batteries from 2pcs | PC | 4000 |

| 5 | Replacing one battery with gas welding | PC | 5000 |

Welding is a special process in which molten metal is poured between the edges of parts heated to a certain temperature. It is important to note that the edges are heated to the temperature required by the technology and characteristics of the material itself.

Gas welding works are carried out to weld metal parts of various shapes, in addition, welding is used to eliminate defects from a metal surface, regardless of its shape and size.

Gas welding work on replacing batteries consists of:

- preparatory part;

- welding (seam application);

- elimination of cracks and cavities from the surface of a metal part;

- smoothing seams (if necessary).

Only specially trained specialists are allowed to perform gas welding works, since only they are able to weld metal surfaces to each other as correctly and efficiently as possible.

As already noted, using gas welding, you can install heating radiators as efficiently and reliably as possible. The main explanation for this is that the metal edges of the pipe and radiator are connected by molten metal, which is formed as a result of the melting of the filler wire. With the help of gas welding, it is easy and most importantly quick to connect steel pipes with a radiator, the outer diameter of which does not exceed 100 millimeters.

Gas welding of heating system elements in a house, apartment, commercial or industrial facility is a process in which the edges of metal parts are joined at high temperatures using special equipment.

Advantages of gas welding when replacing heating:

- pipes and heating devices of different sizes and shapes can be welded;

- a high-quality welded seam surpasses the parts to be joined in strength;

- such connections withstand high pressure and water hammer well;

- subject to the technology, there is no probability of a breakthrough along the seam and depressurization;

- the melting rate is regulated simply by changing the angle of inclination of the flame;

- the seams made are almost invisible (unlike threaded connections);

- all types of radiators are available for welding: steel, aluminum, cast iron, bimetallic;

- gas welding of heating is possible in the absence of electricity (relevant when installing batteries in an apartment in a new building);

- there is no need for a seal, which wear is the most common cause of leaks.

Despite the fact that welding work requires more effort and time, it is thanks to them that the maximum reliability and durability of the installed heating equipment is achieved. For apartment buildings and high pressure circuits, according to many experts, welding is the only possible option for connecting to a common system.

To install and replace radiators with gas welding, you will need special equipment:

- oxygen balloon;

- acetylene cylinder;

- gas reducer;

- burner device.

A mixture of oxygen and acetylene is used as a solder. To increase the strength of the seam, a filler wire is recommended, which allows you to obtain a monolithic connection after cooling.

Replacing gas welding batteries involves performing several sequential stages:

- Turning off the supply and draining the coolant (performed by a representative of the management company).

- Dismantling of old batteries and, if necessary, pipes (they are cut as smoothly as possible with a grinder).

- Assembling (packing) a new battery, cleaning and degreasing the surfaces to be joined.

- Installing the radiator on the mounting place (hinge on the brackets).

- Installation of taps, valves, air vents (Mayevsky crane).

- welding of heating pipes and radiators (connection to the system).

- Checking the quality of the seams and cleaning their surface.

- Heating agent supply and leak test (pressure test).

| Replace (install) the radiator, heating battery, pipes for welding (gas welding). Call. |

| Welding works in apartments .. |

| Replace (install) pipes, a heating radiator, a heating battery for gas welding (welding, welding). Call 8 (926) 439-37-51. |

| Correct gas welding.

|

| Replacement and transfer of pipes for cold, hot water supply and heating. - I will qualitatively perform welding work. - Competently, professionally beautiful .. |

| Gas welding is better than other types (options) when replacing a heating radiator in an apartment. Gas welded seams are more aesthetically pleasing than other joint structures such as nuts, fittings, etc. Also, the places connected by gas welding are very reliable and durable, the tightness in them is not broken, and there are no leaks. With other types of connections, leakage can occur due to overpressure. Connecting structures with threads can simply wear out, and as a result, there will be a breakthrough. This does not apply to gas welding seams. And also for gas welding, no thread seals are required. |

| Action plan for replacing heating batteries in an apartment Main steps: Choosing a new radiator (type, number of sections, place of purchase, delivery, turnkey offer) You call: 8 (926) 439-37-51.we agree with you the time and cost of work, if We need to meet. To replace the batteries, regardless of the season, it is necessary to drain the water from the heating pipes.To do this, you need to contact the management company (ZhEK, HOA, ZhSK, etc.) or negotiate directly with a plumber. The service for disconnecting risers is paid. The average price in the city is 1000 rubles. You can find all the phones on information boards on the ground floor of your house or in receipts for payment of utilities (from a conservator, janitors or grandmothers in the yard). We will come to you at the appointed time. At the same time, a plumber comes to your house and drains the water from the central heating risers. Let's get to work. For the duration of welding work, please do not replace windows, doors and wall chipping on this day. After the end of the work, the plumber turns on the riser. All joints and welding joints are thoroughly checked for tightness. Filling in documents and payment. |

Read more: Boxes for radiators - Sewerage

| Welding in Moscow. Replacement of pipes in apartments with gas welding. 8 (926) 439-37-51. |

Output

In order not to endanger yourself and your neighbors from below, experts recommend giving preference to the gas-welding assembly, despite its high cost. Indeed, for the production of these works, highly qualified specialists are required - welders of the 5-6th grade. Also, strict adherence to safety precautions is necessary: during welding, the scale scatters in all directions and can get on flammable objects.

The threaded connection is quite suitable for the installation of heating systems in the private sector and country cottages, if it is planned to replace some elements with others in the future. Practice shows that it is much more effective to use a quick-disconnect connection - "American" for twisting.

According to Nicra.

Technology and main stages of work

In order to disassemble and remove heating batteries in a multi-storey building, which is on the balance sheet of the housing office in Moscow, before starting, you will need to obtain an appropriate permit for gas welding. Responsible employees of the housing office to check the types of planned operations, personnel approvals and the suitability of welding equipment. After a positive decision of the regulatory authorities, specialists carry out a set of preparatory work.

Workplace preparation

Initially, you need to minimize the potential threats from the operation of the gas welding unit. Furniture close to the work site will need to be moved or covered from potential fire. They also protect flooring and walls opposite the radiator.

After that, the coolant is drained from the heating network. In the event that work is carried out at objects with autonomous heating, the water is drained using a drain valve and an air vent, which must be opened together.

Workplace preparation

In an apartment building, it is not allowed to unauthorizedly close the risers and drain the mains water from them - it is necessary to invite an employee from the operating organization. Then it is necessary to disconnect the defective or old battery. This is easier to do with a sander. This will require a professional to make an even cut.

Assembling the structure

Then the new battery is packaged. If there is a desire to save your funds on the services of hired specialists, then such work from beginning to end is not difficult to perform independently.

Required building materials and accessories:

- A set of passages, blind plugs and nuts for the battery.

- Ball valve with American.

- Mayevsky's tap.

- Adjustable wrenches.

- Investment paste.

- Fumlenta or plumbing tow.

In order to assemble the radiator structure, it is necessary to install plugs, passages, a seal according to the scheme, treat the joints with paste and screw them onto the pipelines at the joints. The assembly of the heater ends with the installation of fittings.An "American" is installed from the edge of the connection with the heating pipe, with the goal of making a unit for adjusting the supply of network water to the heating device. Above, from the opposite edge, a Mayevsky faucet is placed to collect air from the water circuit.

Gas welding connection

The finished radiator is installed in the old place using specialized fasteners, and the straightness is controlled by the mounting level. Before welding, it is necessary to thoroughly clean the end surfaces of the bonded parts from dust and dirt, followed by degreasing.

After that, the incoming and outgoing pipes are welded with a verified slope, which should help prevent the occurrence of air accumulations. For the specified action, the mounting section is heated with a burner, while simultaneously applying the filler wire filling the openings between the connected parts of the system.

The type of weld and high-speed heating mode is selected by a specialist, based on the thickness of the walls, the material of the tubes used and other professional moments.

Cleaning and finishing works

After completing the work of the welder, the pipes look unattractive: dark tan marks and smudges will not adorn the interior decoration. This needs to be corrected.

In order to improve the welding surface, you will need to perform the following operations:

- Sand the pipe with # 3 or # 4 weevil sandpaper. With the careless work of the welder at the installation site, an influx of metal is formed, which some locksmiths try to straighten with the use of a grinder. However, this does not need to be done, since it is possible to violate the integrity of the seam.

- Wash the tube with a damp cloth, then dry.

- Treat the surface of the weld seam with mineral spirits for degreasing.

- Paint twice with an anti-corrosive primer.

- Paint with heat-resistant enamel also until the black streaks are covered.

- Painting operations must be carried out before turning on the heating system. If the work was carried out with the current heating system, the battery is disconnected from the heat and wait until it has completely cooled down.

- It is possible to refine only the tubes or absolutely the entire installation complete with a heating device.

- The color, as a rule, is selected from snow-white, dull-silver, copper-bronze, or directly to the color of the wall.

- For some interior styles, it is possible to apply a contrasting color, in particular, dark chocolate, especially glossy black or brilliant scarlet.

- It is allowed to open the heating system and fill it with water after the final drying of the paintwork.

Cleaning and finishing works

Learn more about the differences

Replacing batteries with gas welding differs from the threaded method in several factors. So, in addition to the already mentioned aesthetics and the absence of massive nuts and fittings, gas welding allows you to create very strong connections.

So, in the threaded method, more than 12 seams are created, and in the gas welding method, as a rule, no more than 5. This protects the batteries from a breakthrough in the heating system during pressure surges. The absence of seals also contributes to the durability of the structure.

The welding connection is indispensable, since this is the only way to replace batteries in systems with high pressure: the thread in such cases simply does not withstand the load and the pipes break through.