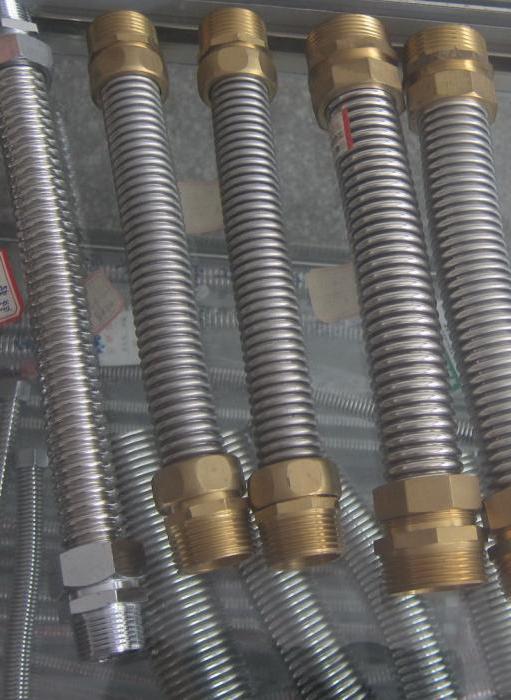

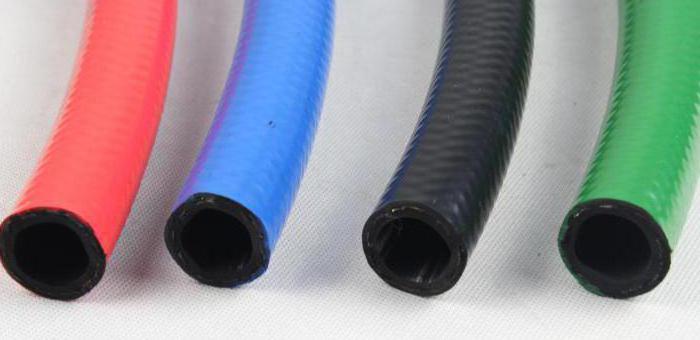

Varieties of gas hoses

If we consider gas hoses, then they should be divided into three types, which differ from each other in the material of manufacture. Thus, bellows liners can be found on sale; rubber sleeves, which are supplied with a metal braid; as well as rubber-fabric elements. Flexible liner based on rubber-fabric sleeves is the softest, this quality can be called negative, since the mechanical rigidity is at a minimum. The advantage is that rubber products are not capable of conducting electrical current. More common today among consumers are hoses with a metal braid. The reason for this popularity is the low cost. Such a gas hose differs from the liners intended for water in that a yellow stripe can be found on its surface. Flexible bellows-type hose is characterized by the maximum rigidity and reliability among other types of hoses. You will have to pay the highest cost for such a product; the regulatory documentation recommends the installation of products of this type. This is due to the fact that such a material perfectly copes with the high pressure created by the gas flow.

Installation rules

Before proceeding with the installation of the flexible gas pipe, it is necessary to shut off the gas pipeline. If we are talking about installing new gas equipment, then you must first dismantle the old device, if necessary. At the next stage, the gas hose is installed, the master must check the tightness of the existing connections, which will help eliminate the possibility of gas leakage. The new device is installed on the surface according to the level, and then a functional check is carried out.

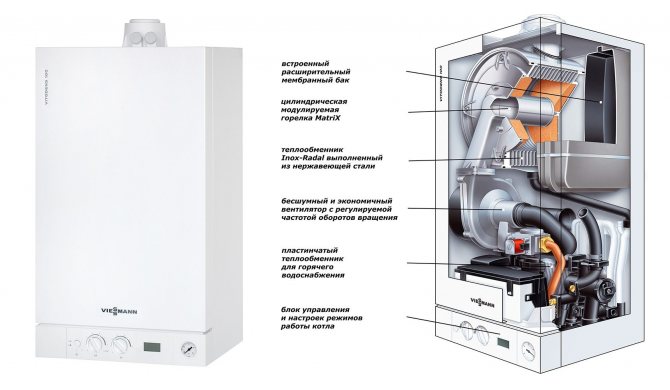

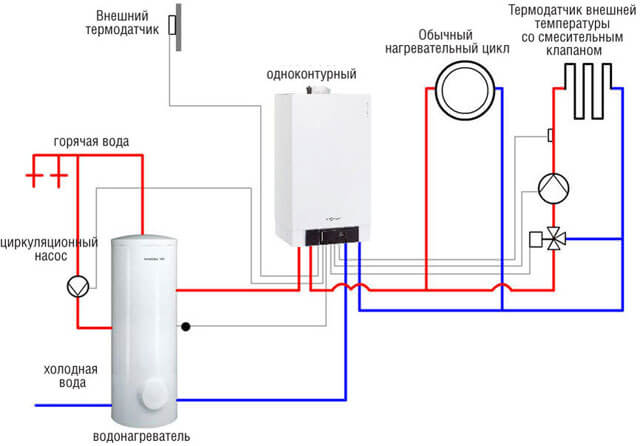

The principle of operation of gas boilers

The main purpose of the gas boilers shown in the photo is space heating. The principle of operation of a gas boiler is as follows: after evaluating the temperature of the coolant in the system, the sensors start the burner. After passing through the heat exchanger, the water is heated to the desired temperature, and then the circulation pump directs the liquid directly into the heat supply line. Having passed through all the elements of the heating system, the cold coolant returns to the boiler.

Knowledge of the principle of operation of a gas heating unit helps to install it.

The main stages of connecting the boiler are as follows:

- It is necessary to consider the method by which the combustion products will be removed from the room where the device is planned to be installed. Almost always, the manufacturer, together with the heating unit, supplies a "chimney package".

- When the installation site has been selected, start work. Wall-mounted models are fixed to the wall using the strips supplied with the boiler. Fasteners are placed at a distance of 80 centimeters from the floor covering. The unit is mounted strictly horizontally. The presence of distortions leads to equipment breakdown or to its poor-quality operation.

- Now you need to connect the gas boiler to the gas pipeline. The plugs should be removed, a strainer and ball valves installed.

- Carry out the wiring of heating circuits and hot water supply.

- They make an electrical connection to the gas boiler, while it is desirable that the outlet is located near the device.

- Connection to the gas main is carried out only in the presence of specialists from the relevant service.

If the connection diagram of a single-circuit gas boiler is easy to implement, then the project for piping a double-circuit unit requires a number of measures to ensure safety:

- the device must be securely fixed to the wall;

- the system intended for the removal of exhaust gases must, in terms of technical parameters, correspond to the power of the heating boiler;

- it is necessary to comply with the technological requirements for the distance around the operated equipment;

- only specially prepared water should be used as a heat carrier, which will not contribute to corrosive processes in the system;

- Provide a valve under the boiler to shut off the gas supply.

In conclusion, it should be noted that only a high-quality installation of gas equipment can guarantee safety for residents of a house or apartment.

An example of a gas boiler connection diagram in the video:

Installation recommendations

When a flexible gas line is installed, it is important to follow some rules, one of them provides for the installation of equipment at a distance of 4 meters or less from a rigid gas pipeline. There must be a dielectric insert between the flexible hose and the gas cock. For flexible piping of household gas equipment, all three types of hoses can be used, which are also called sleeves. Rubber fabrics provide the highest degree of safety for gas equipment. A positive electrical potential is supplied to the pipe through which gas will flow to the residential building. This is necessary so that the pipe in the soil does not corrode. At the entrance to the dwelling, the pipe has a dielectric insert, and the risers are not at potential.

What to do first

Installation of a gas boiler, its connection and start-up - all this together constitutes a whole complex of difficult measures (read: "How to start a gas boiler for the first time"). First of all, the issue with the placement of the heat unit should be resolved. The location of the heating device is influenced by its type.

Floor-standing models of gas boilers are installed in separate, specially prepared rooms. The main reason for this requirement is to ensure safety for people living in a house or apartment (read: "Floor standing gas heating boilers: which one is better"). Wall-mounted appliances are usually installed in the kitchen or bathroom.

Specialist recommendations

When a flexible gas hose is installed, one cannot ignore the likelihood that a current will flow through the bellows or metal braid, which is located at the base of the rubber sleeve. This can be dangerous for the sleeve that is braided. The cross section of the wire is very small, which indicates that the current density will be high. In this case, you need to be afraid that the braid of the hose will heat up like a spiral of an electric stove. When installing a flexible mixer hose, it is recommended to use a real dielectric insert. Most often it is made of plastic or has a metal thread at both ends. Experts advise purchasing a bellows metal hose with yellow dielectric insulation, which is applied over the metal. It is best for the consumer to give up the bare sleeve. Manufacturers apply the coating for aesthetic reasons to make the surface of the hose easier to clean. However, due to the electrical characteristics of this coating, it prevents the occurrence of current in the sleeve if it touches the riser.

Nuances of installation work

It is worth remembering that a flexible gas line must be installed only by specialists.It is necessary to exclude the kink of the hose, but if such a need arises, then it is necessary to ensure that the radius does not reach the minimum level established by the documentation. Before the nuts are connected to the consumer, the wiring must be configured as required. The wiring must not bend in an area that is closer than 7 centimeters from the union nut. This is true if it is connected to a gas appliance. Under no circumstances should the flexible reinforced liner be stretched; twisting of the hose should be avoided. If there is a need to use union nuts, then they should be operated exclusively with flat gaskets. In order to exclude the possibility of breakage of the gaskets, do not overtighten the nuts. If damage has been noticed, then the entire replacement should be carried out.

Features of connecting a gas boiler to a gas pipeline

As already mentioned, information on how the gas boiler connection diagram looks like can be found in the instructions attached to the equipment. One of the important elements for connecting the unit are ball valves, the main purpose of which is to disconnect the lines during repairs (read also: "Connecting the boiler to the heating system - we do it right").

Another detail present in each gas appliance connection diagram is a water filter for metal pipes. When using plastic lines, a filter for the heating system is placed in front of the water meter.

When using a typical piping scheme for a gas heating boiler, the filter is mounted on the return flow of the heating system. This makes it possible to prevent contamination of the unit by foreign objects entering it.

After installing the filters, as provided by the diagram for connecting heating to a gas boiler, they begin to install special taps, which will be required for preventive flushing of the heating structure and dismantling the system. When the connection diagram of a double-circuit gas boiler does not contain horizontal sections, then the installation is carried out in a vertical position.

Drives are considered to be another important component of heat supply systems. They are used, if necessary, to urgently disconnect the boiler from the pipes. The magnetic filter prevents limescale build-up in the heat exchanger. After its installation, many breakdowns will be avoided in the future.

Unfortunately, the quality of natural fuel is low, therefore, to clean the gas from scale, dust and other impurities, a gas filter is installed directly behind the gas cock. This element is necessary, otherwise the service life of the equipment will be significantly reduced. Also, the norms for connecting a gas boiler provide for the presence of flexible corrugated hoses

In order for the heating unit to serve as long as possible, the connection of the gas boiler to the power grid, gas pipeline and heating structure must be performed correctly, based on recommendations from the manufacturer and professionals. If you are not confident in your own capabilities, it is better to turn to specialists.

What else you need to know about bellows liner

A flexible hose for a mixer today can be purchased at a store of relevant goods, this also applies to a bellows hose, which, although it is expensive, has found its distribution among consumers. This product is a corrugated stainless steel hose. At the ends there are stainless steel fittings. Such piping should be fixed to the gas inlet pipe or equipment using flare nuts. Be sure to use metal gaskets, which should be soft, this should include aluminum or copper.Special plastic can also be used as a material for the gasket.

Such a flexible stainless steel hose can have a corrugation and fittings made of different materials. However, experts recommend purchasing products that are completely made from the same base. This requirement is due to the fact that welding of different metals can cause an electrochemical reaction, which contributes to the destruction of the weld. Such a connection cannot be called strong in any way.

Conclusions and useful video on the topic

A few useful tips for installing a gas boiler will help you control the correct installation of the equipment.

With all the perfection of gas equipment, with the presence of automation and serious technological protection, the connection of the system requires compliance with the established rules and regulations. Without this, it is impossible to guarantee the reliability of the gas boilers.

Do you have something to add, or have questions about connecting a double-circuit gas boiler? You can leave comments on the publication and participate in discussions of the presented material. The feedback block is below.