The heating equipment market today offers an impressive list of special devices for organizing a heating system.

A solid fuel boiler is a practical solution in a situation where it is not possible to connect gas or carry out central heating. Wood-fired heating boilers are considered a traditional option and are very popular with buyers. They are installed in residential private houses and cottages, as well as in buildings for other purposes - garages, technical rooms, etc.

Various equipment has certain operating features that should be taken into account at the purchase stage. The main characteristics that determine the choice are the principle of operation, as well as the type of fuel used.

More details:

- Fuel types

- Advantages and disadvantages of using wood-fired boilers

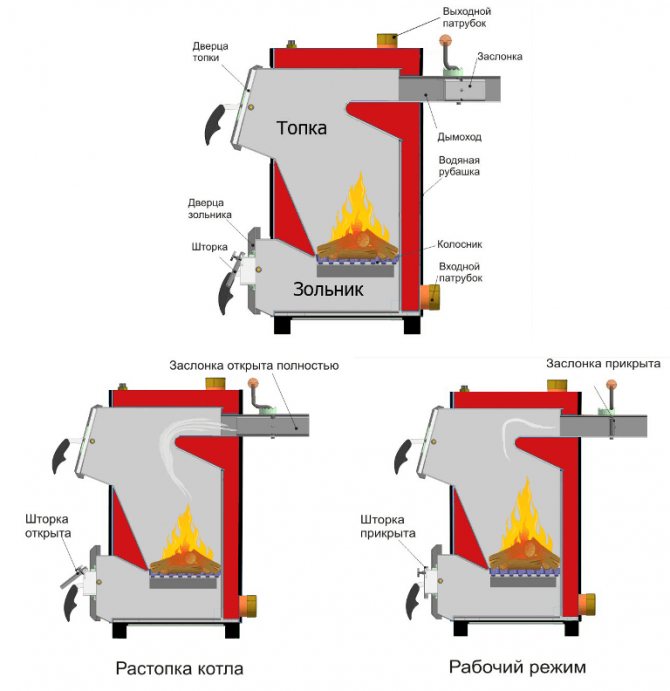

- The principle of operation of a solid fuel boiler Pyrolysis boiler

Preparation for operation

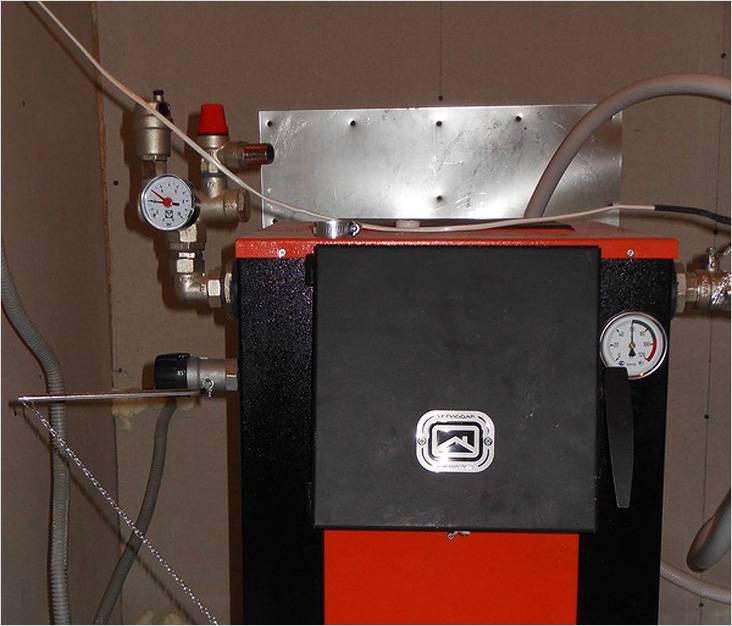

Solid fuel boiler (TTK) is a type of heating equipment that runs on wood, coal or pellets, providing room heating. Regardless of the model chosen and the principles of its operation, there are certain installation rules necessary for compliance.

How to protect the premises and where is it better to put

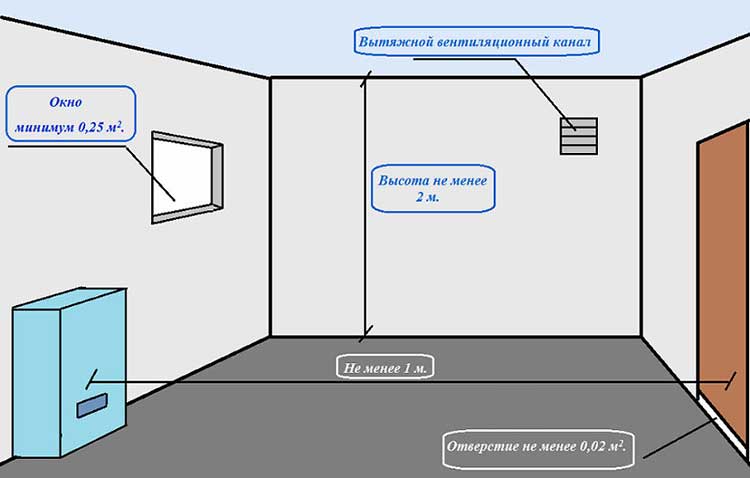

To date, there are no specific requirements for the placement of a structure in a private or apartment building. Some experts recommend that during installation, take into account the rules set forth in SNiP in the section "Boiler Installations". However, the information in the document is more likely to refer to powerful units.

It is highly recommended to consider the following requirements when choosing a location:

- all pipes of the heating system should freely exit from the selected room and be distributed throughout the house or apartment;

- the room should be well ventilated and isolated;

- it is forbidden to install models in bedrooms, especially in children's bedrooms;

- installation in the corridor, kitchen is allowed;

- the device must be freely accessible from any side;

- the ideal option is the construction of a separate extension from foam blocks;

- it is allowed to install boilers in an outbuilding or in a separate boiler room;

- the structure is mounted closer to the outer wall;

- there must be at least 100 cm of free space in front of the unit, at least 60 cm at the back and sides.

If the recommendations are followed, the operation of the device becomes easier and safer.

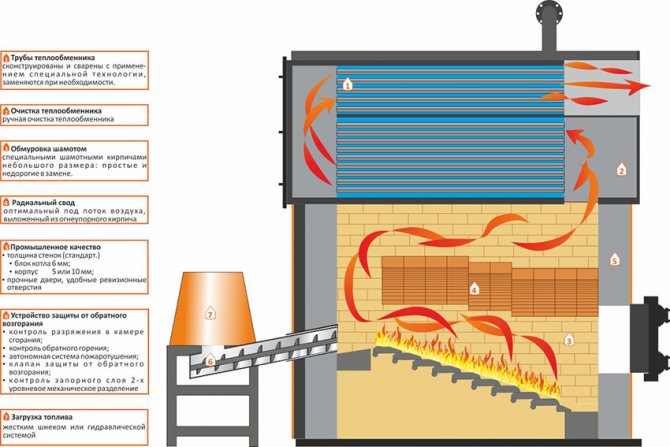

Preparing the premises is equally important. It is necessary to fill in the concrete base in advance for the installation of the TT, punch a hole for the chimney and ventilation. The walls in the room must be protected from fire. You can trim them with thin leaves of metal, asbestos cement or other non-combustible material.

If the room is decorated with wooden plates, it is allowed not to remove them, but simply to protect them with metal sheets. On all sides of the boiler, it is also required to put a metal protruding by 80 cm. This will prevent the floor from igniting when particles of burning fuel fly out of the boiler. If additional electrical equipment will be installed in the room, it is necessary to make a common concrete screed on the floor to protect it from accidental fire.

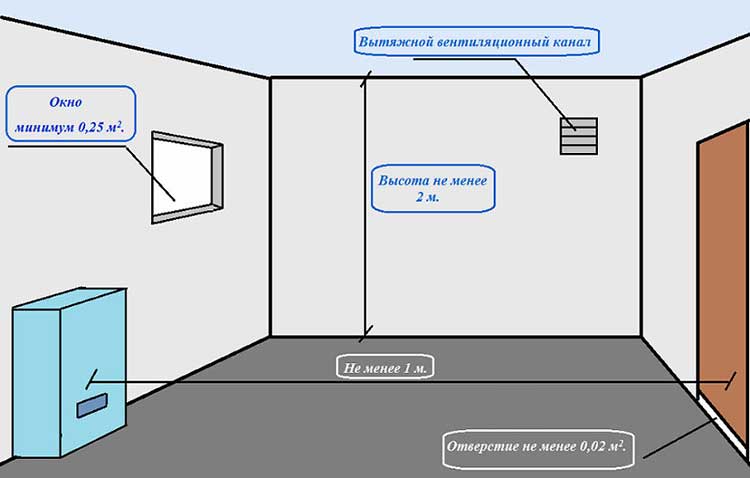

How to make ventilation

After preparing the room and choosing the place for installing the heater, you can proceed to the ventilation equipment. The use of wood or coal involves the formation of a large amount of dust and smoke, so this stage cannot be ruled out.

For unhindered access of cold air and outflow of hot air, it is necessary to make two windows with gratings. The exhaust is located in the upper part of one of the walls of the room and is small in size. The supply window is slightly larger, located at the bottom of an adjacent or opposite wall.

Sometimes the ventilation window is mounted above the boiler, which is not recommended. A gap under the door leading to the living rooms can act as an inlet.

How to properly install supply and exhaust ventilation

There are several objective reasons why ventilation in the boiler room is necessary:

- supplying a sufficient amount of oxygen to the boiler to maintain the combustion process;

- removal outside the premises of carbon monoxide gases that have accidentally entered the premises from the firebox;

- compensation of the amount of air used in the combustion process.

Please note that for the combustion of 1 kg of firewood, 4.6 m3 of air is required, and the combustion of coal requires about 8-9 m3, based on the quality of the fuel.

- Air inlet and outlet openings must be located on different sides of the boiler room. The inlet opening is made at the bottom of the wall as close as possible to the heat generator, and the exhaust outlet is made under the ceiling.

- If the boiler is equipped with a smoke exhauster or a blower fan, the hood should not be placed next to it (read: “How to choose a smoke exhauster for a solid fuel boiler - types, differences”). Otherwise, the draft will reverse, and the exhaust hole will become inlet.

- If the door from the residential building goes into the furnace, then it is advisable to build in the inlet grille in the canvas. Warm air entering the boiler will improve the fuel combustion process.

- The size of the exhaust opening must be smaller than the supply one, since most of the incoming air undergoes a thermochemical reaction and comes out through the chimney in the form of CO2.

You can calculate the required size of the hood, if the boiler power is multiplied by 8 - we get the area of the hole in cm2.

Boiler connection diagrams

After the preparatory work, the device is installed. It is better to entrust the work to professionals in this matter or consult with a specialist before doing it yourself.

Stages of connecting the boiler to the system

Installation of heating equipment is carried out in several stages. Experts strongly recommend that you follow the sequence to get a good result.

The algorithm of actions is as follows:

- Preparing the base on which the device will stand.

- Protection of walls and ceilings, installation of ventilation windows to ensure gas exchange.

- Connecting safety elements and inserting pipes to radiators. The connection diagram is individual for each room, it is developed by specialists.

- Installation of a chimney and a generator if the boiler requires connection to the power supply system.

- Pumping water into the system, identifying leaks and malfunctions.

- Checking the position of all dampers on the device and the chimney.

Then you can start laying fuel and kindling.

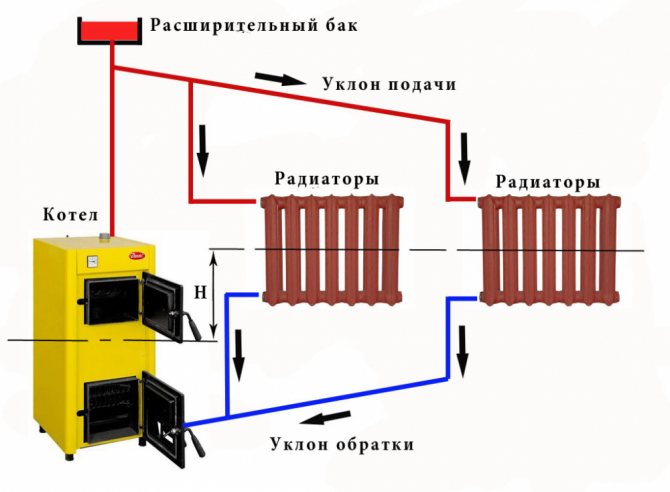

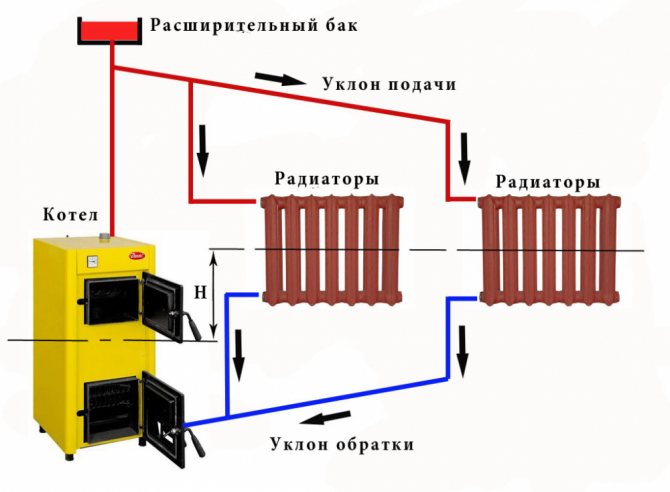

Gravity

A gravity heating system is considered the most preferred option for solid fuel models, especially in a private house. It is easy to install and does not require any special devices. Does not depend on the source of electricity, which is important when installing in settlements remote from the metropolis.

Typically, such a system is installed in an open way, when the expansion tank is much higher than the heating device and all the radiators in the rooms, which allows the coolant to propagate through the pipes under the influence of gravity without an additional pump.

It is important to ensure that all pipes from the radiators are tilted normally so that water can drain freely.

The system has several disadvantages:

- the need for regular pumping of water into the expansion tank due to its rapid evaporation;

- the ingress of air into the system, which causes corrosion of the inner layer of the pipes;

- uneven distribution of the coolant over all radiators.

Despite its drawbacks, the system is popular and often used.

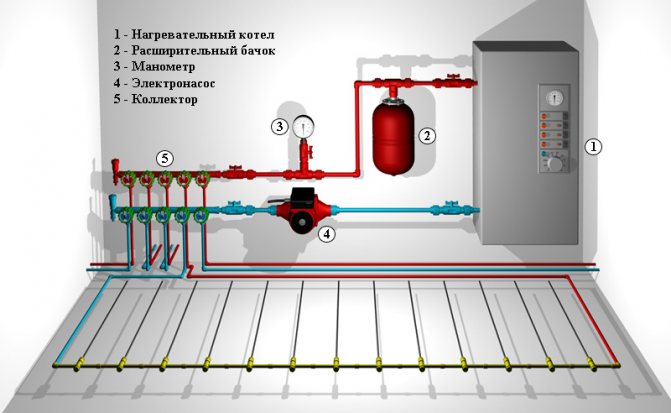

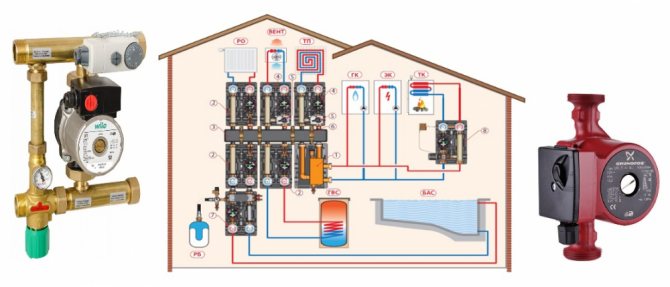

Forced

The forced system is much more convenient and easier to use, it provides an even distribution of the coolant and the same temperature in all radiators thanks to a special pump.

It is installed near the expansion tank or cuts into another place in the system, constantly distills water through the pipes, it evaporates more slowly and does not boil, which is important if the heating device is not equipped with a thermostat.

Requirements for the installation site of the tank when using a forced system are minimal. The slope of the pipes coming from the radiator also does not matter.

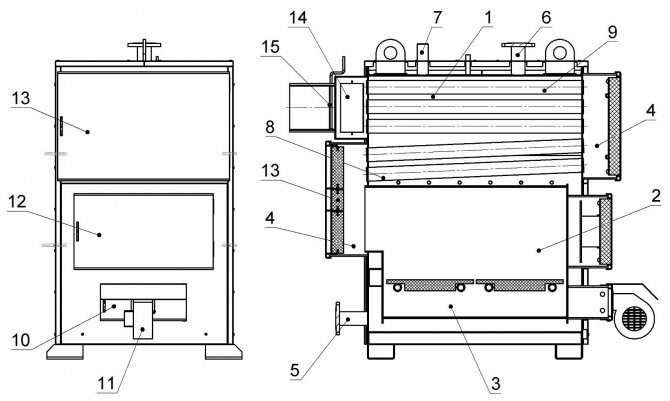

Design features

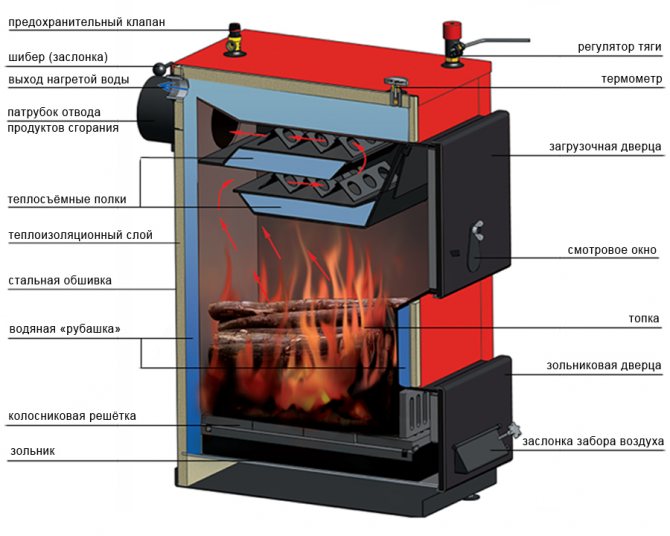

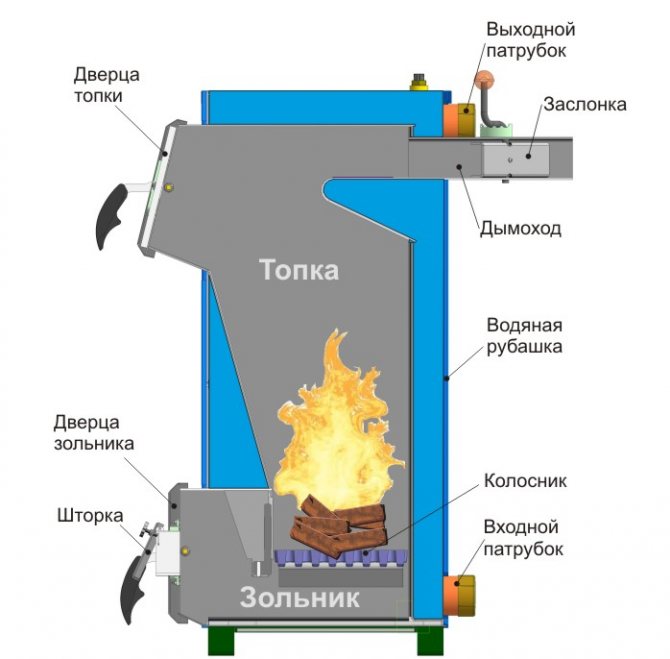

At the moment, several types of water heating equipment are produced, each of which has its own design. Setting the differences between them will allow you to correctly evaluate the technique and choose the appropriate model.

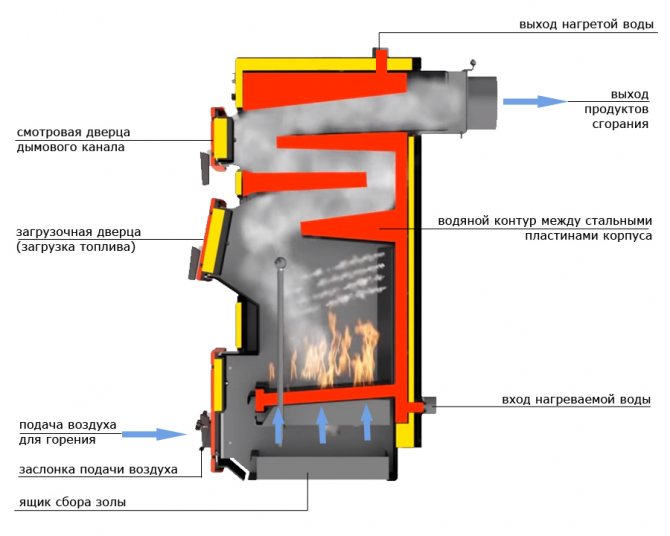

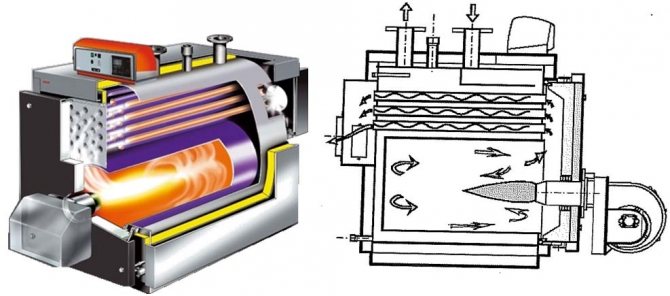

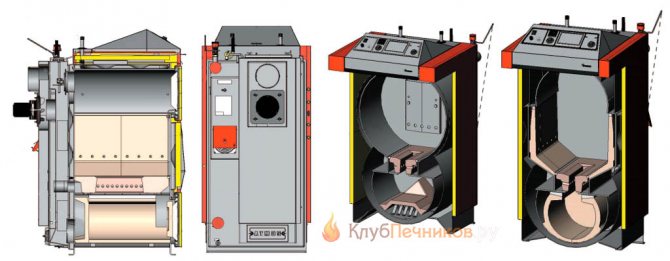

Fire-tube

These types of heaters are equipped with a pressurized gas-tight firebox. For their work, automated burners equipped with blowing fans are used. This feature allows the equipment to work without smoke exhausters, while all the necessary parameters are easily adjustable. As a result, the device is highly efficient and has an efficiency level of 92–95%.

Almost all fire tube boilers are equipped with a cylindrical furnace and smoke tubes inside. Depending on the layout, two- and three-way models are distinguished. This equipment was used in the 19th century and has undergone many changes since then. These boilers are in demand today because they are easy to use and do not require serious maintenance.

Considering the features of the equipment, first of all, it is worth noting that fire-tube boilers can be attributed to gas appliances. On their surface, special pipes are installed along which the coolant moves.

Fire tube boilers are of two types:

- Steam. The heating medium is heated by means of steam, therefore the inside of the boiler is equipped with a special container.

- Hot water. With the help of the liquid, the entire body is heated.

The principle of operation is as follows: gas or fuel is supplied to the burner located on the front of the body, which is burned. The role of the firebox is assigned to pipes located in the water, where all combustible material is burned.

Despite their relatively compact size, such devices are highly powerful and safe to operate. In addition, they can function in an autonomous mode, but this will require additional purchase of special equipment in the form of a pressure gauge, a water pressure sensor, and so on.

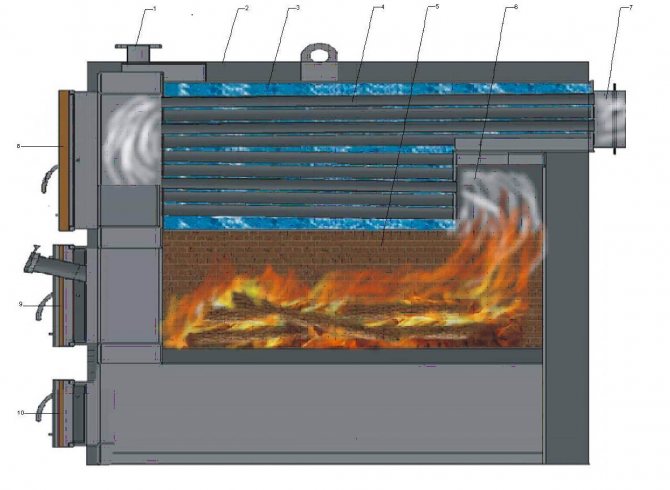

Water tube

In such models, water is heated by passing through metal pipes. The working pipes located outside are heated by the products of fuel combustion. Due to the design features, an increase in the heating surface is allowed, for which a larger number of water pipes are used.

Due to the convection flow in such systems, the movement of water is accelerated, which means that the heat transfer coefficient also increases. The upper limit of the outlet steam temperature reaches +550 ° C.

Water-tube models are more compact than flame-tube models. It is one piece equipment housed in a rugged case. The principle of operation of water tube technology is the natural circulation of water.

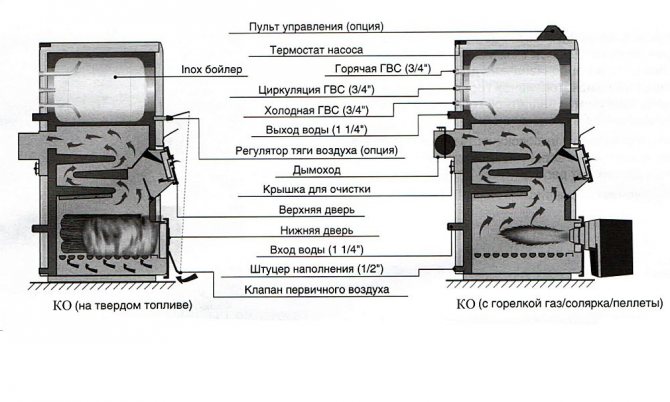

Number of contours

At the moment, the market offers a wide variety of heating equipment.First of all, you need to understand for what purpose the boiler is being bought: only for heating or even preparing hot water. To solve the first problem, a single-circuit model is sufficient - they are more affordable and not so intensive in fuel consumption.

To solve the second problem, a two-circuit device should be chosen. These models, in addition to being able to heat water in a flowing way, are additionally equipped with a built-in boiler, the volume of which varies from 150 to 180 liters. Instantaneous heating is optimal if you need to wash dishes or take a shower in the country.

Step-by-step installation of the heat generator and chimney

Do-it-yourself installation of heating system elements is not difficult, especially with proper preparation of the room and directly the place where the structure will be installed.

The step-by-step installation instructions consist of several stages:

- Installing the device and leveling it vertically using metal pads or special feet. It is necessary to take into account the ratio of the pipe and the hole prepared for the installation of the flue.

- Prepare several insulated pipes or take ordinary ones, wrapping them with basalt fiber.

- Make a hole in the wall that will be 35-38 cm wider than the chimney.

- Install a passage box made of metal, pass a pipe through it, fill the remaining space with basalt wool.

- Outside, the chimney is installed vertically, parallel to the wall. A kind of umbrella is attached to the top, preventing the ingress of a large amount of water, from the bottom - a collector for condensate.

- The part of the chimney coming from the heat generator is mounted at a slight angle towards it.

After completing the work, it is worth making sure that the chimney is not under the ridge of the roof and water will not drain into it during rain or melting snow.

general information

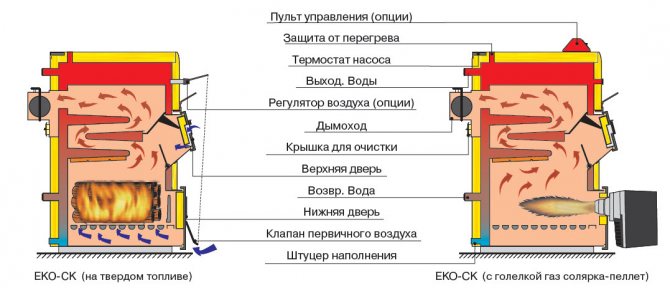

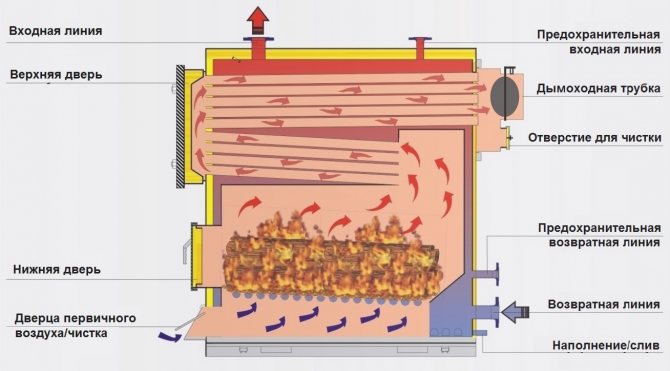

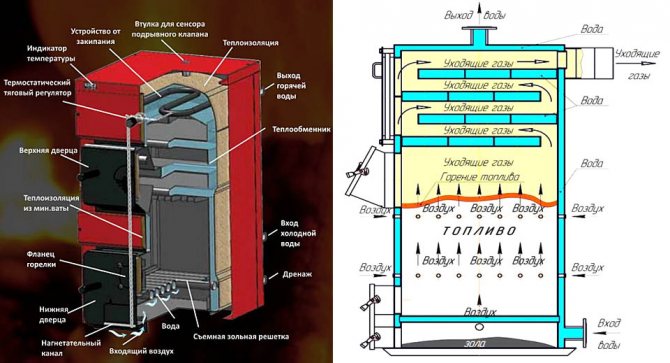

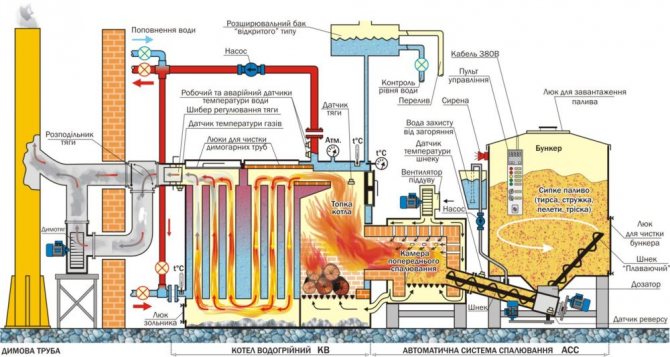

The principle of operation of a solid fuel hot water boiler is similar to any other device that heats the coolant in the heating circuit using thermal energy. A wide variety of solid fuels can be used - wood, coal, pellets and briquettes, as well as any other organic fossil that burns well and is available in large quantities.

The choice in favor of solid fuel hot water boilers is usually made in those places where there is unlimited access to the solid fuel necessary for its operation. In particular, wood-burning boilers are installed at woodworking enterprises, which work, among other things, on woodworking waste. In small boiler houses, lignite and hard coal are used for kindling equipment, and sometimes pellets or peat in briquettes. From the point of view of heat capacity, anthracite or beneficiated ore, as well as coke, have the best characteristics.

Hot water solid fuel boilers have a high heat transfer coefficient, and due to the large surface area of the heat exchanger, they are able to heat a large amount of water.

So, when 1 kg of anthracite is used, up to 7.16 kW of thermal energy is released in the combustion process, while well-dried hardwood firewood gives no more than 2.78 kW.

It is worth noting that the efficiency of hot water solid fuel boilers is significantly lower than that of gas boilers - 70% for wood and 78% for coal. However, heating a large amount of water, even at such a cost, is quite advisable.

Unlike all other solid fuel devices, solid fuel boilers can operate at a constant high load, since they have a power reserve. This effect is achieved through the use of a large number of heat exchangers that heat water for heating and hot water supply.

First heating of the boiler

After checking the heat generator and all valves for leaks, it is allowed to start using the unit for its intended purpose.

The first heating is recommended to be carried out with an open door or window in the room where the TTK is located. During operation, an unpleasant odor may be emitted due to the combustion of a small layer of industrial oil or other components remaining on the device.

The minimum burning time for the first time is 60 minutes, the furnace must be fully loaded. Before setting fire it is worth checking the chimney.

Safety measures during operation

To prevent accidents and other problems, you should carefully study the instructions for use of the solid fuel boiler.

The basic rules are as follows:

- avoid close contact with a functioning device;

- do not leave plastic buckets, wood or other flammable objects near the heat generator;

- do not leave the device unattended;

- prevent complete evaporation of the coolant during combustion, in order to avoid corrosion and rupture of pipes, as well as radiators;

- regulate the air supply to the fuel using the blower door;

- do not put various objects on the boiler;

- when water boils in the system, close the chimney and blower flaps to prevent complete evaporation of water in the expansion tank and pipes;

- fill the tank with water in a timely manner.

If you have a choice, it is worth installing a closed-type forced system, which will facilitate the operation of the equipment.

How the water circuit works

Before choosing and installing a heating system for a house with your own hands, you need to figure out how a wood-burning stove with a water circuit works.

- Heating of water occurs only when burning wood masonry or other type of solid fuel inside the firebox;

- Mostly coal or wood is used in a wood-burning stove;

- One load provides burning for 3-4 hours;

- To ensure a longer burning time, you should choose a gas generator type stove for a house;

- Savings in heat production are achieved by using a high quality heating stove. Also, the efficiency of heat exchange processes and accurate control of the temperature of the coolant affect the efficiency;

- The wall where the water jacket is provided accumulates thermal energy;

- This ensures rapid heating of water and its maintenance in a given temperature range for a long period;

- In practice, it has been proven that a solid fuel stove with a water circuit functions equally effectively with two types of circulation - forced and natural.

Advantages and disadvantages

Choosing a solid fuel stove for your home, which is additionally equipped with a water circuit, you get efficient heating and hot water equipment with a wide range of advantages.

The main positive aspects are:

- Low cost of fuel. This is the most affordable fuel that can be used for heating boilers;

- Equipment availability. The oven itself for the home costs quite little. Some people build them with their own hands. Although it is recommended to give preference to products from a trusted manufacturer;

- High reliability rates. A solid fuel furnace equipped with a water circuit demonstrates excellent reliability indicators, which has been proven by a multi-million audience of users;

- Long service life. Reliability results in excellent durability;

- Rare service intervals. Although the stove uses solid fuels, the equipment does not require complex maintenance. The most important point is to remove ash from the ash pan;

- The benefits of ash. Ash, which is formed as a result of the combustion of solid fuel, can be easily removed by hand. At the same time, you should not throw it into the trash.Since such a stove is the prerogative of private houses, you probably have a plot of land. Ash acts as a highly effective fertilizer;

- Possibility of conversion. A solid fuel boiler is wonderful in that, if necessary, the furnace can be re-equipped by adapting the equipment for operation on gas, diesel fuel, etc.

But in addition to the obvious advantages, such wood-fired home heating systems have disadvantages.

- Relatively low efficiency. With an impressive consumption of wood, the efficiency of the boiler will be no more than 70-80 percent.

- The need for regular loading of the furnace. You have to regularly add firewood to the stove with your own hands. Although there is an automatic feeding oven on sale today. You will need to make one download. Further, the automation of the wood-burning stove will independently add the required amount of firewood to maintain the specified parameters. As a result, one download is enough for several days. The disadvantage of automatic feeding is the certain requirements for the wood or coal used.

Boiler and chimney cleaning and maintenance rules

When the heat transfer of the TTC decreases, its condition should be checked. It may have been caused by soot contamination. For cleaning, it is necessary to wait until the entire structure has cooled completely, open the grates and blower, and use a metal poker to clean the accumulations from the walls.

The soot settles on the remaining fuel, which must also be removed in order to reload the chamber. It is difficult to clean the chimney on your own, especially if there are several bends. Soot and condensate accumulate on its walls, as a result, draft deteriorates, and the risk of fire increases.

Depending on the operating mode and the fuel used, cleaning is carried out 1 or 2 times a year. It is better to entrust the work to professionals, which will avoid injuries and other problems. A cleaned boiler and chimney will ensure high heat transfer and a long service life of the entire system. Study liquid thermal insulation by the link.

liquid thermal insulation

Solid fuel water heating equipment

The main advantage of such boilers is the ability to create a completely autonomous heating and hot water supply system. Availability and safety of fuel storage, ease of repair, long (from 15 to 50 years) service life are also important factors. Modern models allow maintaining the required coolant temperature at the outlet in automatic mode.

A certain inconvenience in the operation of this boiler creates the need for regular fuel loading, which excludes the possibility of automatic heating mode. In addition, maintenance - cleaning from ash or slag, monitoring the combustion chamber - will take time and effort.

Gas generating solid fuel water heating devices are pyrolysis boilers that work on the basis of fuel combustion (additional combustion of wood gas generated by burning wood). In such a boiler, much less soot and ash is formed due to more complete combustion of the fuel. Accordingly, and a higher efficiency (85%), compared with the usual (60%). However, such independently one or two-circuit gas boilers are dependent on electricity, gas and more expensive.