General information

The maximum temperature of the coolant for polypropylene pipes is 950C Celsius. At 1400C this material is easily deformed due to its softness. There is a risk of rupture. If the temperature reaches 2000C, the material starts to melt.

Since the heating of hot water in the heating system of most apartments and houses does not exceed 900C, these products are quite suitable for use. However, they are made from different components, so not every model can withstand even 600C. Also, special requirements are imposed on the products used in the "warm floor" system.

Can polypropylene be used at temperatures above normal? Experts give a negative answer. Yes, the material will be able to withstand a short-term jump, but this temperature should not be constant. Otherwise, the service life of the data is significantly reduced. The 50-year model will barely last a year at double the rate.

Material

Polypropylene, produced at a chemical plant, is a white powder, from which, by melting and subsequent pressing, in fact, pipes and any other products are obtained.

It is produced by polymerizing propylene gas in the presence of metal catalysts. The temperature at which polypropylene begins to soften is 140 degrees Celsius, it melts at 175 degrees.

Here, it would seem, it is possible to complete the article. 175 degrees, superheated steam temperature. Based on this number, polypropylene is suitable for any water supply system with any water temperature.

However, things are not so simple. Another feature of this material is plasticity. Polypropylene has an elongation at break of 200 to 800 percent. This means that if a very, very fat person hangs on a polypropylene pipe, then, before breaking off, it will stretch into a long thin tube.

Why not just 200 or 800 percent? Because polypropylene is more plastic, the higher its temperature. If at twenty degrees above zero polypropylene is a very, very hard material, then already at 130, applying a relatively small force, it will be possible to bend the polypropylene pipe at a right angle.

Advice: if a plan has just emerged in your head on how you can make a polypropylene water supply system of complex shape without fittings, forget about it.

You will just ruin the pipe section.

When bending with heating, the lumen of the pipe will simultaneously greatly decrease, and with it the throughput of the entire water supply system.

In addition, the outer side of the wall will become too thin. The result of this, believe me, will not please you.

Therefore, a sufficiently high pressure in the water supply system at high temperatures can also deform it. Which is definitely undesirable.

It is from these considerations that most manufacturers declare that the maximum operating temperature of polypropylene pipes is 95 degrees Celsius.

Dependence of pressure and temperature

An important parameter is not only temperature, but also pressure. The limiting parameter is 30 kilograms per square centimeter. However, the manufacturer recommends that the pressure not exceed 10 kilograms.

What temperature can polypropylene pipes for hot water with average characteristics withstand? For the longest possible service life, it is recommended that the heating of the liquid does not exceed 700C, and the pressure does not exceed 6 atmospheres.

When choosing pipes for cold or hot water supply, it is important to check the quality of the material.The product must not have:

- Bundles.

- Blotches.

- Bubbles.

Otherwise, the service life will not correspond to the one declared by the manufacturer.

What temperature can polypropylene pipes withstand?

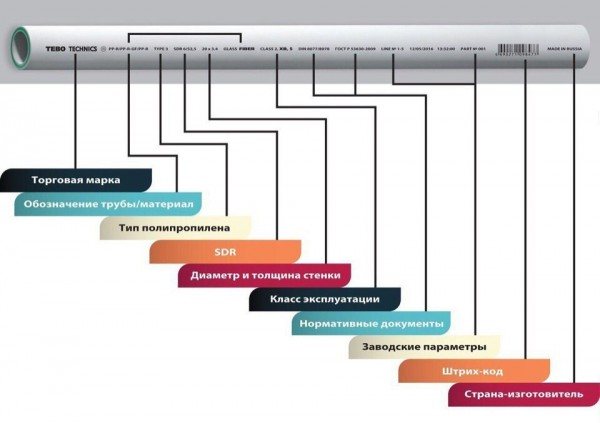

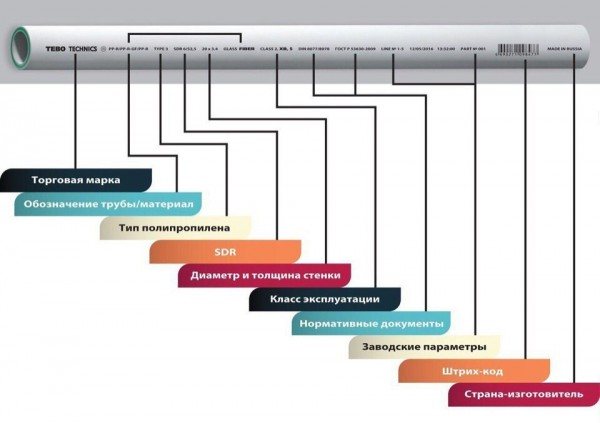

To determine the purpose of a polypropylene pipe in appearance, there is a special marking. In addition to the manufacturer and the brand name, a generally accepted classification is applied to the pipe.

- the name of the polypropylene modification;

- standard proportional ratio;

- nominal outside diameter and wall thickness;

- nominal pressure;

- manufacturer's standards.

The maximum temperature of PP pipes is 95 ° C. This is perhaps the only drawback of polypropylene, it does not withstand high temperatures. At t 140 ° the material becomes soft and easily deformed, and at 175 ° it melts.

The temperature in heating systems for such indicators is also not calculated, therefore PP pipes are quite suitable for using them for heat pipelines.

Short-term increases in temperature indicators rarely lead to failure, but it is important to take into account that when pipes are operated at temperature indicators of 100 °, their service life significantly decreases.

The 50 years declared by the manufacturer, in fact, can turn into a year and a half, because the durability depends not only on its technical characteristics, but also on the operating conditions.

We recommend that you familiarize yourself with: Polypropylene pipes and their sizes: how the parameters affect the operation of the system

Temperature and labeling

You can find out what temperature the products can withstand by marking:

- PN 10. This model is perfect for cold liquids. Polypropylene pipes and RTP fittings for internal sewerage and water supply are designed for temperatures up to 450C.

- PN 16. It can be used both for cold heat carrier and for supplying liquid to the heating system. Water heating can reach 600C.

- PN 20. Water temperature can range from 0 to 800C. This characteristic allows them to be used for heating systems.

- PN 25. A distinctive feature is the reinforcement, due to which the model is able to withstand high pressure and temperature. Product marked PN25 can withstand temperatures up to 950C. Reinforcement can be performed with several materials (more on this later).

Important! It is worth knowing that there is a direct relationship between price and labeling. The higher the number after PN, the more expensive the item will be. Therefore, it is not necessary to purchase pipes with a marking above PN10 for cold water supply and sewerage. But for heating systems, you should choose products PN16, 20 or 25.

What does reinforcement affect?

In order to get good heating of the room, a return pipeline is installed in the apartment and the water heating is increased by 100C. With increasing heating, the material loses its properties and expands in diameter. If the temperature rises significantly, the product may burst. This is especially dangerous when installing communications in a concrete screed. It leads to:

- Cracked concrete.

- Heating system leaks.

In order to reduce the expansion coefficient, manufacturers reinforce pipes - they increase the bearing capacity of polypropylene with another material:

- Aluminum foil that is applied to the outer surface.

- Aluminum, which is located inside the product, closer to the outside (in particular, Valtec PP-ALUX pipes).

- Fiberglass (e.g. Valtec PP-Fiber pipes).

- Composition of fiberglass and fiberglass.

In addition to reducing thermal expansion, reinforcement allows you to maintain the strength of the material during significant heating. Even if the liquid heats up to 1200C, the product will not burst, as will happen with unreinforced counterparts.

Experts recommend choosing fiberglass-reinforced products. At the same cost, such models have a number of advantages:

- Does not require edge stripping before installation.

- They have a short soldering time (the same as for unreinforced analogs).

- There is no internal delamination of the material.

Polypropylene pipes with fiberglass comply with PN25 marking, and therefore can withstand temperatures up to 950C, while maintaining their thickness. Temperature of 1200C is critical for such products. The material can withstand short-term heating, however, with constant exposure, the product's life is significantly reduced.

Summing up

We found out that products for cold water supply are designed for temperatures up to + 450C, for hot water - from 60 to 950C. When choosing communications for the home, it is important to consider several characteristics:

- Water supply type (cold / hot).

- The rise in temperature in the apartment in winter and summer at the place of installation of communications.

- Heating type and building code requirements.

Knowing these parameters, you can choose the most suitable type for a particular case without overpaying for a more expensive option.

Reinforced polypropylene pipes

The conclusion that polypropylene pipes - the operating temperature of which corresponds to the temperature of hot water in the heating system, can be successfully used, is not entirely accurate.

To eliminate the effect of thermal expansion, manufacturers have developed a new type - reinforced polypropylene pipe.

In these products, there is a layer of aluminum foil or fiberglass between the polypropylene layers, which prevents the pipe from expanding much.

Experts recommend using only reinforced polypropylene pipes for the heating system - the temperature they withstand fully complies with the standards of a modern heating system.

When installing heating, you should be aware that not all polypropylene pipes can be used. For example: a pipe of the PN20 brand has an operating temperature of up to 60 degrees above zero, and a product marked with PN25 is capable of withstanding hot water with a temperature of up to +95 degrees.

Installation of polypropylene pipes

When installing polypropylene pipes, take into account their linear expansion due to changes in water temperature. Therefore, it is necessary to mount to the wall without rigid fixing of products.

An important condition must be observed - polypropylene pipes must be able to move slightly when the temperature rises or falls.

This means that they should not be pulled into line and firmly attached to the walls. Otherwise, damage to the layers of the pipe is possible, which can lead to breakage.

And most importantly, you need to remember that polyethylene pipes - what temperature they withstand, which means that in such conditions they must be operated.

It is not recommended to bend pipes made of this material. Although

polypropylene has good ductility, bends and turns should be done using special couplings and fittings. If you try to make a 90-degree turn by hand, then a crack will appear at the bend or the inner diameter of the product will significantly decrease.

In devices where reinforced polypropylene pipes are used, the temperature of the working environment should be within the range of up to 95 degrees. When laying pipes in a concrete screed, for example, when installing underfloor heating, the channel should be made slightly wider than the diameter of the products. This is necessary in order for the pipe to be able to change its dimensions during linear expansion.

When using pipes for supplying cold water, their rigid attachment is allowed, since in this case the operating temperature of polypropylene pipes is low and there is no linear expansion of the material. In addition, the cost of such products is low compared to reinforced pipes, in which hot water is used as a heat carrier.

Reinforcement leads to the fact that the pipeline becomes much more reliable and stronger.

However, it should be remembered that the melting point of polypropylene pipes, regardless of what they are intended for, is 175 degrees Celsius. In this case, complete destruction of polypropylene products occurs.

What pressure can polypropylene pipes withstand?

In accordance with the technical characteristics, the service life of polypropylene pipes is about 50 years. This figure depends not only on the temperature of the working medium in the pipe, but also on its pressure.

Polypropylene pipes can be operated at a working medium pressure of up to 30 kg / sq. see. The higher the temperature, the lower the level of allowable pressure. To put it simply, pipes made of this material must have a working pressure level of up to 10 bar.

Ideal conditions for a polyethylene pipe - the water temperature is not more than +70 degrees at a pressure of 4 to 6 atmospheres.

Polypropylene pipes are in great demand in the construction or repair of pipelines for various purposes. However, it is necessary to consider their working capabilities: temperature and pressure.