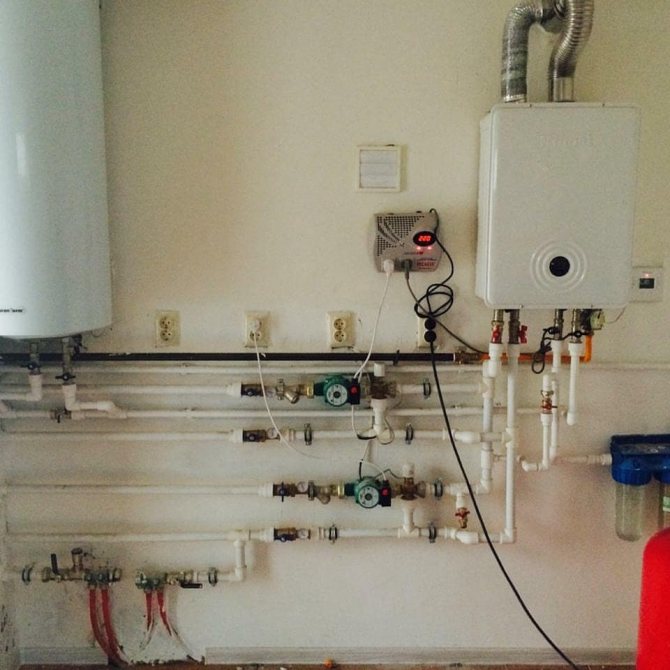

Pipeline communications are being built in residential and commercial, industrial facilities and have different purposes. Functional and efficient systems are constructed using plastic, metal-plastic and metal pipes and a variety of fittings that differ in design and size.

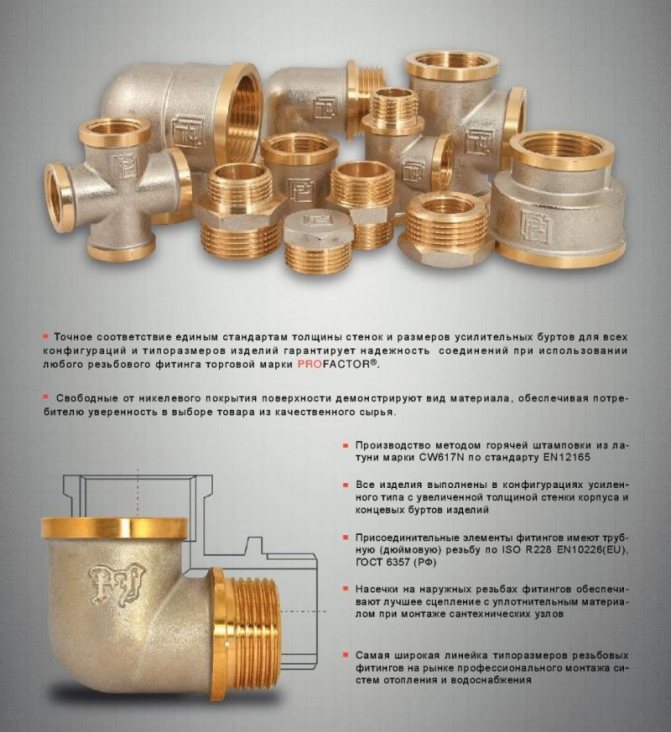

The offered photos of fittings for heating pipes, their descriptions and brief characteristics will help you to navigate correctly in the variety of proposed types.

Such connection elements play an important role in the arrangement of any system, which will simplify the procedures for installing such complexes with your own hands.

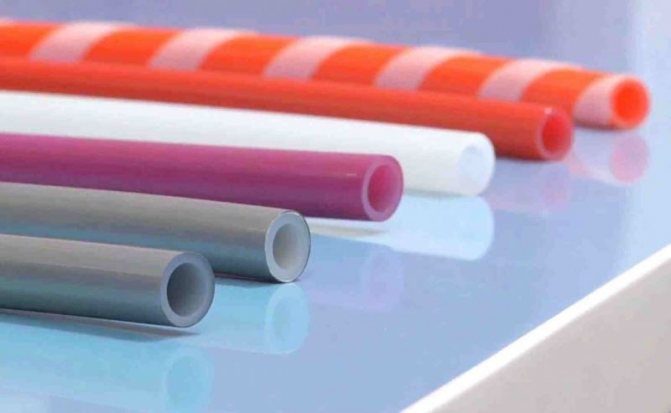

Possibilities and features of plastic products

The affordable price for pipes and fittings for heating is due to the technical features of their manufacture and modern technologies.

Such products have a set of operational advantages, the following parameters are related to the possibilities and features of the use of pipe fittings:

- ease of assembly and installation, subject to accurate reproduction of the instructions;

- high level of maintainability and the ability to replace worn parts;

- the longest possible service life and functionality of individual fittings.

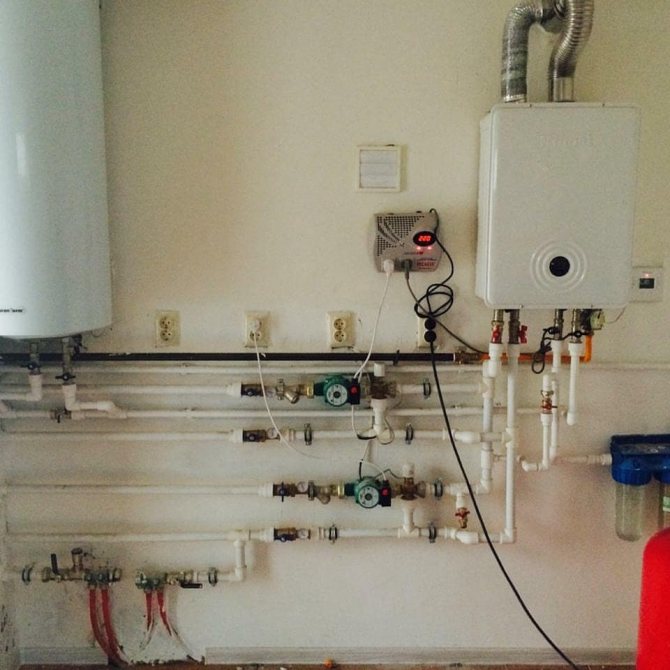

To equip a high-quality and highly efficient heating system in a house or apartment, it is necessary to choose exclusively high-quality fittings.

The connecting elements ensure reliable fixation of the pipes to each other; in a complex configuration, they guarantee the connection of the entire structure.

Features of fittings for connecting metal-plastic pipes

Reinforced-plastic pipes and fittings are widely used for the installation of hot water and heating systems. This spread is caused by the fact that the MP pipeline is made of heat-resistant cross-linked polyethylene, in the inner cavity of which there is an aluminum sheath, due to which the material is able to withstand the temperature of the pumped liquid up to 95 ° and the pressure up to 15.2 bar. Reinforced-plastic pipes and fittings for them are characterized by durability: their service life is at least 50 years.

Reinforced-plastic products are used for heating pipes and hot water

No welding is used to connect metal-plastic pipes. Docking of individual elements of the system is carried out using compression, push fittings and press fittings for metal-plastic pipes.

The last two options are new developments in the field of engineering. The connection of system elements by means of push fittings is carried out in a matter of seconds. This type of metal-plastic fitting consists of a body, a retaining shoe and a ring. The first element is made of polyphenylsulfone or non-ferrous metal. The product has the shape of a corner, a cross, a tee, and is also used as a coupling.

The retaining block is made from the same material as the body. It is fixed on its slip ring, which makes it possible to obtain a non-separable connection. Between the body and the block there are disc and spacer rings, which provide reliable fastening.

Features of push-fitting for metal-plastic pipes

The push-fitting inlet is inserted into the pipe, which is accompanied by a characteristic click. This indicates the reliability of the fastening of the reinforcement. Its feature is the ability to rotate around its axis 360 °.

Thanks to modern developments, push fittings have appeared on the market with many advantages.

This type of connection for plastic pipes with an aluminum sheath can be used for the installation of heating networks, pipelines for cold and hot water supply, and underfloor heating systems, providing high reliability, tightness of connections and durability of the structure. The use of such fittings contributes to the quick installation of the system, since the fixing of the elements is carried out without the use of a special tool, which even a novice master can do. Works can be performed in restricted access conditions.

Push fittings can withstand temperature fluctuations and high temperatures up to 90 ° C. Such connections are able to withstand many freeze / thaw cycles of the system without loss of tightness. These elements are recyclable.

The disadvantages of such fittings for plastic water supply pipes with an aluminum sheath include their high cost. The O-rings are able to take the required position, ensuring the reliability and tightness of the connection, after three hours.

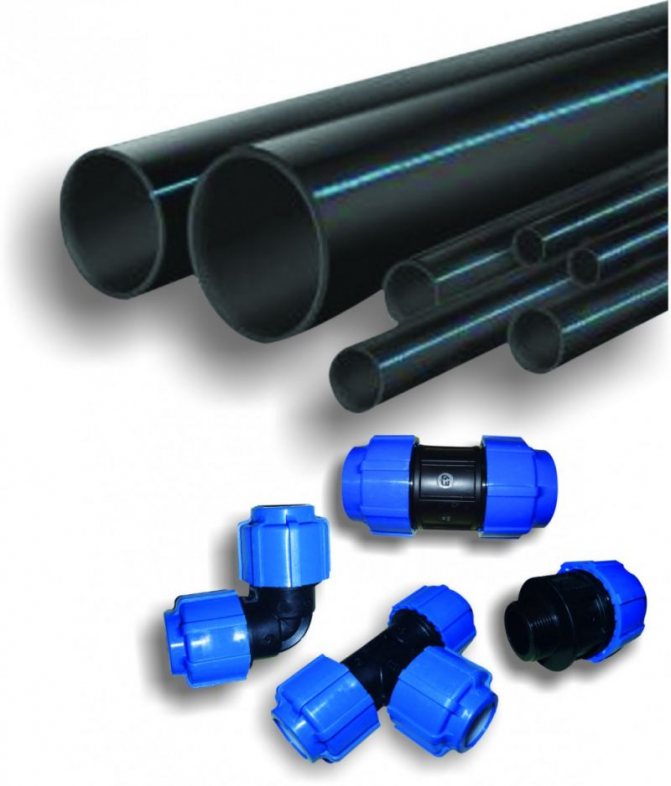

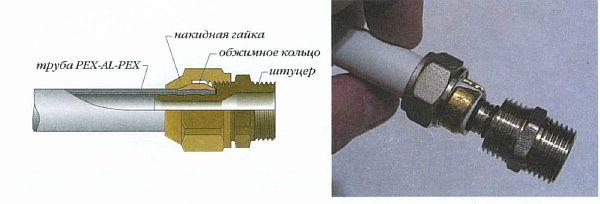

Features of compression fittings for connecting pipes

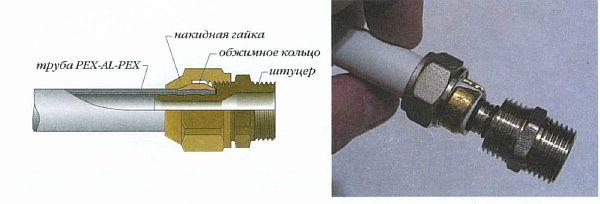

If the question arises of how to connect two plastic pipes of the same diameter, it is worth considering a compression fitting, which consists of a union, a ring, a union nut and a gasket. The first element is inserted into the internal cavity of the pipeline. It is predominantly made of galvanized brass. Grooves are made on the surface of the product, where inclined ribs and sealing rings are inserted, which prevent the connection from opening.

Compression fittings are used to connect pipes with the same diameters.

The forcing ring is equipped with a diagonal slot and a ribbed inner surface, as a result of which the contact between the fitting and the pipe is improved. The element is made of non-ferrous metal. The union nut is made of galvanized steel. It presses the forcing ring against the fitting through the pipe sheath. For the reliability of the connection, a fluoroplastic or Teflon gasket is used, which is put on the fitting, contributing to high-quality insulation.

Related article:

Fittings for polypropylene pipes and other types of polymer products

Varieties of fittings according to configuration, area of use and installation method. Leading manufacturers of fittings.

When installing compression fittings for plastic water supply pipes, no special tools are required. The process is carried out manually. Since this type of fittings is a dismountable joint, it can be used repeatedly. The service life of such a system is about 10 years. It needs constant monitoring of the state of the connections.

As a result of pressure drop and temperature fluctuations in the structure, self-loosening of the union nut can occur, which will cause a leak. Therefore, this type of fitting for a metal-plastic pipe is recommended for outdoor installation of the system.

Installation of a compression fitting is possible without special equipment

Special Features of Compression Press Fittings for Metal-Plastic Pipes

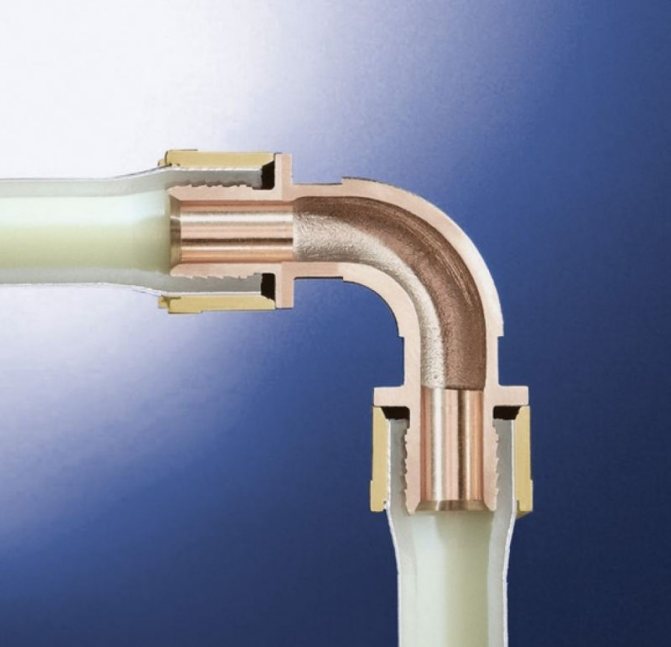

Compression press fittings are represented by elements that consist of a body, a sleeve and a ring. The body is made of bronze or brass, often has a galvanized coating. Depending on the purpose, the element may differ in different designs and be presented in the form of a corner, a plumbing adapter, a tee, a cross or a water outlet.

A sleeve is used to fix the body in the pipe cavity. The element is made of AISI 304 stainless steel. It is usually inserted into the body of the fitting. However, there are options for which the sleeve is located separately. Before fixing, it is inserted into the grooves of the main element.To control the depth of immersion of the pipe in the fitting, some models are equipped with inspection windows, which are located on its body.

The ring serves to securely connect the sleeve and the body, acting as a gasket. The part prevents the occurrence of low voltage currents.

Important! With the help of press fittings, they create a reliable and tight connection of system elements, therefore they are recommended for use when laying water and heating mains in the walls of a building.

Crimp-type press fittings are made of brass or bronze

Before connecting plastic pipes using press fittings, it is necessary to prepare a special tool in the form of press tongs, which even a master with little experience can handle. At the same time, the work takes a minimum of time. As a result of the use of such products, high strength and tightness of the connection of individual elements of the system is ensured, capable of withstanding a pressure of more than 10 atm. The service life of press fittings reaches 50 years.

Such a structure does not need constant maintenance and control, therefore it can be implemented for laying communications with a hidden method in concrete screeds. Press fittings are resistant to linear expansion of metal-plastic pipelines, which can occur during temperature fluctuations of the transported medium and pressure changes. These fittings reduce the installation costs of the system, which is explained by the reduction in pipe consumption and a decrease in the number of fittings used.

The main disadvantage of press fittings is their unsuitability for reuse, since these elements can only be dismantled together with a part of the pipe.

Special pressing tongs are used to fix the compression fitting.

Existing types and purpose of fittings

Modern fittings for plastic heating pipes are offered by manufacturers in a wide variety and, according to the method of installation, they can be divided into the following classes:

- collet, equipped with comfortable thread;

- compression elements of the pipeline;

- press fittings for metal-plastic pipes.

Most often, the use of crimp fittings for the construction of all types of pipelines and heating systems is recorded.

This allows you to quickly and easily replace worn out parts or elements with obvious and physical damage, without involving specialists in such work and independently taking the necessary measures.

What are fittings: characteristics of connecting elements

Fittings - what are they? These are structural elements of the pipeline system that are used for the installation of highways, arrangement of different turns, branches, transitions between different types and diameters of pipes. Thanks to such fittings, the assembly process of the system is fast, while a reliable and tight connection of its component components is created.

Fittings are used to connect pipes made of various materials

Fittings must provide a high degree of strength of the connection, do not interfere with the free passage of liquid, do not lose their original properties when the pressure in the system and the temperature of the transported medium change, be easy to install, have wide distribution and an acceptable cost.

Plastic pipes and fittings for plumbing, sewerage and heating are made of polyethylene, polyvinyl chloride, polypropylene and metallized plastic. Products are characterized by low weight, ductility, corrosion resistance, dielectric properties that increase the safety of use of the material, low thermal conductivity, chemical inertness and ease of installation. For PVC fittings, there are certain restrictions on the temperature and chemical composition of the liquid that is transported.

Important! When installing the system, pipes and fittings must be made of the same material, which will ensure the reliability and durability of its operation.

Plastic pipe fittings are widely used for laying plumbing, sewerage and gas pipelines. When installing networks of plastic elements, you can do without welding, which greatly facilitates the installation process, making it possible to carry out it in difficult, inaccessible places.

Fittings connect sewer, water supply and heating pipes

Installation options and design features

All existing fittings for PVC heating pipes in terms of functionality according to the generally accepted classification are divided into four classes:

- crosses necessary for cutting pipes and branching them;

- couplings used to fix several pipes (different or the same diameter);

- curly elements used to bypass structures without their direct connection;

- shut-off valves, taps and valves or shut-off type fittings for metal-plastic pipes.

Each type of fittings offered by manufacturers has its own purpose and differs in the design features of the installation.

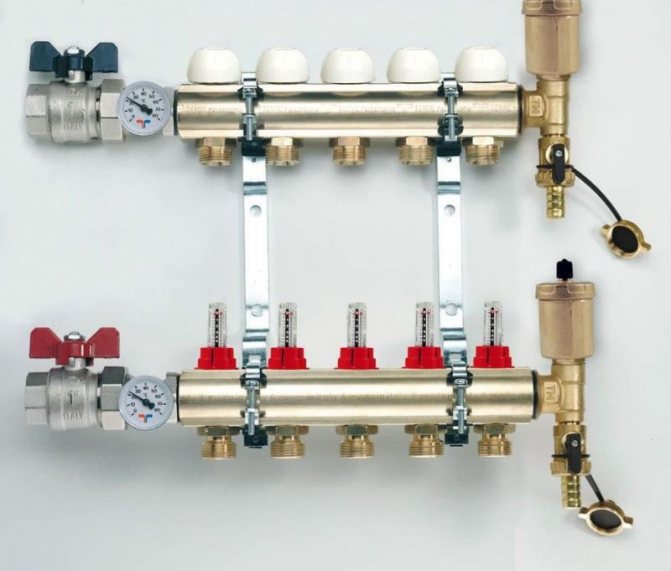

Support fittings and contours

In order to lay a pipeline at the intersection of various trunk lines, as well as to go around an insurmountable obstacle, contours are used (read: "How to make a pipe bypass for stretch ceilings - two proven methods").

Support fittings are primarily used to rigidly fix a system, such as heating or hot water supply. In this case, such fixation is advisable, since pipes made of polymeric materials, when exposed to high temperatures, tend to expand and become more plastic.

As for the sewer pipes, such supports serve to hold the swivel elbows in their original position under conditions of increased mechanical stress.

Thus, if you have the right quantity and range of fittings, the installation of any, even a very intricate system of plastic pipes, will be quick and successful.

Push-in fittings

By design, these elements are a combination of a brass base, a ferrule and a gasket.

Such detachable fittings are offered in the form of tees and crosses, various adapters, they are necessary for fixing several ends of pipes and, when correctly installed, are characterized by a long service life.

Blanking fittings, crosses and tees

By plugs is meant a dead-end element that is fastened by thread or by soldering. The main task of such fittings is to protect plastic pipes from dirt and foreign objects during their transportation or storage, as well as to prevent the leakage of working fluids from the system.

For the installation of branches or combining several lines into one line, plastic fittings for pvc pipes in the form of crosses and tees are used. In tees, center bends can be angled at 30º, 45º or 90º. The type of connection of such elements can be threaded or adhesive. In addition, there are special thread-to-solder adapters.

Compression

This type of fittings is collectively called conditionally detachable, they are distinguished by their simplicity and speed of installation and the strength of the joint formed.

Compression fittings can be used repeatedly and are suitable for arranging heat pipes of varying complexity and design features.

- Safety group for heating - device features, principle of operation and applications (85 photos)

- Heating cable for pipes - tips for choosing, nuances of application and features of operation (140 photos)

A water gun for heating - what is it, the principle of operation and features of the use of the device (110 photos and videos)

Fitting installation and replacement technology

Before proceeding with the installation procedure, it is worth drawing a detailed schematic image of the future pipeline network, as well as preparing all the necessary tools. The first will give a clear understanding of the number of pipes and connecting elements, the second will allow you not to be distracted by searches and not waste extra time. Of the tools you should have at hand:

- Pipe cutter. A special type of scissors that allows you to easily cut any plastic pipes. The cut point is flat and strictly perpendicular to the longitudinal axis of the pipe.

- Calibrator. A device for restoring the shape of a cut, which, after cutting, may appear slightly wrinkled or flattened.

- Set of wrenches.

- Crimping pliers for mounting press fittings. The tool itself is quite expensive, so it makes sense to rent it for a single use.

The preparatory stage of installation is the same for all types of fittings and includes the following steps:

- Pieces of the required length are cut from the bay of a metal-plastic pipe (products of small diameters are often sold in this way). In this case, a small (1-2 cm) margin is taken into account, which will enter the inside of the fitting.

- The edge of the segment is carefully examined and, if necessary, leveled.

- The inner and outer chamfers are removed (for press fittings, only the inner one).

- With the help of the calibrator, the geometry of the cut edge is restored.

The further installation procedure directly depends on the type of fitting.

Compression fitting:

- A nut and a ferrule are put on the prepared pipe section.

- The end of the pipe is fully inserted into the fitting.

- Next, the ring slides over the fitting.

- A nut is screwed onto the thread of the fitting and tightened with two wrenches.

Press fitting:

- A sleeve is put on the prepared edge of the pipe, and a gasket is placed on the fitting.

- The pipe is pushed onto the fitting until it stops.

- Crimping pliers, configured to work with a pipe of this cross-section, are installed close to the edge of the fitting and clamped with force.

- After the first clamping, the tool is rotated 30-40 degrees and re-crimping is performed.

- A properly swaged fitting clearly shows two parallel concave stripes.

We recommend that you familiarize yourself with: Types of steel fittings and features of their installation

The push-fitting is mounted by pushing the fitting into the end of the pipe. The pipe must go all the way, which is controlled through special inspection windows in the device body. A click will indicate the successful fixing of the product. The push-fitting design allows multiple assembly and disassembly of the product.

Note! Press or push fittings crimped in accordance with all the rules can rotate freely around the pipe.

After the completion of the installation of the pipeline system, its tests are carried out by smoothly increasing the supply of the carrier. If these or those connections are leaking, they need to be tightened or redone.

Press fittings

Press fittings are one-piece structures, and specialized tools are used for their installation.

Such models of fittings are represented by angles and tees, couplings, this method of connection is characterized by increased reliability and optimal level of strength.

Fittings advantages

Connecting fittings for metal-plastic pipes have many advantages:

- There is no need for welding.

- The connection is carried out quickly, and most importantly, without any special professional skills.

- Installation does not require any special knowledge and skills.

- There is no need to purchase expensive and complex equipment.

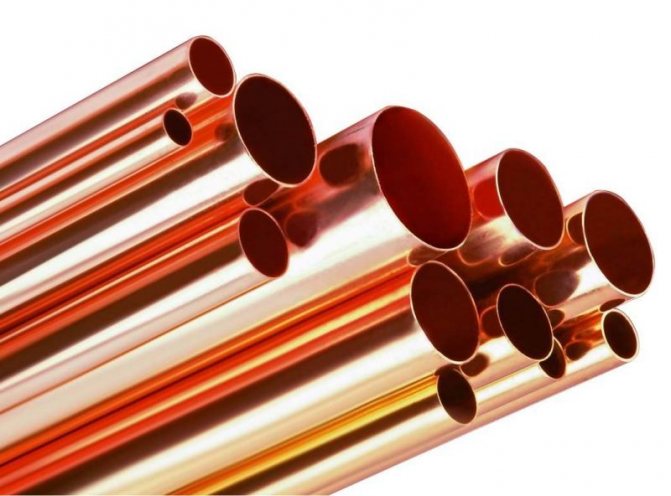

- When working with these fittings, the labor intensity is much lower than, for example, in the case of copper, polypropylene and steel pipelines.

- These connecting parts are produced in various forms, which allows them to be installed on a pipeline of any structural complexity.

ADVICE. These fittings are recommended when laying a structure that needs to be quickly dismantled.Also, these fittings are effective when fast maintenance is required, because the joint can be easily dismantled if the need arises.

Technical properties of fittings for heating systems

Modern fittings for metal heating pipes or metal-plastic structures are classified according to certain criteria.

Such elements should be selected focusing on a whole range of technical and operational properties, the most important of which are:

- scope and in which system the functional element will be installed;

- the material and manufacturing technology of the fitting, the necessary tools for this;

- structural purpose and configuration, intended purpose of the fitting element.

Standard fittings are available in a variety of sizes and configurations to accommodate a variety of designs.

The correct choice of connection elements will ensure a long service life of the entire heating system of its individual elements, increasing the operational properties of the overall structure.

Heat accumulator for heating - description of the system and features of its use in a private house (120 photos)

Pumps that increase pressure - an overview of 2020 models, recommendations for the selection of parameters for the heating system (105 photos)

Heating pressure pumps - manual and automatic models for modern heating systems (90 photos and videos)

Polypropylene fittings

- Catalog

- Polypropylene piping systems

- Polypropylene fittings

Polypropylene fitting with a transition to an external thread VTp.701.0

82 ... 217 p

Polypropylene fitting with transition to female thread VTp.702.0

62 ... 152 p

Polypropylene fitting - coupling VTp.703.0

7 ... 423 p

Polypropylene fitting - transitional sleeve inner-outer VTp.704.0

8 ... 280 p

Polypropylene fitting - transitional coupling VTp.705.0

8 ... 258 p

Turnkey polypropylene fitting with transition to female thread VTp.706.0

275 ... 2676 p

Turnkey polypropylene fitting with transition to external thread VTp.707.0

310 ... 3488 p

Polypropylene fitting with union nut VTp.708.0

128 ... 260 p

Polypropylene fitting with union nut for transition to "Eurocone" VTp.708.E.0

192 p

Polypropylene fitting with union nut for transition to "cone" VTp.708.K

156 p

Polypropylene fitting for manifold with transition to PEX VTp.710.0

326 p

Polypropylene fitting - branch pipe for union nut VTp.721.0

180 ... 503 p

Polypropylene fitting - union nut, female thread VTp.722.0

181 ... 458 p

Polypropylene plank with water sockets VTp.724.0

193 ... 248 p

Polypropylene fitting - tee VTp.731.0

10 ... 634 p

Polypropylene fitting - tee with transition to female thread VTp.732.0

79 ... 198 p

Polypropylene fitting - tee with transition to external thread VTp.733.0

104 ... 242 p

Polypropylene fitting - collector tee VTp.734.0

185 ... 204 p

Polypropylene fitting - reducing tee VTp.735.0

18 ... 1246 p

Polypropylene fitting - two-way tee VTp.738.0

19 ... 40 p

Polypropylene fitting - crosspiece VTp.741.0

19 ... 119 p

Polypropylene fitting - elbow VTp.751.0

8 ... 657 p

Polypropylene fitting - elbow with transition to female thread VTp.752.0

78 ... 197 p

Polypropylene fitting - elbow with transition to external thread VTp.753.0

95 ... 222 p

Polypropylene fitting - water socket with female thread VTp.754.0

81 ... 108 p

Polypropylene fitting - water socket with external thread. VTp.755.0

119 ... 140 p

Polypropylene fitting - elbow with union nut VTp.758.0

133 ... 291 p

Polypropylene fitting - 45 ° elbow VTp.759.0

9 ... 144 p

Split polypropylene fitting with transition to external thread VTp.761.0

151 ... 3240 p

Split polypropylene fitting with transition to female thread VTp.762.0

162 ... 3144 p

Polypropylene fitting - split coupling VTp.763.0

183 ... 2152 p

Polypropylene fitting - coplanar crosspiece VTp.775.0

53 p

Polypropylene bypass with couplings (long) VTp.776.L

34 ... 57 p

Polypropylene bypass with couplings (short) VTp.776.S

23 ... 34 p

Polypropylene fitting - two-plane cross VTp.778.0

23 ... 43 p

Polypropylene fitting - polypropylene collector tee with ball valve VTp.781.0

412 ... 435 p

Polypropylene plug VTp.790.0

7 ... 396 p

Polypropylene plug with thread VTp.791.0

7 ... 23 p

Set of polypropylene plugs with long thread VTp.792.M

52 p

Polypropylene bypass VTp.793.0

28 ... 160 p

Polypropylene compensator VTp.794.0

82 ... 568 p

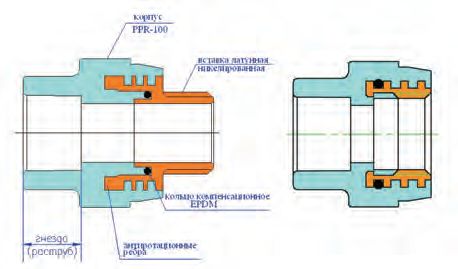

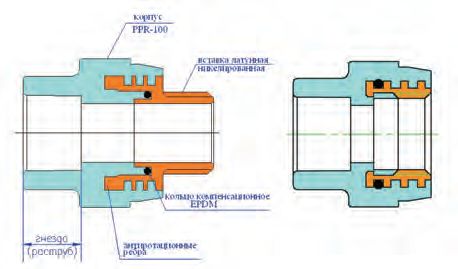

VALTEC polypropylene fittings are designed for the installation of water supply pipelines, heating, transportation of other non-aggressive media to the materials used. The production of products is carried out by modern injection molding machines from PP-R 100 polypropylene. The conical shape of the sockets of polypropylene fittings excludes the formation of sagging, narrowing of channels when welding joints. To connect polypropylene pipelines with threaded elements of the system, combined fittings with brass nickel-plated embedded parts are produced. The patented design of the embedded elements of the combined fittings provides reliable protection against the penetration of the working medium between the body and the embedded element. An EPDM compensation ring is provided between the casing and the metal element. The products are designed for a maximum operating temperature of 95 ° C and a nominal pressure of 25 bar.

VALTEC combined fitting design:

Photo of fittings for heating pipes

- Repair of the circulation pump - the main types of malfunctions, disassembly, repair and assembly of the pump in the heating system (video + photo)

- The choice of a circulation pump - how to calculate the parameters and advice on how to choose a pump for modern heating systems (115 photos and videos)

Cap on the chimney pipe: types, applications, tasks and installation of the element (110 photos)

Did you like the article? Share

0

How couplings work

The device of fittings for metal-plastic pipes is different in each case, although some types of fittings for metal-plastic pipes have structural similarities.

For example, all press fittings work the same way:

- Housing. The form of a particular type of part depends on it. By the type of housing, a certain model of the device is obtained: a coupling, angles or tees.

- Sleeve. This part of the device is called the main one; it is made of stainless steel. On its surface part, pliers are squeezed, making installation measures. At the end of pressing the sleeve, it is no longer able to assume the previous dimensions, and this does not happen not only during installation work, but also during a period of long-term use.

- Ring clip. It is used to join the sleeve and body.

Watch video: cheap option how to connect MP pipes

When installing this type of couplings, you do not need to use sealants or lubricants. The required level of tightness is ensured by deformation of the steel sleeve.

A slightly different device is distinguished by such types of fittings as push couplings. The device in this case is as follows:

- The case, made of polymer, can be compared with metal products in terms of strength.

- Rubber rings - seals. They are able to withstand high temperature loads.

- Ring inside, equipped with a spring. He is responsible for fixing the pipe in the required position.

- A plastic casing, it is placed on the outside, and holds the whole structure.

All the described types of fittings for metal-plastic pipes are distinguished by their ease of installation, which is their significant advantage over other similar devices.

Collet parts

Push-in fittings for metal-plastic pipes are used very often when broaching pipelines. If the joint with collet parts is made correctly, and in accordance with all the requirements, then you will not have to worry about strength and tightness.

It is just as important to become such a nuance that the installation work in this case is performed quickly and easily.All that is required for the installation of collet elements: devices for chamfering; scissors; spanners; calibrator.

The main advantage of the joint formed by the collet connector is the possibility of subsequent disassembly if necessary. But, they need constant maintenance. It implies constant tightening of the union nut.

Collet fittings are produced by many manufacturers, and they are provided in a huge number on the market. So, for example, only Italian firms producing products of this line can be counted more than a dozen, and there are many more Chinese manufacturers.