Purpose and design features

The bracket is designed to hold the pipe in a vertical (or predetermined inclined) position. It does not allow chimneys drawn from individual sections to bend. In addition, the support bracket takes the weight of the chimney.

The wall bracket for fixing the chimney consists of the following main parts:

- split ring enclosing the pipe; supplied with a gasket made of rubber or heat-resistant material;

- console - a spatial structure made of a metal profile or bar, connecting the ring and the platform for fastening;

- mounting platform - a metal plate to which the console is attached and having holes for fixing the structure to a wall or other building structure.

The support, or starting bracket, instead of a ring covering the pipe, has a platform on which the lower end of the pipe rests. Consoles can be triangular for wall mounting and rectangular for floor support.

The starting bracket has a platform on which the lower end of the pipe rests.

The main difficulties in the process of installing heating pipes in the wall

In the process of working with the arrangement of warm walls, a lot of problems can arise, and the main ones are the following:

Expansion by heat

... At the same time, not only the pipe itself increases in volume, but also the plaster with which the wall is finished. This inevitably leads to the appearance of cracks on the surface.

You can cope with such a problem by fulfilling some conditions:

- the heating system should be equipped with a low-temperature type (no more than 40 ° C). Such a device is to some extent similar to the installation of a warm floor: when touching the surface, there should be no unpleasant sensations;

- for work, you should use only those elements whose coefficient of thermal expansion is low, for example, cross-linked polyethylene or metal-plastic;

- it is better to use plaster not ordinary, but with the addition of special plasticizers. Such a mixture tolerates changes in size under the influence of temperature better, so cracks on it usually do not appear.

Heat loss

... It is important to remember that a wall heated to a certain temperature will emit thermal energy not only inside the room, but also outside. To avoid this, an insulating layer of foam or mineral wool should be placed between the heating pipe and the wall surface.

Views

Depending on the design, the following types of chimney brackets are distinguished:

Starter

This is the most durable and powerful type - the entire chimney rests on it. Usually it is made of two cantilever triangles from a durable metal profile with a wall thickness of 1-3 mm. From the side of the wall and from the side of the street, they are connected by jumpers, which add additional rigidity to the structure. A support platform with a cutout for a revision with a valve for draining condensate is mounted on top. Sometimes, instead of a platform, another jumper is used, and the lower edge of the pipe rests on a square contour.

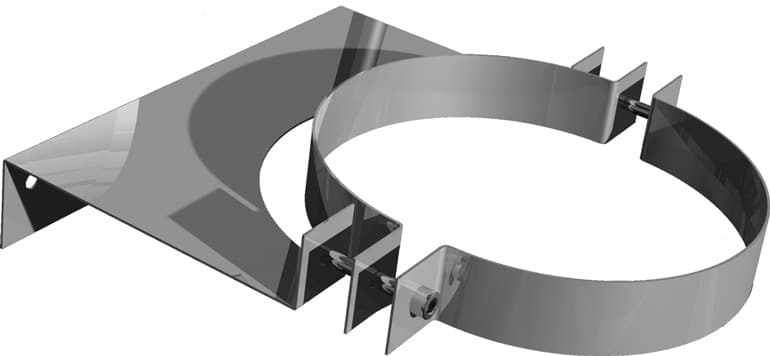

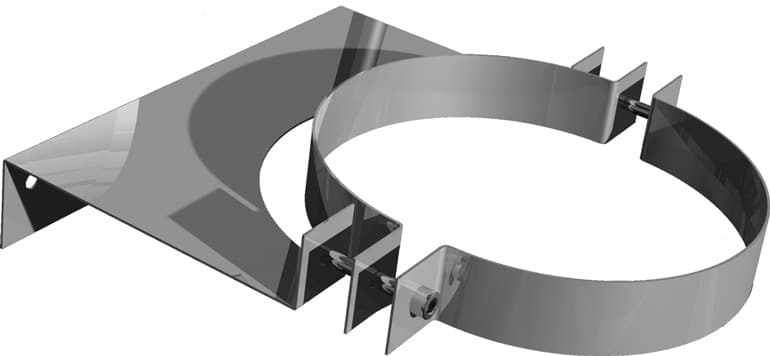

Chimney support bracket

Wall (wall)

these are lighter structures, they do not carry a weight load, their function is limited to fix the vertical position of the pipe. They are a split ring and a lightweight cantilever structure that connects the clamp and the wall mount panel.

Manufactured by stamping and welding from stainless steel, galvanized or painted ferrous metal.

With a small distance from the wall (up to 100 mm), a metal plate located perpendicular to the wall can be used to connect the ring to the mount. It is part of the split ring is welded to the semicircular cutout in this plate, and the other end of the plate is bent and attached to the wall.

With a large distance, the ring is attached to the plate with two metal profile consoles.

Chimney wall bracket

Telescopic

In such structures, you can change the distance from the ring to the wall - one tube of a square profile can move inside another. These brackets are very convenient for mounting the chimney on a solid log wall and other uneven surfaces. After the point of adjustment of the departure, the tubes are fixed with a bolt and nut. A telescopic pipe mount is less reliable than an all-welded one, so they have to be made from a larger section.

Telescopic pipe mount

stiletto heels

Lightweight budget mount. It uses a standard pipe clamp welded to the threaded rod. The hairpin is wrapped in a wooden wall or dowel. Due to the single point of attachment to the wall, the rigidity and ability to withstand wind loads are reduced.

Bracket with studs

This mounting option does not use compression rings or clamps, the chimney is attached to a pair of cantilever guides. With this method of fixing, the ability to withstand lateral wind loads is reduced. Recommended for low-cost starting fixing of indoor chimneys. fastening.

Bracket for chimney

Fastening steel pipes

In some cases, it is necessary to solve the problem of fastening metal pipelines. Such material is still used in the installation of heating and plumbing: pipes made of copper and stainless steel last longer than plastic ones.

The fastener for metal pipes is also made of metal. This could be:

- bracket for fastening pipes;

- clamp with and without rubber gasket;

- bracket.

During installation work, the following nuances must be taken into account.

- When laying pipes horizontally, fewer fasteners are required than when laying vertically: in this case, the weight of the metal does not have a bending effect. The distance between the clamps for a vertically laid water supply system is increased by 10%.

- Thin pipes require more anchoring points than thick pipes.

- In the lower part of a vertically installed pipe, turning into a horizontal plane, an additional rigid metal clamp must be installed for fastening the pipes. The deforming load must not be transferred to the lounger.

In the event that it is necessary to fix or connect rectangular (square) pipes, use fasteners that repeat its contour. This is used when assembling metal framed greenhouses and racks. The attachment for the profile pipe can be T-shaped, cross-shaped and straight.

Manufacturing materials

Fasteners are made mainly of the following materials:

- stainless steel;

- aluminum alloys;

- ferrous metal with subsequent galvanizing or painting.

The stainless steel has an aesthetic appearance, it goes well with the material of the chimney sandwich pipes. Such structures are strong, durable and not subject to corrosion. The disadvantages include the high cost. Independent production of stainless steel brackets is difficult due to the complexity of the technology of welding stainless alloys.

Aluminum structures are lightweight and attractive. They have not yet received wide distribution in our country due to their high cost.

Conventional structural steel is very inexpensive and is available for welding in the home workshop with a conventional welding inverter.This makes it an ideal material for DIY brackets.

The main advantages of wall heating

As it becomes clear, there are many problems with the installation of heating pipes in the wall. However, this method of the device has its own advantages, which distinguish it favorably from other options for traditional heating of residential premises.

The main advantages include the following:

- attractive appearance of the room. There is no longer any need to hide parts of household communications in any way, therefore, much more opportunities for design solutions open up;

- the distribution of heat is more uniform, which is explained by the increase in the area of heat energy output. Due to the fact that the pipes are laid from the very bottom, there are no cold areas in the floor area. Here it is worth remembering that the installation of aluminum plates will help to further improve heat transfer and coordinate the distribution of heat, which also make it possible to use a smaller pipe;

- properly distributed heat will reduce the average temperature in the room, but there will be no discomfort for the residents of the house. However, a decrease in heating indicators by about two degrees will save up to 20% of heat energy;

- thanks to the warm walls, it will be pleasant to be in any area of the room, and not only near the batteries, as is the case with traditional heating;

- in the hot season, it will be much easier to adjust the microclimate inside the room. For this purpose, you just need to activate the in-wall circuit for parsing water. This will solve two important tasks at once: firstly, the water supplied to the mixer will be warmer, and the temperature inside the room will become lower.

In order to design a high-quality and stably functioning in-wall heating system throughout the year, it is very important to follow all the above rules and recommendations.

Such work can be done with your own hands, but in the event of any difficulties, there is always the opportunity to resort to the help of professional and qualified specialists who are able not only to perform the necessary installation work, but also to provide detailed photos of such heating systems and detailed videos on them. correct installation.

One of the options for hidden heating pipes is shown in the video:

Pros and cons

Compared to brick chimneys, sandwich chimneys with wall brackets have the following advantages:

- quick installation;

- no high qualifications are required in furnace work and masonry;

- low cost;

- light weight, no capital foundation required.

The disadvantages include:

- shorter service life, after 5-8 years of constant use, the metal chimney must be replaced;

- brackets are prone to sagging;

- dubious aesthetic value, not every architectural style is in harmony with a metal pipe.

Criterias of choice

When choosing a bracket, consider the following factors:

- chimney diameter;

- maximum and average distance from the wall;

- wall material and pipe material.

With a small distance from the wall, plate wall mounts are chosen; with an increase in the clearance, you will have to switch to cantilever structures.

A small diameter pipe can be secured with a clamp on a hairpin; for heavy sandwich structures, a more reliable fastening will be needed.

Installation rules

In order for the chimney to be fixed securely and not to squirm under the gusts of wind, experienced craftsmen formulated the following rules for installing chimneys:

- it is necessary to fasten the pipe at least every 1.5-2 meters of its height;

- fasteners are installed in the middle third of the chimney section; it is unacceptable to fasten at the junction;

- tees and bypasses of the roof edge are mounted on powerful cantilever guides that can withstand the weight of the chimney part above them.

Before tightening the fasteners, make sure that the mounted part of the chimney is vertical using a level or plumb line.

In what cases are clamps used?

Fastening polypropylene pipes to the wall using clamps is recommended in cases where it is necessary to install large diameter pipes with a sufficiently heavy weight. The clamps are a design with a screw tie and a rubber inner gasket, which is necessary to compensate for vibration. As a result, they securely hold the pipe even in the event of strong vibrations.

The clamps are equipped with a dowel and a stud.

The mount can be made of metal or plastic. When laying polypropylene pipes, it is better to choose clamps from similar raw materials: this way you will ensure the same strength indicators for the entire structure. The mounting of the fixing material can be rigid or floating:

Rigid fastening is done by tightening the clamp very tightly around the pipes. Rigid hitching is required in places below the socket.

Thanks to the rigid fixation, the possibility of displacement of the communication system is excluded. The floating mount indicates the presence of a gap between the pipes and the clamp. The fastener is tightened in such a way as to allow free movement of the pipe. The mobility of the fastener provides the possibility of expansion of pipes during temperature fluctuations.

How the clamp is attached