Any building material has its own operational period. When it ends, you need to replace your worn-out product. This also applies to pipes. Today, polypropylene products are so easy to install that they make it possible to completely replace the heating / plumbing complex without much difficulty. You just need to know how to connect polypropylene pipes.

This material is good because the products have the following properties:

- Durable. They can cope with pressure drops and high temperature exposure without changing their own indicators;

- Long lasting;

- Resistant to corrosive effects;

- Easy to install. For installation, you just need to warm them up with a special device, make the connection through fittings. In order to connect a metal pipe with a polypropylene pipe, fittings are also used.

Instruments

Ease of installation is the first and main advantage of polypropylene pipes, in fact, additional materials and tools will be required.

- polypropylene pipes,

- pencil,

- clips for fixing pipes,

- roulette,

- couplings,

- Merilon heaters,

- corners. We need products of two types: at 45 and 90 degrees,

- MRV-eared. It is used for fixing the mixer,

- MRV and MRN outputs with iron thread,

- soldering iron,

- scissors for plastic products.

Installation

How to correctly install the system using polypropylene pipes, so that the result is durable, we will consider below. If you still have doubts about your skills, or you do not decide on an independent replacement of products, then forget about it forever. The fact is that, in addition, the incorrect soldering of such pipes can be corrected with couplings.

Advice! When choosing polypropylene products, be guided by the diameter of the dilapidated pipes, which will help to significantly simplify the installation of the entire structure.

Welded connections

Welded joints are one-piece. Technology for joining polypropylene pipes: when melting, macromolecules of one part will move to another (interdiffusion).

Melting from heating by an electric welding machine of parts with the same properties organically joins them.

Required tool

- Soldering iron for PP pipes and hacksaw for metal or scissors, tape measure.

- You will also need polypropylene pipes and fittings.: couplings for polypropylene pipes, corners, taps, fum-tape.

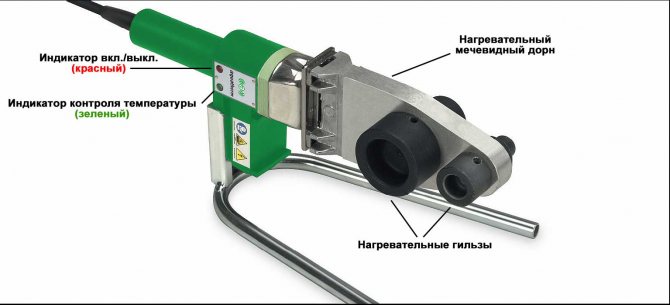

- The welding machine consists of a heating element itself and welding nozzles from 16 to 40 mm in diameter. When its indicator goes out, it means that the required temperature has been reached +260 degrees (in 10 - 15 minutes). At subzero air temperatures, welding is not carried out.

- For pipes with a diameter of less than 63 mm, socket welding is used.

- For pipes with a diameter of more than 63 mm, butt welding is suitable, which does not require any additional parts.

Manual device for welding polypropylene pipes

Socket Welding Procedure

- We cut the pipes at right angles.

- We put a mark - socket depth + 2 mm

Fitting the parts to be connected to the corresponding attachments

- We start the connection of polypropylene pipes by heating the parts with a heating device.

- Then we connect the parts.

- The connection of polypropylene with an aluminum interlayer is possible through perforated holes. This greatly increases the strength of PN 25 pipes.

- Thanks to fittings with brass and chrome inserts, pipes are well connected to steel parts, plumbing fixtures.Shaver is a tool for stripping reinforced pipes.

Welding parameter table

Butt welding

How to connect polypropylene pipes for outdoor sewerage?

By means of butt welding, which is possible if the wall thickness is over 4 mm.

- First, we will rip off the weld spots until they are parallel.

- We heat up, and with centering devices we ensure the accuracy of welding.

Butt welding

Important! When welding, we ventilate the room: polypropylene smokes and emits water vapor and carbon dioxide.

Having understood how polypropylene pipes are connected and observing safety measures, you can quickly and efficiently make any of their connections.

Did you like the article? Subscribe to our channel Yandex.Zen

Diffusion welding

Polypropylene products can be joined by several methods, but the most popular is diffusion welding. For reliable fastening of products, fittings are used here: couplings, angles and adapters.

Polypropylene pipes in the cold water supply system are guaranteed to last up to 50 years. For about a quarter of a century, they will be able to serve in the arrangement of warm water supply. Remember that the life of these products depends on the pressure and temperature of the water in the structure.

The polypropylene pipeline has a huge margin of safety, allowing it to withstand all transformations in the system. So, high pressure and low temperature indicators will not affect the duration of the products in any way. The same effect on polypropylene pipes will have a low pressure with a high temperature. But high pressure and temperature indicators, recorded in the system at one moment, will shorten the life of the products by 5-7 years. In domestic pipelines, there are no excessive loads that are talented to damage the pipes, so there is no need to worry about this.

Advice! Polypropylene pipes, for which permanent joints were used, cannot be subsequently disassembled.

Categories of polypropylene pipes

All polypropylene pipes are divided into:

- PN 25. The pipe withstands 2.5 MPa. It is used in heating systems and warm water supply systems.

- PN 20. A versatile pipe, talented to withstand 2 MPa. It can be used for cold and warm water supply, provided that the system temperature is not more than 80 ° C. A polypropylene pipe of this category belongs to products of great strength, since its inner part is reinforced with foil.

- PN 16. Pipe for low pressure heating systems and cold water supply.

- PN 10. Thin-walled pipe that can withstand a pressure of 1 MPa. It is widely used in underfloor heating structures (but at temperatures no higher than 45? C) and cold water supply (up to +20? C).

A video with good examples of the use of pipes of a certain category will help determine such a difficult choice:

How to connect a polypropylene pipe without the help of welding equipment

For the installation of plumbing systems, which are supposed to be operated at a low pressure level, the low-temperature method of connecting pipes is used. A special glue is used that allows you to connect a polypropylene pipe and a fitting at the molecular level. This type of connection is rarely used to install the entire system, it is a great way to repair the system in rooms with increased fire hazard, or to upgrade an existing system.

Important! After the completion of the installation work, it is necessary to wait some time, from 10 to 20 minutes, depending on the quality of the pipe and the type of polymer chosen for its manufacture.

The adhesive joint is ready for use after the layer of liquefied polymer has solidified, the manufacturer indicates on the packaging the interval that must be waited after completion of the work.

Fittings types

Connect two pipes made of different materials (iron and polypropylene) using special fittings. They also assist in connecting plumbing fixtures to steel fittings. Inserts on fittings are necessary for reliable fastening of products and they can be brass or chrome-plated. How to apply them correctly and where is better, we will not touch on at the moment, but consider only their varieties - these are:

- crosspiece,

- combined tees,

- couplings,

- angular ball valves and straight,

- plug,

- squares at 45 and 90 degrees,

- elbow (triple or for connecting monotonous pipes),

- pass-through water outlet,

- transition. It has an external thread or plastic type DG,

- welded saddle,

- combined couplings,

- combined elbows for pipes,

- combined elbows for devices.

Reinforced plastic and polypropylene

How to reliably connect a metal-plastic pipe with a polypropylene pipe? There are three main ways to create lines like this:

- by means of couplings and a pair of fittings designed for specific types of pipes;

- flanges with metal washers;

- using double-sided polyethylene couplings and fittings: the most reliable and proven method used for heating systems.

The fastening of the branch pipes is done by welding or using a thread. Fittings for metal-plastic are made only of metal. Flanges are not used in such systems. Fum tape provides additional sealing in the joint.

Fitting connection

Pipe joining movement

Bonding polypropylene products is a simple process, but it requires care and accuracy. In order to do everything right, you need to read the instructions that come with the soldering iron. It is better to carry out all work on soldering pipes in stages.

Let's make a diagram first! The new plumbing begins with the marking of taps, filters, bends and other details. After completing the drawing up of the detailed diagram, it is possible to proceed with the partial assembly of the pipeline. Some parts can be connected without soldering using glue, but others require a special tool. To make the soldering process easy, keep the pipes strictly horizontal.

In order to connect the pipes located vertically, you will need an assistant. The second person should only fix the product in its place, and you will begin to solder after removing the soldering iron from the stand. The last stage is the assembly of the remaining parts into a single structure. An assistant will also come in handy here.

To connect polypropylene products with a diameter of more than 63 cm, butt welding is used. This method of fastening products is considered the most reliable, and no additional parts are needed to carry it out.

Welding connection of polypropylene pipes

For welding products with a cross section of up to 6.3 cm, the preferred type is socket or socket welding. In this case, the pipes are joined using the 3rd part - the coupling.

To connect polypropylene pipes with a diameter of more than 6.3 cm, it is recommended to use butt welding.

Socket welding of polypropylene pipes

Figure 5. Table of welding time for polypropylene pipes.

A special welding machine with nozzles is used for welding plastic products (Fig. 4). The heating elements are made in the form of a sleeve for heating the outer surface of the pipe and a mandrel for heating the inner surface. Standard tips are equipped with a Teflon layer and have a diameter of 1.6 to 4 cm.

The welding machine is installed on a table or other horizontal base, with the help of special keys, replaceable heating elements are fixed. After that, the required temperature is set at which the device warms up for 10 minutes. The welding time for polypropylene pipes depends on their diameter (Fig. 5).

Socket welding is performed as follows:

- the ends of the elements to be connected are placed on the attachments;

- the required melting time is maintained according to the table;

- plastic products are removed from the attachments and connected to each other;

- the required cooling time is maintained.

Butt welding of polypropylene pipes

This type of welding can be carried out between products with a wall thickness of at least 4 mm. If their diameter exceeds 5 cm, then a special stationary welding machine is used for work. Such a device is also used when it is necessary to obtain a high-precision weld.

Before starting installation work, the connecting ends should be cut off, which will allow them to be parallel. After that, they can be heat treated using a special heating disc. In the process of work, it is recommended to use centering equipment. The sequence of joining works is similar to that of socket welding.

There is nothing difficult in joining polypropylene pipes. As with most building technologies, correct compliance with all established standards is required. In this case, the process will be performed not only quickly, but also will allow you to achieve a high-quality result.

Fusiotherm apparatus

Cold polypropylene pipes are wound and tightened in their places, after which the joints are processed with the Fusioterm apparatus. If welding of two ends of the products is required, then they must be inserted into a special hole in the apparatus. Then the soldering apparatus is turned on, allowed to warm up to 260 degrees, pipes are inserted into a special hole, withstand a set time, removed and connected.

Advice! The heating temperature must be controlled prior to welding.