Polypropylene used in the production of heating pipes allows them to withstand high temperatures (up to +75 ° C). Products made from this material do not conduct electricity and are lightweight.

In addition, they have low thermal conductivity, and not only professionals can install heating systems with their help. When installing polypropylene pipes with your own hands, take into account their diameter, linear expansion, constant pressure in the system and water temperature.

Advantages of polypropylene pipes

Polypropylene pipelines have become widespread due to the relatively low cost, high quality of products and other advantages of this pipe-rolling material:

- The low degree of thermal conductivity of the polymer product keeps the coolant temperature well.

- The low roughness of the inner walls of the pipes does not reduce the speed of fluid circulation along the circuit and increases the heat transfer of the network.

- A very simple and easy installation of the heating system, which even an inexperienced owner can handle, and the help of a professional welder is required to assemble a steel pipeline.

- Polypropylene pipes are not susceptible to rust and corrosion, which significantly increases the service life of the network.

- Deposits do not form inside PP products, so they do not form plugs and blockages, like their metal counterparts.

- Polymer pipes are distinguished by good flexibility, high mechanical resistance, high temperature and pressure resistance.

- The costs of organizing such a heating system are much less compared to other materials.

- Homogeneous brazed construction without threaded connections is characterized by high reliability.

- The service life of polypropylene heating pipes is on average 30 years.

According to the professional consultants of the Santekhnik Portal resource, polypropylene pipes are the best option for heating systems in a private house or country cottage.

Welding technology

Since only reinforced polypropylene pipes are used in heating systems, then when buying, pay attention to which type of reinforcement is used in the products you have chosen.

PP pipes can have external or internal reinforcement.

Pipes with external aluminum reinforcement are more readily available and therefore more commonly used. This type of reinforcement has almost no effect on the strength of the pipe, but is used to reduce the amount of thermal linear expansion. The use of such pipes somewhat complicates the installation process, since it requires the removal of the outer layer of aluminum by stripping over the entire length of the contact of the pipe with the fitting. In addition, the outer reinforcing layer can be damaged by mechanical stress on the pipe.

Pipes with internal aluminum reinforcement do not have this disadvantage. And, although they do not need to be cleaned, the cut edge of the product must be trimmed using a special tool. This is done so that the cut edge is strictly perpendicular to the outer surface of the pipe. When this condition is met, the cut edge above the reinforcing layer is fused with the layer below it, therefore, even at high pressure in the pipeline, water cannot penetrate between the PP layers and form bubbles in the thickness of the material, which ultimately lead to the destruction of the pipe.

Pipes with internal fiberglass reinforcement have the lowest linear expansion.

Another plus is that the melting points of fiberglass and polypropylene are very close, so there is no need to clean or trim the pipes. When heated, the fiberglass is fused with both layers of PP, forming a monolithic material. The cost of such pipes is the highest.

How do I select elements to assemble a path?

When choosing polypropylene pipes for heating, the technical characteristics must correspond to certain parameters, because the efficiency of the heating circuit depends on this.

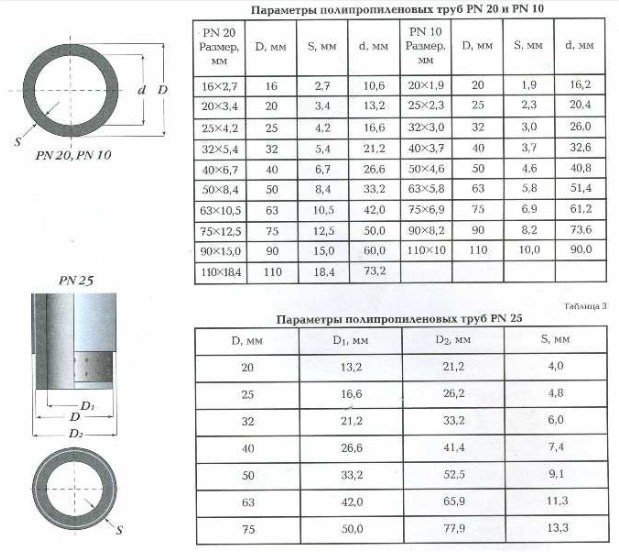

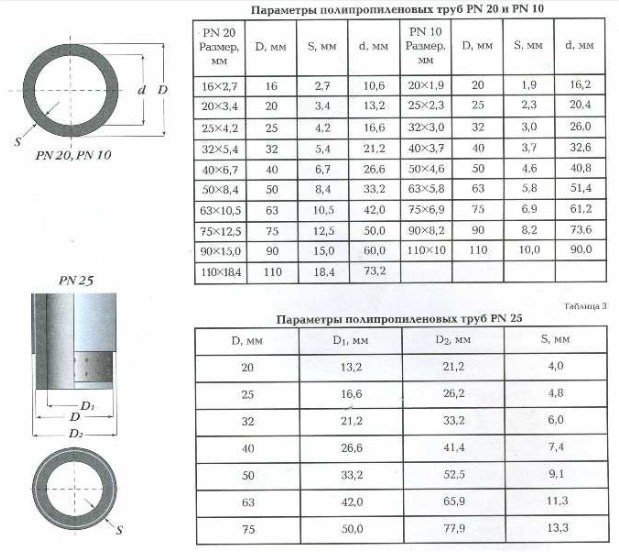

For the installation of hot water supply, the marking of polypropylene pipes for heating must contain the following indicators:

- PN 20;

- PN 25.

This designation indicates that the polymer can function in a system with a temperature coefficient of 90 ° C, and is able to withstand surges up to 100 ° C. Also, these pipes carry a pressure of 20 and 25 atm.

Attention! Reinforced polypropylene pipes with PN 25 marking are the best option for heating mains. The design characteristics of these products increase their strength and allow them to withstand high temperatures without deformation.

When choosing elements for assembling a heating circuit, you should pay attention to the following points:

- The appearance of the blanks. Their surface should be flat, rounded, without damage.

- The material of the products must be homogeneous.

- All parts must be distinctively marked.

To connect individual sections of the network, special fittings are used, without which it is impossible to assemble any heating circuit in a private house. The connecting elements differ in diameter and shape.

The following types of fittings are used for assembling the heating of the house, the mains made of polypropylene pipes:

- Clutch. The simplest part for connecting pipe sections of the same diameter.

- Adapter. Another simple element that is used for mounting pipes with different diameters.

- Corner. Used to connect the pipeline in sections with a turn. With this fitting, you can create a corner in the line without deformation. The corners are equipped with an external metal thread, which makes it possible to connect mixers and other plumbing fixtures.

- Tee. This part makes it possible to connect several pipes at the same time. They can be supplied with leads, both with the same diameter, and with different sizes of the branch pipe.

- Compensator. Since polypropylene tends to expand under the influence of high temperatures, expansion joints are used to protect the line from bends. These products represent a workpiece in the form of a loop, and are installed on sections of a long pipeline.

Attention! For a loop drawn around an object, it is necessary to set contours to prevent kinking of the pipes.

To connect polypropylene parts with metal elements, a type of fitting called "American" is used to achieve maximum joint strength.

When choosing fittings, close attention should be paid to their diameter, which must exactly match the diameter of the pipes. This parameter is indicated in the product labeling. It is best to purchase connectors from the same manufacturers as the pipes in order to achieve the best installation quality.

Preparation for the installation of the heating system

Such a responsible matter as the installation of heating requires careful preparation:

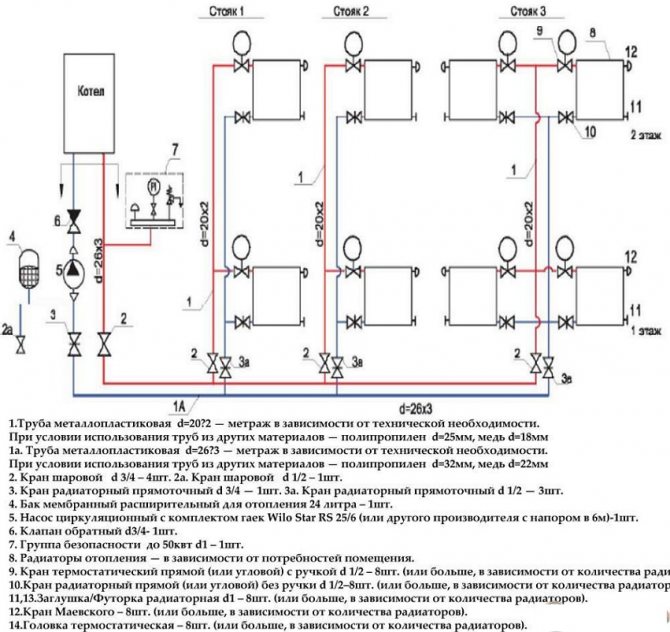

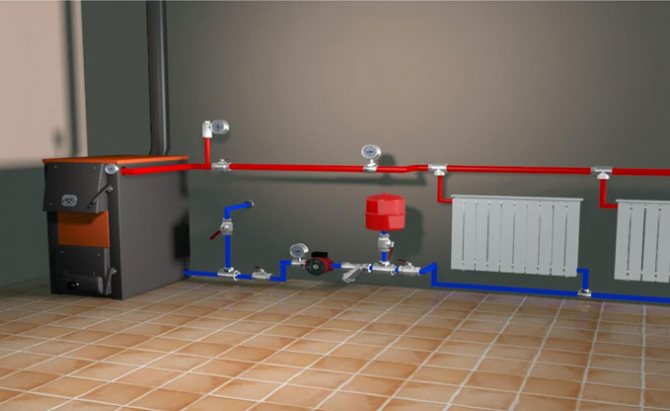

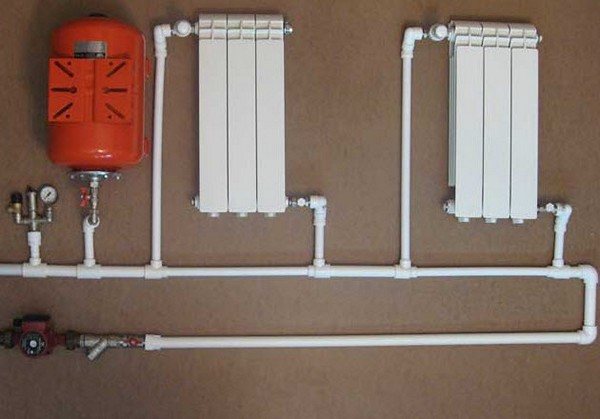

- To begin with, you need to develop on your own or with the help of specialists a diagram of the heating system with all the nuances: the layout of the mains, the locations of the heating devices, the boiler, the expansion tank, the pump (if provided), and shut-off valves.

- Next, you need to purchase equipment, according to the calculated characteristics.

- When purchasing materials, do not forget the connecting elements - fittings, taps and other elements included in the heating system diagram.

- You need to prepare such tools as a tape measure, a marker, scissors for cutting polypropylene pipes, a soldering iron with replaceable nozzles (an expensive tool can be rented).

If you have never soldered PP pipes before, then after harvesting all the necessary pipe sections of the future system, practice on trimming in making soldered joints.

Before starting work, you must also observe the following recommendations:

- Soldering of polypropylene pipes can be done at a temperature not lower than +5 degrees. Otherwise, the PP curing process will proceed too quickly, which will not allow the joint to gain the required strength.

- In order for the soldering to be successful, it is necessary to strictly observe the heating time of the pipe ends in the soldering iron. It can be viewed in special reference tables.

- It is desirable to treat the joints of PP products with alcohol.

Which boiler is best for a polypropylene system?

Before starting the independent assembly of a polypropylene heating system, it is necessary to select an appropriate source of thermal energy:

- Gas. If you plan to connect the heating main to the central gas pipeline, you should purchase and install the appropriate equipment. If there is a desire, it is allowed to abandon the classic chimney by choosing a model of the device with a closed combustion chamber and a coaxial chimney, through which air will flow to the boiler and exhaust gases are removed from it. At the same time, the air exchange pipe can be brought out into the street through a wall or even into a window opening.

- Electric. If it is planned to use electricity as a source of fuel for the boiler, then the choice of an automated boiler equipped with pumping equipment, the necessary safety devices, and an expansion tank will be the best solution. It is easiest to assemble such a heating line with your own hands.

- Solid fuel. This is the most NOT recommended heat source for a polypropylene system, but it is still acceptable. But in the case of using solid fuel as an energy resource, one should responsibly approach the competent development of a piping scheme in order to eliminate many mistakes. Since a solid fuel boiler outputs up to 1000 ° C, it is necessary to install additional piping elements and comply with a number of installation requirements.

Attention! The best option for organizing a polypropylene heating circuit is a modern wall-mounted gas boiler with protective mechanisms, the necessary pumps and devices for automatic control and management.

In the case of using a propylene pipeline, it is better to refuse other energy sources altogether.

Welding of plastic pipes using socket technology

Required tool

When connecting pipes up to 40 millimeters, an installation tool such as a hand-held welding machine is used. For the installation of wider pipes, a stationary pre-alignment device will be required.

Welding tool

The heating element that transfers the initiating heat to the polymer is a special sleeve that melts the outer surface, creating conditions for the boundary mutual diffusion of plastic molecules of the parts to be joined. Both the inner surface of the socket and the outer surface for the end of the pipe inserted into it are subject to heating.

The sleeves are removable parts, they are covered with Teflon, which prevents the melted material from sticking to the heating elements.

Pro tip: Nevertheless, the cleanliness of the working surfaces must be monitored and carefully cleaned from the residues of polypropylene after each working cycle with a rag or wooden spatulas, and this should be done to avoid damage until the polymer has hardened.

The stationary apparatus is installed on the surface so that it does not swing during operation. Before turning on, you need to select the nozzles and install them. If soldering is inconvenient due to lack of space, for example, when installing polypropylene pipes in the bathroom, it is better to involve an assistant.

Nozzles for pipes of different diameters

Socket brazing technology

The technology for installing polypropylene pipes provides for a number of rules:

- It is recommended to cut polypropylene pipes with a sharp knife or metal scissors at an angle of 90 °.

- If they are reinforced, the metal sheathing should be removed at the ends.

- Wear gloves to avoid burns.

- Next, the installation of polypropylene pipes is carried out directly: the instructions for the welding machine, read before starting work, will facilitate it, but, generally speaking, the nozzles should be warmed up to 260 degrees, a lower temperature will not give a strong connection. At the same time, overheating is unacceptable here, since it will lead to the destruction of the polypropylene structure, and even blockage of the pipe.

- Fittings should be welded quickly, checking the joint for distortions and uneven seams.

- After soldering, it is necessary to ensure the immobility of the connected elements relative to each other for a couple of minutes, until the seam hardens.

Socket brazing technology

Video tutorial on installation

Project and wiring diagram

If everyone can mount heating in a country house from polypropylene pipes, then only a specialist can correctly develop a project and a diagram of such a network.

When developing a system, it is required to take into account many factors that affect the performance of the circuit:

- Diameters of rolled pipe billets. The entire heating line is assembled and assembled from pipes of various diameters, which makes it possible to create optimal conditions for high-quality circulation of the coolant.

- Exposure angles of inclination. This is extremely important for a gravity system, and significant for a forced circulation network.

- The brand of the products used. It is recommended to install only reinforced blanks.

- The number and location of radiators affect the temperature characteristics of the room.

- Design features. Depending on this, options with a bottom or top type of feed are used.

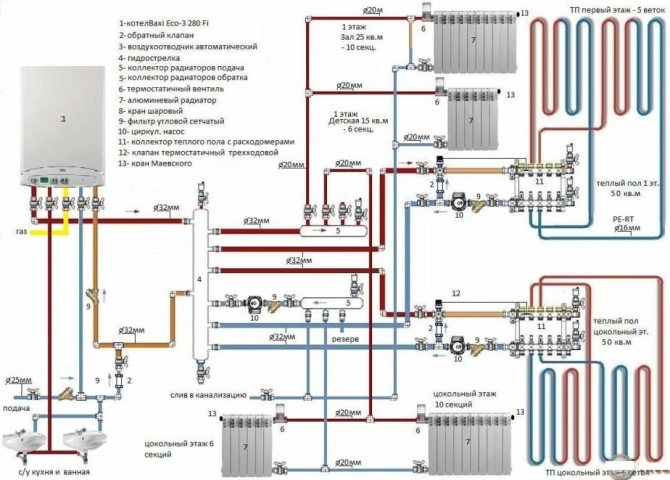

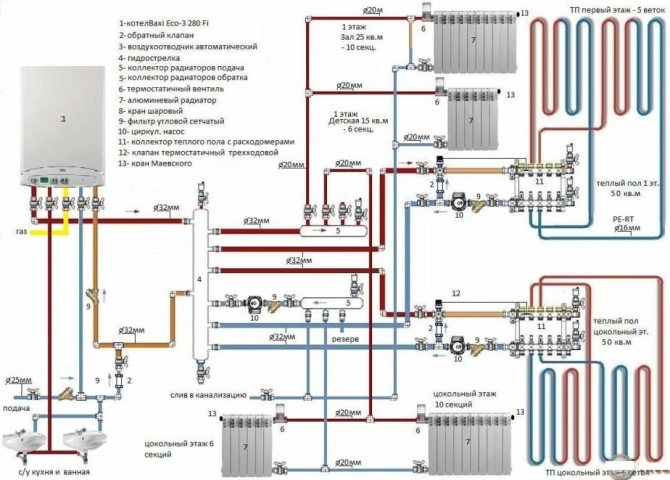

After a thorough examination of the individual structure, the specialist draws up a project, which indicates all the information about the materials used:

- diameters of the line;

- angles of inclination;

- places and methods of fastening, and installation of heating devices;

- boiler piping diagram.

Based on this project and scheme, an estimate is formed for the organization of heating from polypropylene pipes.

Choosing a heating system scheme

To make a heating system from polypropylene with your own hands, you should choose a pipe layout.

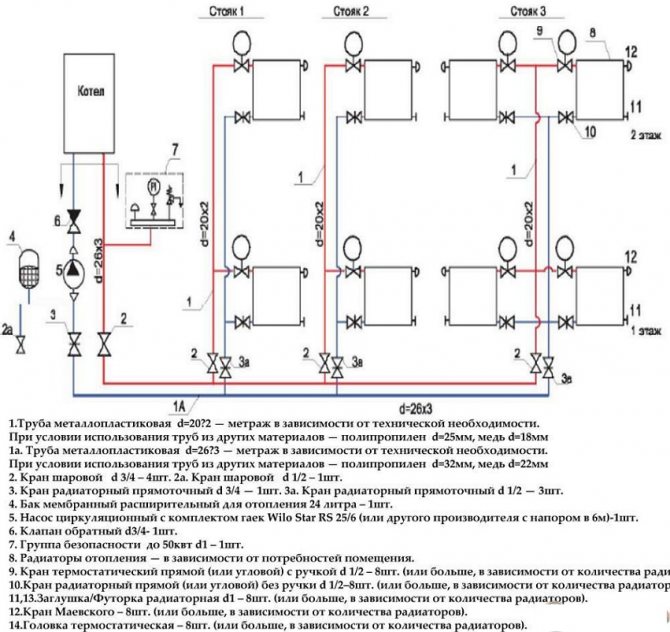

One-pipe wiring is considered the simplest and cheapest. Heating radiators are connected in series, the number of components of the route is small.

The wiring is arranged so that the farther from the heating unit the battery is, the less it will heat up. The water is cooled while driving on the highway. This is the disadvantage of such a pipe layout. It is also called "Leningrad" and is more often used in small houses.

When arranging a heating system with a collector circuit, more money will be spent, but the quality of heating will be higher. The heat in the house is distributed evenly.

The best option is a two-pipe heating system. The pipes fit into the floor or wall of the house.The return and supply lines are located in parallel. All batteries warm up evenly.

Soldering rules for polypropylene products

It is necessary to solder polypropylene pipe-rolls with a special device for soldering polypropylene. The parts that will be soldered are heated at a temperature of 260C, which ultimately creates a permanent connection with the same type of structure. At the same time, the atoms of the elements pass into each other, so the joint is very strong.

The soldering process is carried out in the following sequence:

- The soldering device is connected to the electrical network. It is allowed to start work after the signal indicator goes out a second time.

- The workpieces are cut to the required size. For this, special scissors are used.

- The edge of the pipe intended for soldering must be stripped from the foil to the desired value using a shaver and an ordinary knife.

- The pipe with the corresponding fitting must be put on special nozzles of the soldering device and withstand a certain time. The duration of the warm-up depends on the size of the workpieces.

- Further, the components are joined. In this case, you need to ensure that there is no skew, the elements cannot be moved and rotated.

Attention! Correct fittings placement is essential. If you set the angle in the wrong direction, then you will have to redo the entire node.

Often in the process of assembling the circuit, it becomes necessary to connect polymer parts with metal or metal-plastic pipes. Here you need to pay attention that the diameters of both types of workpieces match each other.

It is worth adhering to the following scheme when connecting polypropylene and metal pipes to each other:

- for connection to metal-plastic products 20 × 2 mm, polypropylene pipes with a size of 25 × 4.2 mm are used;

- PP pipes with a size of 20 × 3.4 mm must be connected to metal-plastic pipes with dimensions of 16 × 2 mm;

- to metal pipes with dimensions of 26 × 3 mm, polypropylene pipes with dimensions of 32 × 5.4 mm are connected.

If the pipes are laid to the radiators in the house from the main pipeline, and the wiring is carried out in accordance with the two-pipe scheme, a polypropylene pipe with dimensions of 20 × 3.4 mm should be laid.

The use of pipe products with a larger diameter does not make much sense. It also makes no sense to use radiator valves larger than 1.2 inches. Therefore, the statement that with an increase in the diameter of polypropylene pipes and thermostatic valves it becomes warmer in the premises, is not true.

Pipes for connection

During the installation of heating, you will have to connect plastic elements with metal-plastic pipes. Their diameters must match.

Connection rules:

- for metal-plastic pipes 20 × 2 mm, polypropylene pipes 25 × 4.2 mm are suitable;

- for pipes with a size of 16 × 2 mm, polypropylene products of 20 × 3.4 mm should be connected;

- for pipes with a size of 26 × 3 mm, polypropylene products of 20 × 3.4 mm must be connected.

Do not use pipes with a large diameter, this will not make it warmer.