Water frozen in a plastic pipe - what to do and how to fix the problem?

Winter prepares unexpected surprises for all of us, sometimes not very pleasant ones. When it comes to communication systems, their failure can turn out to be very deplorable. When it comes to metal communications, then their freezing can be predicted. Another thing is metal-plastic pipes, which are more resistant to frost. However, such pipelines often freeze.

We often hear from residents of private houses such words: water in a plastic pipe has frozen - what to do? It becomes especially offensive when there is no supply of drinking water in the house. Therefore, every home owner needs to know what to do in case of freezing of a plastic water pipe.

Often, the reasons for this phenomenon lie in the initially incorrect laying of communications. All waterways, regardless of the material, should be located at such a depth that does not freeze even in a very harsh winter.

If it is not possible to dig a trench deeply, then it is necessary to reliably wrap the pipes with heat-insulating and moisture-resistant materials. So what to do if the water supply is still frozen? Consider two cases when the water supply system is frozen inside and outside the house.

How to defrost a plastic pipe indoors?

When we say that plastic pipes are frozen inside the building, it means that there is free access to them. For example, they can be located in the attic or in the basement, that is, in places where there is no heating.

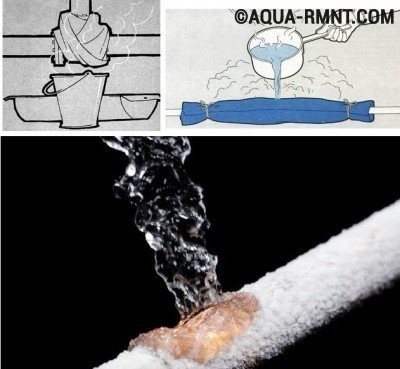

In this case, the defrosting process can be performed in several ways:

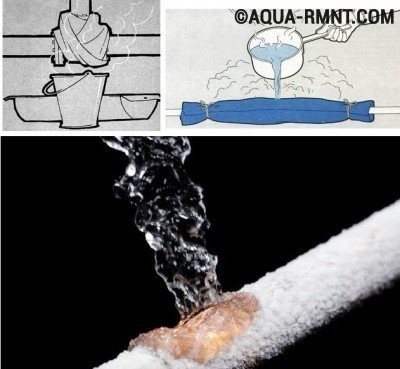

- Using hot water The frozen area is wrapped with a cloth and poured over with hot water. The operating time depends on the length of the ice plug. The defrosted pipe must be covered with insulation to prevent its re-freezing.

The place of freezing is determined by touch. Where the plastic pipe is colder, there is an ice plug.

- With the help of a construction hot air gun. A jet of warm air is directed from the hair dryer to the surface of the pipe. Despite the high efficiency of this method, such work is considered dangerous. If the air is too hot, the PVC may simply melt. Therefore, the temperature of the hair dryer must be set to a minimum.

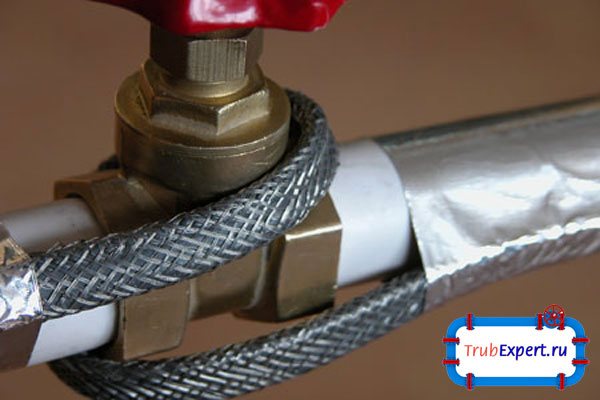

- Using electrical heating. The metal-plastic pipe is wrapped with an electric heating wire, which is connected to the mains. The wire is wound in turns. In the presence of a small frozen area, defrosting occurs quickly enough. Warming up a plastic water pipe takes up to 3 hours.

Attention! During the defrosting process, the water taps must be open, since the melted water must flow freely from the pipeline.

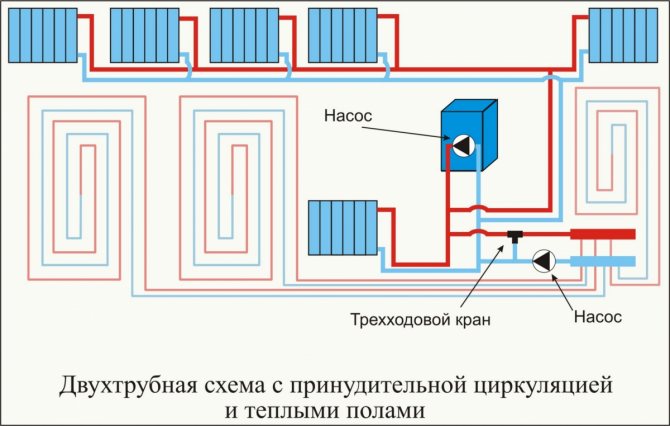

Forced circulation

Such a system is divided into two types:

- one-pipe

- two-pipe

The difference between them is quite large. The piping layout, their number, sets of shut-off, control and control valves are different.

According to SNiP 41-01-2003 ("Heating, ventilation and air conditioning"), the maximum temperature of the coolant in these heating systems is:

- two-pipe heating system - up to 95 ° С;

- one-pipe - up to 115 ° С;

The optimum temperature is from 85 ° C to 90 ° C (due to the fact that at 100 ° C, the water already boils. When this value is reached, you have to use special measures to stop boiling).

The dimensions of the heat given off by the radiator depend on the installation location and the method of connecting the pipes.Heat output can be reduced by up to 32% due to poor piping arrangement.

The best option is a diagonal connection, when hot water comes from the top, and the return flow is from the bottom of the opposite side. Thus, the radiators are checked for testing.

The most unfortunate thing is when hot water comes from below, and cold water from above along the same side.

If communications freeze underground?

The situation is much more complicated if a metal-plastic pipe is frozen underground. The easiest way is to dig a trench that is not very deep. After that, apply one of the methods used for defrosting indoor pipelines. However, in practice, this option is usually unacceptable due to the fact that it is very difficult to dig frozen ground, and the plastic pipe can be accidentally damaged. Therefore, we will consider alternative options.

Defrosting plastic water pipes with hot water

The heated water must be supplied to the inside of the pipe, directly to the ice plug. To do this, you need to disconnect the plastic pipe from the taps. Further work is carried out in the following order. Water is heated in an iron barrel. This can be done over a fire or heated in the house. A smaller diameter pipe or hose is inserted into the plastic pipe. The end of the hose should rest against the ice seal.

After that, you need to supply hot water from the barrel to the hose. This can be done using a pressure pump. Hot water will melt the ice quickly enough. The hose must be pushed forward through the pipe as the ice thaws.

When the whole plug has melted, water will pour out of the pipe with a strong pressure. Then the pump can be turned off. Heating a metal-plastic pipe in this way takes a little time. Preparation for the defrosting process takes much longer.

Tip: open areas of a plastic pipe must be covered with insulation to avoid re-freezing.

Defrosting with electricity

To do this, you need to take a rigid two-core wire and subject it to some refinement. One core of the wire is separated from the other and freed from the insulation. After that, the bare wire is rolled up into a twist. The second wire is folded back and also stripped of insulation. Twisting the wire is done in the same way. As a result of this operation, you should get a wire with two bare twists, located a couple of centimeters from each other.

Attention! During operation, the wires should not touch each other, therefore, the twists should be made very strong, not allowing the wire to unwind. Touching wires can result in electric shock.

The prepared wire is wound inside the pipe to the very ice obstacle, after which it is connected to the network. Heating of water and ice occurs due to the potential difference across the twists. In this case, the walls of the plastic pipe do not melt, since only the inner contents of the pipe are heated. As it defrosts, the wire must be pushed further down the pipe.

The disadvantage of this method is the need to pump out melt water from the pipeline. If it is not pumped out, it may freeze again. A compressor or pump can be used for evacuation.

You can also mention a few more ways to defrost plastic pipes, which are not available to every home owner.

In fairness, we list them:

- use of a steam generator. The steam generator hose is pushed inward through the pipe and steam is released under pressure. Since the steam temperature is higher than that of boiling water, the defrosting process is very efficient. If the plastic pipe is frozen, and you have a steam generator, then you do not need to worry about the pipes. The disadvantage of this method is that not everyone has a similar unit;

- defrosting by means of an autoclave. Hot steam is also used here.It is necessary to heat the water in the autoclave, and push the hose into the pipe. Connect the other end of the hose to the autoclave. As the water boils, the generated steam will go through the hose to the pipe and will melt the ice. Instead of an autoclave, you can use another appliance, such as a steamer.

- warming up by a hydrodynamic machine. This is a special equipment used for industrial purposes. The device creates increased pressure in the pipe, which breaks the ice in literally minutes. A special hose is inserted into the pipe as far as possible. After that, the machine is put into operation. After a couple of minutes, there is no ice in the pipe.

We have examined all the main methods for defrosting plastic pipes. Which of these methods to use, decide for yourself. And next year, try to eliminate the problem of freezing pipes.

In what way is it forbidden to heat technological pipelines - dangerous methods

When we want to heat the pipe from the ice on our own, we should know in what way it is forbidden to heat the technological pipelines. A prohibited way to heat pipes is to use an open flame. To heat ice, use only hot water, fallen or sand at a high temperature.

Fire should not be used, as there is a sharp change in temperature. The pipe may just burst. Metal pipes will still withstand this method of heating. But polypropylene or reinforced-plastic pipes will rupture.

This could lead to a fire and fire in your home. Not to mention the pipes themselves. Consider all safety measures when heating the pipeline and then you will be able to remove ice from the pipes without incident.

What to do when the water supply is frozen: 3 ways to defrost plastic pipes without digging

Plumbing needs to be laid wisely and done so that it functions smoothly all year round. But if mistakes were made during the installation, they will have to be corrected at the most inopportune moment. One of the worst consequences of poor plumbing is water freezing. Consider 3 proven methods for defrosting plastic pipes.

Winter, as always, comes unexpectedly! Let's imagine a situation - you wake up in the morning, there is a bitter frost outside the window, and water does not flow from the tap. An inner voice suggests that the pipe is frozen. What to do?

Often, the water supply system freezes underground, as well as in places of contact with the foundation and reinforced concrete structures. It is not possible to warm up the pipe outside in such places. Here you have to act remotely, inside a thin water conduit.

The principle of defrosting the water supply system is the supply of the coolant to the ice plug. This is very problematic to do. It is not enough to pour boiling water from a kettle inside - it will do nothing. The coolant must be supplied constantly, until the ice plug is completely thawed.

Where to start?

For those using the well, the first step is to make sure that the ice plug is in the pipe and not in the pump or in the street faucet.

This is done simply: the electric pump is disconnected from the water supply and turned on - water has gone, which means there is ice in the pipe. It happens that the faucet in the well freezes. Warm it up with a hairdryer. If there is no result, then the point is in the pipe and you need to choose a convenient way to fix the problem and start work.

It will be useful: Pipe insulation: thermal insulation materials for pipelines, pipe insulation with polyurethane foam, heat insulator

How to protect pipes from freezing

In some cases, defrosting of the heating system may not be noticed. During defrosting, pipes may burst, and as a result, the basement may be flooded. Of course, after such a situation, repairs will have to be carried out, which will require large costs. To prevent this situation, it is recommended to use modern systems that can prevent the coolant from freezing.

A good system is pipe de-icing. In such a system, a resistive cable is laid along the pipe. The cable should be close to the pipe. To protect short pipe sections, a resistive cable can be used, which is equipped with an additional thermostat. The cable can be used for long lengths of pipe. It is more advantageous to use a self-regulating cable.

The pipe de-icing system is also used in drinking water pipes. The only difference is the cable routing. In this case, it is laid inside the pipe.

Method one: defrost the pipe using a miniature boiler

If you decide to use these methods, then take security measures.

- When using a common water supply or well, warn nearest neighbors not to turn on the water while you are defrosting.

- Defrost from the top of the pipe. This is important, since melt water must not be allowed to drain under voltage - this is a guaranteed electric shock!

- Turn off the tap.

To make a boiler you will need:

- rigid two-core cable - 2 * 2.5–4.0 mm (copper, aluminum);

- plug;

- single-phase automatic machine for 10 amperes;

- insulating tape.

The cable will fit both two-core and three-core - the third core is not required.

The machine is needed to avoid a short circuit and overheating of the wire - it will not be cost-effective to throw it out after the first use. And also the use of an automatic machine will not allow the house to be de-energized in the event of a short circuit. The 10 amp breaker is taken from the approximate capacity of the device - it does not exceed 250 watts.

The length of the cable must be calculated from the length of the water supply. Here the principle is simple - the farther the plug, the longer the wire.

What should be done

- Install a plug on one end of the wire.

- Mount the machine on one wire at a distance of 30-50 centimeters from the plug. It is advisable to install it in a protective box, but if it is not there, then insulate the open places.

- Strip the other end of the wire from the braid by 20 cm, strip it by 7-10 cm, and then make two insulated coils from each bare wire. The number of turns on the coil is 3–6. The more turns, the more powerful the device. The distance between the coils is 1.2–1.5 cm.

The device is ready - proceed to defrost

Be sure to turn off the water! When defrosting, water will pour out of the pipe under pressure. This is dangerous because an electrical device with exposed elements is operating inside.

The first step is to disconnect the pipe at the highest point and open access to the water supply. It is better to carry out the procedure from home.

The remaining water must be drained from the disconnected pipe - the working area must be dry. If there is water to the brim in the lower, frozen pipe, it should be pumped out a little so that it does not go out during boiling.

Further, with an unconnected wire, we grope for an ice plug. When the wire rested against it, we plug the device into an outlet.

The water is heated depending on its amount in the water conduit. This may take 5-15 minutes.

After the water has warmed up and the ice has begun to melt, move the boiler close to the ice plug. It is necessary to push the boiler until it is completely thawed.

Useful Tips

If a large section of the conduit is frozen and it takes more than 20 minutes to defrost, then it is advisable to interrupt the procedure for 5-10 minutes.

Pour salt water into the pipe to be effective. It has better electrical conductivity and will increase the power of the boiler.

Method two: we create a circulation of hot water in a frozen pipe

The principle is based on the constant supply of hot water to the ice mash. So, we are making a water circulator!

For the manufacture of the device you will need:

- washer reservoir or vehicle fuel pump;

- car battery or household step-down transformer (power supply);

- wire, clamps;

- a tube from the hydraulic level or any plastic tube of a suitable diameter;

- capacity (basin, bucket);

- kettle or boiler;

- water, salt.

Useful Tips

It is not necessary to remove the washer from your car, especially if it is a foreign car. You can easily buy it in the store, new or used by advertisements. The price of a VAZ washer is from 200 to 700 rubles.

And the fuel pump can also be used. If it is not in the garage, then you can buy a used one for no more than 1000 rubles.

The pipe or hose must be matched to the length of the water pipe.

When using a hydro-circulator, use clean water.

For large pipes, a rubber hose such as oxygen can be used.

What to do when using a washer

- Connect the tube to the reservoir.

- Place the tube in the water line until it freezes.

- Heat salt water to a temperature of 60–70 degrees.

- Pour water into the tank.

- Connect the washer to the power supply.

Hot water will begin to flow into the water line and melt the plug. As the defrost proceeds, the pipe must be advanced to the place of the blockage. Hot water must be constantly refilled so that the tank does not run empty.

Salt will speed up the defrosting process, and will also prevent water from freezing if work is carried out in severe frost.

What to do when using the pump

- Connect the tube to the pump, securing it with a clamp.

- Connect the pump and prepare it for operation.

- Pour salt water into a container and place a boiler.

- Place the container under the pipe so that the water is drained back.

- Place the tube into the water supply.

- Place the pump in a container.

- Turn on the boiler and wait for the water to heat up.

- The water is hot - turn on the pump.

Useful Tips

Water should not be heated more than 70 degrees. The heated tube will soften, making it difficult to advance.

As it thaws, the pipe should be advanced close to the congestion.

If there is an angle connector on the water supply and the tube does not move, then it is worth increasing the water temperature to 90 degrees and maintaining circulation. Hot water will have a positive effect anyway, but it will take some time.

Defrosting pipes with bends

If freezing has occurred in a pipe with bends or bends, a sufficiently rigid oxygen hose is used. A light watering hose for defrosting pipes using this method is unsuitable: hot water will soften it and cannot be pushed through.

If a frozen pipe has several turns, bends or layering at different levels, then the question of how to defrost the pipes can be successfully solved by effective and affordable improvised means.

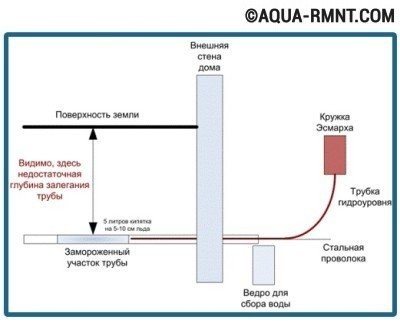

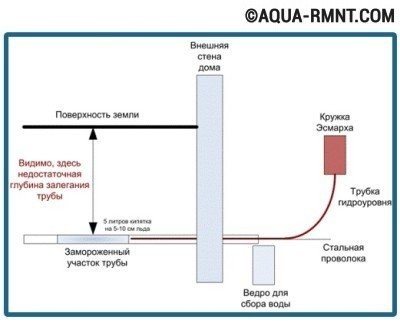

This is a steel, hardened wire with a diameter of 2 mm or more and the presumably required length, a building hydrotechnical level of the same size and an Esmarch mug - an enema or a large funnel, since it will take a lot and for a long time to fill it.

- The steel wire, as well as the hydraulic level tube, must be aligned and screwed, bending the end of the wire with a loop for rigidity, to the level with insulating tape. Let the end of the tube protrude 1 cm in front of the wire - the wire does not stick out, does not scratch the tube and does not slow down from this when moving forward.

- At the other end, attach the level tube to the Esmarch mug and push the wire and tube into the tube until they hit the ice. Since the diameter of the level tube is smaller than the diameter of the water pipe, and besides, it is very flexible, therefore the spring tube easily passes through the pipe, overcoming any turns.

- Then, for an accelerated solution to the problem of how to quickly defrost the pipe, we pour very hot water into Esmarch's medical mug or funnel, and put a bucket under the water pipe: after all, how much hot water we fill, so much will pour into a bucket of cold water. You must first fill up to 10 liters of hot water, and only then push the pipe further.

- As the ice melts, gradually push through the tube with the wire.

This process is long and takes on average 1 hour to release 1 meter of frozen pipe.

- To speed up the solution to the question of how to quickly defrost pipes, ordinary kitchen salt dissolved in hot water will help. The solution must be very concentrated - we do not regret the salt. This method is the most effective, works great and has been repeatedly used even by professionals in the case of an ambulance, and the costs are minimal.

Advice!

Having successfully solved the problem of how to defrost a pipe in the ground, it is necessary to ensure an abundant flow of water: let water constantly flow from the tap in a thin stream.

This will prevent new freezing, because the ground around the pipe is frozen and the possibility of a repetition of the trouble is not excluded.

- In the summer, you will have to protect the pipes from freezing by properly covering it with plates of extruded polystyrene foam or other insulation: glass wool, mineral wool, and so on.

Method three: we warm the water supply with a homemade steam generator

When the farm has a steam generator, then there are no questions, but if not, then you can quickly make the simplest installation.

To make a steam generator you need:

- sealed container: flask, pressure cooker, gas cylinder;

- a tube from the hydraulic level, any silicone or plastic tube of the required length;

- fitting for the size of the tube, gaskets for the fitting;

- clamp.

You can also use as a container: a freon cylinder, a fire extinguisher, a receiver from KAMAZ, in general, what is found on the farm. You can even adapt a moonshine still, but those who have it know the device perfectly and do not need advice.

What should be done

If you are using a jar or an old pressure cooker, drill a hole in the lid and install the fitting.

When using a gas cylinder, the union must be welded into the upper part of the container. The tap must be turned out - water will be poured into this hole.

After the fitting is installed, a tube is attached to it with a clamp. Further, water is poured into the container, about 1/4 of the volume, sealed and heated to a boil. Any heat source is suitable for heating: a gas and electric stove, a blowtorch, in extreme cases, a kindled brazier.

After boiling, the water is converted into steam and begins to come out of the tube. The tube must be placed in the water conduit and pushed through as the ice plug thaws. Steam effectively melts the ice - you don't have to wait long for the result.

From the author

I faced this problem twice and both times I used the first option. It is inexpensive, fast and efficient, but be careful when using electricity!

Learn on: how to prepare engineering systems for winter; how to prepare a bathhouse for winter, which will not be heated; and also watch a video on how to build a house for a penny on a small plot.

Emergency defrosting of a plastic pipe: professional advice

If there is no water in the tap, and it is cold winter outside, then there is a high probability that an ice plug has formed somewhere in the water supply system. In harsh climatic conditions, it is necessary to protect communications from freezing, a frozen pipe leads to a lack of water in the tap and to significant financial losses when eliminating the accident. It is much cheaper to anticipate possible problems at the construction stage than to warm up a frozen water supply in winter.

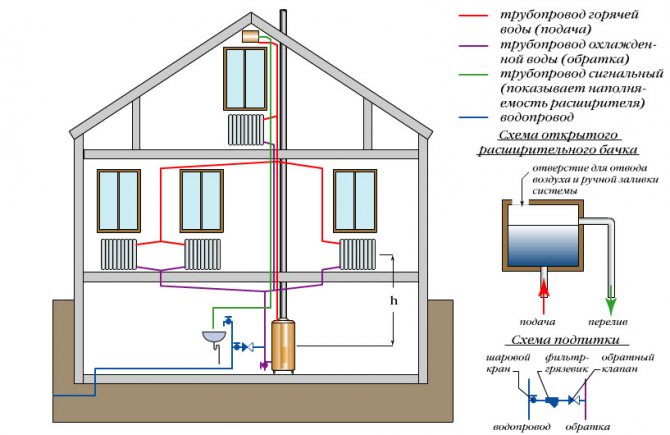

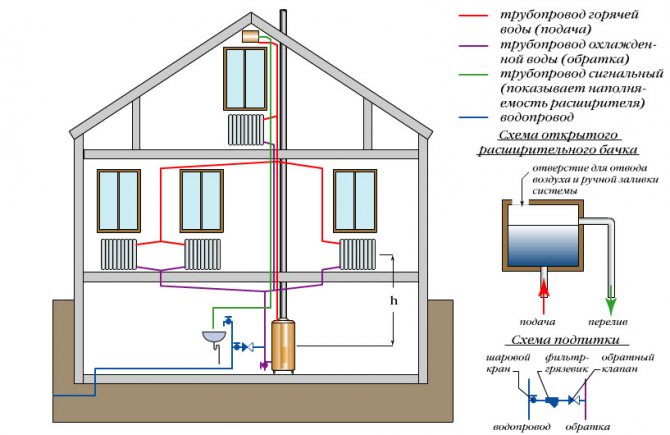

Natural circulation

The coolant circulates without interruption. This is due to the fact that the change in temperature and density of the coolant occurs continuously. Because of this, heat is distributed evenly over all elements of the natural circulation heating system.

The circulating water pressure directly depends on the temperature difference between hot and cooled water. Typically, in the first heating system, the coolant temperature is 95 ° C, and in the second 70 ° C.

Causes of freezing of the pipeline

Often the cause of freezing is an error in the calculations at the construction stage.The worst case is the freezing of the underground water supply system. It is difficult to find a water pipe underground, and there is a very high risk of damaging the plastic in frozen ground. There are several simple rules, the observance of which will help to avoid problems during operation:

- the smaller the pipe diameter, the deeper the trench;

- when laying a water supply system, take into account the freezing of the soil in the most severe winter;

- if it is impossible to dig a trench of the required depth, provide thermal insulation;

- so that the water does not stagnate, lay the pipe with an inclination towards the source.

It will be useful: Preparing the land in the greenhouse before planting: how to treat the soil in the greenhouse, replacing phytosporin in the soil, potassium permanganate

Typically, the pipeline freezes in border areas, between the ground and the air, between the air and the wall. The use of plastic pipes can only partially solve this problem. Although the thermal conductivity of plastic is lower than that of metal, additional thermal insulation is required.

Passive methods of insulating a water pipe

It is necessary to take measures so that the water in the pipe under the ground does not freeze in a private house at the stage of construction of the building (laying of communications). For this, passive, that is, without the use of energy sources, methods of protecting the pipeline are used. These include:

- installation of a trench for an external highway below the freezing depth by 15 ... 20%;

- backfilling of the trench and backfilling of the pipe with crushed stone, expanded clay or other material, providing a quick drain of water seeped from the surface;

- the use of thick-walled large-diameter pipelines, the creation of a slope towards a well or well;

- organization of a heat-insulating layer around the pipeline and the places of its connection with in-house communications;

- joining the mains with the water supply and / or sewage system inside the house with easily removable elements - this will allow you to quickly check the pipeline for the presence of ice plugs and eliminate them.

External methods of defrosting plastic pipes

There are several options for defrosting the outside plumbing. Before starting to eliminate the accident, you need to find out where the ice plug formed. This is done by touch, where the coldest area is - there is a problem. To prevent excess pressure from damaging the pipes and to ensure the release of melt water, be sure to open the tap before defrosting. The easiest way to heat the water supply is with hot water, steam, or electricity:

- With boiling water. The pipe is wrapped with a rag and sprinkled with hot water. In this case, the temperature is increased gradually so that the pipe does not crack. A good way for open areas, the only drawback is a large amount of dirt at the accident site. On the street it does not matter, but indoors it can cause certain inconveniences.

- Warming up with warm air. Use a building hair dryer, or supply warm air in another way. Well suited for pipes made of metal, a plastic pipe with this option for eliminating an accident can melt, you need to carefully monitor the air temperature. The thermal conductivity of a plastic pipe is lower than that of a metal pipe, so this method is far from ideal.

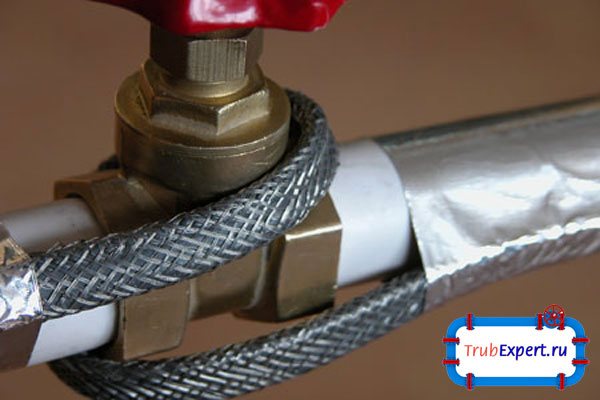

- Heating by electric current, using a cable from the "warm floor" system. The area where the water supply is frozen is wrapped with foil, with a wire on top. A layer of insulation is wound on top, all this is fixed with tape, defrosting occurs in 2-4 hours. For pipes made of plastic, this method is optimal, but requires additional equipment.

Plastic and metal-plastic water pipes should never be warmed up with an open flame.

This method is common for various types of defrosting, but fire is destructive for plastic. The material from which the pipe is made melts very easily.

- Heating with steam takes place through a heat-resistant tube inserted into the water supply. Its diameter is selected in such a way that the drainage of melt water is ensured. One end of the tube is pushed onto a steam generator or pressure cooker, the inner end is inserted into the water supply until it stops. If there is no steam source in the house, hot water can be used. It is advisable to fill it through a pressure pump. If there is no pump, use a funnel, however, it is more difficult to warm up the frozen area in this way.

- Unlike metal, plastic water pipes can be warmed up with a homemade electric boiler. For this, a wire is taken, its ends are stripped. Bare wires are fixed at a distance of 1 to 3 cm, the distance depends on the width of the pipe. The resulting structure is inserted into the pipe until it stops, up to the plug. After that, a current is applied, as the ice is defrosted, the wire moves forward. When carrying out work, it is necessary to ensure the pumping of melt water, otherwise it may freeze again.

In most cases, you can solve the problem of frozen pipes on your own. However, sometimes it cannot be overcome without the help of specialists. A hydrodynamic machine, an autoclave, a powerful steam generator - these expensive mechanisms are unlikely to be required by everyone, but the availability of such equipment by professionals helps to quickly cope with a difficult situation.

Calculation of the optimal temperature of the heater

Most importantly, the most comfortable temperature for human existence is + 37 ° C.

When choosing a radiator, you need to calculate whether the thermal power of the device is enough to heat the room. There is a special formula for this:

S * h * 41: 42,

- where S is the area of the room;

- h is the height of the room;

- 41 - minimum capacity per 1 cubic meter S;

- 42 - nominal thermal conductivity of one section according to the passport.

Please note that a radiator placed under a window in a deep niche will give almost 10% less heat. The decorative box will take 15-20%.

When you use a radiator to maintain the required room temperature, you have two options: you can use small radiators and increase the water temperature in them (high temperature heating), or you can install a large radiator, but the surface temperature will not be so high (low temperature heating) ...

With high temperature heating, the radiators are very hot and burns if touched. In addition, at a high temperature of the radiator, the decomposition of the dust that has settled on it can begin, which will then be inhaled by people.

When using low-temperature heating, the appliances are slightly warm, but the room is still warm. In addition, this method is more economical and safer.

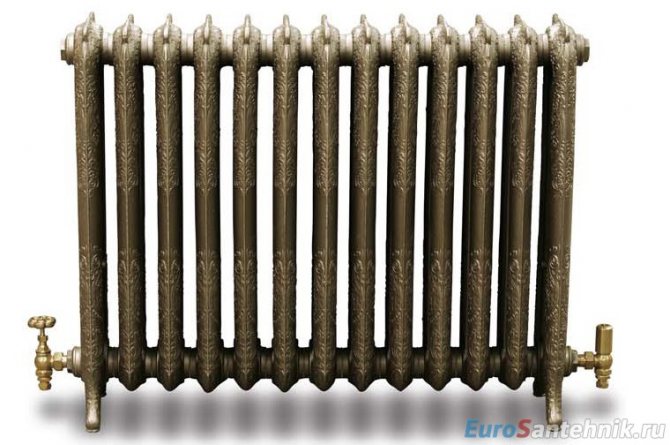

Cast iron radiators

The average heat output from a separate section of a radiator made of this material is from 130 to 170 W, due to the thick walls and the large mass of the device. Therefore, it takes a long time to warm up the room. Although there is a reverse plus in this - a large inertia ensures a long retention of heat in the radiator after the boiler is turned off.

The coolant temperature in it is 85-90 ° C

Aluminum radiators

This material is lightweight, easy to heat up and with good heat dissipation from 170 to 210 watts / section. However, it is negatively affected by other metals and may not be installed in every system.

The operating temperature of the coolant in the heating system with this radiator is 70 ° C

Steel radiators

The material has an even lower thermal conductivity. But by increasing the surface area with partitions and ribs, it still heats well. Heat output from 270 W - 6.7 kW. However, this is the power of the entire radiator, and not of its individual segment. The final temperature depends on the dimensions of the heater and the number of fins and plates in its design.

The operating temperature of the coolant in the heating system with this radiator is also 70 ° C

So which one is better?

Probably, it will be more profitable to install equipment with a combination of the properties of an aluminum and steel battery - a bimetallic radiator. It will cost you more, but it will also last longer.

The advantage of such devices is obvious: if aluminum can withstand the temperature of the coolant in the heating system only up to 110 ° C, then bimetal up to 130 ° C.

Heat dissipation, on the contrary, is worse than that of aluminum, but better than that of other radiators: from 150 to 190 W.

Crash eliminated, what's next

After eliminating the traffic jam, it is time to think about preventing a similar situation in the future. To do this, you can do the following:

- If the water supply pipe is frozen underground, most likely a leak has formed or the waterproofing is broken. Yes, it is difficult to carry out repair work in winter, but with the onset of the warm season, you will have to do it.

- If there is a plug in the places where the pipe passes through the wall, additional heat and waterproofing is required. You may need to widen the hole in the wall to do this.

- Open sections of the pipeline can be provided with additional thermal insulation and an electric heating system with a self-regulating cable. It is not necessary to keep the heating system on all the time; 15-20 minutes a day is enough.

- In the event of an abnormally cold winter, it is sufficient to keep the water tap open as a temporary measure. Yes, the action will lead to additional costs, but the constant flow of water will not allow it to freeze.

PVC pipes are more resistant to freezing, they can withstand up to three freeze-thaw cycles. However, you should not test them for strength, it is better to prepare in advance and not experience problems with water supply for many years.

How to quickly defrost plastic water pipes underground

Pipes freeze for various reasons: insufficient laying depth, lack of insulation, small volume of transported water, use of the pipeline in frost. Defrosting a water supply system in an accessible place does not cause difficulties. The question of how to defrost a plastic water pipe underground requires attention.

Nowadays, high-density polyethylene pipes are used for water supply, which does not deteriorate when freezing, has anti-corrosion properties and does not conduct electric current. But heating the water supply system is not possible by all available methods.

Active methods of protecting pipes from freezing

If simple insulation and deepening of communications does not ensure trouble-free operation, you have to look for other methods of protection.

- Heating of a pipe with a cable. This creates a uniform heating of the pipe to a temperature that prevents the liquid from freezing in it, regardless of the ambient temperature.

- Increase in pressure and / or temperature of the fluid in the pipe. This allows you not to fear the occurrence of ice plugs even in severe frosts.

- Creation of a heat-insulating layer around the pipe with rigid protection from the environment ("pipe in pipe").

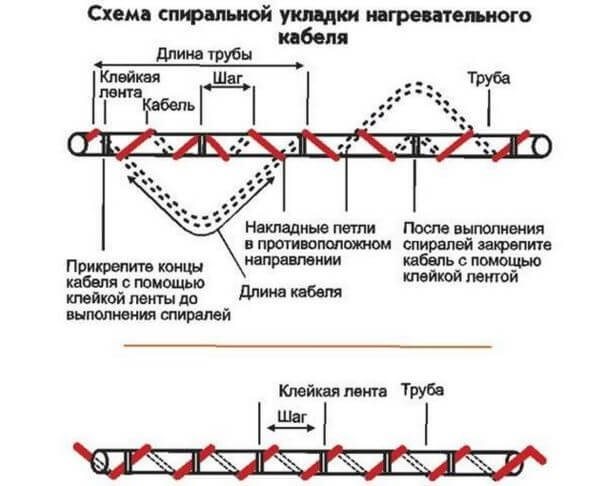

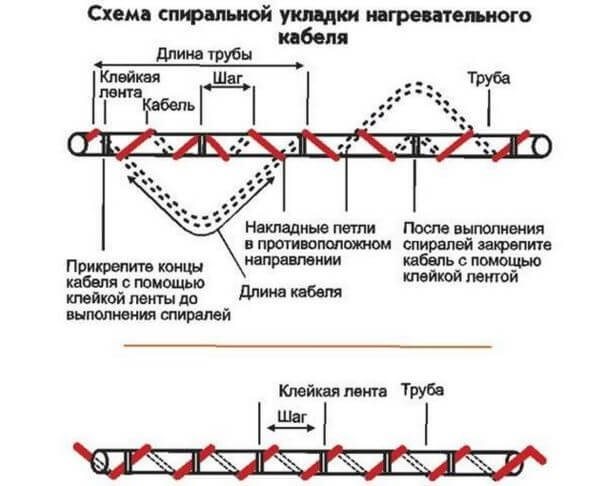

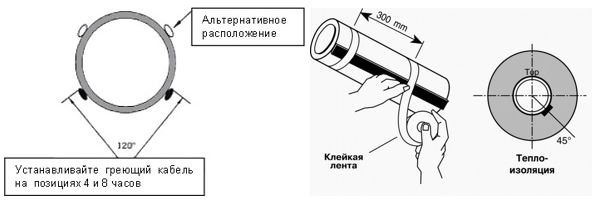

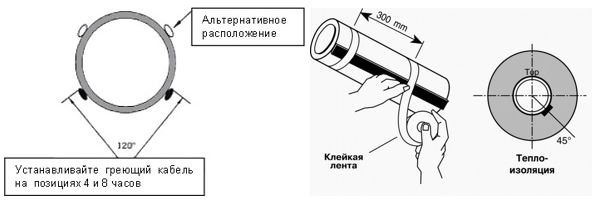

Thermal insulation is useful for any option for heating a pipe, the presence of a hard shell (pipes of a larger diameter) allows you to protect the site from mechanical stress and subsidence of the soil. Increasing the pressure or temperature in the pipe is not possible in all types of water supply. Therefore, the option with cable heating of the main line in the presence of a heat-insulating layer is considered optimal. The principle of such heating is shown in the diagram.

In order to insulate the pipe in this way for the winter, you must:

- calculate the pitch of the winding spiral (usually 10 ... 15 cm);

- with this step, wind a spiral of foil tape around the pipe;

- wind the cable over the tape without tension, fixing it with foil tape from above (also in a spiral);

- arrange thermal insulation over the pipe with the cable;

- fix the thermal insulation material by winding with sanitary tape or in another way, paying special attention to the joints of the insulation fragments.

Depending on the conditions under which the heating cable is being installed (before or after pipe laying), either sequential winding with periodic fastening is used, or overlapping of overhead loops in different directions.

If, for some reason, spiral winding is impossible or undesirable, use a straight gasket.

The joints between the individual sections, the places where the pipe exits to the surface are insulated separately and additionally, so that it is possible, if necessary, to dismantle the insulating layer for repair or inspection of the pipeline.

For more efficient operation of the heating system, in addition to the power supply cable, temperature sensors are installed. They are located evenly along the entire length of the section (usually 3 ... 5 pieces are enough) and either use the control system to send data on a critical drop in pipe temperature to an external device, or give a command to increase the current in the heating cable.

You can also insulate pipes in a private house using a self-regulating cable inside the pipe. However, the installation of such a device requires good skills and knowledge; it is difficult for a layman. In addition, such heating of communications can be arranged only during their initial installation. The installation process is covered in the video.

When deciding how to insulate a sewer pipe, it is worth giving preference to external thermal insulation and heating. This is due to the increased chemical activity of household wastewater, which quickly destroys even the sheaths of heating cables that are resistant to biological effects.

How to find a frozen area

Before defrosting a frozen water supply, find the place where the ice block has formed. Search methods:

- Visual inspection. When freezing, the liquid increases in volume and leads to swelling, the place of freezing is colder to the touch.

- Internal check. If complete inspection is not possible, use flexible wire or rope. The area where the cable does not go further will be the place where the plug will form.

How to thaw the icy area will depend on the availability of free access to the problem.

Small energy source.

Electric boiler as a small source of energy. Simple but not cheap option.

In order for the heating system to survive a cold night or several frosty days, a small source of energy can be provided, with sufficient power to keep the system from freezing. It can be an electric boiler or heating element built into a solid fuel boiler. You can also use a gas or electric water heater connected to the heating system. I also do not exclude the possibility of connecting a gas or liquid fuel burner with low fuel consumption to the main solid fuel boiler. Now on many solid fuel boilers already at the plant they provide for the possibility of installing a burner. So here, it all depends on your imagination and the state of your wallet. Naturally, all this will work only in the case of forced circulation.

Effective ways to solve the problem

It is difficult to heat a water pipe in the ground. In this case, it is impossible to apply external thawing methods. We'll have to defrost the system from the inside. Let's take a look at some of the common ways to remove ice plugs.

Hot water application

Prepare a metal-plastic branch pipe, the cross-section of which is 2 times smaller than the diameter of the main pipe. Gently bring it inside the pipe to the frozen area and pour boiling water, which will gradually wash away the ice. When defrosting water pipes using this method, do not forget to turn on the tap so that the pressure in the system remains low.

Heating with a building hairdryer

This heating method is suitable for a water supply system that is located in the public domain. An air stream is directed to the icy area. To avoid deformation of the plastic, the temperature of the hair dryer should be set to a minimum. After heating with hot air, wrap the section of the pipeline with insulation.

De-icing with electric shock

It is permissible to fight pipe freezing with a welding machine. But it should only be used to thaw a water supply system made of steel, copper and other metal products.

Metal is a conductor of electric current. Electrons and ions under the action of an electric field, moving and colliding with each other, form energy. The latter turns into warmth. Plastic is not conductive. Therefore, it is senseless and irrational to use a welding machine on plastic products.

Soldier's boiler for plastic pipes

Due to its salt content, water is an electrolyte. Therefore, to heat it up, you need a pair of energized electrodes. This method is only suitable for a polyethylene water supply system and is based on the principle of the boiler.

You will need: a two-wire copper wire and steel wire, tools. Wire strands are stripped and wrapped around the wire. Make sure that the turns do not come into contact with each other, as a short circuit may occur. A plug is attached to the free end of the wire. Lower the homemade boiler into the pipe to the cork made of ice, plug it into the network. After a while, the water supply will warm up, the icing will melt.

How to prevent system freeze

To do this, remember the following:

- Lay the pipes at a sufficient depth, below the level of freezing of the earth.

- The water supply system should not run next to reinforced concrete structures (foundations, beams and supports), since this material has a higher thermal conductivity. If you cannot find another place for laying, insulate the pipes.

- Those places where the sewerage passes through the walls of the building are recommended to be insulated with polyurethane foam, glass or mineral wool.

- Use pipes with a diameter of at least 50 mm.

- When choosing between polymer products, remember that polyethylene reacts stably to the freezing and thawing process. Polypropylene may burst after two defrosts.

- If the pipeline does not work regularly in winter, then it is better to drain the water from the system.

It will be useful: White ceiling what walls and floor: gray-white walls in the interior, why white, orange floor and varnish, manufacturers

It is also possible, if possible and finances, to lay a heating cable.

Heating cable application

The cable is used to heat the water supply system and prevent freezing of plastic and metal pipes. Nuances in use:

- the operating time of the device should not be constant, night time is sufficient;

- It is recommended to use the heating cable immediately when laying a pipeline section that is prone to freezing;

- the device is divided into 2 types: a cable with a self-regulation function and a simple one.

Subject to the conditions for laying the plumbing system, you will not have to face the problem of freezing.

Put your likes, subscribe to our channel and you will not miss many more useful articles! And visit our website, there is still a lot of useful information regarding pipes.

How to warm up a frozen water supply system: an overview of 5 effective ways to solve the problem

Owners of private houses often face a situation in winter when it suddenly turns out one morning that the water from the tap is not flowing: the water supply is frozen. There are several reasons why water freezes in the water supply system: a decrease in the air temperature outside to extremely low temperatures, insufficient depth of pipes (without taking into account the depth of freezing of the soil), the water in the pipe is stationary due to low or zero flow (at night or in the absence of owners ), insufficient insulation of pipes.Usually, all of these reasons, taken together, lead to freezing of the water supply system. What to do, is there a way out of this situation, after all, without water, as you know - and not there, and not here? Yes there is. Consider some ways to warm up a frozen water supply, which, however, will require a lot of patience and some skill from you.

At what temperature does water freeze in pipes: we save pipes from freezing (video)

The stable operation of the pipeline in the house is the result of careful maintenance of the pipes. This is especially true in winter. When severe cold sets in, the water in the pipes can simply freeze. If this happens, use only safe methods of heating pipes and then water will flow through your pipes again.

The rupture of water supply or sewage pipes is one of the most unpleasant options for winter problems in private and apartment buildings. In addition to interruptions in water supply and drainage, there is a high risk of flooding of residential and auxiliary premises, soil erosion, damage to the power grid. The main way to protect pipelines from freezing and, accordingly, ruptures during a sharp cold snap is a reasonable laying and high-quality thermal insulation.

Overview of different methods

The water supply system can be defrosted using various methods of external thermal effect on the pipe, or by defrosting it from the inside.

Method 1. We use hot water

If there is a suspicion that the water supply is frozen in an open area - at the entrance to the house, in an unheated basement, etc., boiling water is used to warm it up.

To do this, the pipe must first be wrapped with any rags that will absorb water and prolong the contact time of the pipe with boiling water. Pour hot water until the ice starts to melt. And to speed up the process, the tap must be left open.

The easiest way to warm up a frozen pipe is to pour boiling water

This method is used only indoors, because if the pipe is underground, it will take a long time to warm it with boiling water - at least 12 hours.

Method 2. We use a building hair dryer

The pipe can be defrosted using hot air produced by a powerful construction hairdryer. The surface of the pipe is blown from all sides, and to reduce heat losses, it is recommended to erect a small pavilion made of polyethylene film over the frozen pipe, for example. If the pipe is plastic, you need to correctly calculate the heating so as not to melt it.

Solving the problem of defrosting a water pipe using a conventional hair dryer, but you can also use a building

With a slight freezing of the pipe, you can use a household hairdryer or fan heater to warm it. If there are turns, constrictions, entrances to fittings, they also need to be warmed up, since ice particles can get stuck there. And in this case, do not forget to leave the tap open.

Method 3. Electric current comes to the rescue

How to warm up frozen water pipe using electric current?

Heating up a metal water pipe

can be produced using a welding transformer: the positive wire is connected to one end of the pipe, and the negative wire to the second. In this simple way, the problem can be solved in a few minutes: the ice plug will melt.

The time for warming up frozen water supply metal pipes with a welding transformer is minimal

Heating up the plastic pipeline

can be done using a two-core copper wire with a cross section of 2.5 mm. This method is similar to the principle of operation of a familiar home boiler. The wires are separated. One of them is simply bent, and the second is exposed and 3-5 turns are twisted around the wire, cutting off the excess end. The same is done with the first core, leaving 2-3 millimeters from the turns of the second core. It is necessary to pay attention that the wires do not touch, otherwise a short circuit will result. A plug is connected to the other end of the wire. The wire is pushed into the plastic pipeline and connected to the electrical network.Passing through the water, the current heats it up, and the ice begins to melt. The method is good in that only water heats up, the wires remain cold and this prevents accidental melting of the plastic pipe. To quickly blow out the melted water, you will need an additional compressor.

Method 4. We heat the pipeline with improvised means from the inside

How to warm up the water supply if it has many bends and sections? For such a case, you can build a special device. You will need a wire, a water level tube, Esmarch's medical mug (in a simple way - an enema), which consists of a rubber container with a rubber hose and a small tap for draining water. The hydraulic level tube is fastened to the wire using electrical tape so that the end of the tube is slightly longer than the wire. Push it into the water supply until it stops. Hot water flows out of the rubber tank into the pipeline. It is necessary to organize collection of melt water.

Schematic representation of the wire and enema rewarming process

As the ice thaws, the pipe with the wire is pushed further. The process of warming up a frozen water supply using improvised means is quite laborious and requires a lot of patience and time (about 1 hour per meter of frozen pipe), but the costs are minimal.

Method 5. Calling specialists

You can also warm up the water pipe from the inside with the help of special equipment - a hydrodynamic unit, the direct purpose of which is preventive flushing of water and sewer pipes.

Hot water with a temperature of 150 degrees is supplied under high pressure (90-100 atm) through the hose. The water boiler of the installation runs on diesel fuel, and the unit is powered by a power grid with a capacity of at least 7 kW and a voltage of 380V. For this method, it is necessary to call specialists, so this method is not suitable for everyone.

Preventive actions

Everyone knows that it is better to limit the amount of fatty and spicy foods than to subsequently be treated for gastritis or ulcers. The same can be said about the topic that we are discussing with you today. If the heating system is frozen, then first of all the problem must be eliminated. And when this is done, think about whether it is possible to prevent trouble in the future. We assure you that this will be much cheaper than eliminating a full-scale accident at sub-zero temperatures.

Flushing

It is carried out strictly before the beginning of the heating season, or when the valve is closed. The procedure consists in pumping hot water through the pipes until you get a completely transparent liquid at the outlet. If the heating system has been turned off for a long time, you will additionally need a metal brush for rough mechanical cleaning. The process is quite long and laborious, but it can significantly reduce the likelihood of an accident during the heating season.

Installation of heating radiators

Why do this, you ask, if they seem to work fine? The fact is that over time, the batteries become clogged from the inside, the gaps through which the coolant circulates narrow, which leads to a decrease in the efficiency of the system and increases the risk of an accident. If the radiator is relatively "young" (3-5 years old), then of course there is no point in spending money. But if he "remembers" the times of stagnation, pioneers and May Day demonstrations, replacement is the best way out.

Installation of pipes with PU-insulation

The best option for those cases when the design of the heating system of the cottage is just underway, and the house itself has not yet been commissioned. Such pipes allow you to pinpoint the location of a leak or thinning of the shell, avoiding a significant investment of time and money in case of finding a problem area. Ideally, polyurethane foam pipes should be installed all the way from the junction to your home.

Leak test

The point is that the pressure in a newly filled and closed circuit should correspond to that which is at the outlet after a few hours (days). If the readings taken by the pressure gauge are lower (ie, for example, there was 1 atmosphere, but we have “only” 0.8), then there is a leak somewhere. Naturally, it is better to engage in such checks before the onset of the heating season.

Elimination of air congestion

To do this, simply bleed off the air remaining from the summer in the radiators (you need a manual tap or an automatic valve). The latter are located in the upper section of the subcontour.

Antifreeze

If you are connected to a closed (individual) heating circuit, it is better to fill it not with ordinary water, but with a special liquid that never freezes. Propylene glycol, ethylene glycol, or a combination of both are suitable.

Additional pipe protection

The method is especially good for preventing freezing in rarely visited rooms (for example, in the basement). The anti-icing system, in fact, is "tying" the pipe with a special thermoresistive cable, followed by winding a good insulation.

I would like to make a separate note of one point. If the heating system in a private house is frozen, sometimes the culprit is ... insufficient chimney draft. The connection here is the most direct. If the chimney is covered with combustion products, and coniferous trees are used for the furnace, the boiler often goes into economy mode, which lowers the temperature of the carrier, which, in turn, increases the likelihood of freezing. Therefore, before the heating season, it is worth calling a specialist and cleaning the dirt.

sincerely wishes that even harsh winters do not affect the warmth and comfort of your home. We are always happy to help you with any heating problem. Contact us at the first sign of trouble and make sure that high-quality customer-oriented service is fully compatible with affordable prices!