Understanding a shut-off valve

The shut-off valve is installed to mechanically interfere with the free movement of liquids and gases through the pipeline. Stopping and emptying the line from the contents may be necessary due to leaks, depressurization, critical changes in temperature or pressure. That is, the content is either completely driven out of the site, or its movement is blocked.

Devices are installed on the mains with gases, oil products, hot and cold water. It can be both household utilities, gas stations, and more industrial-scale structures or, for example, a city heating network.

Stop valve

There are disposable devices that are equipped with replaceable valves or are subject to complete replacement after operation. They are usually made of plastic. Reusable metal equipment is in great demand due to its long service life.

Now about the interests of both. And why do you need a bypass tap?

So, we look at the root. Hot water runs to us from the city to the house through large pipes. These pipes, as we all know, for the most part are in a deplorable state:

- The first deplorable condition is rusty water in rusted pipes. As a result, dirt clogs our batteries, water does not pass through them well and blocks the flow of water to neighbors. Who is guilty?

- The second deplorable state is frequent accidents, leading to the fact that whole houses stand in the winter without heating. Who is guilty?

If, as a result of these incidents, your pipes are clogged or you have sat for several days without heat, then according to the receipt you will still regularly pay as much as you were charged, as if everything was at the highest level and you received quality services. Either the most desperate or who have a lot of free time go to court.

| By reading my blog, you are probably making repairs. Add to your bookmarks this page... All useful home improvement stores are located here. |

The result is your dissatisfaction with the state of affairs.

For homeowners' associations, housing cooperatives, etc., it is not interesting to take into account the interests of each individual tenant, it is too dreary and costly! It is much easier to prescribe uniform rules for everyone and punish the disobedient. Put the tap on the jumper - bad! Even if the tap is always open, it's still bad! Not allowed! And someone goes to the meeting, understanding why the person put it. Who is guilty?

1st option

Now let's take a look at each individual resident. He is alone with his problems. Let's imagine that he has many children and a large room that needs to be heated. So he put a battery, put a jumper, and the water pressure is weak. Well, so weak that it does not go through the battery at all: out of 12 knees, only 3 are hot, the rest are barely warm. And the plumber made all the pipes of the same diameter.

What do you order this tenant to do. You say the battery is probably clogged. Okay. So he turned off the taps on his battery, took it off, washed it, cleaned it, or even put a new one, ... but there is no pressure ... or it is not enough ... Children are freezing ...

This is where a crane is needed. I closed it completely on the lintel and all the water then went through the battery. I am not suggesting that this is a normal operating condition. Not! But during periods when accidents occur, a very weak pressure of water is supplied to the batteries. People are freezing. As a temporary solution, why not run all the water through the battery.But here the whole responsibility lies with this person. He must open the bypass valve when the accident is eliminated.

The main conflict of this solution is that by letting absolutely all the water through his battery, this tenant slightly lowers the temperature of the incoming water for the neighbor from below, since the battery in any case manages to give a certain amount of heat to the room.

Thus, each subsequent neighbor, with the same actions, further lowers the water temperature for the downstream. However, in conditions of low pressure, when the water flow mainly flows through the jumper, the batteries practically do not heat up for everyone, so it is better for everyone to have minimal heat than to sit without heat for anyone at all.

There is also a second pitfall here. When closing the faucet on the lintel, that is, letting all the water through the battery, you need to be absolutely sure that your battery is not clogged. Otherwise, you risk blocking the entire riser, but then just wait for the arrival of angry neighbors.

2nd option

Another episode. Imagine that suddenly the battery began to heat up badly with a sufficiently good pressure - dirt got into one of the taps that shut off the battery. As a result, the entire hot water flow will be redirected to the bypass. Not everyone can quickly disconnect the battery and clean it.

For example, a single elderly woman will not do this. And if a local plumber is sick, and there is no money for a private trader, then she may have to sit without heat for several days. Temporarily shutting off a lintel tap can sometimes be a lifesaver. If the entire stream is directed directly into the battery, there is a small chance that the dirt will push through and the battery will function again.

Again, in this case, be sure to remember to open the tap after solving the problem. If, with this method, the dirt has not pushed through, nothing can be done, the jumper must be opened and already wait for the arrival of the master.

It turns out that sometimes a bypass tap can come in handy. Yes, in 95% of cases it should be open and provide a free flow of water through the apartment. But there are situations when his presence can help out. However, because of the conflict of interests, it is very difficult for people to come to an agreement with each other.

From all this, we can conclude that the problem is complex.

If water did not come to us through rusty pipes, if the water pressure was always normal, if the plumbers always observed the correctness of maintaining the diameter of the pipes during installation, if the people themselves were attentive to what the masters do to them, then they would not a bypass tap would be needed.

But in practice, we see a different picture. Therefore, it would be wrong to make extreme only tenants in this situation.

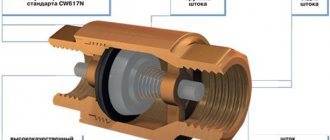

Design features

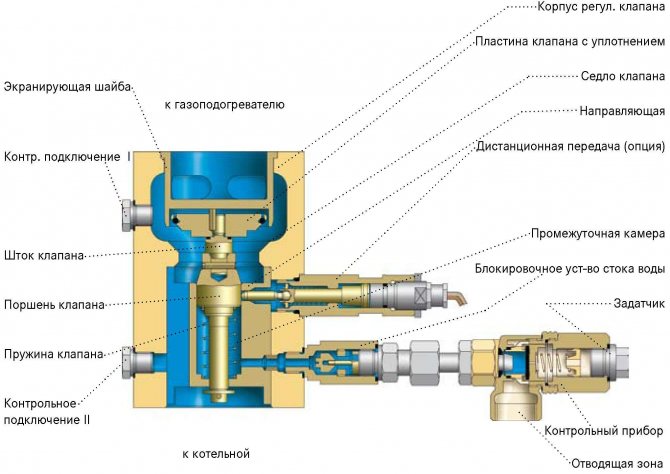

The device is based on a die-cast body, seat and cover. They are made of cast iron, galvanized steel, brass or polymer materials with high strength values. The second element is for installing the valve in the pipeline.

The shutter mechanism is presented as follows:

- spring that drives the device (shutter and return);

- the stem responsible for the dynamics of the valve;

- Absorbent pad to prevent condensation and leakage.

Electric or pneumatic actuators are responsible for triggering the device. The valve is controlled in two ways: manually by the operator or automatically. Without human intervention, triggering occurs, as a rule, due to built-in sensors.

Device with sensor

Principle of operation

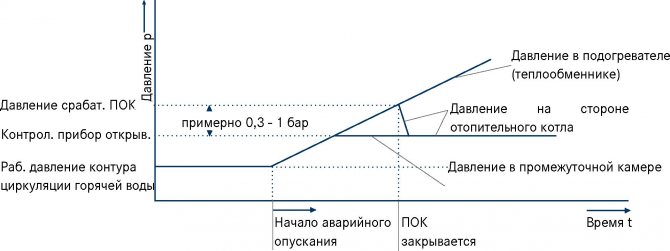

The functionality of the shut-off device is to ensure that the content of the pipeline stops its movement in a specific section or along the line as a whole. In this case, a shut-off valve must shut off the flow quickly in order to minimize the risk of accidents.There are several reasons for their occurrence:

- violations of the technology of installation of the pipeline, filters;

- non-compliance with safety requirements;

- end of life of constituent components;

- various kinds of malfunctions;

- unexpected changes in pressure or temperature inside structures.

Devices equipped with special sensors are considered more practical. This is due to automatic operation for a short period of time (from fractions of a second to minutes). The speed depends on the characteristics of the sensors and the quality of the hardware settings. Trained service personnel are responsible for the latter.

Electromagnetic gas instrument

It is worth saying that the device can be one-week or two-week. In addition, gas shut-off valves with signaling devices can be of either the first or the second type. The presence of an alarm in the case of gas is especially important, since it is necessary not only to shut off the system, but also to inform the operator that a leak has occurred.

As for the single-seated valve, it cuts off the flow of the working medium from only one side. Most often, the dimensions of such valves will not be more than 50 mm. The two-seat device allows you to pass the gas flow in two directions at once, but at the same time it is less tight than a single-seat one.

It is also worth paying attention to the fact that it is very important to choose the right device. If an electromagnetic design is chosen, then it must clearly correspond in its characteristics to the scope of application. Here it is important to pay attention to the coincidence not only in the transported working medium, but also in the pressure in the pipeline, as well as in the temperature of the medium. In addition, since this is a safety part, the speed of its response in an emergency should be as fast as possible.

Positive aspects of using a shut-off valve

Compared to valves, which initially performed the task of shutting off the movement of liquids and gases, stop valves are equipped with various kinds of automatic response mechanisms. It consists either in giving signals to the operators, or directly blocking the free passage through the pipeline.

Shut-off valve

Today devices eliminate some of the disadvantages of prototype equipment. For example:

- due to mud flows and impurities, false alarms are excluded;

- more sealed housings are better able to handle small pressure drops;

- response speed is minimized to a few seconds.

In addition, modern shut-off valves shut off movement in both directions. And there are additional elements in the designs. For example, silicone spring washers or shims.

Purpose of the device

The described valve is designed to immediately turn off the device, part of the pipeline, or completely the entire system in the event of an emergency.

The electromagnetic gas shut-off valve, which is installed in both gas and water environments, is triggered due to the influence of external energy sources on it. This is what is the main difference from all other protective and shut-off types of fittings. The device is powered by a number of sensors, and in addition, it can be controlled remotely. As for the areas of application of gas shut-off valves, there are a lot of them. They are successfully used in the medical and food industries, have shown themselves well in the energy sector, as well as in everyday life.

It is even possible to single out some designs and devices that cannot function normally without such cut-off devices.

Firstly, this includes all heating and water supply systems. In this case, the valve will shut off the supply of working fluid in the event of an accident.Secondly, any types of devices in which the control of the supply of fuel (water, gas or oil products) is carried out in automatic mode. The air supply system is also not complete without gas shut-off valves. In agriculture, they are actively used in the arrangement of irrigation systems.

If we talk only about the solenoid valve, it is the most commonly used in the power industry.

Main types of devices

Pipe fittings differ in design and purpose. So, normally open devices are distinguished. They are responsible for dealing with flow in relation to traffic. Normally closed shut-off devices are usually manually operated and open in an emergency to release the contents of a tank or line.

Devices for water, oil products and gas are considered separately. The actuation can be carried out by means of a mechanical load, a spring mechanism, a pneumatic or magnetic drive. The devices are also different in characteristics, connection methods, work in one or two directions. And depending on the materials used, manufacturers offer disposable and reusable shutoff valves.

Angular

Angle valve

The field of application includes lines for liquid products flowing under high pressure. The equipment body is made of high-strength steel. The equipment has a piston hydraulic drive. The principle of operation is designed for incoming and dispensing movements.

Checkpoint

It is important to install a direct-acting shut-off valve in pipelines where there is a risk of leaks. The content in this case can be both clean and with impurities or impurities, bubble inclusions. At the same time, microparticles do not settle and do not accumulate in the nodal joints. With regard to materials, the main criteria are impact resistance, wear resistance and protection against corrosion damage.

Two-seat

This instrument has two seats and plugs. Installation is permitted on pipelines with large cross-sections and high pressure drops. Double-seated shut-off valves are used in explosive conditions and active chemical reactions.

Single-seat

Such a shut-off device is installed on pipelines of relatively small diameter. The same applies to the amplitude of low pressure drops. The device has a built-in plunger that blocks the flow in one direction.

Single seat valve

Auto

Shut-off valves of this type usually have a steam damper. It works within 1.5-10 seconds after a malfunction occurs. They are also characterized by durability and minimal susceptibility to deformation. For greater efficiency, devices are equipped with special controllers. They react to changes in pressure, temperature, in the composition of the content, which must remain constant.

Heating circuit. What is the dispute about, in fact

The heating scheme assumes both the presence of a tap on the bypass, and its absence. Let's take a look at these 2 options:

with valve on bypass:

without valve on bypass:

If you climb the Internet, you can find completely opposite points of view of both individuals and companies involved in the installation of central heating batteries.

If you look at the root, the problem is much deeper than it might seem at first glance. And it lies in the plane of affecting the interests of individuals and entire organizations.

Let's once again remember a little why a bypass is needed in principle. A bypass (aka jumper) is installed in front of the battery, providing an independent hot water flow through your apartment. In short, whether you have a battery or not, whether it is in good condition or bad, water must pass through your apartment regardless of these factors through the jumper.

Therefore, the fact that the jumper is needed is an indisputable argument. If, for example, you do not have a bypass at all, and only a battery is connected to the pipe, then this threatens with very unpleasant consequences:

- If the battery suddenly leaks, then there is no way to stop the leak - the bay of the neighbors from below is guaranteed.

- If the battery is suddenly clogged, then you blocked the entire riser, and your neighbors were left without water.

You can't argue against these arguments.

And then, regarding the crane on the bypass, whether it is needed, there are constant disputes.

By the way, I will say that both options for installing heating batteries, which you saw above in the pictures, were made by 2 different licensed companies. Each has its own truth!

| In this catalog you will find high-quality components for water supply: ball valves, manifolds, fittings, water supply, fasteners, metal-plastic and steel pipes, etc. |

Isolation Valve Selection Guide

One of the main criteria is the speed of response of the device. Especially if the flow of liquid or gas occurs under high pressure. However, this is not the only parameter. The following is also important:

- Application area. This concept hides the flowing substances, their composition, the degree of aggressiveness.

- Operating conditions include pressure and temperature.

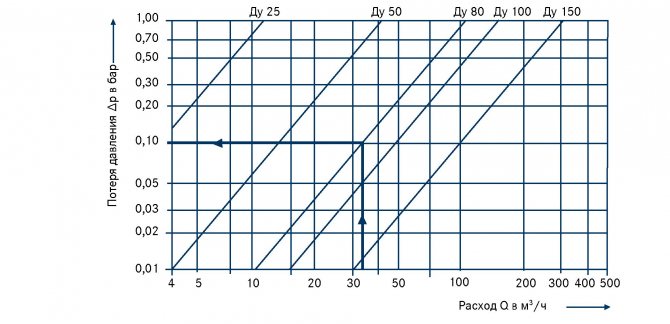

- Throughput refers to the cross-section of the line.

- Tightness. The reliability of the equipment depends on this indicator.

- Durability affects the durability of the devices.

Cast iron valve

When choosing a shut-off valve, consideration is given to the design and action in one or two directions. With regard to materials, not only the body is considered, but also gaskets, oil seals, seals.

Shut-off valve installation rules

The installation of the shut-off device is carried out according to the manufacturer's instructions. Self-installation is allowed only on the water supply system in the private sector. In this case, the warranty service and the operation of the device may not correspond to the declared due to the inexperience of the installer. Therefore, it would be right to entrust the work to specialists.

Mount gate valves in accessible places for maintenance or replacement of equipment. At the same time, areas in which stagnation and hydraulic “bags” can form should be excluded. There are also rules regarding the location:

- on vertical tanks, the upper bottom is considered (or on a helmet tube);

- on horizontal - in the vapor phase zone (upper generatrix of the cylinder).

An important point is the elimination of freezing of the contents of the pipeline in the nodal connections. And the cross-section of the branch pipe should be 1.25 times greater than the total analogous indicator relative to the valves installed on it.

The ratio of the diameter of the pipe and valve

Operational advice

It is prohibited to use equipment to regulate the flow of the content of the line. Therefore, the valves must be in the fully open or closed position. During installation and maintenance, it is important to exclude any clogging of the inner surface of the case and the ingress of foreign objects. Operation is feasible only in strict observance of the instructions, any other purpose is unacceptable.

Moments related to safety are spelled out in GOSTs 12.2063-2015 and 32569-2013, in the norms established by such organizations as Rostekhnadzor, the Customs Union, the Eurasian Commission. It is also important to use personal protective equipment. And only trained specialists with permits are allowed to service devices, replace them.

Shut-off valves are widely used due to their intended purpose. Thanks to these devices on the highways there is a chance to localize the consequences of problems, correct them and put them back into operation. This is true both for utility networks and large-scale pipelines.