Recently, a material such as heat-insulating paint has become popular in the construction market.

Insulating paint received its recognition due to its cheap cost.

With the help of this heat-insulating material, you can save electricity, and therefore your money.

Thermal insulating paint is divided into different types and before buying it is necessary to familiarize yourself with the characteristics of each and with the scope of their application.

In contact with

Varieties

Thermal insulating paint has several varieties:

- The first type is water at the base of the paint. Environmentally friendly paint. The material does not burn.

- Acrylic based paint.

- Thermal insulating paint that is used for painting walls and ceilings.

- Thermal insulating paint suitable for painting water pipes and gas pipes.

- Thermal insulating paint - used for painting outside the house, as it is waterproof and heat resistant.

What varieties are divided into, features of each type,

The market for insulating coatings in this category offers several varieties, differing in composition and application methods:

- ceramic

- penoizol (expanded polystyrene).

General advantages - fast coating, good thermal insulation properties. In all other respects, these compositions are slightly different from each other: in terms of use, composition, specific properties.

Heat loss indicators before and after insulation

Ceramic heat paint

It looks like a substance (mastic) that resembles an acrylic paintwork. There are several types of names of this insulation on sale. However, their consistency, technical data and composition are identical:

- The binder is a water-acrylic solution.

- Additional constituents are silicone resin, rubber or other components with similar properties.

- Ceramic granules of regular round shape.

After application, it forms an ultra-thin layer with very high thermal insulation values. It is widely used in construction. In addition to thermal insulation functions, it is also used as protection against corrosion.

Ceramic liquid insulation

Expanded polystyrene compounds

It also has many names, it depends on the manufacturer and the country of manufacture. Comprises:

- Urea-formaldehyde resin, which is also included in the composition of cold hardening foams.

- Foaming substance.

- Water.

- Phosphoric acid.

The percentage of resin is the main indicator of density. To mix the ingredients of the composition, special equipment is used (a gas-liquid apparatus that runs on compressed air). As a result, the components, I mix, turn into a foamy mass.

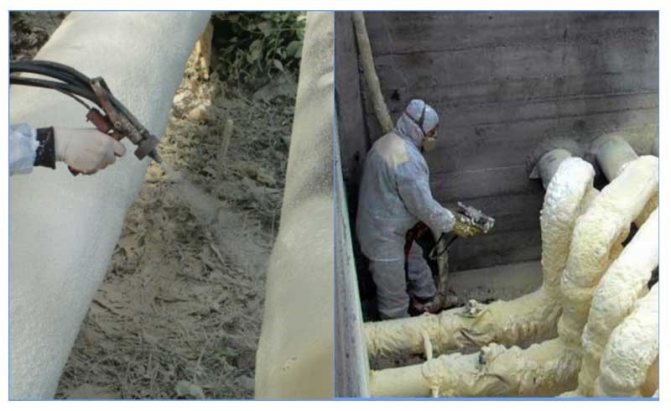

Spray applied. To do this, you need a special spray bottle. This application technology allows you to tightly fill voids, cracks, cracks. Has a slightly yellowish tint.

The coating has no seams, which makes it possible to effectively use it in those places and areas where the indicators of tightness, strength and reliability are very important and high.

Styrofoam insulation of the pipeline

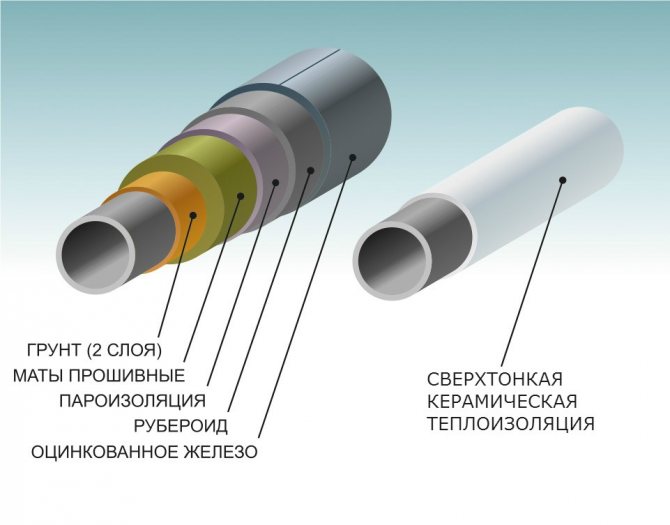

All types of pipes can be insulated with heat-insulating paint, regardless of their purpose. This approach is a reliable protection against: heat loss and corrosion.

What does it consist of

First of all, thermal insulation paint contains water.It also contains acrylic dispersion (adding various stabilizers to acrylic acid) - it is one of the main elements of any paint, thanks to this component, the paint retains its color, saturation and shine for a long period of time. Acrylic dispersion protects the surface from various environmental influences.

Perlite is added to the heat-insulating paint. Perlite is used to improve sound and heat insulation functions.

And also heat-insulating paint includes fiberglass, foam glass, microspheres made of ceramics - all these components of this paint are aimed at warming a dwelling.

Heat-insulating paint, when applied to the surface, lays down 5 millimeters thick.

Note: the main advantage of this material is the uniform application of paint over the entire painting surface. This advantage will help hide all defects and irregularities in the wall or ceiling.

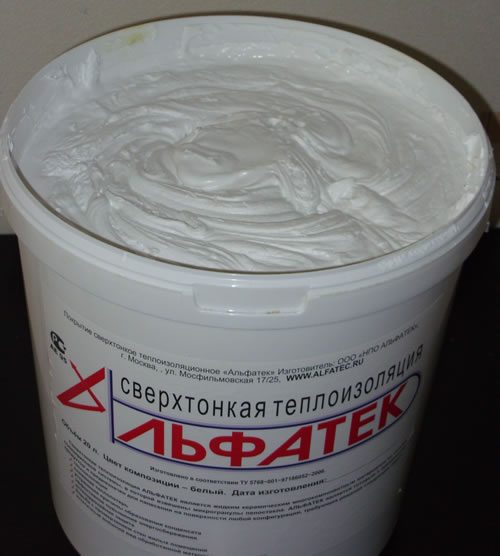

Thermal insulating paint is available in the form of a thick mixture. It is either white or gray.

What is it, how it works

Thermal insulating paint for pipelines is a substance in the form of a mastic mass, with a consistency like ordinary sour cream. Used to handle load-bearing structures, cisterns and piping systems. It was invented, initially, especially for the space industry. Now it is used in the construction, assembly and repair industries, construction of buildings.

The heat-reflecting capabilities of this coating are such that even with a thickness of only 1 mm, it well prevents heat loss where it is especially required. It can be applied to any surface: walls, ceilings, tubes and other structures.

After application, the substance, polymerizing, turns into an elastic matte coating, acting as a temperature barrier. By keeping it inside the system, it does not let it radiate outward. Reducing heat loss occurs due to the fact that the coating has:

- A very small proportion of substances with heat-conducting properties. It consists of only 20% of the components endowed with these capabilities.

- Losses per convention for this substance are also insignificant. The material consists of microscopic "balls". Which fill the rarefied air streams.

- The efficiency of heat saving (which is 90%) is achieved due to the fact that the coating acts on the principle of a classic thermos.

In addition to heat-saving functions, it serves as an additional protection against corrosion and other negative processes that pipe products may undergo.

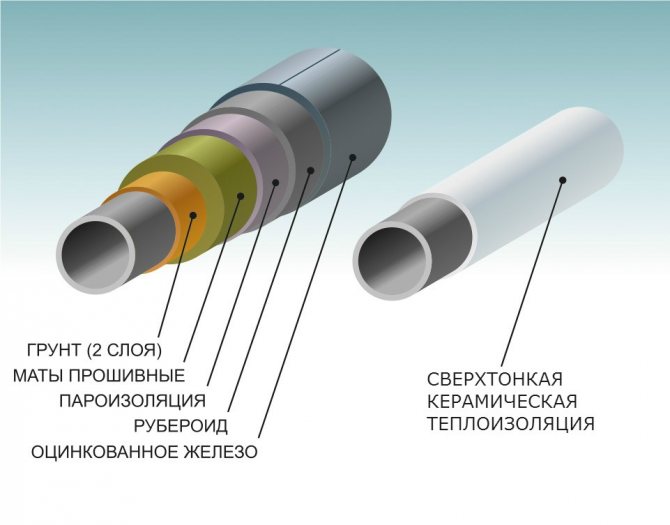

Such pipeline insulation is more than a worthy alternative to traditional mineral wool and other heat insulators known hitherto.

Traditional pipe insulation and ultra-thin heat insulator in a comparative section

Benefits

Thermal insulating paint has a number of advantages:

- huge service life (service life can reach up to 45 years);

- the paint can withstand temperatures up to 280 degrees Celsius;

- you can insulate any room, even in those places where it is difficult to do it;

- the possibility of painting metal objects;

- the procedure for applying thermal insulating paints is very simple and does not require certain abilities, absolutely any person can work with this building material;

- the material from which the paint is made does not burn and does not emit toxic particles;

- in the future you will be able to save on electricity;

- many areas of application of thermal insulation paint;

- has increased moisture resistance;

- the surface where the paint is applied does not lend itself to rust.

What is it made of, what technical characteristics does it have

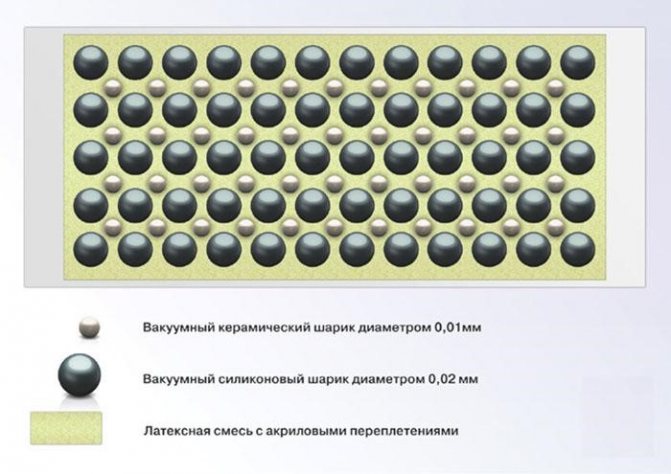

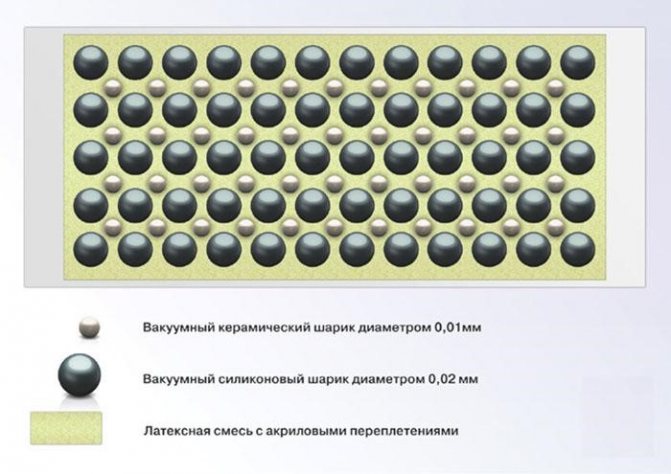

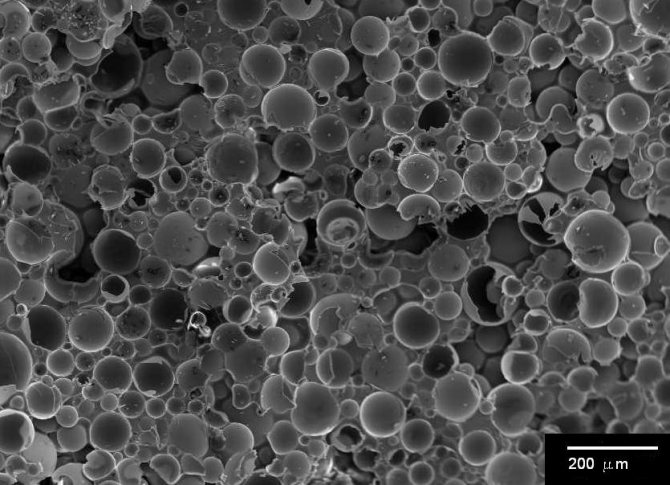

Liquid insulation is an innovative material with very high thermal insulation values. This is a composite coating made of polymers containing hollow ceramic microspheres.

Insulation composition

The structure of this substance is as follows:

- The base is a binder - a mixture of water and acrylic. Designed to promote uniform distribution over the surface, enhance the adhesive ability of surfaces.

- The filler is ceramic granules, microscopic in size, which are filled with gas. Due to their presence, thermal insulation increases significantly.

- Additional components are rubber, silicone and other components with properties that improve the water resistance and elasticity of the coating.

Thermal insulation of this insulation, in combination with other types, increases their ability to retain heat.

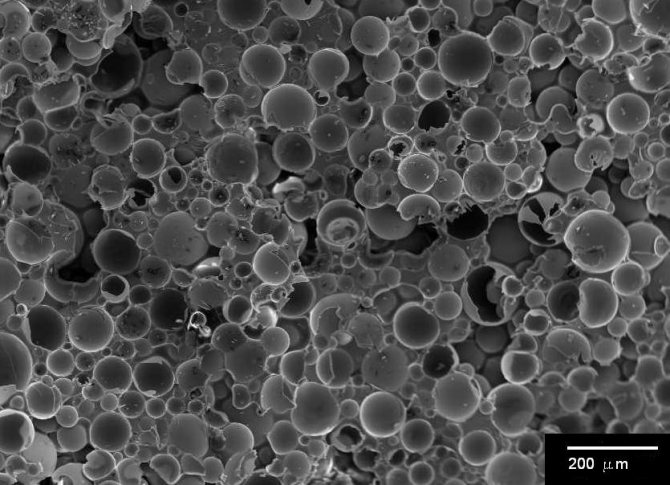

After application and complete polymerization, the specific gravity of the voids is in the range - 75-80%.

Molecular structure of liquid pipe insulation

Specifications

Indicators of this parameter are given in tabular form:

| Parameter | Description |

| Density (kg / l) | 0.6 (that is, a 10L bucket filled with paint will not weigh 10 kg, its actual weight is only 6 kg) |

| Color | Lactic |

| The presence of granules | With tactile contact (to the touch), slight roughness is felt |

| Quality | In case of delamination, a massive layer should be present, consisting of a layer of granules. |

Coating under the microscope

Distinctive features

In total, there are four features of heat-insulating paint:

- heat-insulating paint has a protective property, it protects against the release of heat or the entrance of cold, prevents the appearance of corrosion and wet substances;

- items on which heat-insulating paint has been applied increase their validity period;

- paint saves heat, you will be able to save electricity, and therefore your money;

- The material from which the insulating paint is made is completely environmentally friendly, without emitting any toxic and other harmful substances.

These four points distinguish thermal insulation paint from other materials intended for painting objects.

It is interesting! Do-it-yourself wooden door insulation: types of insulation and procedure

Types and manufacturers of liquid insulation

The compositions differ according to the areas used:

- Universal thermal insulation for application to the external and internal surface of walls, floors or ceilings.

- Facade thermo-mixtures for outdoor use, characterized by high moisture resistance.

- Paint for insulation of metal structures, water and gas pipelines, equipment.

Among the well-known and trustworthy manufacturers, the company Korund is worth highlighting. It produces ultra-thin insulation for public and residential buildings, heating systems and pipelines.

The safety and absence of harmful components in the composition of the liquid insulation is offered by the company Astratek. Its products prevent the formation of condensation, are applied to surfaces with temperatures up to + 150º C. Products are divided into three lines: facade, metal and universal.

Bronya insulating paint is made on an acrylic basis with the addition of vacuum-filled ceramic spheres. It is used for heating systems and chimneys, it is not afraid of moisture and ultraviolet radiation. The special composition Zim is designed for application and operation at low temperatures. Insulation for the facade is vapor permeable, it protects the surface of the walls from mold and mildew.

Selection Tips

There are several tips to help you when purchasing thermal insulation paint.

Let's take a look at them:

- Attention: since the painting consumes too much material, it is necessary to calculate everything in advance and purchase the required amount of heat-insulating paint. You need to calculate like this: first you need to find out the material on which the paint will be applied (metal, wood, and others). Then you need to mark all the irregularities or bulges of the surface, decide what thickness of heat-insulating paint you will apply, measure the surface to be painted.

- Remember: it is important to choose several manufacturers at once and compare the characteristics of each - this will help you choose the required material.

- Sold separately for interior paint, and separately for exterior, remember this.

- If painting is carried out outside the room, then you need to choose a paint with high water resistance and heat resistance. You also need to know the weather forecast for the day when the painting will be carried out.

- If painting is carried out indoors, then before buying, you should familiarize yourself with the composition of the paint and make sure that it does not contain toxic or other harmful elements.

- If water pipes or gas pipes are being painted, the thermal insulation paint must have the highest temperature resistance.

- It is best to use a spray gun when painting the surface - it will help you distribute the paint evenly.

- If the area of the room is small, then an ordinary roller is also suitable for painting the surface.

- The thermal insulation paint must be applied in several layers (three layers).

It is interesting! How to choose a spray gun - types of electric spray guns

How to choose and use insulation paint correctly?

First of all, before purchasing, it is necessary to decide what the material will be used for, what functional loads will be assigned to it, and also calculate the required amount.

It is recommended to choose from several manufacturers, read about the composition of various paints, the pros and cons of each brand, the differences between them.

- For finishing and additional insulation of facades, you should choose a composition with maximum vapor permeability and a minimum degree of waterproofing.

- When choosing paint for internal structures, it is recommended to carefully study the composition and make sure that there are no toxic and harmful components.

- The composition for painting the pipeline should be selected with maximum temperature resistance.

It is rational to paint large rooms or objects by means of a spray gun or a compressor, allowing you to evenly distribute the material over the entire surface, and for small areas it is more convenient to use a roller or a paint brush.

To ensure stable thermal insulation, it is recommended to apply the paint in 2-3 layers.

For painting pipes

Pipes are covered with various other insulation materials, but they do some harm to human health. When using these malicious materials, you also get a very short lifespan. Therefore, practically no one uses them for thermal insulation of pipes.

Heat insulating paint will help you keep your funds, health and warmth. This paint fully meets the parameters that are needed for pipe insulation. Heat will persist for tens of years until the service life of this material (heat-insulating paint) ends. This is the best option for insulation.

Features of applying ultra-thin insulation

Despite the excellent adhesion of liquid thermal insulation, the surface of walls or metal structures must be prepared. The base for painting is cleaned of dust, grease, corrosion. A loose surface is treated with a primer in order to reduce the consumption of an expensive composition. Stir the paint before application, add water if necessary.

It is recommended to apply liquid insulation at an air and surface temperature not lower than + 7º C, humidity should not exceed 80%. When working outdoors, it is better to choose a calm day, this will reduce material consumption.

Thermal insulation of walls and other structures with the help of insulating paint is only gaining momentum, but it has excellent prospects.

Main manufacturers

Thermal insulating paint can be purchased on absolutely every construction market.

There are many different manufacturers of this popular insulation, but we will discuss the most important ones:

- Thermal insulating paint from. Mostly paint from this manufacturer is used for heating equipment. Indoors it is used as a decorative element. It is an excellent insulation material for any surface. offers customers four types of heat-insulating paint.

- Thermal insulating paint produced by Astratek. The paint is water-based. It is completely environmentally friendly and harmless material. The thickness of the applied paint layer reaches 3 millimeters. The service life is 30 years. The paint from this manufacturer is capable of withstanding temperatures up to 170 degrees Celsius. "Astratek" gives customers a choice of only three types of heat-insulating paint.

- Heat insulating paint from. This industrial paint is most often used for painting pipes with various media (water, gas and other liquid streams). The most widespread paint "Bronya" received in the industrial sphere. Bronya provides three types of heat-insulating paint for buyers in the construction market.

It is interesting! Do-it-yourself wall insulation with ecowool: advantages and disadvantages, installation stages

Pros and cons of innovative composition

The main advantages of ultra-thin thermal insulation are:

- A tangible reduction in heating costs.

- Protection of a metal surface from corrosion, and concrete from destruction.

- The material is environmentally friendly and hypoallergenic.

- The coating performs its protective and insulating function for 12-40 years.

- Application of paint does not require special efforts and tools, it is easily sprayed in hard-to-reach places.

- The insulating layer is fireproof and resistant to mechanical stress.

- Insulating paint has an attractive appearance and does not change under the influence of ultraviolet radiation.

- A layer of liquid thermal insulation replaces 50 mm of mineral wool.

- If a separate area is damaged, it is easy to correct any defect with tinting.

- Design operating temperature from -50º to + 200º C.

The disadvantages of the composition include the high cost and high consumption for the walls.

Positive and negative sides

Like any other coating, heat-saving paint has a number of positive and negative characteristics. (See also the article Facade finishing: options.)

Similar formulations are ready to use

Pros of coverage

Among the pronounced positive aspects, it is worth highlighting:

- significant savings in heat;

- the opportunity to save on heating the room;

- protection of any surfaces from the negative effects of corrosion;

- protection against moisture penetration;

- beautiful, bright shine, which makes the coating aesthetic;

- ease of application;

- hypoallergenic.

Cons of coverage

If we talk about the negative aspects, then it should be noted separately that the material has:

- high price;

- quite a large expense;

In addition, this coating is not recommended for use inside a heated room, since the finished walls will not "breathe".

Due to the high consumption, the paint is packed in containers of 20 liters