- How to find out the amount of refrigerant in the system?

- How much refrigerant is needed for recharging

- How to determine the lack of freon

- How to fill the air conditioner

- Refueling rules

- System diagnostics

Almost all modern split systems, without exception, operate on the basis of refrigerants. Therefore, at a certain period, any owner is faced with the problem of refueling or refilling the system with refrigerant and the question, and how much freon is in the air conditioner at the moment and how much needs to be refilled?

How to find out the amount of refrigerant in the system?

It should be noted initially that the standard name "freon" summarizes all refrigerants known today. Moreover, this gas not only possesses the properties of a heat carrier, but also serves as a kind of lubrication for the compressor installed in the air conditioner in the outer compartment.

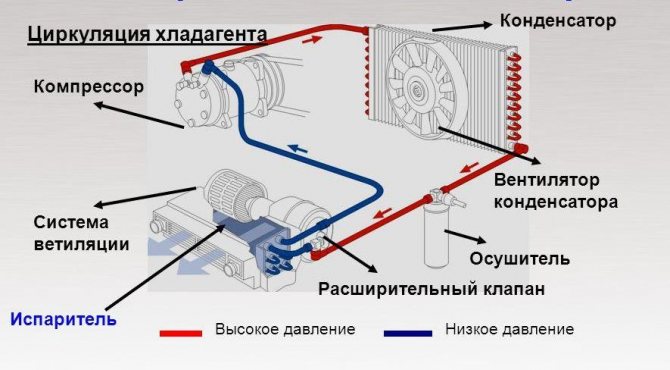

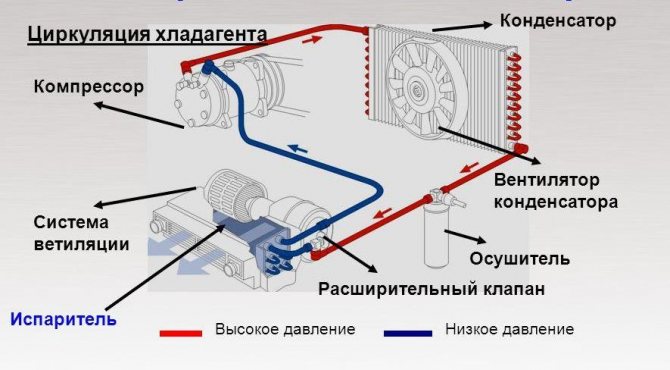

Recall that a standard air conditioning system in any room consists of two compartments, which are located outside and inside the room. They are connected by pipelines through which this gas circulates - freon. As a rule, copper pipes of a small cross section are used for this.

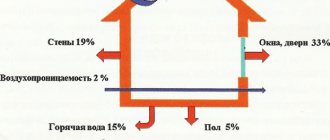

The volume of freon in the air conditioner is a value that directly depends on the length of these same copper pipes connecting the two blocks, and on the power of the compressor located inside the block. Based on this data, there is no single value suitable for all devices.

Manufacturers charge systems based on the length of the pipelines. As a rule, its length is not less than 3 meters and more than 5 meters. Basically, the manufacturer charges about 15 grams of refrigerant per 1 meter of track. Do not forget that the power indicator also has an effect, therefore the approximate content of freon in powerful air conditioners is about 0.6 kg, and in less powerful about 0.09 kg.

Of course, during the operation of the device, any refrigerant can gradually evaporate. This is sometimes faster because copper piping can be damaged and leaks occur. Sometimes the rapid evaporation of freon is also affected by poor-quality compounds, which also lead to leakage. In such cases, refueling or refueling of the device will be carried out only after complete evacuation of the entire system.

Differences between refrigerants freon R22, R410A, R407

The refrigerant freon R-22 is positioned as a chemical compound of the "chlorodifluoromethane" class. The peculiarity of this compound is that leakage from the system does not have a negative effect on the composition. Accordingly, the leak can be easily repaired by the usual refueling method. This type of refrigerant is not critical to the charging technique, and therefore can be charged with both liquid and vapor phases.

The refrigerant freon R410a is represented by a mixture of three chemicals, each of which has a different operating pressure and, more importantly, molecules of different sizes. The leakage factor is characterized by the fact that the three components leak at different rates. Therefore, charging with R410A freon is performed exclusively by the liquid phase.

Moreover, in the case of R407 freon, refueling of the system is not allowed in principle. In cases of R407 leakage, it is necessary to remove the remaining refrigerant completely, install new filter driers, and recharge the system only with the liquid phase (the cylinder is turned upside down). True, in practice it has been noted that with small refrigerant leaks, refueling of R407 is quite possible. For R410A, the criteria are even softer.

Limitations of the Montreal Protocol

According to the Montreal Protocol signed by many countries, the production volume of the R22 product is annually limited. It is planned to completely phase out the use of this substance by the time of 2030. This is done due to the ambiguous chemical composition of the refrigerant. Freon R22 contains a certain amount of chlorine, a substance capable of destroying the ozone layer of the stratosphere.

As production decreases annually, the demand for this type of refrigerant has exceeded supply. The R22 refrigerant price has reached an unprecedented high. The growth in the cost of this substance (for example, in the United States) has amounted to almost 400% over the past two years. Commercially, another freon, R410A, remains stable in price.

Buy R410A

Refrigerant R410 - quite popular and widespread, at the dawn of its appearance was considered an environmentally friendly substance, ended up as a contender for exclusion as it depletes the ozone layer

Meanwhile, the US Environmental Protection Agency (EPA) is currently concerned that R410A is also contributing to global warming. American experts are calling for an early phase-out of this type of refrigerant. Hearings are now underway with stakeholders regarding the final decision on the fate of the R410a refrigerant.

Substitutes for refrigerants used for charging

There are several "interchangeable" refrigerants that are rarely found in the chemical market. For example, freon NU22 ("New 22") is one of such products. Substance - a mixture of several chemicals that maintains the same treatment for R410A Freon with respect to leaks and charging procedures.

You should not try to add NU22 freon to an existing system with R22 refrigerant without first removing this brand of freon from the system. If you ignore the warning and refuel, this option will inevitably lead to a sharp increase in operating temperatures and pressures.

Also, when solving the problem of how to refuel the air conditioner, it should be borne in mind that the choice to refuel freon NU22 instead of the traditional R22 will lead to a decrease in the performance and efficiency of the air conditioning system.

Freon is different

A technological replacement for the traditional R22 refrigerant is the new development of the NU22 refrigerant. However, in practice, the new substance shows a decrease in the performance of the air conditioner.

You can often hear the question - is it not easier to replace R22 freon with R410A? The answer is unequivocal - no, since both refrigerants work with different oils designed to lubricate the internal parts of the compressors. As a rule, R22 freon is used in conjunction with simple mineral oil:

- non-toxic,

- safe,

- stable.

At the same time, R410A refrigerant is used together with exotic polyolester oil used in jet turbine engines. Obviously, the refrigerant used in the air conditioning system must match the type of lubricating oil. This is one of the reasons that do not allow replacing R22 with R410A.

In addition, oil for R410A refrigerant is an "ultra-hydroscopic" product. Therefore, care must be taken to avoid moisture and water vapor. Mineral oil for R22 refrigerant is only partly hygroscopic. Accordingly, the degree of care about moisture contamination is less critical.

Additionally, the necessary tools should be mentioned:

- separate micron pressure gauge,

- efficient vacuum pump.

The vacuum pump must provide 500 micron pressure to operate with R410A refrigerant due to its high moisture sensitivity.

Video: how to fill the air conditioner for beginners

The video below demonstrates the sequence of steps in the entire process.This video material allows you to study in detail the procedure for filling (refueling) an air conditioner with the subsequent application of the skill in practice:

How to determine the lack of freon

Of course, before dealing with the issues of refueling, each owner does not hurt to know how to determine the fact that there is not enough refrigerant in the device and either its complete replacement or refueling is required. The following factors indicate the lack of freon:

- the split system has become much less efficient in dealing with indoor air cooling;

- the air conditioner has stopped cooling the air at all;

- ice or frost appeared in the places where copper pipes were connected on the outdoor unit, resembling a "fur coat" in old Soviet refrigerators.

Before refueling, one should also take into account the fact that it is necessary to determine the pressure on the cooling split system from the type of freon charged into it. There are several brands of this refrigerant available today.

For example, if 22 freon is charged into the air conditioner, and the street temperature varies between 25-30 degrees, then the pressure should correspond to an indicator of 4.5 bar. If the temperature indicator is below 15 degrees, then the pressure will be 3.5 bar.

If freon 420 is charged into the split system, then at a temperature range of 25 to 30 degrees, the pressure indicator will be 6.5 bar. And at 15 degree temperature readings, the pressure will be 5 bar.

Specialists who service air conditioners know all the nuances and subtleties, but if you decide to independently determine the amount of refrigerant and refuel, then these nuances should be taken into account.

Refueling stages

Refueling air conditioners in a car is a procedure that can be handled by any car enthusiast who is minimally versed in their device.

Leak detection

If freon is lost more than the norm, it is recommended to carry out a diagnosis. It requires special equipment. For example, a leak detector. This device will not only show the presence of a leak, but also determine its exact location.

If instrumentation is not available, UV dye can be used to find leaks. It is added along with freon and the system is turned on several times. Then they take a UV lamp, and with its help they look for refrigerant leaks. Where it flows, yellow-green smudges will appear.

The reason for the leakage of freon can be the loss of the tightness of the pipes due to mechanical or corrosive damage. Rusting inside the condenser can cause a similar effect.

Pressure test

Nitrogen is used to test if the system can withstand the high pressure. It is run into the air conditioner and the pressure is determined. After waiting about half an hour, they look at the pressure gauge. If the initial pressure value has not changed, then the system is tight.

You can check the air conditioner with pressure at the service station for about 300-400 rubles. Without this check, it makes no sense to charge freon, since a drop in pressure means a leak, therefore, after 3-4 days the refrigerant will leave the system.

Evacuation

If the system contains less than half of the freon norm, it means that air and moisture have penetrated into it - this cannot be avoided. The equipment will function after refueling, but not at full capacity. There is a high risk of breakage and corrosion.

If you do not remove moisture from the system, the air conditioner may break down and expensive repairs will be required. It is much cheaper to carry out the evacuation procedure, which will remove air and water from the system. For this, a vacuum pump is used.

Procedure:

- Start the heater in the car to warm up the interior and condense the water.

- Connect a vacuum pump to the compressor. After unscrewing the nipple, turn the tap located under it - turn it counterclockwise.

- Start the pump, let it run for about a quarter of an hour. Then close the taps and turn off the pump.

Evacuation must be carried out 3-4 times in a row. You must wait at least 4 hours, and only then proceed to refueling.

Refueling

Freon is pumped in a strict sequence. The car owner who fills this unit for the first time is advised to familiarize himself with the procedure.

Step-by-step instruction:

- Screw the adapter with the valve to the bottle containing the refrigerant.

- Connect a hose to the adapter.

- Connect the other end of the hose to the pressure gauge. Attach another hose to it. This completes the assembly of the filling system.

- Set the parameters of the gauge station sensors. Use the calibration rotary knob to set the temperature.

- Connect the system to the nipple located on the low pressure pipe. The main thing is not to mix up the pipelines. Having found the desired fitting, remove the protective cap from it and clean the adjacent area.

- Connect the hose from the pressure gauge to the nipple.

- According to the instructions, refueling is carried out through the low pressure line with the engine running. Set to 1500 rpm.

- Let the system run for a few minutes. Then turn the bottle upside down and unscrew the valve on the adapter. The refrigerant now starts flowing into the air conditioner. While pumping is in progress, observe the pressure level on the instruments. If it rises above 285 kPa, the compressor will break.

- Continue pumping until cooled air flows into the cabin - about 5-8 C °. When the hose near the low pressure fitting becomes ice-cold, refueling can be stopped.

On a note! To eliminate odors, germs, fungus and dust, it is recommended to periodically use special fluids for cleaning air conditioners.

While pumping freon, you can check how correct the process is by looking at the filter-dryer window. If there are no bubbles in it and liquid is visible, then the refueling is carried out correctly.

How to fill the air conditioner

In fact, you can complete the refueling process yourself.

- Weigh the refrigerant bottle.

- Further, by opening the valve, you can allow the gas to move freely into the air conditioner pipeline.

- The valve is closed when the required amount of freon leaves the cylinder.

Experts recommend not refueling, but refueling the system with gas. To do this, the freon remaining in the system is released outside using a special fitting, and using the scales, the cooling system is refueled and filled with exactly the amount indicated on the metal table by the manufacturer. This option will be more efficient and simpler.

According to the advice of the same experts, it is better not to refuel the air conditioner system a little than to pump excess freon into it. The fact is that an excessive amount will prevent the refrigerant from passing from a liquid to a gaseous state, it simply will not have time to transform.

A more complicated refueling process is refueling the required amount with reference to the temperature. In this case, a thermometer is brought to the fan, which should show a value corresponding to the indicator in the passport.

If the temperature is in the range of 5-8 degrees, then this indicates that there is a sufficiently powerful compressor in the unit. The device itself is operating normally and there is sufficient refrigerant in the system to operate efficiently.

But this action is absolutely inapplicable to an inverter device. In it, the compressor directly depends on the thermal loads that it experiences, therefore, its power constantly has a different value.

Basic principles of air conditioner refueling

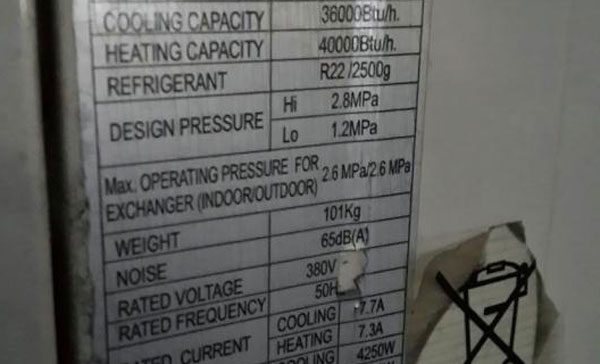

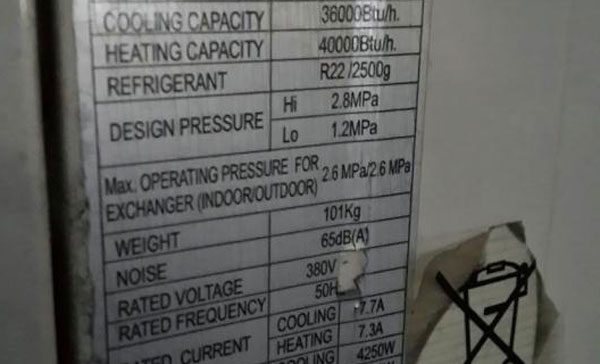

Any industrial refrigeration appliance is equipped with an indicator of characteristics in the form of a label-label, which is located on the housings of both indoor and outdoor modules.Using this plate, a potential air conditioner refueller can always determine the brand of freon, as well as the critical pressures of the low and high side of the system.

AIR CONDITIONING

The source of the parameters and characteristics of the air conditioner is a plate on the case. Thanks to this source, the general principle of filling the device becomes clear, in particular, with the refrigerant freon R22

In addition, the characteristics on the air conditioner plate provide information on the quantitative parameter of filling the system with freon in grams. The weight characteristics are convenient to use if the air conditioner is filled with R22 freon using a scale for a filling cylinder. Electrical parameters are also available on the label, in particular, the type of connection network (single-phase, three-phase) and load currents.

Required technological tool for filling R22

Actually, the toolkit of a mechanic filling any type of air conditioner with R22 freon seems to be quite simple. In fact, the set of tools that is required at the time of refueling includes:

- Gauge station.

- Hex keys.

- Electronic (pointer) scales (optional).

- Vacuum pump (if filling with empty or leaking device).

The gauge station is supplied by default with at least three high pressure hoses. In some cases, filling air conditioners (for example, with R410A freon), a fitting adapter for a smaller diameter may be required.

Buy station

Classical gauge station - a tool that is mandatory for the refueling (refueling) procedure of an air conditioning unit with R22 freon and others

Hex keys are required to open / close the shut-off valves during refueling. Electronic or dial scales are desirable but optional. Usually this tool is used by a professional service, as well as a vacuum pump (refueling "from scratch" or in case of leaks). Therefore, for the option of a simple refueling of the installation with R22 freon, only a couple of instrumental units are required.

The process of filling (refueling) the air conditioner with R22 freon

Of course, to fill the unit with refrigerant, you will need a filling source - a bottle with R22 freon. The standard container contains 11.3 (13.6) kg of refrigerant. Accordingly, for household systems that consume 1 - 3 kg of freon, the contents of one cylinder are enough for several refueling.

The main feature of refueling air conditioners with R22 freon is such a moment as the state of the cylinder at the moment the refrigerant is supplied to the system. Unlike R407 and R410A freons, the cylinders with which must be turned upside down (liquid phase), the R22 refrigerant allows any position of the cylinder. That is, filling is allowed, both in liquid and gas phase.

Buy freon 22

Traditionally, a container (cylinder) filled with R22 refrigerant is light green in color. But in addition to this distinctive feature, there is also a corresponding marking on the body of the container.

The step-by-step procedure for refueling (refueling) looks like this:

- Unscrew the protective caps from the brass valves of the high and low side pipelines. These taps are installed on the outdoor (street) unit of the air conditioner, usually in the lower area under the electrical terminal.

- Prepare the gauge station by connecting the middle nipple to the suction line of the vacuum pump via a high-pressure hose. The left fitting of the manometric station (low pressure gauge) is connected through another hose to the fitting of the low pressure pipe of the air conditioner.

- Bring the pressure inside the compressor system to vacuum (indication of the lower end of the pressure gauge scale) by starting the vacuum pump in operation.This procedure is usually done for the case of the first freon refueling or when the system is checked for leaks.

- Switch off the vacuum pump after reaching vacuum. Disconnect the hose from the pump connection and transfer it to the connection of the freon cylinder R Loosen the connection of the same hose at the gauge station and slightly open the valve on the cylinder. In this way, residual air inside the hose is squeezed out. Tighten loose fitting.

- Open the valve on the R22 bottle and the valve on the gauge station on the line connected to the low pressure side of the air conditioning system. So, due to the pressure difference, some of the refrigerant moves into the system. For further refueling, it is necessary to turn on the device.

Tracking the status at the time of refueling (refueling)

The condition of the air conditioner filling with R22 freon is further monitored visually by the pressure gauge, as well as by the condition of the pipeline surfaces that remained uninsulated at the points of connection with the taps. As the refrigerant fills, the surface of the high side (smaller diameter) piping begins to frost. Accordingly, the pressure on the pressure gauge increases.

Manovacuum meter

Working pressure (55 psi optimal), which ensures the normal operation of the air conditioner - shown on the pressure gauge on the left, connected to the low pressure line during the filling of the unit

For an air conditioning system on R22 freon, the optimum pressure on the low side is 50-60 psi. If measured by traditional parameters kg / cm2, these figures are comparable to the figures 3.6 - 4.0 kg / cm2, respectively. Once these parameters are reached, the frost-covered part of the high side tube thaws.

It remains to close the tap on the filling cylinder and at the gauge station. Disconnect the hose fitting from the air conditioner valve with a quick movement. When the hose is disconnected, a small part of the freon is allowed to escape, which is inevitable, given the design of the return nipple. This completes the procedure for refueling the air conditioner.

Refueling rules

In order to refuel on your own and without prejudice to the device, you must adhere to certain rules.

- One of the easiest and safest ways to refuel is by using weight. All the necessary information is indicated on a plate attached to the body of the device. New outdoor units do not need refueling if the piping length is not more than that specified by the manufacturer.

- Split - systems that have been in operation for a long time and have been dismantled need to be refilled only by 10% of the total mass of the refrigerant. This information is again indicated on the nameplate.

- Sometimes, if the installation or piping is incorrect, the amount of refrigerant in the unit may be low. And in order to correct the situation, you need to release all the freon in the device outward, trying to keep the oil inside the compressor. For this, the valve through which the filling takes place is slightly opened. Within a few hours, all freon will be released from the system. If the oil starts to flow out with the gas, then you need to open the valve even less. When all the refrigerant comes out, you can refuel with new freon.

Precautions when working with freon

If you are going to fill the air conditioner with your own hands - remember:

- Chlorine brands are harmful to the body. Avoid contact with mucous membranes (eyes, mouth), and do not inhale them.

- With a high concentration of freon, you can get poisoned. Therefore, do not work indoors - be sure to open the window and door, if available - turn on the hood (in the kitchen and in the bathroom).

- If liquid freon gets on the skin, you can get frostbite. Therefore, you only need to work with rubber gloves and closed clothing (not a T-shirt or a T-shirt with shorts).

If during operation the refrigerant gets on the skin or mucous membranes, it must be immediately washed off with water, and the place must be lubricated with petroleum jelly.

If you experience symptoms of suffocation, or any other abnormal signs, you must immediately stop work, leave the room and ventilate it.

Why do you need a screen for an air conditioner, and how to make it yourself?

Why can the air conditioner gurgle, how is it dangerous and what to do?

Similar posts

System diagnostics

After you calculate how much freon is required to refuel the split system and fill the required amount, it is advisable to check the device for leaks and check the compressor.

As mentioned above, it is undesirable to perform brute-force with the amount of freon. If the amount of refrigerant exceeds the norm by 10%, then this will not lead, of course, to wear on the compressor, but will cause malfunctions in its operation. If you notice that the compressor is not working efficiently, you can try to refuel about 10% of the freon, while the system itself should work properly. If its performance has not improved after refueling, then most likely it is not a lack of refrigerant. Perhaps there was some kind of breakdown inside.

If you decide to charge the system yourself, pay attention to the type of refrigerant used in it. Currently, the devices use a completely safe gas, which not only excludes the possibility of an explosion, but also does not harm the environment when it enters the atmosphere.

The first models of air conditioners came with the use of R-22 freon. But it was found that it destroys the ozone layer of the earth and works ineffectively at low temperatures, so manufacturers abandoned its use and switched to more modern and completely safe refrigerants.

Thus, you can calculate the required amount of freon, refuel the system and buy the necessary refrigerant completely on your own.

Tips & Tricks

When refueling the air conditioner with your own hands, you need to follow the recommendations. This applies not only to the selection of freon, but also to the whole process..

- The benchmark is made exclusively for the brand of freon specified in the instructions. Typically, this is R410a. Sometimes there are R 22 or R 134a. If you come across R 12, then you should not take it, since this brand is outdated.

- Depending on the brand of freon, a manometric manifold is selected. Its hoses are configured to work only with a specific type of gas. This is due to the fact that the refrigerant contains mineral and synthetic oils.

- The amount of freon is taken with a margin. It is required for purging hoses and filling lines over 3 m. The standard weight is 1 kg.

- During work, you need to devote time to finding places for freon leaks. If found, deal with their elimination.

- Operate the valves in the sequence shown.

- Do not ignore the hose purge step. Oxygen and moisture must not be allowed to enter the system.

- Be sure to tighten the cylinder valve before disconnecting the hoses.

We recommend that you familiarize yourself with: The principle of operation of the air conditioner: how to turn on the device for heating

Freon amount for refueling

The exact amount of refrigerant is important for the correct and safe operation of the unit. With an insufficient or excess amount of freon in the system, critical conditions occur, under which damage to the compressor is possible. An excess of freon turns out to be more destructive for the air conditioner than its disadvantage: the system was refueled and everything should work well, but the device stops turning on. When checking, it turns out that the compressor is damaged by water hammer due to improper refueling, and it needs to be replaced.

Signs of excess freon:

- Excess refrigerant in the air conditioner reduces the performance of the unit.If, after refueling, the split system works weakly, it is turned off and another master is invited - from a specialized service.

- The pressure in the evaporator is increased, because freon cannot completely get into it, and half of the substance is in the condenser.

- The gas entering the condenser is not cooled sufficiently, which increases the pressure in the condenser as well.

The compressor fails for two reasons:

- Due to damage to the electric motor of the compressor at high current, which rises as the condensing pressure rises.

- Due to water hammer when excess refrigerant enters the compressor.

Determine the amount of freon by looking at the manufacturer's instructions and recommendations. Some types of refrigerants have a higher pressure during operation, so they charge less substance. In this, non-professional craftsmen are most often mistaken, so it is better to deal with specialists who have extensive work experience.

What pressure should be in the car air conditioner

To measure the freon pressure in an auto-air conditioner, you will need a special measuring tool - a manometer, but it is better to use a special manometric station for measurements, equipped with appropriate hoses and connecting pipes. All car services that value their reputation are equipped with such stations. The measurement is carried out in the low pressure line, where the refrigerant is in the gaseous phase, and it is mandatory when the unit is turned on. You can find out what pressure in the car air conditioner is normal by studying the technical description of the car.

When measuring the pressure in the air conditioner circuits, it is necessary to compare with the standard, taking into account the outside air temperature. The higher the temperature, the higher the pressure will be, since when heated, the evaporation of liquid freon increases. Pressure rates in an air conditioner for different temperatures can be found in special tables. The overwhelming majority of modern car air conditioners use R134a refrigerant, for which the pressure at an outside temperature of about 20 degrees should be 250-270 KPa. If the measurement result differs significantly from the norm, then you need to think about a deeper diagnosis and finding out the reasons for the strong difference between the recommended and real pressures.

How to find out about an insufficient amount of freon

If the volume of the air conditioner filling has decreased, this is noticeable by the following signs:

- frost forms on the indoor unit;

- traces of ice are present on the outdoor unit;

- there are traces of oil on the pipes;

- the performance of the device is noticeably reduced - with the settings, some indicators, on the thermometer in the apartment - others.

Frost in the indoor unit indicates a lack of freon

Freon leakage occurs for several reasons. The air conditioner vibrates during operation, and vibrations create conditions for the divergence of welds on copper pipes. If the tubes themselves are poorly sealed during installation, cracks will form.

It is most difficult to locate the leak, especially if the line is laid in grooves and covered with a layer of plaster. If the length of the line is short, and the indoor and outdoor units are located next to each other, it will be easier for the technicians to disassemble the system and troubleshoot. For such work, it is advisable to immediately call the repair team, since it is difficult to carry out diagnostics and refueling without special equipment - there is a risk of completely disabling the equipment.

At the first sign of icing, the air conditioner is turned off and the technicians are called in.

Before the arrival of the master, it is advisable to clean the indoor unit from dust and dirt, because the decrease in the operation of the system occurs from the adhesion of a layer of dust and grease on the mesh filter, as a result of which the air flow is not sufficiently sucked inside.

Before starting the check with the gauge manifold, the specialist will clean the external unit and only after cleaning will check if there is a freon leak in the air conditioner.