05.02.2017

Despite the fact that in recent years, pipes made of polymer materials have become increasingly popular, steel products are still in considerable demand. They are still widely used in a number of construction, industrial sectors, and also in the household. Steel pipes (especially galvanized ones) are characterized by strength, durability and extreme ease of installation. What determines the range of steel pipes? First of all, GOSTs, which were regulated in the period from 2003 to 2006, as well as individual regulatory documents that have been in force since the second half of the last century.

Steel pipe assortment

- 1 Key GOSTs for pipes made of steel

- 2 GOST 10707-80

- 3 GOST 30732-2006

- 4 GOST 10706-76 (91)

- 5 GOST 2591-2006 (88)

- 6 GOST 10705-91 (80)

- 7 GOST 9567-75

- 8 GOST 12336-66

- 9 GOST 31447-2012

- 10 Features of the production of seamless pipes 10.1 Video - How to make seamless steel pipes

To begin with, let's take a brief look at the main GOSTs that determine the characteristics of the products described in the article.

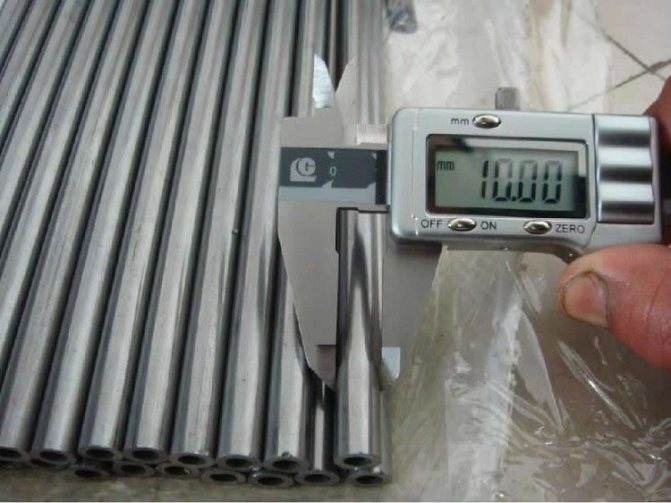

GOST 10707-80

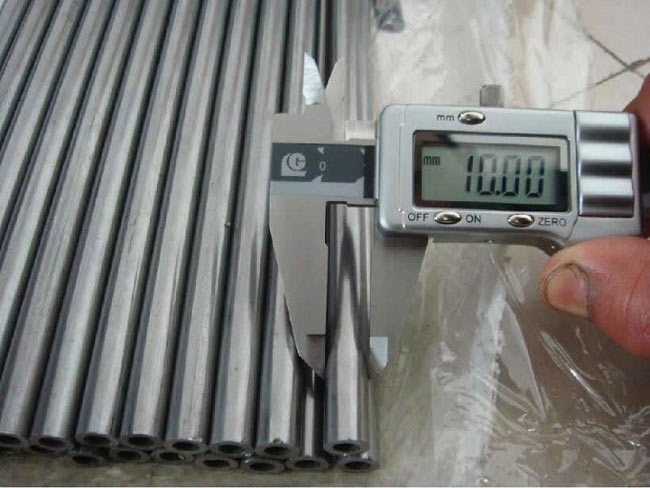

It was developed to regulate cold worked electrowelded products that have varying degrees of accuracy. According to this document, the diameter of the pipes can be from 0.5 to 11 centimeters. Characteristically, only carbon steel is used in the production process. Sometimes another GOST is indicated as a regulatory document (we are talking about 10707-91). This can hardly be considered a mistake, since this year the GOST, regulated in 1980, was extended.

GOST 10707-80. Electric-welded cold-deformed steel pipes. Download file (click on the link below to open the attached file in a new window). GOST 10707-80

Table # 1. Outside diameter and wall thickness of electric-welded cold-deformed steel pipes.

| Outside diameter | Weight 1 m, kg, with wall thickness, mm | |||||||||||||

| pipes, mm | 0,5 | 0,6 | 0,7 | 0,8 | 0,9 | 1,0 | 1,2 | 1,4 | 1,5 | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 |

| 5 | 0,055 | 0,065 | 0,074 | 0,083 | 0,091 | 0,099 | — | — | — | — | — | — | — | — |

| 6 | 0,068 | 0,080 | 0,092 | 0,103 | 0,113 | 0,123 | — | — | — | — | — | — | — | — |

| 7 | 0,080 | 0,095 | 0,109 | 0,122 | 0,135 | 0,148 | — | — | — | — | — | — | — | — |

| 8 | 0,192 | 0,110 | 0,126 | 0,142 | 0,158 | 0,173 | 0,201 | — | — | — | — | — | — | — |

| 9 | 0,105 | 0,124 | 0,143 | 0,162 | 0,180 | 0,197 | 0,231 | — | — | — | — | — | — | — |

| 10 | 0,117 | 0,139 | 0,161 | 0,182 | 0,202 | 0,222 | 0,260 | 0,297 | 0,314 | — | — | — | — | — |

| 11 | 0,129 | 0,154 | 0,178 | 0,201 | 0,224 | 0,247 | 0,290 | 0,331 | 0,351 | 0,371 | 0,408 | 0,444 | 0,447 | 0,524 |

| 12 | 0,142 | 0,169 | 0,195 | 0,221 | 0,246 | 0,271 | 0,320 | 0,336 | 0,388 | 0,410 | 0,453 | 0,493 | 0,532 | 0,586 |

| 13 | — | 0,184 | 0,212 | 0,241 | 0,269 | 0,296 | 0,349 | 0,401 | 0,425 | 0,450 | 0,497 | 0,543 | 0,586 | 0,647- |

| 14 | — | — | 0,230 | 0,260 | 0,291 | 0,321 | 0,378 | 0,435 | 0,462 | 0,489 | 0,542 | 0,592 | 0,640 | 0,709 |

| 15 | — | — | 0,247 | 0,280 | 0,313 | 0,345 | 0,408 | 0,470 | 0,499 | 0,529 | 0,586 | 0,641 | 0,694 | 0,771 |

| 16 | — | — | 0,264 | 0,300 | 0,335 | 0,370 | 0,438 | 0,504 | 0,536 | 0,568 | 0,630 | 0,691 | 0,749 | 0,882- |

| 17 | — | — | — | — | — | 0,395 | 0,468 | 0,532 | 0,573 | 0,608 | 0,675 | 0,740 | 0,803 | 0,894 |

| 18 | — | — | — | — | — | 0,419 | 0,497 | 0,573 | 0,610 | 0,647 | 0,719 | 0,789 | 0,857 | 0,956 |

| 19 | — | — | — | — | — | 0,444 | 0,527 | 0,608 | 0,647 | 0,687 | 0,764 | 0,838 | 0,911 | 1,02 |

| 20 | — | — | — | — | — | 0,469 | 0,556 | 0,642 | 0,684 | 0,726 | 0,808 | 0,888 | 0,966 | 1,08 |

| 21 | — | — | — | — | — | 0,493 | 0,586 | 0,677 | 0,721 | 0,765 | 0,852 | 0,937 | 1,02 | 1,14 |

| 22 | — | — | — | — | — | 0,518 | 0,616 | 0,711 | 0,758 | 0,805 | 0,897 | 0,986 | 1,07 | 1,20 |

| 23 | — | — | — | — | — | 0,543 | 0,645 | 0,746 | 0,795 | 0,844 | 0,941 | 1,04 | 1,13 | 1,26 |

| 24 | — | — | — | — | — | 0,567 | 0,675 | 0,780 | 0,832 | 0,884 | 0,985 | 1,09 | 1,18 | 1,35 |

| 25 | — | — | — | — | — | 0,592 | 0,704 | 0,815 | 0,869 | 0,923 | 1,03 | 1,13 | 1,24 | 1,39 |

| 26 | — | — | — | — | — | 0,617 | 0,734 | 0,849 | 0,906 | 0,963 | 1,07 | 1,18 | 1,29 | 1,45 |

| 27 | — | — | — | — | — | 0,641 | 0,764 | 0,884 | 0,943 | 1,00 | 1,12 | 1,23 | 1,35 | 1,51 |

| 28 | — | — | — | — | — | 0,666 | 0,793 | 0,918 | 0,980 | 1,04 | 1,16 | 1,28 | 1,40 | 1,57 |

| (29) | — | — | — | — | — | 0,691 | 0,823 | 0,953 | 1,02 | 1,08 | 1,21 | 1,33 | 1,45 | 1,63 |

| 30 | — | — | — | — | — | 0,715 | 0,852 | 0,987 | 1,05 | 1,12 | 1,25 | 1,38 | 1,51 | 1,70 |

| 32 | — | — | — | — | — | 0,764 | 0,911 | 1,06 | 1,13 | 1,20 | 1,34 | 1,48 | 1,62 | 1,82 |

| (33) | — | — | — | — | — | 0,789 | 0,941 | 1,09 | 1,17 | 1,24 | 1,39 | 1,53 | 1,67 | 1,88 |

| 34 | — | — | — | — | — | 0,814 | 0,971 | 1,13 | 1,20 | 1,23 | 1,43 | 1,58 | 1,73 | 1,94 |

| 35 | — | — | — | — | — | 0,838 | 1,00 | 1,16 | 1,24 | 1,32 | 1,47 | 1,63 | 1,78 | 2,00 |

| 36 | — | — | — | — | — | 0,863 | 1,03 | 1,20 | 1,28 | 1,36 | 1,52 | 1,68 | 1,83 | 2,07 |

| 38 | — | — | — | — | — | 0,912 | 1,09 | 1,26 | 1,35 | 1,44 | 1,61 | 1,78 | 1,94 | 2,19 |

| 40 | — | — | — | — | — | 0,962 | 1,15 | 1,33 | 1,42 | 1,52 | 1,70 | 1,87 | 2,05 | 2,31 |

| (41,5) | — | — | — | — | — | 0,999 | 1,19 | 1,37 | 1,46 | 1,56 | 1,74 | 1,92 | 2,11 | 2,37 |

| 42 | — | — | — | — | — | 1,010 | 1,21 | 1,40 | 1,50 | 1,59 | 1,79 | 1,97 | 2,16 | 2,44 |

| 43 | — | — | — | — | — | 1,04 | 1,24 | 1,44 | 1,54 | 1,63 | 1,83 | 2,02 | 2,21 | 2,50 |

| 45 | — | — | — | — | — | 1,08 | 1,30 | 1,51 | 1,61 | 1,71 | 1,92 | 2,12 | 2,32 | 2,62 |

| (46) | — | — | — | — | — | 1,11 | 1,33 | 1,54 | 1,64 | 1,75 | 1,96 | 2,17 | 2,38 | 2,68 |

| 48 | — | — | — | — | — | 1,16 | 1,39 | 1,61 | 1,72 | 1,83 | 2,05 | 2,27 | 2,48 | 2,81 |

| (49) | — | — | — | — | — | 1,18 | 1,41 | 1,64 | 1,76 | 1,87 | 2,10 | 2,32 | 2,54 | 2,87 |

| 50 | — | — | — | — | — | 1,21 | 1,44 | 1,63 | 1,79 | 1,91 | 2,14 | 2,37 | 2,59 | 2,93 |

| 51 | — | — | — | — | — | — | — | 1,71 | 1,83 | 1,95 | 2,18 | 2,42 | 2,65 | 2,99 |

| 53 | — | — | — | — | — | — | — | 1,78 | 1,91 | 2,03 | 2,27 | 2,52 | 2,76 | 3,11 |

| 54 | — | — | — | — | — | — | — | 1,82 | 1,94 | 2,07 | 2,32 | 2,57 | 2,81 | 3,18 |

| 55 | — | — | — | — | — | — | — | 1,85 | 1,98 | 2,11 | 2,36 | 2,61 | 2,86 | 3,24 |

| 56 | — | — | — | — | — | — | — | 1,89 | 2,02 | 2,15 | 2,41 | 2,66 | 2,92 | 3,30 |

| 57 | — | — | — | — | — | — | — | 1,92 | 2,05 | 2,19 | 2,45 | 2,71 | 2,97 | 3,36 |

| (59) | — | — | — | — | — | — | — | — | 2,13 | 2,27 | 2,54 | 2,81 | 3,08 | 3,48 |

| 60 | — | — | — | — | — | — | — | — | 2,16 | 2,30 | 2,58 | 2,86 | 3,14 | 3,55 |

| 63 | — | — | — | — | — | — | — | — | 2,28 | 2,42 | 2,72 | 3,01 | 3,30 | 3,73 |

| 65 | — | — | — | — | — | — | — | — | 2,35 | 2,50 | 2,81 | 3,11 | 3,41 | 3,85 |

| 68 | — | — | — | — | — | — | — | — | 2,46 | 2,62 | 2,94 | 3,26 | 3,57 | 4,04 |

| 70 | — | — | — | — | — | — | — | — | 2,53 | 2,70 | 3,03 | 3,35 | 3,68 | 4,16 |

| 73 | — | — | — | — | — | — | — | — | 2,65 | 2,82 | 3,16 | 3,50 | 3,84 | 4,35 |

| 75 | — | — | — | — | — | — | — | — | 2,72 | 2,90 | 3,25 | 3,60 | 3,95 | 4,47 |

| 76 | — | — | — | — | — | — | — | — | 2,76 | 2,94 | 3,29 | 3,65 | 4,00 | 4,53 |

| 77 | — | — | — | — | — | — | — | — | — | — | — | — | — | 4,59 |

| 80 | — | — | — | — | — | — | — | — | — | — | — | — | — | 4,78 |

| 83 | — | — | — | — | — | — | — | — | — | — | — | — | — | 4,96 |

| (87) | — | — | — | — | — | — | — | — | — | — | — | — | — | 5,21 |

| 89 | — | — | — | — | — | — | — | — | — | — | — | — | — | 5,33 |

| 90 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 100 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| (101) | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 102 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 110 | — | — | — | — | — | — | — | — | — | — | — | — | — | — |

Table 2. Limit deviations for the outer diameter and wall thickness of pipes.

| Pipe dimensions, mm | Limit deviations of pipe sizes with precision manufacturing | ||

| the usual | increased | precision | |

| Outside diameter: | |||

| from 5 to 10 | + -0.15 mm | + -0.10 mm | — |

| St. 10 to 20 | + -0.20 mm | + -0.12mm | + -0.10 mm |

| » 20 » 30 | + -0.25mm | + -0.15 mm | + -0.12 mm |

| » 30 » 40 | + -0.30mm | + -0.20 mm | + -0.15 mm |

| » 40 » 50 | + -0.35mm | + -0.25mm | + -0.20 mm |

| » 50 » 60 | +-0,75 % | +-0,6 % | + -0.25mm |

| » 60 » 70 | +-0,75 % | +-0,6 % | + -0.30mm |

| » 70 » 80 | +-0,75 % | +-0,6 % | + -0.35mm |

| » 80 » 90 | +-0,75 % | +-0,6 % | + -0.40 mm |

| » 90 | +-0,75 % | +-0,6 % | + -0.45mm |

| Wall thickness: | |||

| up to 1 | + -0.12 mm | + -0.10 mm | + -0.10 mm |

| St. one | +- 10% | +-8 % | +-7,5% |

Table 3. Mechanical properties of thermally treated pipes.

| steel grade | Ultimate tensile strength sВ, N / mm2 (kgf / mm2) | Limitfluidity sТ ,. N / mm2 (kgf / mm2) | Elongation after breaking s5,% |

| not less | |||

| 08kp | 294 (30) | 175 (18) | 27 |

| 08, 08ps, 10kp | 314 (32) | 196 (20) | 25 |

| 10ps, 15kp, St2sp, Ce2ps, St2kp, VSt2sp, VSt2ps, VSt2kp | 333 (34) | 206 (21) | 25 |

| 10 | 353 (36) | 216 (22) | 24 |

| 15, 15ps, 20kp, St3sp, ST3ps, ST3kp | 372 (38) | 225 (23) | 22 |

| 20, 20ps, St4sp, St4ps, St4kp | 412 (42) | 245 (25) | 21 |

| 08U | 255 (26) | 174 (18) | 30 |

Now let's move on to the next variation.

Steel pipe table: diameters, price per meter of rolled steel

The cost of one meter of these products is determined by their mass. In this case, a certain relationship can be traced: the thicker the product made of steel, the greater its weight. On the Internet, you can find many tables that contain information about the prices of various parts, classified by the inner diameter. Steel pipes belong to the middle price segment. They are more expensive than polymeric ones, but they surpass them in strength and pressure resistance.

It should be noted that various alloys and protective additives can be used for the production of steel pipes. It also affects the final cost of the products. For example, galvanized parts or stainless steel pipes have a higher price than elements made from ordinary steel.

Table 4. The cost of the most popular water and gas pipes made of steel:

| Dу, mm | price, rub. (for 1 m) |

| 50 | 80-170 |

| 15 | 32-70 |

| 40 | 80-108 |

| 32 | 53-95 |

| 20 | 40-50 |

Thus, the diameter of water pipes and gas transportation products affects their cost. Parts that have a cross section of more than 100 mm are practically not used in everyday life.The cost of such pipes is quite high, since 1 m of a part can weigh more than 10 kg. The heaviest pipe has a diameter of 1220 mm and a wall thickness of 16 mm. The weight of a meter of such a part is approximately 475 kg.

Diameter is a necessary characteristic, without which the laying of a pipeline structure is impossible. When determining this parameter, it is necessary to clearly understand that there are several of its varieties. In the tables that can be found in the relevant regulatory documentation, the inner diameter of steel products is most often indicated. If you decide to use a special formula to determine the cross section, it is recommended that you pay attention to the examples containing the solution.

GOST 30732-2006

This document applies not only to steel pipes, but also to various types of connecting elements that have a thermal insulating layer. By the way, pipes, the thermal insulation layer of which is made of polyurethane foam and enclosed in a special PET shell, are actively used in the arrangement of underground heating mains.

Note! The temperature of the working fluid in this case is allowed no more than 140 degrees (or 150 degrees, but this is a short-term indicator).

At the same time, the indicator of the limiting pressure in this case can be a maximum of 1.6 MPa, which is not so much.

GOST 30732-2006. Steel pipes and fittings with thermal insulation made of polyurethane foam with a protective sheath. Download file (click on the link below to open the attached file in a new window). GOST 30732-2006

Table 4. Dimensions of pipes in a polyethylene sheath (in millimeters).

| Outside diameter and minimum wall thickness of steel pipes * | Type 1 | Type 2 | ||||

| Average outer diameter of insulated pipes with polyethylene sheath | Estimated thickness of the polyurethane foam layer | Average outer diameter of insulated pipes with polyethylene sheath | Estimated thickness of the polyurethane foam layer | |||

| Nominal | Limit deviation (+) | Nominal | Limit deviation (+) | |||

| 32?3,0 | 90; 110; 125 | 2,7; 3,5; 3,7 | 26,0; 36,5; 43,5 | — | — | — |

| 38?3,0 | 110; 125 | 3,2; 3,7 | 33,0; 40,5 | — | — | — |

| 45?3,0 | 125 | 3,7 | 37,0 | — | — | — |

| 57?3,0 | 125 | 3,7 | 31,5 | 140 | 4,1 | 38,5 |

| 76?3,0 | 140 | 4,1 | 29,0 | 160 | 4,7 | 39,0 |

| 89?4,0 | 160 | 4,7 | 32,5 | 180 | 5,4 | 42,5 |

| 108?4,0 | 180 | 5,4 | 33,0 | 200 | 5,9 | 43,0 |

| 133?4,0 | 225 | 6,6 | 42,5 | 250 | 7,4 | 54,5 |

| 159?4,5 | 250 | 7,4 | 41,5 | 280 | 8,3 | 55,5 |

| 219?6,0 | 315 | 9,8 | 42,0 | 355 | 10,4 | 62,0 |

| 273?7,0 | 400 | 11,7 | 57,0 | 450 | 13,2 | 81,5 |

| 325?7,0 | 450 | 13,2 | 55,5 | 500 | 14,6 | 79,5 |

| 426?7,0 | 560 | 16,3 | 58,2 | 600; 630 | 16,3 | 77,6; 92,5 |

| 530?7,0 | 710 | 20,4 | 78,9 | — | — | — |

| 630?8,0 | 800 | 23,4 | 72,5 | — | — | — |

| 720?8,0 | 900 | 26,3 | 76,0 | — | — | — |

| 820?9,0 | 1000 | 29,2 | 72,4 | 1100 | 32,1 | 122,5 |

| 920?10,0 | 1100 | 32,1 | 74,4 | 1200 | 35,1 | 120,5 |

| 1020?11,0 | 1200 | 35,1 | 70,4 | — | — | — |

| 1220?11,0 | 1425 | 38,2 | 79,0 | — | — | — |

| 1420?12,0 | 1600 | 41,2 | 90,0 | — | — | — |

| * The wall thickness of the steel pipe is set in the project. By agreement with the design organization, it is also allowed to use pipes of other diameters. | ||||||

Table 5. Dimensions of pipes in a steel casing (in millimeters).

| Outside diameter of steel pipe and minimum wall thickness of steel pipe * | Dimensions of galvanized sheet steel sheath | Estimated layer thickness polyurethane foam ** | |

| Nominal diameter | Minimum thickness | ||

| 32?3,0 | 100; 125; 140 | 0,55 | 46,0; 53,5 |

| 38?3,0 | 125; 140 | 0,55 | 43,0; 50,5 |

| 45?3,0 | 125; 140 | 0,55 | 39,5; 47,0 |

| 57?3,0 | 140 | 0,55 | 40,9 |

| 76?3,0 | 160 | 0,55 | 41,4 |

| 89?4,0 | 180 | 0,6 | 44,9 |

| 108?4,0 | 200 | 0,6 | 45,4 |

| 133?4,0 | 225 | 0,6 | 45,4 |

| 159?4,5 | 250 | 0,7 | 44,8 |

| 219?6,0 | 315 | 0,7 | 47,3 |

| 273?7,0 | 400 | 0,8 | 62,7 |

| 325?7,0 | 450 | 0,8 | 61,7 |

| 426?7,0 | 560 | 1,0 | 66,2 |

| 530?7,0 | 675; 710 | 1,0 | 71,5; 89,0 |

| 630?8,0 | 775; 800 | 1,0 | 71,5; 84,0 |

| 720?8,0 | 875; 900 | 1,0 | 76,5; 89,0 |

| 820?9,0 | 975; 1000 | 1,0 | 76,5; 89,0 |

| 920?10,0 | 1075; 1100 | 1,0 | 76,5; 89,0 |

| 1020?11,0 | 1175; 1200 | 1,0 | 76,7; 89,2 |

| 1220?11,0 | 1375; 1400 | 1,0 | 79,0; 91,5 |

| 1420?12,0 | 1575;1600 | 1,0 | 77,0; 89,5 |

| * The wall thickness of the steel pipe is determined by the project. ** The value is for reference. | |||

Table 6. Dimensions of polyethylene sheathing pipes (in millimeters)

| Average outer diameter | Wall thickness | ||

| Nominal | Limit deviation | Minimum | Limit deviation |

| 90 | +0,9 | 2,2 | +0,4 |

| 110 | +1,0 | 2,5 | +0,5 |

| 125 | +1,2 | 2,5 | +0,5 |

| 140 | +1,3 | 3,0 | +0,5 |

| 160 | +1,5 | 3,0 | +0,5 |

| 180 | +1,7 | 3,0 | +0,5 |

| 200 | +1,8 | 3,2 | +0,5 |

| 225 | +2,1 | 3,5 | +0,6 |

| 250 | +2,3 | 3,9 | +0,7 |

| 280 | +2,6 | 4,4 | +0,7 |

| 315 | +2,9 | 4,9 | +0,7 |

| 355 | +3,2 | 5,6 | +0,8 |

| 400 | +3,6 | 5,6 | +0,9 |

| 450 | +4,1 | 5,6 | +1,1 |

| 500 | +4,5 | 6,2 | +1,2 |

| 560 | +5,0 | 7,0 | +1,3 |

| 630 | +5,7 | 7,9 | +1,5 |

| 710 | +6,4 | 8,9 | +1,7 |

| 800 | +7,2 | 10,0 | +1,9 |

| 900 | +8,1 | 11,2 | +2,2 |

| 1000 | +9,0 | 12,4 | +2,4 |

| 1100 | +9,9 | 13,8 | +2,7 |

| 1200 | +10,8 | 14,9 | +2,9 |

| 1425 | +12,6 | 17,3 | +3,4 |

| 1600 | +14,4 | 19,6 | +3,9 |

Table 7. Deviation of the center lines of the steel pipe and shell (in millimeters).

| Outer diameter of shells | Centerline deviation |

| Up to 160 incl. | 3,5 |

| St. 160 to 400 incl. | 5,0 |

| St. 400 to 630 incl. | 8,0 |

| St. 630 to 800 incl. | 10,0 |

| St. 800 to 1200 incl. | 14,0 |

| St. 1200 to 1375 incl. | 16,0 |

| St. 1375 to 1600 incl. | 18,0 |

Table 8. Calculated values of the thickness of the PU foam insulation for different areas (in millimeters).

| Outside diameter of pipes | Calculated values of PU foam insulation thickness / outer diameter of shells | ||||||

| European regions | Ural | Western Siberia | Eastern Siberia | Far East | |||

| South | Centre | North | |||||

| 57 | 31,5/125 | 31,5/125 | 31,5/125 | 31,5/125 | 31,5/125 | 38,5/140 | 31,5/125 |

| 76 | 29/140 | 29/140 | 39/160 | 39/160 | 39/160 | 39/160 | 39/160 |

| 89 | 32,5/160 | 32,5/160 | 42,5/180 | 42,5/180 | 42,5/180 | 42,5/180 | 42,5/180 |

| 108 | 33/180 | 33/180 | 43/200 | 43/200 | 43/200 | 43/200 | 43/200 |

| 133 | 42,5/225 | 42,5/225 | 42,5/225* | 42,5/225 | 42,5/225 | 54,5/250 | 42,5/225 |

| 159 | 41,5/250 | 41,5/250 | 55,5/280 | 41,5/250* | 55,5/280 | 55,5/280 | 55,5/280 |

| 219 | 42/315 | 62/355 | 62/355 | 62/355 | 62/355 | 62/355 | 62/355 |

| 273 | 57/400 | 57/400 | 57/400* | 57/400 | 57/400* | 81,5/450 | 57/400 |

| 325 | 55,5/450 | 55,5/450 | 79,5/500 | 55,5/450* | 79,5/500 | 79,5/500 | 79,5/500 |

| 426 | 58,2/560 | 58,2/560* | 92,4/630 | 92,4/630 | 92,4/630 | 92,4/630 | 92,4/630 |

| 530 | 79/710 | 79/710 | 79/710 | 79/710 | 79/710 | 79/710 | 79/710 |

| 630 | 72,5/800 | 72,5/800 | 72,5/800* | 72,5/800 | 72,5/800 | 72,5/800 | 72,5/800 |

| 720 | 76/900 | 76/900 | 76/900 | 76/900 | 76/900 | 76/900* | 76/900 |

| 820 | 72,5/1000 | 72,5/1000 | 122,5/1100 | 72,5/1000 | 72,5/1000* | 122,5/1100 | 72,5/1000* |

| 920 | 74,5/1100 | 74,5/1100 | 120,5/1200 | 74,5/1100 | 74,5/1100* | 120,5/1200 | 74,5/1100* |

| 1020 | 70,5/1200 | 70,5/1200* | ** | 70,5/1200* | ** | ** | ** |

| 1220 | 79,0/1425 | 79,0/1425 | ** | 79/1400* | ** | ** | ** |

| 1420 | 90,0/1600 | 90,0/1600 | ** | 90,0/1600* | ** | ** | ** |

| * The thickness of the pipe insulation is taken less than the calculated one according to the conditions of normalized heat loss. ** The thickness of the pipe insulation is determined by the non-standard outer diameter of the polyethylene sheath. | |||||||

Diameters of steel pipes: what are these indicators for and how they are determined

Knowing the exact value of the diameter that a water or gas pipe has, it becomes possible to calculate the volume of a substance transported through communications. The use of such pipes in construction requires a clear definition of the dimensional characteristics necessary for the calculation of economic systems.

An example is the heating system. The diameter of pipes in such communications must be clearly calculated so that in the winter period the system provides uniform heating of living quarters.

Calculation of the diameter of a steel pipe allows you to determine its throughput

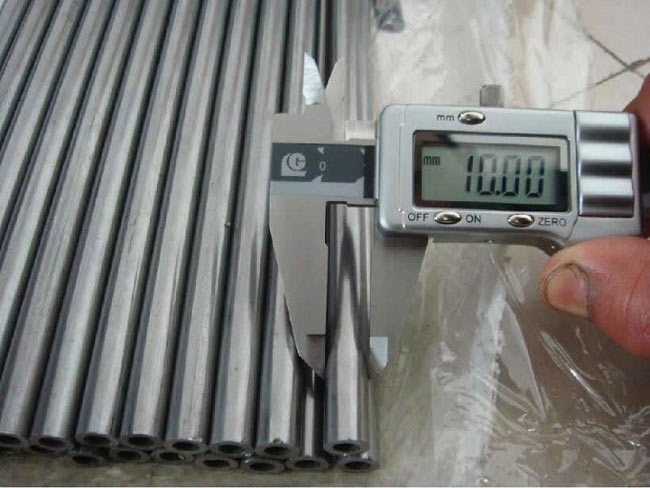

Today, there are several common methods for calculating the diameter of steel pipes. The size chart that can be found in the regulatory documents is the simplest one. You can also determine this parameter using online calculators. Such programs are located on specialized sites on the network, so it is not difficult to find them.

Independent calculation of the diameter of the communication is carried out using mathematical expressions. The type of formula depends on the operational purpose of the communication. For example, the following equation is used to determine the diameter of the heating pipe:

D = sqrt ((3.14 x Q) / (V x DT)), where:

D - diameter (internal); Q is the heat flow rate, calculated in kW; V is the velocity of the substance transported through the pipeline (measured in m / s); DT is the temperature difference at the starting and ending point of the system (input / output); sqrt - square root.

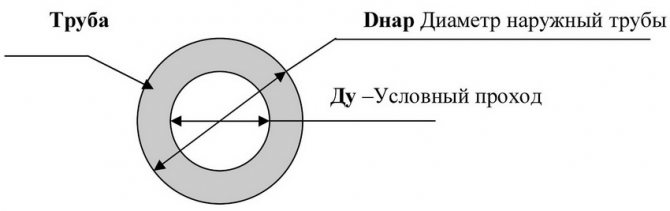

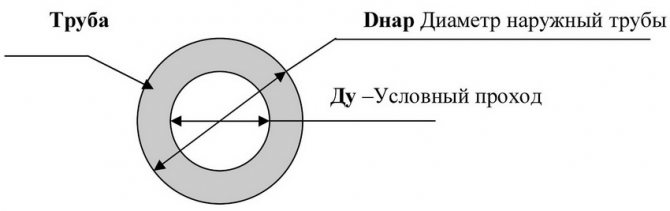

Steel pipe schematic showing outside and inside diameter symbols

This formula allows you to fairly accurately determine the diameter of the pipe. The designation of this indicator in the diagrams makes it possible to correctly calculate the required pressure and the amount of the transported substance per unit of time.

What pipe diameters exist: their varieties

Today, diameters are divided into several types, depending on what exactly this value characterizes. To use this parameter in calculations, it is recommended to study the types of diameters.

Nominal size of pipes (DN). Indicator of the internal space of the pipe. This parameter is calculated in mm or inches. In the second case, the value is rounded. Knowledge of this parameter allows you to select accessories (fittings) of the required size for pipes.

Nominal diameter. This indicator is very similar to the previous type, but it has some differences. For example, the main characteristic of the nominal parameter is its high accuracy, which does not tolerate rounding.

Steel pipe diameter is measured in millimeters or inches

Inner diameter (Du). This indicator is a physical quantity that is measured in mm. The inner diameter is used when calculating the permeability of a piping structure. This value should not be confused with the nominal pipe diameter.

Note! To calculate this parameter, there is a special formula: Dy = Dн - 2S.

Outside diameter (Dн). According to this parameter, all pipes made of steel are divided into 3 main groups: small, medium and large. Each group has its own size range and purpose. The easiest way to determine this indicator is from the table of steel pipes. GOSTs regulating such products can be easily found on the Internet using the search box of your browser.

It is necessary to note such a parameter as wall thickness. This value refers to physical and affects the quality characteristics of the part. For example, the volume of the product and its mass depend on the thickness of the walls. The wall thickness is calculated in mm. To determine it, the following simple formula is often used:

t = Dн - Dу

There are special formulas for determining the pipe diameter

GOST 10706-76 (91)

Here we are talking about electrically welded products, still made of steel, but with a straight seam. Pipes of this kind are actively used for general purposes. Note also that the minimum pipe diameter, according to this regulatory document, should be 42.5 centimeters, and the maximum - 162 centimeters.

GOST 10706-76 (91).Longitudinal electric-welded steel pipes. Download file (click on the link below to open the attached file in a new window). GOST 10706-76 (91)

Table 9. Longitudinal electric-welded steel pipes.

| Outside diameter, mm | Theoretical mass of 1 m of pipes, kg, with wall thickness, mm | ||||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | 3,0 | |

| 10 | 0,222 | 0,260 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| 10,2 | 0,227 | 0,266 | — | — | — | — | — | — | — | — | — |

| 12 | 0,271 | 0,320 | 0,366 | 0,388 | 0,410 | — | — | — | — | — | — |

| 13 | 0,296 | 0,349 | 0,401 | 0,425 | 0,450 | — | — | — | — | — | — |

| 14 | 0,321 | 0,379 | 0,435 | 0,462 | 0,489 | — | — | — . | — | — | — |

| (15) | 0,345 | 0,408 | 0,470 | 0,499 | 0,529 | — | — | — | — | — | — |

| 16 | 0,370 | 0,438 | 0,504 | 0,536 | 0,568 | — | — | — | — | — | — |

| (17) | 0,395 | 0,468 | 0,539 | 0,573 | 0,608 | — | — | — | — | — | — |

| 18 | 0,419 | 0,497 | 0,573 | 0,610 | 0,719 | 0,789 | — | — | — | — | — |

| 19 | 0,444 | 0,527 | 0,608 | 0,647 | 0,687 | 0,764 | 0,838 | — | — | — | — |

| 20 | 0,469 | 0,556 | 0,642 | 0,684 | 0,726 | 0,808 | 0,888 | — | — | — | — |

| 21,3 | 0,501 | 0,595 | 0,687 | 0,732 | 0,777 | 0,866 | 0,952 | — | — | — | — |

| 22 | 0,518 | 0,616 | 0,711 | 0,758 | 0,805 | 0,897 | 0,986 | — | — | — | — |

| (23) | 0,543 | 0,645 | 0,746 | 0,795 | 0,844 | 0,941 | 1,04 | 1,13 | 1,26 | 3/4 | — |

| 24 | 0,567 | 0,675 | 0,780 | 0,832 | 0,884 | 0,985 | 1,09 | 1,18 | 1,33 | — | — |

| 25 | 0,592 | 0,704 | 0,815 | 0,869 | 0,923 | 1,03 | 1,13 | 1,24 | 1,39 | — | — |

| 26 | 0,617 | 0,734 | 0,849 | 0,906 | 0,963 | 1,07 | 1,18 | 1,29 | 1,45 | — | |

| 27 | 0,641 | 0,764 | 0,884 | 0,943 | 1,00 | 1,12 | 1.23 | 1,35 | 1,51 | — | |

| 28 | 0,666 | 0,793 | 0,918 | 0,980 | 1,04 | 1,16 | 1,28 | 1,40 | 1,57 | — | |

| 30 | 0,715 | 0,852 | 0,987 | 1,05 | 1,12 | 1,25 | 1,38 | 1,51 | 1,70 | — | |

| 32 | 0,765 | 0,911 | 1,06 | 1,13 | 1,20 | 1,34 | 1,48 | 1,62 | 1,82 | 2,02 | |

Continuation of table. eight

| Outside diameter, mm | Theoretical mass of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | |

| 33 | 0,789 | 0,941 | 1,09 | 1,17 | 1,24 | 1,38 | 1,53 | 1,67 | 1,88 | 2,09 |

| 33,7 | — | 0,962 | 1,12 | 1,19 | 1,27 | 1,42 | 1,56 | 1,71 | 1,92 | 2,13 |

| 35 | — | 1,00 | 1,16 | 1,24 | 1,32 | 1,47 | 1,63 | 1,78 | 2,00 | 2,22 |

| 36 | — | 1,03 | 1,19 | 1,28 | 1,36 | 1,52 | 1,68 | 1,83 | 2,07 | 2,29 |

| 38 | — | 1,09 | 1,26 | 1,35 | 1,44 | 1,61 | 1,78 | 1,94 | 2,19 | 2,43 |

| 40 | — | 1,15 | 1,33 | 1,42 | 1,52 | 1,70 | 1,87 | 2,05 | 2,31 | 2,57 |

| 42 | — | 1,21 | 1,40 | 1,50 | 1,59 | 1,78 | 1,97 | 2,16 | 2,44 | 2,71 |

| 44,5 | — | 1,28 | 1,49 | 1,59 | 1,69 | 1,90 | 2,10 | 2,29 | 2,59 | 2,88 |

| 45 | — | 1,30 | 1,51 | 1,61 | 1,71 | 1,92 | 2,12 | 2,32 | 2,62 | 2,91 |

| 48 | — | — | 1,61 | 1,72 | 1,83 | 2,05 | 2,27 | 2,48 | 2,81 | 3,12 |

| 48,3 | — | — | 1,62 | 1,73 | 1,84 | 2,06 | 2,28 | 2,50 | 2,82 | 3,14 |

| 51 | — | — | 1,71 | 1,83 | 1,95 | 2,18 | 2,42 | 2,65 | 2,99 | 3,33 |

| 53 | — | — | 1,78 | 1,91 | 2,03 | 2,27 | 2,52 | 2,76 | 3,11 | 3,47 |

| 54 | — | — | 1,82 | 1,94 | 2,07 | 2,32 | 2,56 | 2,81 | 3,18 | 3,54 |

| 57 | — | — | 1,92 | 2,05 | 2,19 | 2,45 | 2,71 | 2,97 | 3,36 | 3,74 |

| 60 | — | — | 2,02 | 2,16 | 2,30 | 2,58 | 2,86 | 3,14 | 3,55 | 3,95 |

| 63,5 | — | — | 2,14 | 2,29 | 2,44 | 2,74 | 3,03 | 3,33 | 3,76 | 4,19 |

| 70 | — | — | 2,37 | 2,53 | 2,70 | 3,03 | 3,35 | 3,68 | 4,16 | 4,64 |

| 73 | 3/4 | 3/4 | 2,47 | 2,64 | 2,82 | 3,16 | 3,50 | 3,84 | 4,35 | 4,85 |

| 76 | — | — | 2,58 | 2,76 | 2,94 | 3,29 | 3,65 | 4,00 | 4,53 | 5,05 |

| 88 | — | — | — | — | 3,21 | 3,60 | 4,00 | 4,38 | 4,96 | 5,54 |

| 89 | — | — | — | — | 3,45 | 3,87 | 4,29 | 4,71 | 5,33 | 5,95 |

| 95 | 3/4 | — | — | — | — | — | 4,59 | — | 5,70 | — |

| 102 | 3/4 | 3/4 | 3/4 | — | — | 4,45 | 4,93 | 5,41 | 6,13 | 6,85 |

| 108 | 3/4 | — | — | — | — | 4,71 | 5,23 | 5,74 | 6,50 | 7,26 |

| 114 | — | — | — | — | — | 4,98 | 5,52 | 6,07 | 6,87 | 7,68 |

| 127 | — | — | — | — | — | 5,56 | 6,17 | 6,77 | 7,68 | 8,58 |

Continuation of table. eight

| Outside diameter, mm | Theoretical mass of 1 m of pipes, kg, with wall thickness, mm | |||||||||

| 1,0 | 1,2 | 1,4 | (1,5) | 1,6 | 1,8 | 2,0 | 2,2 | 2,5 | 2,8 | |

| 133 | — | — | — | — | — | 5,82 | 6,46 | 7,10 | 8,05 | 8,99 |

| 140 | — | — | — | — | — | 6,13 | 6,81 | 7,48 | 8,48 | 9,47 |

| 152 | 3/4 | — | — | — | — | 6,67 | 7,40 | 8,13 | 9,22 | 10,30 |

| 159 | — | — | — | — | — | 6,98 | 7,74 | 8,51 | 9,65 | 10,79 |

| 168 | — | — | — | — | — | 7,38 | 8,19 | 9,00 | 10,20 | 11,41 |

| 177,8 | — | — | — | — | — | 7,81 | 8,67 | 9,53 | 10,81 | 12.08 |

| 180 | — | — | — | — | — | — | — | — | — | — |

| 193,7 | — | — | — | — | — | — | 9,46 | 10,39 | 11,79 | 13,18 |

| 219 | — | — | — | — | — | — | — | — | 13,35 | 14,93 |

| 244,5 | — | — | — | — | — | — | — | — | — | — |

Continuation of table. eight

| Outside diameter, mm | Theoretical mass of 1 m of pipes, kg, with wall thickness, mm | ||||||||||

| 3,0 | 3,2 | 3,5 | 3,8 | 4,0 | 4,5 | 5,0 | 5,5 | 6,0 | 7,0 | 8,0 | |

| 26 | — | — | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| 27 | — | — | — | — | — | — | — | — | — | — | — |

| 28 | — | — | — | — | — | — | — | — | — | — | — |

| 30 | — | — | — | — | — | — | — | — | — | — | — |

| 32 | 2,15 | — | — | — | — | — | — | — | — | — | — |

| 33 | 2,22 | — | — | — | — | — | — | — | — | — | — |

| 33,7 | 2,27 | — | — | — | — | — | — | — | — | — | — |

| 35 | 2,37 | — | — | — | — | — | — | — | — | — | — |

| 36 | 2,44 | — | — | — | — | — | — | — | 3/4 | 3/4 | 3/4 |

| 38 | 2,59 | — | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| 40 | 2,74 | — | — | — | — | — | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| 42 | 2,89 | — | — | — | — | — | — | — | — | — | 3/4 |

| 44,5 | 3,07 | — | — | — | — | — | — | — | — | — | — |

| 45 | 3,11 | — | — | — | — | — | — | — | — | — | 3/4 |

| 48 | 3,33 | 3,54 | 3,84 | — | — | — | — | — | — | — | — |

| 48,3 | 3,35 | 3,56 | 3,87 | — | — | — | — | — | — | — | — |

| 51 | 3,55 | 3,77 | 4,10 | — | — | — | — | — | — | — | — |

| 53 | 3,70 | 3,93 | 4,27 | — | — | — | — | — | — | — | — |

| 54 | 3,77 | 4,01 | 4,36 | — | — | — | — | — | — | — | — |

Table 9. Limit deviations for the outer diameter of the pipe

| Outside diameter of pipes, mm | Limit deviations for the outer diameter with manufacturing accuracy | |

| the usual | increased | |

| 10 | + -0.2 mm | 3/4 |

| St. 10 to 30 incl. | + -0.3 mm | +-0,25 |

| » 30 » 51 » | + -0.4 mm | +-0,35 |

| » 51 » 193,7 » | +-0,8 % | +-0,7 % |

| »193,7 » 426 » | +-0,75 % | +-0,65 % |

| » 426 » 1020 » | +-0,7 % | +-0,65 % |

| » 1020 | +-0,6 % | + -6.0 mm |

Rolling technology

Products of various diameters made of steel are of two types:

- Seamless.

- hot rolled (from a billet heated to a certain temperature).

- cold rolled (from a chilled billet).

- Welded.

- longitudinal seam.

- spiral seam.

Using various technologies, you can roll steel pipes for any purpose:

- round - for gas transmission systems, storage and distillation of liquids (water supply and sewerage);

- profiled (square, rectangular) - for the installation of metal structures.

Seamless products are rolled from a round billet, welded ones - from sheet metal.

Modern rolling production

The range of rolled steel is extremely wide. Differences in technological processes make it possible to produce various standard sizes of products in one or several ways. For each method, one or several state standards have been developed, which contain requirements for the physical and chemical composition, geometric dimensions and deviations, weight and purpose. Let's consider some of the features of popular methods of manufacturing finished steel products.

When standardizing product production, several different types of diameters are used:

- Conditional - Du.

- Nominal - Dn.

- Outer.

- Interior.

Due to the breadth of the product range, it became necessary to bring the standards for finished products from different materials - rolled steel and polymers - to conformity. In this case, the main standard is the diameter table.

| Conditional passage, mm | Thread diameter, '' | Outside diameter, mm | ||

| Steel | Polymer | |||

| Suture | Seamless | |||

| 10 | 3/8 | 17 | 16 | 16 |

| 15 | ½ | 21,3 | 20 | 20 |

| 20 | ¾ | 26,8 | 26 | 25 |

| 25 | 1 | 33,5 | 32 | 32 |

| 32 | 1 ¼ | 42.3 | 42 | 40 |

| 40 | 1 ½ | 48 | 45 | 50 |

| 50 | 2 | 60 | 57 | 63 |

| 65 | 2 ½ | 75,5 | 76 | 75 |

| 80 | 3 | 88,5 | 89 | 90 |

| 90 | 3 ½ | 101,3 | 102 | 110 |

| 100 | 4 | 114 | 108 | 125 |

| 125 | 5 | 140 | 133 | 140 |

| 150 | 6 | 165 | 159 | 160 |

Conversion of dimensions is necessary in the case when combined systems are mounted in which pipes made of steel and plastic are used.

GOST 10705-91 (80)

In this case, we are talking about longitudinal electric-welded products, the diameter of which ranges from 1 to 63 centimeters. In the production process, the same carbon steel is used. Pipes are characterized by a fairly wide scope of application, but, as a rule, they are found in pipelines intended for transporting water.

GOST 10705-91 (80). Electric-welded steel pipes. Download file (click on the link below to open the attached file in a new window). GOST 10705-91 (80)

Table 11. Electric-welded steel pipes - mass fraction of the element,%

| steel grade | Mass fraction of the element,% | ||||||||||

| Carbon | Silicon | Manganese | Aluminum | Titanium | Chromium | Nitrogen | Calcium | Sulfur | Phosphorus | ||

| no more | |||||||||||

| 22GU | 0,15-0,22 | 0,15-0,30 | 1,20-1,40 | 0,02-0,05 | 0,03 | 0,4 | 0,012 | 0,02 | 0,01 | 0,02 | |

Table 12. Mechanical properties of the base metal of heat-treated and hot-rolled carbon steel pipes.

| steel grade | Ultimate resistance in, N / mm2 (kgf / mm2) | Yield strength t N / mm2 (kgf / mm2) | Elongation 5,% | steel grade | Ultimate resistance in, N / mm2 (kgf / mm2) | Yield strength t N / mm2 (kgf / mm2) | Elongation 5,% |

| not less | not less | ||||||

| 08U | 255 (26) | 174 (18) | 30 | 15, 15ps, 20kp, St3ps, St3sp, St3kp | 372 (38) | 225 (23) | 22 |

| 08kp | 294 (30) | 174 (18) | 27 | ||||

| 08, 08ps, 10kp | 314 (32) | 196 (20) | 25 | ||||

| 10, 10ps, 15kp, St2sp, St2kp, St2ps | 333 (34) | 206 (21) | 24 | 20, 20ps, St4sp, St4ps, St4kp | 412 (42) | 245 (25) | 21 |

Basic GOSTs for steel pipes

The technical characteristics of each type of steel pipe, depending on the method of its manufacture, are determined by the corresponding GOST. It is necessary to familiarize yourself with the content of regulatory documents at least in order to know the features of the operation of a certain type of pipes.

GOST 30732-2006. Regulatory document number 30732 was adopted in 2006 and applies to pipes and steel fittings with thermal insulation. Steel pipes made using polyurethane foam (PU) insulation with a polyethylene sheath or a protective steel coating are used for laying heating networks under and above the ground. They are designed for a coolant temperature not exceeding 140 degrees (with a short-term rise to 150 degrees). The maximum allowable working pressure for steel pipes with insulation according to the state standard 30732-2006 with the presence of PPU insulation is 1.6 MPa.

GOST 2591-2006 (88). GOST, which defines the range of hot-rolled steel products, has been in effect since 2006. Some sources use the old GOST - 2591-81. The provisions of the document apply to square steel products obtained by the "hot" method. GOST 2591-2006 (88) includes all products with side sizes ranging from 6 to 200 mm. The production of larger square pipes is possible only upon agreement of the terms of the manufacturer's contract with the buyer.

GOST 9567-75. The 1975 version of the document is currently in use. This standard specifies the provisions to be followed in the manufacture of precision steel pipes. These products are distinguished by increased manufacturing accuracy: they can be both cold-deformed and hot-rolled (they can also be galvanized or chrome-plated). Pipes of increased accuracy in accordance with GOST 9567-75 are mainly used in the machine-building industry.

GOST 9567-75 defines the parameters for the production of hot-rolled steel pipes

GOST 52079-2003. Document number 52079-2003 defines the standards to which longitudinal and spiral welded steel products are subject. Their diameter is in the range of 114-1420 mm. Such oversized pipes are used in the field of gas trunklines, pipelines for the transmission of oil and oil products. GOST 52079-2003 permits the transportation of non-corrosive-active products only.

Welded steel products of large diameters in accordance with GOST 52079 can serve as a means for transporting substances under constant pressure (working), not exceeding 9.8 MPa. The ambient temperature can drop to -60 degrees.

Important! GOST 52079-2003 has officially ceased to be valid since 01.01.2015. It was replaced by the document GOST 31447-2012.

GOST 12336-66. The normative document GOST 12336-66 applies to closed-type profile products having a rectangular or square section. From 01.01.1981 GOST 12336-66 was canceled, its functions began to be performed by TU 14-2-361-79. However, the provisions of document 12336-66 have remained relevant to this day.

GOST 10705-91 (80). Determines the technical conditions for the creation of longitudinal electric-welded steel pipes with a diameter of 10-630 mm. Steel pipes are produced in accordance with GOST 10705-91 (80) from carbon or low-alloy steels. The scope of application of these structures is diverse: they are mainly used when laying pipelines for transporting water. The provisions of the standard do not apply to steel pipes used in the manufacture of heat and electric heaters.

Pipes manufactured in accordance with GOST 10705-91 - the basis of water supply systems for household and industrial use

GOST 10706 76 (91). Got spread to electric-welded steel pipes with a straight seam, used for general purposes. The diameter of the pipes according to document 10706-76 (91) can be in the range of 426-1620 mm.

GOST 10707 80. Regulates the regulations for electrowelded cold-worked pipes of various degrees of accuracy: normal, high and precision. Products according to document number 10707-80 are produced with a diameter of 5 to 110 mm. For the production of pipes, unalloyed (carbon) steel is used. Sometimes manufacturers of electric-welded (longitudinal) steel pipes indicate in the technical passport a link to the document GOST 10707 91.This is not a mistake as the 1980 standard was extended in 1991.

We will consider in more detail the main GOSTs below.

GOST 9567-75

An interesting fact: today the version of GOST is used, which was adopted back in 1975. On the product side, we are talking about precision steel tubes with increased precision. These can be both hot and cold rolled products, as well as chrome / galvanized elements. The scope of such pipes is mainly the engineering industry.

GOST 9567-75. Precision steel pipes. Download file (click on the link below to open the attached file in a new window). GOST 9567-75

Table 13. Dimensions and weight of 1 m of hot-rolled pipes.

| Outside diameter, mm | Weight of 1 m of pipes, kg, with wall thickness, mm | |||||

| 2,5 | 2,8 | 3,0 | 3,5 | 4,0 | 4,5 | |

| 25 | 1,387 | 1,583 | 1,628 | 1,856 | 2,072 | 2,275 |

| 28 | 1,572 | 1,740 | 1,850 | 2,115 | 2,368 | 2,608 |

| 32 | 1,819 | 2,016 | 2,146 | 2,460 | 2,762 | 3,052 |

| 38 | 2,189 | 2,431 | 2,589 | 2,978 | 3,354 | 3,718 |

| 42 | 2,435 | 2,707 | 2,885 | 3,323 | 3,749 | 4,162 |

| 45 | 2,620 | 2,914 | 3,107 | 3,582 | 4,044 | 4,495 |

| 50 | 2,929 | 3,259 | 3,477 | 4,014 | 4,538 | 5,049 |

| 54 | — | — | 3,773 | 4,359 | 4,932 | 5,493 |

| 57 | — | — | 3,995 | 4,618 | 5,228 | 5,826 |

| 60 | — | — | 4,217 | 4,877 | 5,524 | 6,159 |

| 63,5 | — | — | 4,476 | 5,179 | 5,869 | 6,548 |

| 68 | — | — | 4,805 | 5,561 | 6,313 | 7,047 |

| 70 | — | — | 4,957 | 5,740 | 6,511 | 7,269 |

| 73 | — | — | 5,179 | 5,999 | 6,807 | 7,602 |

| 76 | — | — | 5,401 | 6,258 | 7,103 | 7,935 |

| 83 | — | — | — | 6,862 | 7,793 | 8,712 |

| 89 | — | — | — | 7,380 | 8,385 | 9,378 |

| 95 | — | — | — | 7,898 | 8,977 | 10,043 |

| 102 | — | — | — | 8,502 | 9,667 | 10,880 |

| 108 | — | — | — | — | 10,259 | 11,486 |

| 114 | — | — | — | — | 10,851 | 12,152 |

| 121 | — | — | — | — | 11,542 | 12,929 |

| 127 | — | — | — | — | 12,133 | 13,595 |

| 133 | — | — | — | — | 12,725 | 14,261 |

| 140 | — | — | — | — | — | 15,037 |

| 146 | — | — | — | — | — | 15,703 |

| 152 | — | — | — | — | — | 16,369 |

| 159 | — | — | — | — | — | 17,146 |

| 168 | — | — | — | — | — | — |

| 180 | — | — | — | — | — | — |

| 194 | — | — | — | — | — | — |

| 203 | — | — | — | — | — | — |

| 219 | — | — | — | — | — | — |

| 245 | — | — | — | — | — | — |

| 273 | — | — | — | — | — | — |

| 299 | — | — | — | — | — | — |

| 325 | — | — | — | — | — | — |

Table 14. Dimensions and weight of 1 m cold-rolled and cold-drawn pipes.

| Outside diameter, mm | Weight of 1 m of pipes, kg, with wall thickness, mm | ||||||||

| 0,2 | 0,25 | 0,3 | 0,4 | 0,5 | 0,8 | 1,0 | 1,2 | 1,5 | |

| 4 | 0,0187 | 0,0231 | 0,0274 | 0,0355 | 0,043 | 0,063 | 0,074 | 0,083 | — |

| 5 | 0,0237 | 0,0293 | 0,0348 | 0,0454 | 0,0555 | 0,0829 | 0,0986 | 0,112 | 0,129 |

| 6 | 0,0286 | 0,0355 | 0,0422 | 0,0552 | 0,0678 | 0,103 | 0,123 | 0,142 | 0,166 |

| 7 | 0,0335 | 0,0416 | 0,0496 | 0,0651 | 0,0801 | 0,122 | 0,148 | 0,172 | 0,203 |

| 8 | 0,0385 | 0,0478 | 0,0570 | 0,0750 | 0,0925 | 0,142 | 0,173 | 0,201 | 0,240 |

| 9 | 0,0434 | 0,0540 | 0,0644 | 0,0847 | 0,105 | 0,162 | 0,197 | 0,231 | 0,277 |

| 10 | 0,0483 | 0,0601 | 0,0718 | 0,0947 | 0,117 | 0,182 | 0,222 | 0,260 | 0,314 |

| 11 | 0,0533 | 0,0631 | 0,0792 | 0,105 | 0,129 | 0,201 | 0,247 | 0,290 | 0,351 |

| 12 | 0,0582 | 0,0724 | 0,0886 | 0,114 | 0,142 | 0,221 | 0,271 | 0,320 | 0,388 |

| 13 | 0,0631 | 0,0786 | 0,0940 | 0,124 | 0,154 | 0,241 | 0,296 | 0,349 | 0,42 |

| 14 | 0,0681 | 0,0848 | 0,101 | 0,134 | 0,166 | 0,260 | 0,321 | 0,435 | 0,462 |

| 15 | 0,0730 | 0,0909 | 0,199 | 0,144 | 0,179 | 0,280 | 0,345 | 0,408 | 0,499 |

| 16 | 0,0779 | 0,0971 | 0,166 | 0,134 | 0,191 | 0,300 | 0,370 | 0,438 | 0,536 |

| 18 | 0,0878 | 0,109 | 0,131 | 0,174 | 0,216 | 0,339 | 0,419 | 0,497 | 0,610 |

| 19 | 0,0927 | 0,116 | 0,138 | 0,183 | 0,228 | 0,359 | 0,444 | 0,527 | 0,647 |

| 20 | 0,0977 | 0,122 | 0,146 | 0,193 | 0,240 | 0,379 | 0,469 | 0,556 | 0,684 |

| 21 | 0,103 | 0,128 | 0,153 | 0,203 | 0,253 | 0,399 | 0,493 | 0,586 | 0,721 |

| 22 | 0,108 | 0,134 | 0,161 | 0,213 | 0,265 | 0,418 | 0,518 | 0,616 | 0,758 |

| 23 | 0,112 | 0,140 | 0,168 | 0,223 | 0,277 | 0,438 | 0,543 | 0,645 | 0,795 |

| 24 | 0,117 | 0,146 | 0,175 | 0,233 | 0,290 | 0,458 | 0,567 | 0,375 | 0,832 |

| 25 | 0,122 | 0,153 | 0,183 | 0,243 | 0,302 | 0,477 | 0,592 | 0,704 | 0,859 |

| 26 | 0,127 | 0,159 | 0,190 | 0,253 | 0,314 | 0,497 | 0,617 | 0,734 | 0,906 |

| 27 | 0,132 | 0,165 | 0,198 | 0,262 | 0,327 | 0,517 | 0,641 | 0,764 | 0,943 |

| 28 | 0,137 | 0,171 | 0,205 | 0,272 | 0,339 | 0,537 | 0,666 | 0,793 | 0,980 |

| 30 | 0,147 | 0,183 | 0,220 | 0,292 | 0,364 | 0,576 | 0,715 | 0,852 | 1,054 |

| 32 | 0,157 | 0,196 | 0,235 | 0,312 | 0,388 | 0,616 | 0,764 | 0,911 | 1,128 |

| 34 | 0,167 | 0,208 | 0,249 | 0,331 | 0,413 | 0,655 | 0,814 | 0,971 | 1,202 |

| 35 | 0,172 | 0,214 | 0,257 | 0,341 | 0,425 | 0,675 | 0,838 | 1,000 | 1,239 |

| 36 | 0,177 | 0,220 | 0,264 | 0,351 | 0,438 | 0,694 | 0,863 | 1,030 | 1,276 |

| 38 | 0,186 | 0,233 | 0,279 | 0,371 | 0,462 | 0,734 | 0,912 | 1,089 | 1,350 |

| 40 | 0,196 | 0,245 | 0,294 | 0,391 | 0,487 | 0,773 | 0,962 | 1,148 | 1,424 |

| 42 | — | — | 0,309 | 0,410 | 0,512 | 0,813 | 1,011 | 1,207 | 1,498 |

| 45 | — | — | 0,331 | 0,440 | 0,549 | 0,872 | 1,085 | 1,296 | 1,609 |

| 48 | — | — | 0,353 | 0,470 | 0,586 | 0,931 | 1,159 | 1,385 | 1,720 |

| 50 | — | — | 0,368 | 0,489 | 0,610 | 0,971 | 1,208 | 1,444 | 1,794 |

| 51 | — | — | 0,375 | 0,499 | 0,623 | 0,990 | 1,233 | 1,474 | 1,831 |

| 53 | — | — | 0,390 | 0,519 | 0,647 | 1,030 | 1,282 | 1,533 | 1,905 |

| 54 | — | — | 0,397 | 0,529 | 0,660 | 1,050 | 1,307 | 1,563 | 1,942 |

| 56 | — | — | 0,412 | 0,548 | 0,684 | 1,089 | 1,356 | 1,622 | 2,016 |

| 57 | — | — | 0,419 | 0,558 | 0,697 | 1,109 | 1,381 | 1,651 | 2,053 |

| 60 | — | — | 0,442 | 0,588 | 0,734 | 1,168 | 1,455 | 1,740 | 2,164 |

| 63 | — | — | — | — | — | 1,227 | 1,529 | 1,829 | 2,275 |

| 65 | — | — | — | — | — | 1,267 | 1,578 | 1,888 | 2,349 |

| 68 | — | — | — | — | — | 1,326 | 1,652 | 1,977 | 2,460 |

| 70 | — | — | — | — | — | 1,365 | 1,702 | 2,036 | 2,534 |

| 73 | — | — | — | — | — | 1,424 | 1,776 | 2,125 | 2,645 |

| 75 | — | — | — | — | — | 1,464 | 1,825 | 2,184 | 2,71 |

Features of steel water and gas pipes GOST 3262-75

The steel water and gas pipe (GOST 3262-75 regulates the product mix, the rules for accepting these products and the technical requirements for their manufacture) has found wide application in construction and mechanical engineering. It is used when laying engineering communications (mainly water supply networks). This is due to the compliance of high performance characteristics with the declared technical requirements.

The water and gas pipe is made from a billet made of carbon steel. The prepared strip is sent for molding. Then, its ends are connected using electric arc welding to obtain a one-piece pipe. The finished product is subjected to heat treatment, due to which it is possible to increase its strength and resistance to the negative influence of external factors, which increases the operational characteristics of the pipe.

The final stage of the technological process is the so-called X-ray inspection, thanks to which it is possible to verify the absence or presence of defects in the weld.

Depending on the strength, the products can be light, medium and reinforced, depending on the wall thickness. Steel pipes are also characterized by an accuracy index. Products of ordinary precision are represented by non-galvanized pipes, the manufacture of which does not provide for precise control of the chemical composition of the raw material. The high precision group includes galvanized pipes used in the installation of global piping systems where special material characteristics are required.

The water and gas pipe is made from a billet made of carbon steel

Assortments of steel water and gas pipes

The range of products is regulated by GOST 3262-75. Steel pipe can be either with cylindrical thread or without it. Water and gas supply products are produced in two types: galvanized and non-galvanized. They can have a diameter of 10-80 mm. Depending on the size of the outer diameter and nominal bore, the wall thickness of the products is determined, which varies from 2.5 mm to 4.5 mm.

This affects the weight of the pipe, on the value of which its cost depends. In this case, it should also be borne in mind that galvanized steel pipes are heavier than ferrous metal products. The length of the pipe is in the range of 4-12 m. Depending on this indicator, the products can be measured or unmeasured. The regulatory document strictly defines the presence of permissible deviations, the excess of which is diagnosed as a product defect.

Important! In the case of a rolled thread, it is allowed to reduce the length of the product by no more than 10%.

According to the current GOST for pipes, the surface of the product should not contain delamination, sunsets and cracks. However, the presence of insignificant deformations and flaws is allowed, which were formed as a result of the technological process and do not have a negative impact on the quality of the product.This can be scale, stripping, or dents.

The wall thickness of the water and gas pipe varies from 2.5 mm to 4.5 mm

If the product is galvanized, it must have a continuous coating with a thickness of at least 30 mm, which is not applied to the threads and pipe ends. Such a surface should not include impurities in the form of oxides, sintered charge, hartzinc, it cannot have blistering and contain signs of flaking from the steel base of the coating. In some places there may be slight deposits of zinc and some roughness. Interspersed with local flux spots and weak traces of pipe gripping by the lifting mechanism are allowed.

Important! In the absence of a galvanized coating within 0.5% of the total surface area, error corrections are allowed after the completion of the technological process.

Galvanized water and gas pipes must pass the distribution test. As a result of the check, the ability of the product to expand is determined until the appearance of visible cracks during the movement of the cone-shaped body in its cavity.

The length of the water and gas pipe is in the range of 4-12 m

Longitudinal electric-welded pipe GOST 10704-91

Longitudinal electric-welded steel pipes (GOST 10704-91 establishes their range) are a popular type of steel products, which is justified by a wide range of subspecies and low cost.

In accordance with GOST 10704, pipes are made by using metal strips of a certain size, made of carbon or alloy steel. The workpieces are cut into strips of a given width and sent to welding, where they become an endless steel strip. On a roller machine, a blank with a circular cross-section is formed from the strip, the ends of which are welded by one of the known methods. After hardening, the finished product undergoes calibration and seam quality control. The finished pipe is cut into measured pieces of a given length.

According to GOST 10704-91, a longitudinal electric-welded pipe can have a diameter of 10-1620 mm. The standard also regulates the wall thickness of the product, which is in the range of 1-32 mm, which depends on the pipe diameter. The measured length of pipes is 500-600 cm for a diameter of up to 70 mm, 600-900 cm for a diameter of 70-219 mm, 10-12 m for a size of 219-426 mm. Products over 426 mm in diameter have an unmeasured length.

Manufacturing technology of electric-welded pipes GOST 10704-91 implies the use of metal strips

Important! Longitudinal electric-welded pipe can be made of any length based on an individual order.

According to GOST 10704-91, electric-welded pipes belong to one of the accuracy classes. For first class products, the ends are cut evenly, and then all burrs are removed. The second grade of accuracy assumes the presence of rough ends with burrs.

In accordance with GOST 10704-91, an electric-welded steel pipe can belong to one of the following categories (depending on the chemical composition):

- group A includes products that can withstand high mechanical loads;

- group B - pipes that perceive chemical influences of various kinds;

- group C - products that combine the characteristics of groups A and B;

- group D consists of pipes that have increased resistance to internal and external pressure.

Longitudinal electric-welded pipe can be made of any length based on an individual order

Advantages and scope of longitudinal steel pipes

Longitudinal electric-welded steel pipe (GOST 10704-91 regulates the possible dimensions of the product and the maximum deviations from them) can have a round, oval or rectangular profile. The products are characterized by the following advantages:

- increased throughput;

- reduced susceptibility to aggressive environments, due to which the product can be used at different facilities;

- resistance during contact with chemical elements, which makes it possible to use pipes at enterprises;

- low rate of thermal expansion;

- high strength;

- resistance to mechanical stress;

- long service life;

- low cost.

High technical and operational features make it possible to use longitudinal electric-welded steel pipes (GOST 10704 allows them to be made up to 18 m long) when installing main and local communication distribution networks of water supply, heating, gas supply. They are often used to transport oil (or in other aggressive environments). With the help of square profile elements, according to GOST 10704-76, you can create various structures in the construction industry.

Longitudinal electric-welded pipes can be used in the installation of main and local communication distribution networks of water supply, heating, etc.

Important! Because the stiffeners provide good flexural strength, longitudinal electric welded pipes are a good alternative to I-beams.

GOST 12336-66

This regulatory document was developed to regulate closed-type profile pipes, which have a square or rectangular cross-section. It is worth noting that the effect of this GOST was canceled at the beginning of 1981 (instead, TU 14-2-361-79 began to be used), however, the key provisions of the document are still relevant even today. Therefore, we attach the corresponding tables.

Table 15. Rectangular pipes in accordance with GOST 12336-66.

| h | b | s | r1 | A | Iy | Wy | iy | Sy | Iz | Wz | iz | |||||

| mm | mm | mm | mm | cm2 | cm4 | cm3 | mm | cm3 | cm4 | cm3 | mm | |||||

| 63x32x2 | 63.000 | 32.000 | 2.000 | 4.000 | 3.470 | 17.100 | 5.420 | 22.200 | 3.420 | 5.980 | 3.740 | 13.100 | ||||

| 63x32x2.5 | 63.000 | 32.000 | 2.500 | 5.000 | 4.230 | 20.100 | 6.390 | 21.800 | 4.100 | 7.020 | 4.390 | 13.000 | ||||

| 63x45x2.5 | 63.000 | 45.000 | 2.500 | 5.000 | 4.880 | 26.100 | 8.280 | 23.100 | 5.080 | 15.570 | 6.920 | 17.900 | ||||

| 63x45x3 | 63.000 | 45.000 | 3.000 | 6.000 | 5.730 | 29.800 | 9.460 | 22.800 | 5.880 | 17.700 | 7.890 | 17.600 | ||||

| 70x36x2 | 70.000 | 36.000 | 2.000 | 4.000 | 3.910 | 24.100 | 6.900 | 24.900 | 4.330 | 8.650 | 4.800 | 14.900 | ||||

| 70x36x2.5 | 70.000 | 36.000 | 2.500 | 5.000 | 4.780 | 28.700 | 8.200 | 24.500 | 5.210 | 10.200 | 5.680 | 14.600 | ||||

| 70x50x2.5 | 70.000 | 50.000 | 2.500 | 5.000 | 5.480 | 36.700 | 10.500 | 25.900 | 6.390 | 21.900 | 8.760 | 20.000 | ||||

| 70x50x3 | 70.000 | 50.000 | 3.000 | 6.000 | 6.450 | 42.100 | 12.000 | 25.500 | 7.420 | 25.100 | 10.000 | 19.700 | ||||

| 80x40x2.5 | 80.000 | 40.000 | 2.500 | 5.000 | 5.480 | 43.400 | 10.800 | 28.100 | 6.850 | 14.800 | 7.410 | 16.400 | ||||

| 80x40x3 | 80.000 | 40.000 | 3.000 | 6.000 | 6.450 | 49.700 | 12.400 | 27.800 | 7.960 | 16.900 | 8.460 | 16.200 | ||||

| 80x56x3 | 80.000 | 56.000 | 3.000 | 6.000 | 7.410 | 64.000 | 16.000 | 29.400 | 9.810 | 37.000 | 13.200 | 22.300 | ||||

Table 16. Square pipes in accordance with GOST 12336-66.

| b | s | r1 | A | Iy = Iz | Wy = Wz | iy = iz | Sy = Sz | P | |

| mm | mm | mm | cm2 | cm4 | cm3 | mm | cm3 | kg / m | |

| 63×3 | 63.000 | 3.000 | 6.000 | 6.810 | 39.500 | 12.550 | 24.100 | 7.500 | 5.350 |

| 63×4 | 63.000 | 4.000 | 8.000 | 8.750 | 48.300 | 15.340 | 23.500 | 9.380 | 6.870 |

| 63×5 | 63.000 | 5.000 | 10.000 | 10.500 | 55.100 | 17.500 | 22.900 | 11.000 | 8.260 |

| 70×3 | 70.000 | 3.000 | 6.000 | 7.650 | 55.600 | 15.900 | 27.000 | 9.430 | 6.010 |

| 70×4 | 70.000 | 4.000 | 8.000 | 9.870 | 68.700 | 19.600 | 26.400 | 11.900 | 7.750 |

| 70×5 | 70.000 | 5.000 | 10.000 | 11.900 | 79.200 | 22.600 | 25.800 | 14.000 | 9.360 |

| 80×3 | 80.000 | 3.000 | 6.000 | 8.850 | 85.300 | 21.300 | 31.000 | 12.600 | 6.950 |

| 80×4 | 80.000 | 4.000 | 8.000 | 11.500 | 100.700 | 26.600 | 30.500 | 16.000 | 9.010 |

| 80×5 | 80.000 | 5.000 | 10.000 | 13.900 | 124.000 | 31.100 | 29.900 | 19.000 | 10.900 |

| 80×6 | 80.000 | 6.000 | 12.000 | 16.200 | 139.000 | 34.800 | 29.300 | 21.600 | 12.700 |

| 90×3 | 90.000 | 3.000 | 6.000 | 10.100 | 124.000 | 27.600 | 35.100 | 16.200 | 7.890 |

| 90×4 | 90.000 | 4.000 | 8.000 | 13.100 | 156.000 | 34.700 | 34.600 | 20.700 | 10.300 |

| 90×5 | 90.000 | 5.000 | 10.000 | 15.900 | 184.000 | 40.900 | 34.000 | 24.700 | 2.500 |

| 90×6 | 90.000 | 6.000 | 12.000 | 18.600 | 208.000 | 46.100 | 33.400 | 28.400 | 14.600 |

| 100×3 | 100.000 | 3.000 | 6.000 | 11.300 | 173.000 | 34.600 | 39.200 | 20.200 | 8.830 |

| 100×4 | 100.000 | 4.000 | 8.000 | 14.700 | 219.000 | 43.900 | 38.700 | 26.000 | 11.500 |

| 100×5 | 100.000 | 5.000 | 10.000 | 17.900 | 260.000 | 52.000 | 38.100 | 31.200 | 14.100 |

| 100×6 | 100.000 | 6.000 | 12.000 | 21.000 | 296.000 | 59.100 | 37.500 | 36.000 | 16.500 |

| 100×7 | 100.000 | 7.000 | 14.000 | 23.900 | 326.000 | 65.200 | 36.900 | 40.300 | 18.800 |

| 110×3 | 110.000 | 3.000 | 6.000 | 12.500 | 234.000 | 42.500 | 43.300 | 24.700 | 9.780 |

Range of square steel pipes: GOST 2591-88 (2006)

Rectangular and square shaped pipes are not widespread in the field of water and gas supply, but they are effectively used in construction as load-bearing and support structures. Thin-walled profiles are used in the furniture and advertising industry.

A significant indicator of the quality of a square steel pipe is its mass: this provision is also stipulated in GOST 2591-88 (2006). The mass index per 1 running meter with a density value of steel (black steel) of 7.85 g / cm3 should be equal to from 0.269 kg - the thinnest pipe; 70.33 kg - for the thickest.

GOST 2591-88 for steel square pipes says that the value of the curvature of square rolled products should not exceed 0.5% of the length for products with a diameter of 25 mm and 0.4% for products with a length of more than 25 mm. At the request of the customer, this indicator can be reduced to 0.2%.

There are standard parameters and tolerances for each pipe length.

Deviations on the sides of square rolled products according to GOST 2591-88 can be in both positive and negative ranges. With the usual accuracy of rolled products, a minus deviation from -2.5 mm (for oversized products with a side of a square of 200 mm) to -0.5 (thin-walled products, a side of a square - 13-25 mm) is allowed. And, accordingly, plus: from +0.9 mm to +0.3 mm.

Important! The range of steel square cold-deformed closed-type pipes is determined by GOST 12336-66.

The range of rectangular steel pipes is determined by GOST 8645-68. Products manufactured according to this standard can be hot-woven, cold-drawn and seamless. From the point of view of strength, seamless structures benefit, but their cost does not allow them to be used in large quantities.

Profile (both square and rectangular) steel pipes according to GOST are often welded. Modern technological methods make it possible to regulate the strength of the seam using induction currents, while the products will remain relatively inexpensive. Welded seams can be cleaned and processed, or they can be left uncleaned: it all depends on the further method of operation.

Galvanized profile pipes are produced in the same way: a steel tape with a pre-applied protective coating is used. In some cases, galvanizing of finished products is used.The profile tube is lowered several times into the molten zinc tank.

GOST for rectangular steel pipes does not divide products into groups depending on the grade of steel used in the manufacture. GOST allows that black steel will be used in the production of a profile steel pipe, which is inferior to more expensive brands in presentability and corrosion resistance.

To protect the profile pipes from corrosion, they are coated with zinc

A rectangular steel pipe in accordance with GOST 8645-68 can have various sizes: the most demanded on the smaller side are 40 mm, at most - from 60 mm to 100 mm. Profile pipes, whose dimensions on the larger side exceed 60 mm, have high bending strength at a relatively light weight, which makes them very popular in the field of engineering and construction.

GOST 31447-2012

Establishes standards for spiral / longitudinal seam products made of steel. The diameter of pipes of this type starts from 11.4 centimeters and ends with 142 centimeters. Agree, very large pipes, which is why they are mainly used in the construction of large gas and oil pipelines. The working pressure indicator at this time should be no more than 9.8 MPa, while the minimum air temperature around the pipeline is -60 degrees.

GOST 31447-2012. Welded steel pipes for main gas pipelines, oil pipelines and oil product pipelines. Download file (click on the link below to open the attached file in a new window). GOST 31447-2012

Table 17. Assortment and theoretical weight of pipes.

| Nominal outer diameter of pipes, mm | Theoretical mass of 1 m of pipe, kg, at nominal wall thickness, mm | ||||||||||||

| 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| 114 | 8,21 | 10,85 | 13,44 | 15,98 | 18,47 | 20,91 | — | — | — | — | — | — | — |

| 121 | 8,73 | 11,54 | 14,30 | 17,02 | 19,68 | 22,29 | 24,86 | 27,37 | — | — | — | — | — |

| 133 | 9,62 | 12,72 | 15,78 | 18,79 | 21,75 | 24,66 | 27,52 | 30,33 | — | — | — | — | — |

| 140 | 10,14 | 13,42 | 16,65 | 19,83 | 22,96 | 26,04 | 29,07 | 32,06 | 34,99 | 37,87 | 40,71 | — | — |

| 146 | 10,58 | 14,01 | 17,39 | 20,71 | 23,99 | 27,22 | 30,41 | 33,54 | 36,62 | 39,65 | 42,64 | — | — |

| 152 | 11,02 | 14,60 | 18,13 | 20,60 | — | — | — | — | — | — | — | — | — |

| 159 | 11,54 | 15,29 | 18,99 | 22,64 | 26,24 | 29,79 | 33,29 | 36,74 | 40,15 | 43,50 | 46,80 | — | — |

| 168 | 12,21 | 16,18 | 20,10 | 23,97 | 27,79 | 31,57 | 35,29 | 38,96 | 42,59 | 46,16 | 49,69 | — | — |

| 178 | 12,95 | 17,16 | 21,33 | 25,45 | 29,52 | 33,54 | 37,51 | 41,43 | 45,30 | 49,12 | 52,90 | — | — |

| 219 | 15,98 | 21,21 | 26,39 | 31,52 | 36,60 | 41,63 | 46,61 | 51,54 | 56,42 | 61,26 | 66,04 | 70,77 | — |

| 245 | — | 23,77 | 29,59 | 35,36 | 41,09 | 46,76 | 52,38 | 57,95 | 63,47 | 68,95 | 47,37 | 79,75 | — |

| 273 | — | 26,54 | 33,04 | 39,51 | 45,92 | 52,28 | 58,59 | 64,86 | 71,07 | 77,24 | 83,35 | 89,42 | |

| 325 | — | 31,67 | 39,46 | 47,20 | 54,89 | 62,54 | 70,13 | 77,68 | 85,18 | 92,62 | 100,03 | 107,38 | 114,68 |

| 356 | — | 34,72 | 43,28 | 51,79 | 60,24 | 68,65 | 77,01 | 85,32 | 93,58 | 101,80 | 109,96 | 118,07 | 126,14 |

| 377 | — | — | 45,87 | 54,89 | 63,87 | 72,80 | 81,68 | 90,51 | 99,28 | 108,01 | 116,70 | 125,33 | 133,91 |

| 426 | — | — | 51,91 | 62,15 | 72,33 | 82,47 | 92,55 | 102,59 | 112,57 | 122,51 | 132,41 | 142,25 | 152,04 |

| 530 | — | — | — | 77,53 | 90,29 | 102,99 | 115,64 | 128,24 | 140,79 | 153,30 | 165,75 | 178,15 | 190,50 |

| 630 | — | — | — | — | 107,55 | 122,72 | 137,83 | 152,90 | 167,91 | 182,88 | 197,80 | 212,67 | 227,49 |

| 720 | — | — | — | — | — | 140,47 | 157,80 | 175,09 | 192,32 | 209,51 | 226,65 | 243,74 | 260,78 |

| 820 | — | — | — | — | — | 160,20 | 180,00 | 199,75 | 219,46 | 239,12 | 258,71 | 278,28 | 297,77 |

So, we examined the range of steel pipes, as well as the key GOST standards that establish their characteristics. Therefore, it remains only to dwell on some other less important points.

Pipe diameter measuring systems: table (inches and millimeters)

Products, the diameter of which is calculated in inches (for example, 5 ″), are used when laying water pipelines and gas transmission structures. On the Internet, you can find tables containing this value in both millimeters and inches. Some of the schemes combine both measurement systems, which is very convenient. A 5-inch pipe corresponds to a standard 125 mm bore.

Measurement of the diameter of pipes in inches is used during the installation of water and gas transmission lines, as this simplifies the overall calculation. One inch equals 25.4 mm. It is important to remember that when measuring a pipe, 1 inch has a different size, namely 33.5 mm. This is explained quite simply: the dimensions of the pipes are calculated by the inner diameter, and not by the outer one. When drawing up a wiring plan and a diagram, this discrepancy must be taken into account. Such information allows you to answer the question of how to measure the diameter of the pipe and avoid mistakes.

Table 1. DN in millimeters and inch size designation system for steel pipes:

| Dу, mm | Thread diameter, inches |

| 150 | 6″ |

| 40 | 1 1/2″ |

| 80 | 3″ |

| 15 | 1/2″ |

| 100 | 4″ |

| 32 | 1 1/4″ |

| 50 | 2″ |

| 125 | 5″ |

| 25 | 1″ |

Helpful information! As a rule, no problems arise when installing only steel products, since they are measured in inches. However, when it becomes necessary to replace the old communication from steel with plastic, confusion can occur. Therefore, it is worth remembering that actual and metric inch sizes are different.

In most cases, the installation of inch pipes does not cause any difficulties. The nature of the discrepancy lies in the designation of steel products (water and gas), which are sold and marked with a nominal diameter, while their real cross-section has other dimensions. As an example, we can give a simple calculation of the dimensions of a pipe, the outer diameter of which is 140 mm, and the wall thickness is 5.5 mm.

To avoid mistakes when planning communications, it is necessary to take into account both the outer and inner pipe diameters.

A simple equation is used to determine the actual diameter:

D = Dн - t x 2

After introducing the required values, this formula takes the following form: D = 140 - 5.5 x 2 = 129 mm. This indicator corresponds to the real diameter of the pipe, in which the section of the outer wall is 140 mm. However, the nominal bore or inner diameter of an inch pipe (or millimeter) is the dominant value. In this case, this value is 125 mm, it is for it that most construction calculations are made.

For joining steel and plastic pipes, special transition elements are used - fittings. Such adapters allow you to connect two pipes with different cross-sectional parameters, made of different materials. In order not to make a mistake when installing communication or replacing it, it is recommended to take into account both the outer and inner diameters of steel pipes.

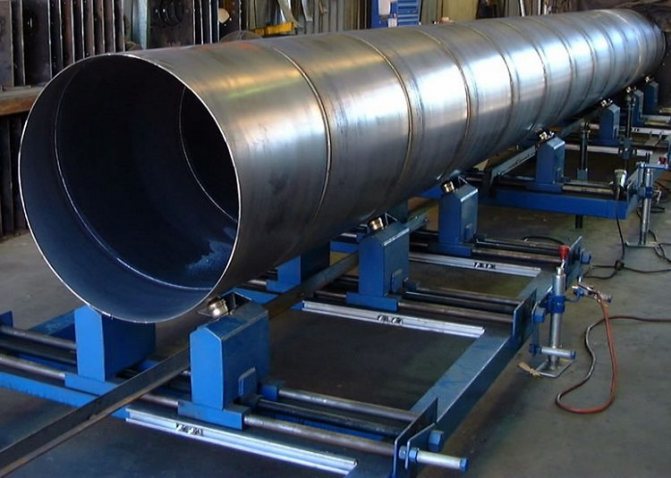

Features of the production of seamless pipes

These products are manufactured from grade 35 or 45 steel using a special continuous mill. What is characteristic, in the process, special blanks are used (the latter are called black blanks), which are first stitched by means of a roller machine, and then transported to a circular saw, which cuts off the end of the pipe. Further, the shape of the pipe is straightened using a cross-roll mill, and the ovality of its cross section is correspondingly reduced.

So now you know everything there is to know about steel pipe assortment. There is a lot of information, but we are sure that you can easily figure it out. For even more familiarity with the technology for the production of pipes from steel, we recommend watching the thematic video material below. That's all, good luck and warm winters!

Seamless gas pipes: assortment

When installing oil and gas pipelines, seamless hot and cold rolled steel pipes are used. As a starting material, a cast or forged cylindrical billet is used, from which a hollow cylinder is obtained by piercing. The final shape of the product is given on a rolling line. Seamless (seamless) pipes are distinguished by their ability to withstand the high pressure of the transported media, therefore they can be used in networks of the first pressure category. These are more expensive products in comparison with welded ones, therefore it is not advisable to use them for household purposes for low-pressure gas pipelines.

Hot-deformed pipes are the result of the first stage of billet machining. The wall thickness reaches 75 mm, the products can be used in harsh operating conditions. The range and properties of steel seamless gas pipes are regulated by GOST 8732-78. To obtain rolled products with accurate dimensions and good surface quality, hot-rolled pipes are subjected to cold deformation. These products can be small in size and are manufactured in accordance with GOST 8734-75.

Steel profile pipe assortment

Profile pipes made of steel are actively used in various fields of construction, mechanical engineering, and furniture production. Products on the modern market are presented in a wide variety. The assortment of profiled steel pipes allows to classify products. The tables contain information on the species composition of pipes, indicating characteristics in the form of size, weight and wall thickness of the products. The assortment is compiled separately for each type of pipes, which is established by the corresponding GOST. Profile pipes are made by welding or rolling using a special machine.

Important! Profiled steel pipes cannot be used for transporting gases and liquids, creating water supply systems, heating and ventilation.

In accordance with GOST 13663-86, the assortment of steel shaped pipes determines the standard, non-standard and flat-oval type of section. The first option covers rectangular and square products, which are the most popular.Having four stiffening ribs, the products, despite their low weight, are able to withstand significant mechanical loads. They are used in the construction and repair of towers, buildings, towers and bridges.

Profile pipes made of steel are used in various areas of construction, as well as in furniture production

Non-standard shaped pipes have a triangular, polygonal, segmented or drop-shaped cross-section. Such products find their application in extraordinary architectural solutions. The latter option is used for the construction of small structures with low weight. The area of use of pipes depends on the size of the section. Products with a low value are used for the installation of cable products, in the furniture industry and as a basis for creating decorative elements.

Profile pipes of medium and large cross-section can be used in the construction of load-bearing structures, where these elements will act as support beams and partitions. They are widely used for production equipment and technology, when creating outdoor advertising media. According to GOST 30245-2012, square steel pipes, the range of which has been expanded to a profile size of 500x500 mm with a wall thickness of up to 22 mm, can be used for these purposes.

The profile pipe has the following advantages:

- high durability of products;

- increased resistance to weight loads and mechanical stress;

- convenient form, providing simplified loading, transportation, unloading and installation;

The scope of application of the steel profile pipe is very wide.

- light weight of the product, which helps to reduce time and effort when laying it;

- versatility of use;

- affordable cost.

The main disadvantage of a shaped tube is the difficulty in bending. This defect requires the involvement of specialists and the use of special equipment in the form of a pipe bender. Another problem is corrosion instability. To avoid the destruction of the structure of the product, its surface is galvanized. This process is strictly regulated by the current standard.

Table of assortment of steel pipes of rectangular profile type

Profiled steel pipes of rectangular cross-section are rationally used in the construction of structures for which the direction of the main load is determined. This type of material is used in the construction of columns, beams, racks and frames of structures. Determines the range of rectangular steel pipes GOST 8645-68. Shown here are electric-welded, furnace-welded and seamless cold-worked and hot-rolled products.

The steel profile pipe makes it possible to implement various architectural solutions and bold design ideas

According to the assortment, a rectangular steel pipe has the following characteristics: width varies within 15-230 mm, height - 10-100, wall thickness - 1-20 mm. The length of products can be measured and unmeasured. Pipes made by the hot-rolled method are characterized by a measured length of 4-12.5 m, by a cold-drawn method - 1.5-9 m, which corresponds to an off-gauge length, and 4.5-11 m - a measured one. For electric-welded pipes, the off-gauge length is 1.5-9 m, the measured length is 5-9 m.

This type of metal products has the following advantages:

- light weight, which provides convenient transportation and installation;

- high bending strength;

- right angles for easy storage and good mating with a flat base;

- the opportunity to implement various architectural solutions and bold design ideas.

The most demanded product sizes are presented in the table:

| Size, mm | Length, m | Weight linear m, kg |

| 15x10x1 | 6 | 0,348 |

| 15x10x1.5 | 6 | 0,488 |

| 20x15x1.5 | 6 | 0,810 |

| 25x15x1.5 | 6 | 0,930 |

| 25x15x2 | 6 | 1,225 |

| 30x10x1.5 | 6 | 0,841 |

| 30x10x2 | 6 | 1,08 |

| 30x20x1.5 | 6 | 1,08 |

| 30x20x2 | 6 | 1,39 |

| 35x15x2 | 6 | 1,39 |

| 35x15x3 | 6 | 1,95 |

| 40x20x2 | 6 | 1,7 |

| 40x20x3 | 6 | 2,42 |

| 45x20x2 | 6 | 1,86 |

| 45x20x4 | 6 | 3,36 |

| 50x30x3 | 6 | 3,36 |

| 60x30x2 | 6 | 2,79 |

| 80x40x2 | 6 | 3,01 |

| 80x40x2 | 6 | 3,73 |

| 100x50x2 | 12 | 4,58 |

| 100x50x3 | 12 | 6,93 |

| 100x60x3 | 12 | 7,6 |

The range of square pipes according to GOST 8639-82

Profile pipes of square cross-section, the standard sizes of which are determined by GOST 8639-82, are very popular in the construction industry. The assortment of rectangular steel pipes contains a smaller assortment in comparison with products with a square profile. Here are presented pipes with an outer wall diameter of 10-180 mm and a wall thickness of 1-14 mm. The smallest value of the wall thickness belongs to the welded products of this type. An important parameter, which is regulated by the standard, is the cross-sectional area. This value, which is in the range of 0.343-89.59 mm², allows you to determine the rigidity of the structure. The length of products, according to the range of square steel pipes, can be 6-12 m.

Profile pipes of square cross-section are cold-rolled, hot-rolled and made using welded technologies.

Profile pipes of square section are very popular in the construction industry, they are hot-rolled and cold-rolled.

The square shaped tube is characterized by increased stability. Convenient size allows quick installation work. This type of pipe is often used as a reinforcing element required for the construction of frames and supports. The material is used in the construction of greenhouses, gazebos, advertising products, mechanical engineering, in interior design, machine tool construction, furniture industry, construction of fences, manufacturing of non-standard production equipment.

The table shows the most popular standard sizes of a square shaped pipe:

| Linear parameters, mm | Length, m | Weight linear m, kg |

| 10x10x1 | 6 | 0,269 |

| 15x15x1.5 | 6 | 0,605 |

| 20x20x1.5 | 6 | 0,841 |

| 20x20x2 | 6 | 1,075 |

| 25x25x2 | 6 | 1,39 |

| 25x25x3 | 6 | 1,95 |

| 30x30x2 | 6 | 1,7 |

| 30x30x3 | 6 | 2,42 |

| 30x30x3.5 | 6 | 2,75 |

| 35x35x2.5 | 6 | 2,46 |

| 35x35x3 | 6 | 2,89 |

| 40x40x3 | 6 | 3,36 |

| 40x40x4 | 6 | 4,3 |

| 45x45x4 | 6 | 4,93 |

| 45x45x5 | 6 | 5,94 |

| 45x45x6 | 6 | 6,86 |

| 50x50x5 | 6 | 6,73 |

| 50x50x8 | 6 | 9,69 |

| 60x60x5 | 6 | 8,3 |

| 70x70x4 | 6 | 8,07 |

| 70x70x6 | 6 | 11,57 |

| 80x80x5 | 6 | 11,44 |

| 90x90x6 | 6 | 15,34 |

| 100x100x5 | 12 | 18,54 |

Assortment of welded rolled products with a spiral seam

The range of this type of metal pipes is regulated by one regulatory opinion. It concerns the production of large-sized structures with a circular cross-section and is called GOST 8696-74. It indicates that the size range of welded products with a spiral seam includes pipes with a diameter of 159 to 2520 millimeters. The wall thickness of a 159 mm pipe should be exactly 3.5 mm. The largest type of welded pipe with a spiral seam has a size of 2520 millimeters, the wall thickness in this case is 25 millimeters. Of course, you will not find such oversized products in everyday practice, they are used to perform tasks of a specific level.