Main \ Catalog of goods \ Sealing cords (bundles) made of foamed polyethylene \ "VILATERM" cord | harness

Full name of the product of the sealing harness Vilatherm Is a heat-insulating cord (bundle) for insulation and sealing of cracks and seams, made of foamed polyethylene foam. Insulation cord Vilatherm replaced the Gernit PRP gasket and compares favorably in all respects from many similar materials previously produced, namely:

- high quality,

- moisture-proof,

- not subject to decay,

- flexible and elastic material;

- chemically resistant and neutral to building materials;

- has a low specific gravity; easy to use;

- has a low coefficient of thermal conductivity and vapor permeability,

- high service life (25 years),

- environmentally friendly

- and the most important thing - ECONOMICALLY PROFITABLE.

What is Vilatherm?

Vilatherm is an elastic porous molded product based on polyethylene foam. The material is produced by direct extrusion and physical foaming. Due to the peculiarities of the technology, the finished tourniquet receives certain physical and mechanical characteristics, which set the main list of its positive qualities.

Save photo

You need to log into your account

To add a photo to yourself, log in or register.

The manufacturer introduces to the market a wide range of round elastic cords with and without a hole, that is, tubular type - a hollow cord, as well as a one-piece bundle.

With the purchase of material, you can receive accompanying documents attached to the batch - certificates of quality and conformity, certificates from SanEpidNadzor, which issue an opinion on environmentally friendly products.

Characteristics of Vilaterma

- Flexible elastic cord with a porous closed cell structure. Material of various densities, hollow and solid for selection according to the requirements of certain applications;

- The material is malleable for a wide variety of manipulations - it bends, twists, tied in a knot. Continuous laying in a seam of any shape and thickness is possible, with a change in its parameters linearly or depending on geometric indicators;

- Moisture-permeable material, strong enough for mechanical damage and tear. Shrinks, crumples, stretches and straightens out when the bookmark is removed from the preform;

- It is realized in skeins, in separate cut pieces of 3 meters, of any other size. Vilaterma color - white;

- Possesses chemical resistance, is a sound insulator and heat insulator!

Main advantages

When choosing a material for certain jobs, it is important to take into account not only the characteristics, but also the advantages over other materials used in this area, or direct competitive analogs. This will allow the most accurate comparison to select the product that suits your requirements!

Among the main advantages of Vilaterm are the following:

- It is very convenient to work with the material. Cutting with an improvised tool, the use of cuts and residues is practically waste-free. The ability to replace the material with another one with different characteristics;

- Ease of purchase. Large assortment of standard sizes: diameter of heat-insulating bundle from 6 to 80 mm, length - any;

- Convenience of delivery.Light weight, so you can deliver the cord in a package, bag, trunk, and in small quantities, even in your hands, giving it a comfortable shape and fastening it with tape;

- Choice by structure and type of material - a hollow tube and a one-piece, more compression-tight cord;

- Density of Vilaterma - 25-40 kg / m3, choice for different requirements and working conditions;

- Working temperature of the material from -60 ° С to + 80 ° С;

- Elasticity - 0.26-0.36 MPa;

- Thermal conductivity of Vilaterm - 0.04 W / m ° С;

- Water vapor permeability is about 0.002 mg / MhPa;

- Water absorption within 3% by weight!

You can compare the data with other materials, because there are really a lot of analogues, and even earlier, few people used a porous elastic tourniquet in their work. It is today that advertising campaigns for it are strong, and thanks to this, the products overwhelm the market!

Assigning material

- Construction - log houses, log cabins, panel residential and technical, industrial facilities;

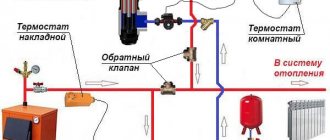

- Finishing works: sealing expansion and heat shrink joints, joints inside the premises. Work with ceilings, floors, installation of damping lines, laying in shrinkage joints, for soundproofing partitions by limiting vibration transmission;

- Outdoor work: sealing of seams and joints of wall panels in low-rise and high-rise construction, seams of blind areas, garden paths, preliminary laying of concrete sites in the seams;

- Thermal insulation work with roofs, walls, floors - reducing heat loss and limiting the access of cold air;

- Application as a sealant in almost any related field;

- Insulation of doors and windows, slopes and junctions of frame structures and the main walls of the building;

- Sealing of structural joints of various parts and their bases in refrigeration units, ventilation ducts and equipment;

- Use as a shell, a shell for water supply and sewage pipes for protection, as well as limiting heat loss, eliminating condensation!

In practice, Vilatherm cord can be applied many more places on demand and compliance. But it is worth starting from the main directions!

Insulation of the apartment from the outside.

Very often, even after high-quality sealing of interpanel seams using advanced technologies, it is cold in the apartment and blows from the outside wall, especially on the upper floors. The reason is low-quality panels and the dilapidation of a panel house. Since in our realities it is not customary to repair the facades of panel houses, over time, microcracks form on the panels through which cold air passes without hindrance. The reason for the occurrence of microcracks is the transition of temperature through 0 degrees. For example, in the daytime when it rains, water is absorbed by the facade, and at night at temperatures below zero, the ice breaks the facade material. The cracks get bigger each time.

The best solution for insulating a panel facade or insulating outside a separate apartment is the "wet facade" technology.

First, a special insulation is mounted on the surface of the panel facade. Insulation material, usually mineral wool or polystyrene, should be specifically designed for a “wet façade” and not for a ventilated façade or floor insulation.

Then plaster is applied to the insulation along the grid.

And at the end they paint in the color of the facade.

Advantages of the "wet facade": - Insulates the room forever; - Can be done locally, on separate apartments or rooms, and not on the entire facade, as in the case of a ventilated facade; - The wet facade painted in the color of the facade does not stand out from the rest of the apartments. See also: Insulation of panel facades "Warm facade".

Application of Vilaterm: myths and refutation

It would be possible to give only a dry list of the scope of Vilaterm, but it is more interesting to touch upon the advertising description from many sellers on the Internet and building stores, wholesale bases.Often, they are seriously exaggerated, pointing out non-existent advantages and qualities of the material. Therefore, it is worthwhile to additionally study the main advertising theses on the application and positive properties, as well as give them a true assessment, perhaps a refutation, comment on each separate point!

- Wide application in construction, renovation and finishing works as a heat insulator, sealant and sound insulator. Yes, this is a perfectly true statement;

- The material is used to exclude leaks from the outside into the interior through cracks and interpanel joints. In fact, Vilatherm only seals the seam, and therefore, as a waterproofing material, only partially works. To ensure high-quality protection, a whole range of works will be required, using additional materials, for example, waterproofing mastic;

- Crevices and cracks filled with Vilatherm become hydrophobic. The concept is rather vague, as it should be indicated, as in the previous paragraph, that only in complex application. Independently, the material, if it is not provided with additional protection with mastic, due to the influence of the atmospheric environment, will lose its properties - crumple and shrink, while passing more and more water;

- Vilatherm removes mold and mildew, dampness from the walls. The material certainly does not have such properties. But as a warning of these problems, it works;

- Thermal insulation of facades and walls. Vilatherm has certain thermal insulation properties. But it will not make the wall warmer when laid in interpanel seams. You can use it, but only for its intended purpose;

- High-quality insulation and sealing of joints between reinforced concrete slabs in construction. This is indeed the case. One of the best modern sealing materials and representatives of insulation systems;

- Noise isolation of the room. Minimal noise reduction from the outside when laying in a seam. But for high-quality sound insulation of a separate room or object, work is carried out with all structural planes - walls, floors, ceilings. Also, it is necessary to choose the right doors and windows;

- Thermal insulation of pipes in private housing construction. If the combination of characteristics is permissible, then this type of work can also be applied by completing the external finishing of water supply or sewage pipes;

- Vilatherm is suitable for sealing joints when installing window systems and doors. Correct statement, the foamed elastic tourniquet does an excellent job with such tasks;

- Vilatherm in work with floating floors, dry screed device. Yes, the material is suitable for the installation of a damper zone around the perimeter, sealing. But more often a foam tape of a similar structure is used. It all depends on the choice of craftsmen at the place of work;

- Furniture production - as form-building elements. Perhaps, but the application is not widely developed;

- Insulation of old wooden windows, doors, any structural openings. Maybe! And in this area, the material has long proven itself well;

- Car repair - noise insulation of car and truck bodies. True statement!

In fact, as mentioned earlier, in the construction industry and related areas, due to the characteristics and features of this product, it will be quite easy to find an application for it!

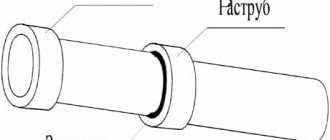

Features of the "warm seam" technology

According to tradition, insulation strips of jute, flax with hemp or batting were laid between the cracks of the logs, then they began to apply an available insulating mass.

It is much more convenient to carry out work with a cord for insulating a wooden house made of modern elastic material, and then apply an insulating agent. As a result, the joints will be reliably protected from the penetration of air and moisture for a long time, and will prevent insects from entering the house.

To carry out work using the "warm seam" technology, in addition to the heat-insulating cord, you will need a sealant suitable for wooden houses, and some tools.

It is convenient to carry out the work using:

- spatula;

- pistol;

- brushes;

- sponges;

- spray bottle.

It is better to prepare a couple of spatulas by choosing a tool that matches the size of the seam width. The pistol can be taken with a regular one, but the work will quickly compete with pneumatic models. For large volumes of surfaces, pneumatic pistols should definitely be used, because it is physically impossible to do everything by hand in the foreseeable future.

You may need a brush to remove excess, and a spray bottle with a sponge to wet the surface.

Any insulating composite for wood is suitable as a sealant; acrylic products are the cheapest.

How to work with Vilatherm

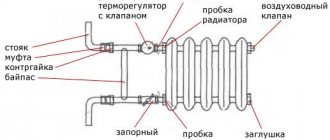

Internal work. When laying the sealant in the seams during internal work, its further protection is optional. Requirements for dry processes are minimal. It is enough to firmly press the cord into the cavity, trying to lay it straight, without twisting along the length. Such a device is allowed when sealing windows and doors, interpanel seams before plastering and finishing, when pouring floors. Bonding of material is possible!

Outdoor work. When sealing external seams with Vilatherm, additional foam and waterproofing materials are used. This requirement works in the field of sealing interpanel vertical and horizontal seams. On a loaded plane, as well as when installing a blind area, platforms and paths, the material is installed without mounting foam, on an adhesive base or liquid sealant, with additional mastic waterproofing!

Step-by-step instruction on technology:

- The cord fits into the seam based on its dimensions. Stretching or compressing the material along its length is not recommended, as this will violate its density, leading to the material protruding from the seam;

- For sealing joints of static structures, cracks in sites, heat-shrinkable seams of the pavement, material is used with a diameter tolerance of up to 40-50% greater than the width of the cavity. It should fit snugly into the mold;

- Cutting the cord is done with a knife or scissors. Tearing the seal is not worth it, as it has good tensile strength. By making an effort to break, you break the structure of the material;

- It is possible to work with seams of any shape and length. Sealing at the joints of individual Vilaterm sections up to 10-20 mm;

- After installing the cord in the mold, additional protection against moisture and ultraviolet radiation is mandatory!

Technology for processing interpanel seams from the outside

To process seams in a panel house from the outside, special equipment and permission to work at height are required. It is possessed by specialized repair organizations employing industrial climbers. However, residents of the first floor can insulate their apartment on their own, using inventory ladders or scaffolds.

Sealing with polyurethane foam

To seal the joints with polyurethane foam, special equipment is required. The joint is cleaned of the remnants of the old insulation and the working mixture is applied through a nozzle. In air, it polymerizes and forms an elastic foam that completely fills the joint, all cracks and depressions. After hardening, the foam is trimmed with an assembly knife. From above, the composition is covered with a layer of sealant.

Sealing with polyurethane foam

If the seam is plastered, as well as in the case of a narrow groove, use the technology of insulation with polyurethane foam. A small hole should be drilled in the plaster every 25-35 cm. The tip of a gun or tube from a balloon is inserted into it and the foam is blown out until it appears from the adjacent hole. At the same time, they move from top to bottom.

After the foam has hardened, the excess is cut off with a knife, and the holes are plastered or sealed with a sealant.

Thermal insulation "warm seam"

Before thermal insulation, the joint surfaces are cleaned of the remnants of old insulation, debris and dust, dried and degreased. Tubes or bundles of insulation are tightly packed into the gap, they must be held in it due to friction. Potholes and chips on the edges of the slabs are filled with polyurethane foam. From above, the insulation is covered with a layer of sealant.

This is more expensive. but on the other hand, it guarantees the best insulation and prevents the violation of thermal insulation with possible movements of the building.

Vilatherm and polyurethane foam: the difference in insulation and sealing of seams

In this comparison, you can work without tabular data, because there is a standard experience of masters, which shows that in almost any region, polyurethane foam, which is not protected by painting, plaster or mastic from the influence of the external environment, becomes unusable at the junction of the first and second seasons. Finally spoils and spills out after 2 years, in more suitable conditions - after 3 years.

Vilatherm and similar materials based on foamed polyethylene show more serious service lives in an unprotected environment - about 8-10 years. At the same time, there is minimal shrinkage, primary damage to the external structure, drying out of the material.

Using polyurethane foam or foamed polyethylene cord, the materials should be additionally waterproofed. But in the event of a violation of the protective layer, Vilatherm minimally absorbs moisture and temperature fluctuations, when the polyurethane foam begins to actively accumulate and pass water through itself into the interior. It remains to add here the conditions of negative temperature, and the sealing material is almost completely damaged, although the mastic protective layer is still more or less suitable externally!

With foam, internal damage is more likely. And the problem is that even when inspecting the building before possible preventive work, only an experienced craftsman will notice minimal damage and start working with the seams. If such a moment is missed, moisture will begin to accumulate inside, complementing the necessary conditions for the development of a pathogenic environment. And according to the first opinion, the insulated and sealed seam will already cause dampness and mold on the inner walls!

Working with Vilatherm is pleasant and simple, but most importantly, it is convenient and inexpensive. The sealing harness is available in different sizes, is on sale at almost any retail outlet, and costs from 3 rubles per running meter. Decent option at an affordable price!

What gives warmth insulation

The smallest spaces between logs and other wood materials create a large number of problems that can darken the life of the owners of the building. Insulation of seams in a wooden house leads to a sum of positive results:

- getting rid of drafts;

- reduction of heat loss;

- financial benefit when paying for heating;

- absence of microbes and molds;

- compliance with sanitary standards;

- long-term integrity of the structure;

- exclusion of the possibility of the appearance of new cracks during shrinkage;

- nice design appearance.

The set of advantages looks convincing in order not to doubt the need to insulate the joints with high-quality sealants, using the "warm joint" technology.