Do you want to have a small secluded corner in your apartment where you could dream, work, or do what you love in winter and summer? Modern technologies in the field of construction and design make it quite possible to make a habitable living space out of a balcony. Its space, of course, cannot be expanded, but you can also place a couple of useful zones on what you have.

Insulation fastening methods

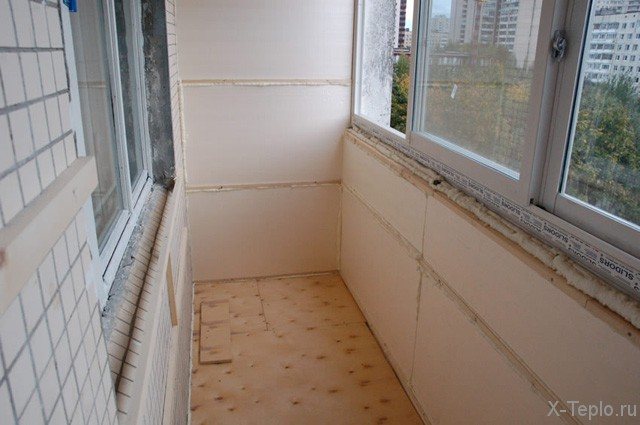

There are two ways to fix the insulation. The first way is to attach it directly to the wall surface using dowels or glue. The second way is to install insulation in a specially mounted wooden or metal niche.

How to insulate a loggia when combined with a room

In order to attach the insulation to the surface on the dowel-fungi, it will be necessary to make a small hole in the insulation, drill a hole in the wall and drive a plastic dowel into it. Then you install the dowel-fungus in the insulation and pull it to the wall with a self-tapping screw.

Warming the loggia from the inside with your own hands step by step instructions

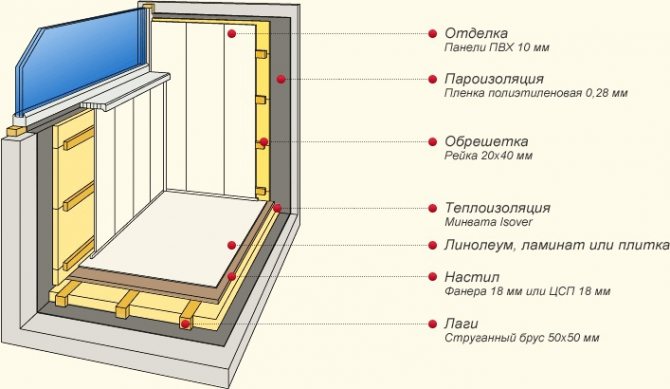

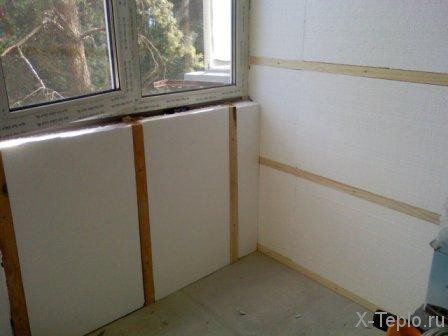

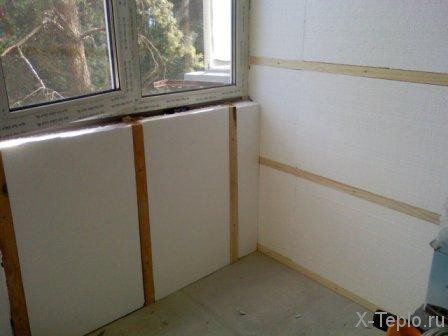

To make a frame, you will need to prepare wooden blocks with a thickness equal to the thickness of the insulation. The bars must be treated with a special solution against decay. These bars must be fixed throughout the entire perimeter on the floor and on the ceiling, as well as around the entire perimeter of the parapet. It is necessary to fix a block on the floor that will divide the floor along the balcony into two parts.

We insulate the loggia: an overview of the most popular thermal insulation materials

Initially, any loggia is an unheated room. If you decide to glaze it and further use it as an additional living space, then you should definitely carry out thermal insulation. Next, we will consider the options offered by specialists today and what materials for insulating a loggia are especially in demand in the construction markets.

Styrofoam use

Polyfoam is a plastic material with a cellular structure. All internal voids are filled with gas, which ensures low thermal conductivity of the foam. Polyfoam is produced in the form of square sheets with a side size of 1 m and a thickness of 2, 3, 4, 5 and 10 cm. The material can have different densities, but the greatest demand is for foam with a density of 15-25 kg / cm 2.

Polyfoam will certainly interest those who are looking for ideas for quick, effective, and most importantly, not too expensive insulation of the balcony. What is the attraction of this thermal insulation material?

- Insulating a balcony with foam plastic will cost you inexpensively, since the prices for the material are quite affordable;

- Polyfoam is characterized by a low level of thermal conductivity;

- Polyfoam is not toxic, therefore it does not require mandatory insulation during installation and operation;

- Polyfoam is easy to transport and install;

- Polyfoam is suitable for both external and internal insulation work;

- Pathogenic microorganisms are practically not colonized in the foam.

What to look for when using Styrofoam?

- Polyfoam is loved by rodents, so you should protect the loggia from mice attacks;

- It is not recommended to carry out foam insulation in windy weather due to its large windage;

- Care should be taken when working with paints and varnishes and solvents;

- Installing foam inside the balcony will reduce the free space by 2-10 cm.

Using isolone

Another material with very attractive characteristics is isolone.Such a heat insulator will be an effective solution to the problem for those who plan to insulate a loggia and wish to save as much useful space as possible. Foamed polyethylene is called Izolon. During its production, foaming of polymer raw materials is carried out in the presence of a special catalyst and under high pressure conditions. As a result, izolon takes the form of a roll material consisting of thousands of sealed bubbles filled with air. Thanks to this structure, the thermal conductivity of the isolon is very low, and the sound absorption, on the contrary, is very high.

Another notable feature of the insulation of the balcony with this material is that the heat is not only not released into the environment, but reflected back into the room. This is possible due to the fact that the walls are trimmed with isolon, covered with foil on the outside.

Among other characteristics of izolon, it should be noted complete moisture resistance, resistance to gasoline and other petroleum products, as well as complete safety for human health.

Very often izolon is used not as an independent insulation, but as one of the layers of the “heat-insulating pie”. So, good results are shown by insulation with expanded polystyrene with an additional top layer of isolon.

Izolon is supplied in rolls, therefore, before installation, it must be cut into pieces of suitable sizes. The joints between the pieces are glued with ordinary clerical or special construction tape.

How are you with penoplex?

Penoplex is a more modern analogue of foam. Accordingly, the insulation of the loggia with its use is carried out using a similar technology. Penoplex is called extruded polystyrene foam. If you come across the abbreviations XPS or EPS, then you should know: we are talking about Penoplex. Its main difference from foam is a higher density, which means greater rigidity and resistance to damage due to mechanical stress. For comparison: if the foam for thermal insulation works is chosen with a density of 10-25 kg / sq. cm, then penoplex - 35-45 kg / sq. cm. The increased rigidity of this material makes it an ideal heat insulator not only for walls, but also for the balcony floor. The OSB panel covering can be laid directly on the penoplex, without mounting the lag.

Other attractive characteristics of penoplex

- Ease of installation due to the presence of special grooves along the edges of the slabs;

- Long service life - up to 40 years;

- Moderate combustion toxicity (T2).

Mineral wool - a proven option

Mineral wool based on glass, slag or stone is one of the leaders in the modern market of thermal insulation materials. Warming a loggia with such material will also cost relatively inexpensively, which, however, will not affect the quality in any way.

Mineral wool is supplied in the form of rolls and in the form of layers, packed in bales. Its internal structure can be layered (horizontally and vertically), as well as spatial or corrugated. It depends on the raw materials that are used in the manufacture of mineral wool.

The thickness of the layers of mineral wool varies in the range from 20 mm to 20 cm. For the most effective insulation, cotton wool is used, on one side covered with foil. This, firstly, facilitates installation, and secondly, it helps to reflect heat back into the room.

In addition, mineral wool

- is resistant to temperature extremes;

- does not collapse under the influence of chemicals;

- provides excellent sound insulation;

- does not require preliminary leveling of the walls.

However, please note that caution should be exercised when working with mineral wool, namely, use overalls and personal protective equipment (gloves, goggles, respirator).This is to prevent dust and formaldehyde resins from negatively affecting your health.

Foil polystyrene foam is the best solution

What is the insulation of a balcony with such a material? Expanded polystyrene is also called gas-filled polystyrene. To minimize heat loss, it is equipped with an aluminum foil backing.

Although the moisture absorption of polystyrene foam does not exceed 0.25 mm per year, it is not recommended to install it on a floor or wall subject to dampness, since the foil will prevent them from drying out properly. As a result, mold or mildew may develop under polystyrene foam.

Expanded polystyrene is resistant to temperature extremes in the range of 80 °: from minus 40 ° C to plus 40 ° C. This heat insulator exhibits the same stability when interacting with alcohols. The integrity of expanded polystyrene can be violated only under the influence of solvents, but when insulating a balcony, it is quite possible to do without the use of such means.

Styrofoam is considered to be a highly flammable material. Its ignition occurs already at 210-310 ° C, therefore, the most serious manufacturers add flame retardants to the raw materials, which significantly reduce the combustibility of expanded polystyrene. The presence of such components in the composition of the heat insulator can be recognized by the letter "C" in the marking of the material, for example, PSB-S.

As a rule, expanded polystyrene is supplied in the form of rolls 1 m wide. The thickness of the insulation is 10-50 mm.

Expanded clay

Expanded clay is obtained by thermal transformation of low-melting clay. As a result, expanded clay takes the form of granules with a porous structure. During thermal insulation works, expanded clay is used only as a backfill at the stage of floor insulation. Expanded clay is especially well suited for arranging wooden floors.

Expanded clay absorbs water well, but gives it up slowly, therefore it is recommended to cover the backfill with plastic wrap before pouring the concrete screed. Please note that the thickness of the screed must be at least 5 cm, otherwise cracks may appear.

The use of foam blocks in thermal insulation works

If you are interested not only in the insulation of the balcony, but also in the strengthening of its metal parapet, we recommend using foam blocks. Foam blocks are an environmentally friendly heat and sound insulating material. It is easy to transport and install.

Optimal insulation of the loggia is achieved by finishing the parapet with foam blocks and foam.

Foam blocks are also irreplaceable when erecting partitions on adjacent balconies of neighboring apartments.

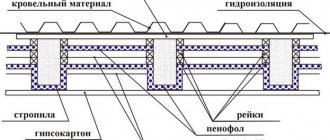

Penofol

Insulation of the loggia, interfloor, basement and attic floors, foundations, roofs - all these works can be carried out with foam foam. This material is suitable for both external and internal thermal insulation.

The most commonly used types of penofol:

type A - foiled on one side; type B - foiled on both sides; type C - foil-coated on one side, and covered with a self-adhesive backing on the other; types R and M - embossed (foiled on one side); type ALP - foil-coated on one side, laminated with polyethylene film on the other.

Features of penofol installation technology

Penofol is very often used when arranging a warm floor in a loggia. Please note: it is necessary to create an air gap both under and above the foam layer. This will make the insulation as effective as possible.

Before laying the insulation on the base of the balcony floor, a crate made of a thin wooden bar is mounted. Its thickness should be at least 2 cm. Next, penofol is laid and fixed to the frame bars with a stapler. It is recommended to make a small overlap of the material on the walls, as well as to avoid the formation of joints in the corners of the balcony, as in these places the so-called. cold bridges.

Penofol is laid end-to-end, without overlap. Seams are glued with aluminum tape.

The penofol layer is covered with drywall, not forgetting about the air gap. Finishing is already carried out on the drywall.

So, now you know what types of thermal insulation materials are most often used today to insulate a balcony. In conclusion, we recall once again that insulation and finishing materials should be selected taking into account the fact that a loggia is, as a rule, a small room, thus free space must be saved.

Penoplex

Penoplex insulation is a modern heat-insulating material that has a very low coefficient of thermal conductivity, low vapor permeability and does not absorb water. The required thickness of the foam for insulating the loggia depends on the region and can range from 40 to 60 mm. You can easily insulate the loggia with penoplex with your own hands. The first step is to insulate the floor, then the walls and parapet, and lastly the ceiling. If the new finish will be applied in the form of plaster or a cement-sand mixture, then the insulation will need to be attached to the dowel-fungi, and if the new finish is in the form of plastic panels, waterproof gypsum board or other similar material, then in order to fix the insulation, a frame will need to be made. First, a layer of waterproofing is fixed, and then sheets of foam are laid on it. All seams between the sheets of insulation and the bars are foamed with polyurethane foam. It is recommended to cover the insulation with a layer of vapor barrier made of foil-clad polyethylene film or thin foil-clad foamed polyethylene, while the foil should look inward. After that, you can attach the finishing material to the bars. Thus, they insulate the ceiling on the loggia, as well as the walls and parapet.

How to properly insulate the loggia from the inside with your own hands with penoplex

Insulation of the floor on the loggia with penoplex is done in different ways. If tiles or linoleum are laid on the floor, then a reinforced mesh is attached to the bars over the insulation and a mortar with a thickness of 4 cm is laid.After the screed hardens, tiles are laid on it with special tile glue or linoleum is glued. If the floor is covered with some kind of material, such as boards, chipboard, laminate or other similar material, then the insulation is placed between the beams and covered with material. In both cases, all joints between heaters must be foamed with polyurethane foam.

How to choose a heater for a loggia or balcony correctly

Balcony - a special design, and it is not recommended to make it heavier. And if you consider that before insulation you will need to install double-glazed windows, which will entail strengthening the fence, then the insulation should be made of minimally lightweight materials.

How to choose insulation for a loggia or balcony, and not get confused in the existing options? We will try to answer this question and help you understand the quality, composition, pros and cons of the heaters available for sale.

To begin with, it must be said that all materials for insulation have a different structure and installation method. Some, such as izolon, are sold in a roll, others - polystyrene and polystyrene foam, have a hard, porous structure, while others are soft and elastic like cotton wool. It is easiest to work with those materials that are harder, but they do not fully meet the requirements of insulation. For greater thermal insulation, they have to be supplemented with isolon.

Basic requirements for heaters:

- Low thermal conductivity;

- Resistance to deformation from temperature changes;

- Ecological cleanliness;

- Mechanical strength;

- Ease of installation;

- Resistance to dampness, water, heat;

- Durability;

- Compatibility with other materials.

When doing repair work, it must be borne in mind that some materials, such as polystyrene, have disadvantages.Almost all of them are destroyed when exposed to solvents, they can crumble and break under load.

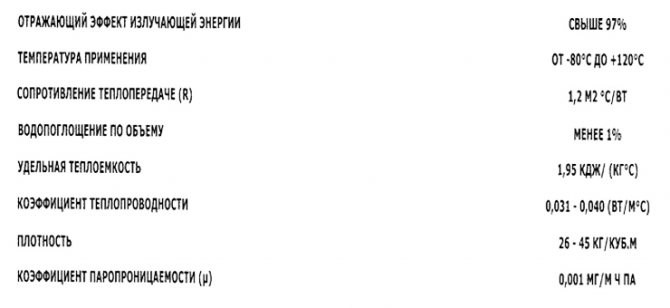

Izolon

Foil isolon is of two types: cross-linked polyethylene foam in which the cellular structure is closed and uncrosslinked gas-foamed polyethylene foam in which the molecules are not chemically bonded to each other. For insulation, cross-linked polyethylene foam is used, and not cross-linked polyethylene foam is used mainly as a packaging material or as a vapor barrier. Izolon is a very light and flexible material that has good sound insulation properties. Izolon is an environmentally friendly material, durable and, if properly used, can last up to 90 years. Izolon has a low level of thermal conductivity and can be operated at temperatures from -80 to +80 degrees. Izolon with foil can reflect up to 95% of heat. Isolon is produced with a thickness of 1 to 50 mm. To insulate the loggia, an isolon 10 mm thick is used.

How can you insulate a loggia with an isolon

Insulation of the loggia with isolon begins from the walls, then the floor and, last of all, the ceiling. Wooden blocks are nailed to the walls, floor and ceiling at a distance from each other in the width of an isolon. Lay the izolon with the foil side inside the loggia so that the heat is reflected from it and remains inside. All the resulting joints between the Isolon sheets must be foamed with polyurethane foam, and then glued with metallized tape. You can fix the isolon on the bars with staples. Then finishing material is attached to the bars, and boards, plywood or OSB boards on the floor.

Electrical constructions

An electric underfloor heating in a frame sauna is an excellent solution that allows you to avoid excessive stress, which is important for saunas that are not made well. In fact, this type is very similar to water floors. In the same way, a heat conductor is placed in the thickness of the screed, however, in this case, the heating cable plays its role.

Electric underfloor heating

It is of two types:

- single core - both ends must be connected to a thermostat;

- two-core - has less electromagnetic radiation.

It is much easier to make such a warm floor in a sauna in a private house, since its connection does not require unnecessary efforts to connect communications - it is enough to have access to electricity.

The list of advantages of cable floors includes:

- the ability to regulate the temperature;

- easy installation;

- lower cost compared to a water heating system;

- shorter installation time.

The only drawback is the tangible power consumption.

Installation of underfloor heating in a sauna begins with cable holders. It is not necessary to align the base to the system - this can be done using the final screed.

It is important to remind that:

- the pitch between the turns must be at least 10 and at least 40 cm;

- the distance from the wall must be at least 5 cm;

- it is undesirable to lay the cable under furniture.

There are no special requirements either for fasteners or for bends, but care must be taken that the insulation is not broken anywhere.

Cable fixing option

Otherwise, the system will be incapacitated. The cable is connected to the thermostat, after which everything is filled with a final tie.

When asked if a heated floor is made in an electric type sauna, the answer is unequivocal: yes. Despite the high humidity, the cable does not pose a threat to life, since it is isolated from its effects. Nevertheless, if wooden boards are planned to be used for the floor, it is recommended to treat them with anti-feathers. This will eliminate the possibility of a fire.

Do-it-yourself electric underfloor heating in a bathhouse is much easier to do than to equip a water heater. This is not their only advantage.There are several varieties of this insulation, each with its own advantages and disadvantages.

Electrical structures are the most expensive option for floor heating in a bath, but the highest quality

The main advantages of this type of insulation are automatic temperature control and its compatibility with any type of coating. The main disadvantage is the very high power consumption. The structure consists of a mesh base with a heating cable laid on it.

The cable comes in two versions - single-core and two-core. When buying, it is important to pay attention to this - despite the higher cost, a two-core cable has important advantages in installation and use. The power of the electromagnetic field emitted by a two-core cable is several times less than that of a single-core cable. Both contact ends are close to it, they do not need an additional lead to the thermostat, so it is much easier to mount it.

When choosing a convection cable, consult a specialist, he will help you choose the most suitable option

Infrared foil insulation is a thermal film rolled into a roll. It is based on a polymer shell, into which flexible carbon strips, 0.3 mm thick, are sealed. The film is laid on top of a heat-reflecting material, and covered with polyethylene for waterproofing on top and a floor covering is laid.

The screed is optional, but it will improve the tightness and mechanical reliability. Infrared foil insulation has a number of advantages:

- due to the parallel connection of elements, the breakdown of some of them does not affect the performance of the entire system;

- there is no ultraviolet radiation;

- the infrared spectrum of radiation is useful for humans;

- not afraid of heavy floor coverings (porcelain stoneware, ceramic tiles).

Rod infrared insulation looks similar to a rope ladder due to the rods connected in parallel to the power wires. Such an installation of heaters makes the use of mats (another name for this insulation), as well as a film insulation, very reliable. Mats are mounted inside a cement screed or tile adhesive. The main disadvantage of this heater is its extremely high cost.

Penofol

This material is a polyethylene foam covered with polished foil. Penofol is flexible, lightweight, waterproof and vapor-proof, has good heat-insulating and sound-insulating properties. Penofol can be foil on one side or on both sides, and some have a self-adhesive base. When insulating loggias, Penofol is used in conjunction with other insulating materials, such as foam. To insulate the loggia with foam without foam, you will need to use a very thick foam, and in a combined thickness of 40 mm.

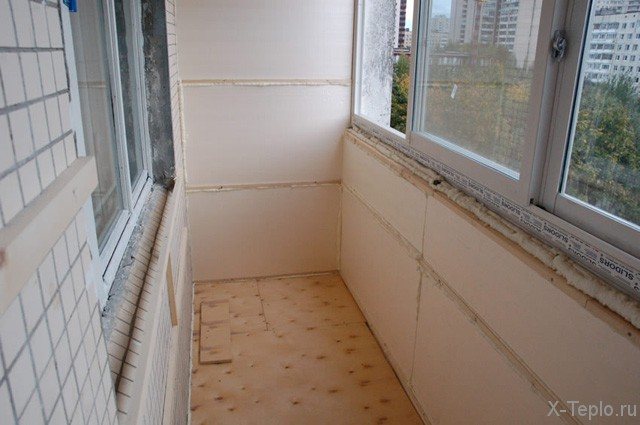

Step-by-step warming of the loggia with your own hands step-by-step photo instructions

First, the loggia is insulated with foil foil 5 mm thick with foil inside and fixed to the bars with the help of staples. Styrofoam sheets are laid on top of it. It is necessary to foam all the seams in the foam with polyurethane foam. On top of the foam, 3 mm foam foil is laid inside the room and is also fixed to the bars with staples. If a joint is formed between the sheets of penofol, it is foamed and then sealed with foil tape. After that, a crate is attached to the bars, which will create an air gap between the insulation and the finishing material. The lathing can be made of wooden slats with a section of 2 by 4 cm. The laths are nailed perpendicularly to the bars every 40-50 cm. When insulating the floor on the loggia with your own hands, you do not need to do the lathing. On the floor, you can lay bars with a larger section so that a gap of at least 1.5 cm is created between the insulation and the flooring.Having laid the insulation on top, it is closed with plywood or boards on which you can then lay, for example, a laminate.

How to choose a heater for a balcony (video)

Whatever materials you choose to insulate your balcony, remember that the work must be carried out with high quality and scrupulousness, otherwise the heat will not be retained, and your repair will not justify itself. If you do everything right, and even equip heating on the balcony, you can enjoy your stay on it all year round.

- Author: admin

Rate the article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Expanded polystyrene

This material is very similar to Styrofoam. However, this is an environmentally friendly material that has such advantages as durability, lightness, low thermal conductivity and good sound insulation. Warming of the loggia with expanded polystyrene is made with plates from 40 to 60 mm thick, depending on the region.

How to properly insulate a loggia with your own hands step by step photo

First, the waterproofing of the loggia is laid from the inside, that is, a waterproofing material, such as a polyethylene film, is laid on the surface of the walls, floor and ceiling. Then they begin to lay the sheets on the ceiling, then on the walls and, last of all, on the floor. Having laid all the sheets, you need to foame all the seams with polyurethane foam, which does not contain toluene, which can dissolve polystyrene foam. A vapor barrier layer must be laid on top of the expanded polystyrene; foil-clad polyethylene film is best for this. It is recommended to glue this foil directly to the expanded polystyrene with polyurethane glue. All seams on the vapor barrier must be sealed with foil tape. After that, you can start finishing.

Styrofoam

The most popular material for balcony insulation. It costs about 80 rubles. (1 sq. M, 0.2 cubic meters).

Polyfoam is produced by the method of steam foaming of polystyrene. It is distinguished by its low weight, high heat-insulating properties and low water absorption, easy to install and easy to process, it has no shrinkage. Low cost is also important. When choosing a foam, you should pay attention to its density, the lower it is, the less durable the material.

The disadvantages of the material include the release of harmful styrene into the surrounding space, which forms at a temperature of + 40C.

Mineral wool

This material has been used for a long time. Mineral wool is not afraid of fire, is harmless, and has good thermal insulation properties.

Insulation of the loggia photo

When insulating a loggia with cotton wool, it should only be laid in a pre-prepared frame made of wooden bars with a cross section of 5 by 5 cm. The loggia must be waterproofed when insulated with mineral wool. As a waterproofing, you can use a polyethylene film or roofing felt. Then mineral wool is unrolled in the frame. First, it is rolled out and attached to the walls, then laid on the floor and lastly attached to the ceiling or the space between the slab and the finishing material is filled with it. Mineral wool is best fixed to the wall using dowels. Having made the insulation of the loggia with mineral wool, it is necessary to seal all the joints formed between the wool with tape. A vapor barrier in the form of a foil-clad polyethylene film is spread over the mineral wool. The foil should look inward. There should also be a vapor barrier on the ceiling, even if the cotton wool is not attached to the ceiling, but is simply crammed between the finish and the ceiling slab. When you finish the correct insulation of the loggia, finishing work begins.

Final design

After installing the insulating floor, it is the turn of the top coating. The sanitary condition of the bath rooms, as well as their aesthetic appearance, depends on it. Each room has a different type of topcoat.

Ceramic tiles or porcelain stoneware are best suited for the washing room. These materials have good waterproofing and heat transfer properties, they are durable and very practical during cleaning.

It is better to decorate the dressing room and dressing room with laminate or linoleum. The last option is considered budgetary. But it should be borne in mind that certain types of linoleum, heating up strongly, emit poisonous gases.

Do not forget to equip the interior design of your bath, to ensure the fullness of aesthetic beauty

It is not recommended to decorate bath rooms with parquet, as well as any design made of wood. Regularly wet and dry, the tree loses its shape and cracks. In addition, it is an excellent heat insulator and therefore not suitable for underfloor heating.

The device of underfloor heating in the bath is available to everyone. You just need to choose the most rational design option that is optimal in terms of financial investments, installation and maintenance, take the time to install it, and comfortable conditions during bath procedures are guaranteed.

Scope of application ↑

The use of foil-clad isolon is common in areas such as:

- Mechanical engineering (most often used for thermal insulation and noise insulation of car interiors)

- Construction (thermal insulation and noise insulation of various premises, underground structures, interfloor floors)

- River and sea transport (barrage booms, life jackets)

- Medicine (insoles for special shoes, orthopedic products, packaging for medical equipment)

- Packaging (shockproof and shock-absorbing packaging for fragile products such as household and electronic appliances, dishes; packaging in low temperatures)

- Recreation and sports (elements of sports equipment, gyms, rugs, etc.)

Foil isolon for insulation of a balcony or loggia

In recent years, the "warm floor" system has gained wide popularity among residents of apartments and private houses. This system implies performance of the functions of energy saving, thermal insulation, as well as sound insulation and an even distribution of heat over the entire surface of the floor.

How to lay foil isolon correctly? When insulating the walls of the balcony, you should be very careful when choosing a material for thermal insulation. It must meet all the criteria: have low thermal conductivity, light weight, high waterproofing properties, be easy to install / dismantle, and be waterproof. Having made a choice in favor of foil-clad isolon, you can be sure that all these criteria will be ideally met.

Having insulated the balcony, you can often face such a problem as the appearance of water. This can happen due to the fact that you have chosen only internal insulation, while it is also necessary to insulate the balcony from the outside.

In urban development, it is sometimes simply impossible to carry out external insulation, in the end, warm air, when passing through the insulation, enters the cold street directly, and then turns into water, which subsequently flows down the walls of your balcony and forms puddles. To avoid this, experts strongly recommend using glass and mineral wool or extruded polystyrene foam in combination with foil isolon.

Since when insulating a balcony in a small apartment every millimeter matters, small thickness along with the unique vapor barrier and heat-saving characteristics of Isolon make it irreplaceable.

It is also possible to use izolon for insulation, soundproofing of a balcony without additional insulation, however, it should be borne in mind that in this case it is necessary to choose a foil isolon with a thickness at least twenty millimeters.

In this case, it is recommended to install cable floor heating, in other words, a warm electric floor.

It is also important to note that when laying isolon, it is important to glue the joints with aluminum foil tape in order to ensure a high level of vapor barrier.

Warming a loggia with an isolon - how to do it yourself?

Insulation of the loggia with an isolon canvas

Everyone who has had to deal with the insulation of a balcony knows firsthand about condensation and its appearance. Moreover, many did not understand where small puddles appeared on the balcony in winter. To avoid this unpleasant phenomenon, you need to choose the right material in order to insulate the balcony area. As experts advise, it is best to insulate a loggia or balcony using an isolon canvas.

What kind of material is this, what is remarkable and why is it better to give preference to it?

Isolon is called elastic polyethylene foam. It has cells with a uniformly closed structure. This type of insulation is produced in very different thicknesses, which allows you to purchase the material that is most suitable for this very indicator. Thanks to this, it is possible to protect the balcony area from piercing winds and frost in the best possible way.

An important detail: It is best to use foil material for the insulation process, which has such an important ability: it perfectly reflects heat. Moreover, it is not at all difficult to insulate the loggia with the help of isolon material.

Advantages of foil insulation

The structure of foil-insulated sheets

The advantages of insulation include:

- elasticity;

- hygiene;

- ecological cleanliness;

- ease of installation and machining;

- almost complete absence of water absorption;

- high thermal insulation performance;

- light weight;

- excellent sound insulation;

- resistance to any chemicals;

- low emissivity;

- high reflective effect.

Due to all the listed properties of foil insulation, it will be possible to perform the maximum thermal insulation of the balcony area.

On a note: Using this type of insulation will also help save money, since the material itself is inexpensive, and you will not need to purchase a vapor-waterproof film.

Installation of Isolon when insulating a balcony

Insulation material is laid

Even beginners in construction can insulate the balcony from the inside, it is enough just to know some of the features when working with this material and prepare the following tools:

- furniture stapler;

- screwdriver and drill;

- wooden planks.

To arrange effective heat preservation, you need to create such a "thermos" for which an air cushion must be left between the wall surface and the insulation. This is done as follows:

- Fasten well-dried timber strips to the wall and floor so that the frame does not deform later.

- For walls, the width of the slats is 4 cm, the thickness is 2 cm, for the floor the same width, but 4 cm thick.The step between them should be no more than 70-90 cm.

- In the intervals between the lags, you need to lay penofol, which is an excellent vapor barrier.

- Now you need to strengthen the isolon itself to insulate the balcony. This is done as follows: one edge of the canvas is fixed on the extreme bar, then, pulling it slightly, fix it on the next. And so on until the end. The main thing in this case is that the sheet of foil insulation should be a little stretch. You can use a stapler or small nails to attach the canvas.

- Insulation of seams on the canvas. You can use any adhesive tape for this.

- For subsequent finishing work, you need to attach wooden blocks on top.

- On the surface of the floor, you need to lay a floorboard, on the walls - panels of the same wood or plastic.

- The final step will be to seal all the cracks with silicone and treat all wooden elements with an antiseptic.

Advice: Although the work of insulating the loggia room with insulated canvases is not very difficult, it is somewhat difficult to perform it alone, so it is advisable to do everything with an assistant.