Arrangement of a country house in the absence of communal plumbing and sewerage systems is a daunting task for any homeowner. In addition to providing residents with drinking water, it is necessary to solve the problem of draining gray water and sewage, while not forgetting about the insulation of the sewer pipes of the external sewage system.

This problem is solved in various ways; in order to choose the appropriate option, it is useful to know how the pipes of the external sewage system are insulated in the ground and to study this technology. This will allow for correct and long-term insulation of the sewage system with minimal time and financial losses.

Fig. 1 Sewerage of a private house - device

Do I need to insulate the sewer and problems with freezing pipes

When draining sewer and gray waters of a private house at subzero temperatures of the external environment, they can freeze, and this will cause the following unpleasant consequences:

- Frozen water will impede drainage from the home, thus creating significant difficulties for private living in the winter.

- Also, when defrosting, water expands, which causes damage to pipelines and clogging of the earth with sewage, which worsen the ecological situation.

- Ice plugs that prevent the outflow of contaminated water will cause it to stagnate in the drainage system - as a result, unpleasant odors will appear in the home, interfering with comfortable living.

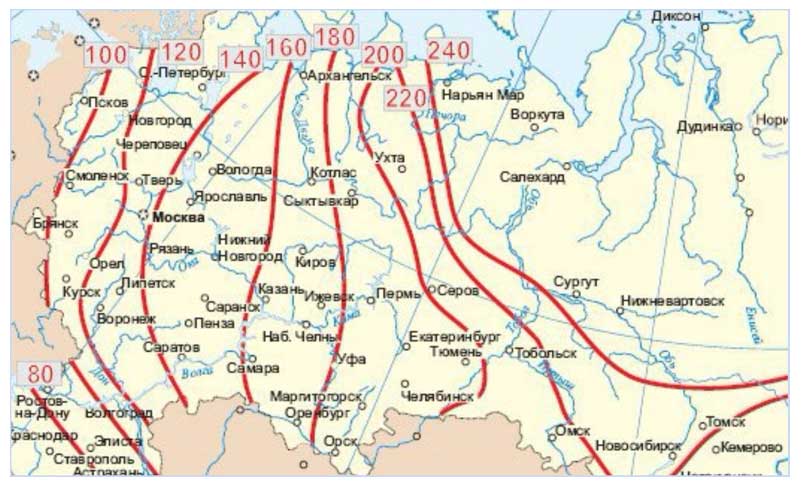

Fig. 2 Map of the level of soil freezing - an example

Insulation of sewer pipes of an external sewage system - generally accepted methods

When deciding how to insulate the sewer in a private house, they consider a number of methods, the main ones are:

- Deepening in the ground. To implement this method, a prerequisite is placing the pipe on the street in a trench below the maximum freezing point for a given area.

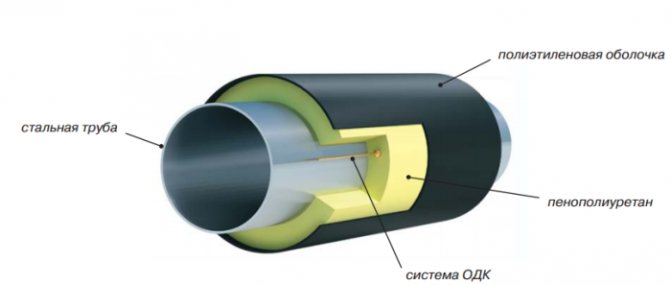

- Using an electrical cable. This technology of external sewerage insulation is easily implemented thanks to the manufacturer, who produces reliable moisture-resistant electric heating cables that are placed inside the pipeline or special slots in the pipes.

- The use of heaters. This method of thermal insulation can be quite simply implemented thanks to the manufactured casings made of various types of insulation with a diameter suitable for sewerage insulation.

- Combined methods. An excellent solution to thermal insulation of sewer pipelines is the use of additional insulation by placing them in a sheath of insulation at an average depth in the ground. Another common option is to place the heating electric cable in a sheath of insulation, while the sewer main is at a short distance from the earth's surface.

Fig. 3 Installation of pipes in a trench

Overpass device

This method is used in the presence of marshy or rocky soil, as well as in permafrost conditions. Sewer pipes on the overpass (props) are mounted inside a box made of heat-insulating material. The disadvantage of the method is the presence of overhead communications. Plus - the convenience of erecting the structure. This method of insulation for outdoor sewerage is common in cold areas.

The protective box is used when laying sewage under the floor. Several tasks are being solved: insulation, protection against mechanical damage, ease of access in case of emergency.

Warming with the help of soil when laying the pipeline below the freezing depth

Insulation of sewer pipes in the ground by this method is the most accessible process, because in areas with a temperate climate, the depth of soil freezing is about 1.5 meters. When determining the depth, you can be guided by special maps of freezing of the earth for different regions, laying the pipeline below the freezing depth has the following features:

- When installing the pipeline in the middle lane or northern latitudes, a large amount of excavation will be required - this will lead to high financial costs.

- The volume of land sampling and costs will increase even more if the distance of the sewer main from the house is too large, because there is 110 mm along the entire route. the pipeline must provide a minimum technical slope of 20 mm. per running meter. Compliance with this condition leads to the fact that at a 50-meter distance, the height difference can reach one meter - therefore, the lowest point will be at a depth of 2.5 meters.

- The deep burial of the pipeline makes it difficult to carry out repair work in the event of damage.

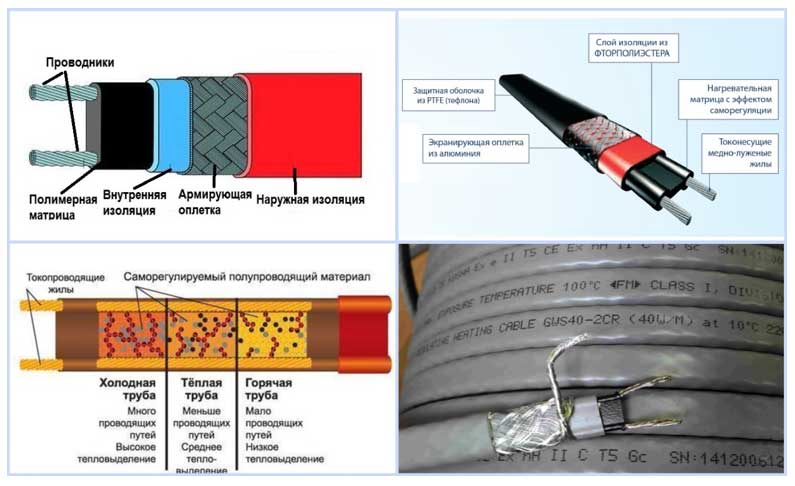

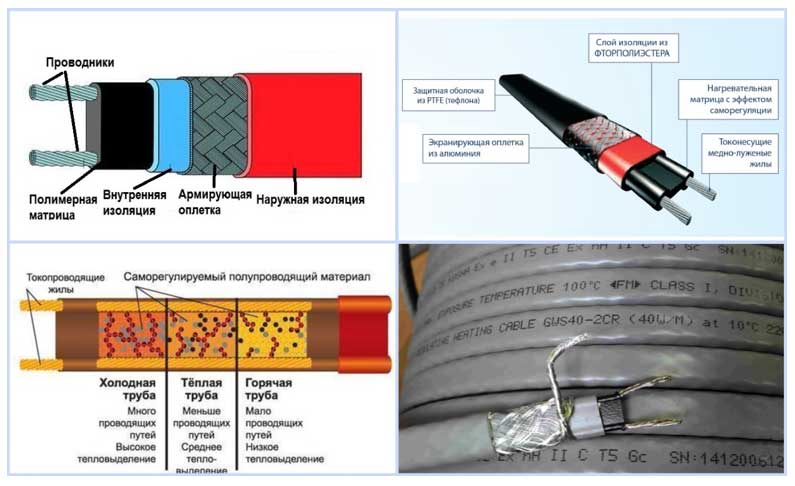

Fig. 4 Thermal insulation of the sewer with a heating cable - type of wire

Recommendations for choosing a method of pipe insulation

Insulated sewer pipes

It is possible to recommend what exactly to choose for insulating a sewer pipe only if climatic conditions are taken into account. The thickness of the material will depend on how far the temperature drops, as well as how deep the line is.

When using glass wool, the place where the insulation will be made is taken into account. When embedded in the ground, it is necessary to buy a waterproofing material and wrap it tightly into the pad so that moisture does not get inside.

If the budget allows, it is more practical to use expensive materials so as not to overpay for pipe repairs or replacement of insulation later.

Heating of external sewerage using a cable

When deciding how to insulate sewer pipes in a private house, many choose a heating cable. During installation, it is placed along or wrapped around the pipeline, if strong heating is required, a common option is to place the heating wire inside the line. The use of electric heating has the following features:

- The electric cable is quite expensive, the price of one running meter is about 15 USD.

- With electric heating, it is possible to place the sewer mains in the ground not too deeply, the usual depth of its occurrence is no more than 0.5 meters and can be reduced by using a powerful electric cable with a small winding pitch.

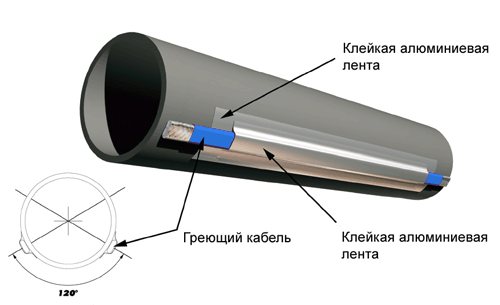

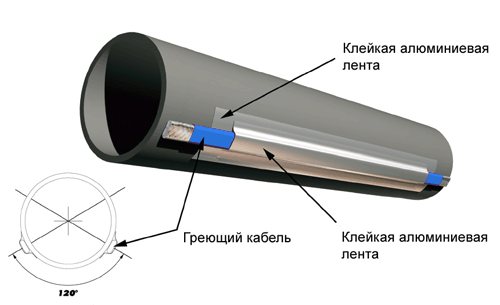

- The heating wire can be placed in pipe channels specially made for laying it or attached to a plastic pipeline with foil adhesive tape with your own hands.

Installation of insulation for sewer communications in the ground

Insulation is laid when all pipes have already been laid and connected to the sewer itself.

Moreover, all pipes run at a slope of 1 centimeter per one running meter.

When installing insulation, you should pay special attention to the fact that no bare areas remain, otherwise this whole procedure will be useless.

Also, the beginning and end of the pipe, the joints are especially carefully processed. In such places, you can put several layers of insulation for confidence.

Otherwise, the installation of insulation is very simple and takes little time.

Installation features

Having chosen the necessary insulation, immediately read the instructions for it, since each of them has its own characteristics.

If you additionally make waterproofing, then you should immediately calculate how much material you need.

On the bends of the pipes, you need to do more thorough insulation and waterproofing, any of the above materials is suitable for this.Thanks to their convenient cylindrical shape and plasticity, they will be able to repeat any bend without breaking.

You can additionally insulate the sewer pipes using a heating cable for pipes. It maintains the temperature of the pipe well, preventing it from freezing.

The cable can be an independent insulation, but most often it is wrapped on top with another layer of any insulation.

You can see an approximate heating cable insulation diagram in the figure below.

Thermal insulation with heating cable

This cable gives almost 100% guarantee that the pipe will not freeze in any conditions.

Installation rules

Insulation with the selected material is performed before backfilling the pipe with earth, while all the edges of the pipes and seals must be sealed with a sealant so that moisture from the pipes does not spoil the material.

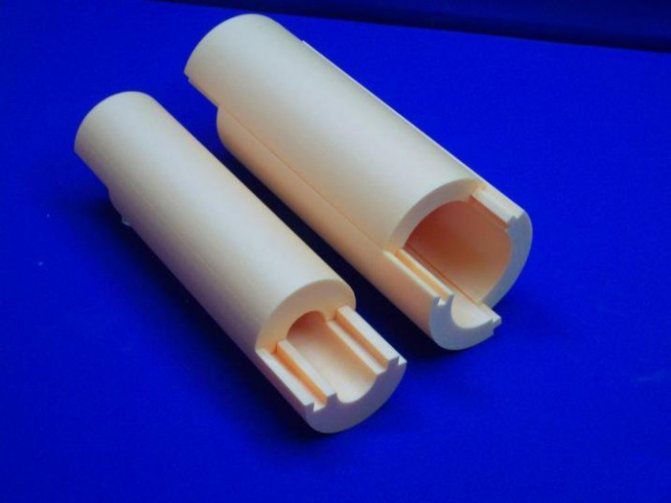

If you chose foam shells for insulation, then you just need to put them on the pipe and additionally fix them with aluminum self-adhesive tape.

If it is mineral wool or basalt fiber, then they must be laid with the foil side outward, as shown in the photo below.

Installation of glass wool with waterproofing

In this case, all joints must be glued with construction tape very carefully so that there is no access to moisture.

Also, pipes are insulated only in dry weather, dirt and other debris must be removed from them so that nothing prevents the insulation from adhering tightly to the pipe.

Warming by means of heat-insulating materials

When determining how to insulate a sewer pipe on the street, insulation is often chosen with the help of insulation materials widely used in the construction industry. Usually, for ease of installation, they have a cylindrical shell with an inner diameter corresponding to the standard size of the sewer pipe.

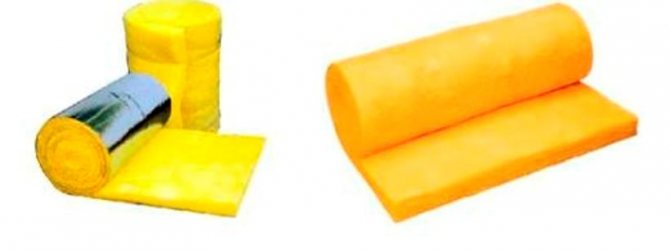

Glass wool

The main heat insulator is long glass threads, which are obtained from broken glass by heating to 40 ° C and blowing from a centrifuge - this significantly reduces the cost of the manufacturing process.

Fig. 6 Glass wool insulation for sewer pipes

Fibers 3 - 15 microns thick. are suspended in an air environment, therefore the material has a low density and high resistance to vibration, in addition, glass wool has the following useful properties:

- The material is non-flammable, has high thermal stability and can withstand temperature ranges from -400 to +700 C.

- Its thermal conductivity ranges from 0.045 to 0.065 W / m * C., which is a rather low indicator, second only to some polymer materials.

- Glass wool permeates steam and is not afraid of moisture, resistant to a large number of aggressive chemicals and biological effects.

- The material is environmentally friendly and harmless to human health.

The disadvantages of glass wool as a heater include its low density, tendency to shrinkage and inconvenience of installation.

Glass wool is produced in rolls and slabs; foil-clad cylindrical shells with a corresponding inner diameter are most suitable for insulating sewers.

When installed under a layer of earth, glass wool will be compressed and can absorb moisture - this significantly reduces its heat-insulating properties and limits its use as a heat insulator for a sewer line.

Fig. 7 Thermal insulation of sewer pipes in the ground with mineral wool

Mineral wool

Mineral wool is produced in two types - slag wool and basalt. The first has a low density and high water absorption, it is not recommended to use it on metal surfaces and in living quarters - due to these properties, it has very limited use.

Basalt mineral wool, which is produced by melting basalt and forming a thin fiber from it, rightfully occupies a leading position among heaters, having the following useful properties:

- Low thermal conductivity 0.04 W / m. * C. contributes to the widespread use of the material in the construction industry for insulating various types of surfaces and pipelines.

- The material is non-flammable, resistant to many chemicals and temperature extremes, and is environmentally friendly.

- Cotton wool is resistant to moisture, but can saturate it, therefore it is recommended to use it in a dry environment.

- Unlike glass wool, basalt wool has a higher density, making it easier to install and more efficiently used in conditions of pressure on the surface.

Insulation for sewer pipes

What kind of insulation to use for sewer pipes laid in the ground?

An indispensable condition for a comfortable existence in the house is a normally working sewage system. To prevent ice plugs from forming in pipes in severe frosts, sewer pipe insulation

on the street.

To prevent pipes from freezing, various methods are used, including the installation of insulation materials. Consider what insulation options can be used in private construction.

There is an opinion that the sewer pipe, in principle, cannot freeze, since the liquid in it does not stand, but moves. In addition, waste water tends to be hot because everyone uses hot water. Nevertheless, the insulation of sewer pipes cannot be called a useless operation, since in severe frosts the system may not be able to cope with the load.

Sewerage insulation methods

The consequences of freezing a pipeline can be catastrophic. Not only that, due to the ice plug, the drains will stop leaving and it will become impossible to use the sewage system, it is also possible that the pipeline will collapse, caused by the expansion of water during freezing.

When deciding how to insulate sewer pipes, several options are possible.

Laying pipes in deep trenches

One of the most effective ways to protect the sewage system from freezing is to lay pipes to a sufficient depth, since below the freezing point of the soil, a constant temperature of about 10 degrees Celsius remains all year round. With this method of laying, the water in the pipes cannot freeze, even if the speed of its flow is minimal.

However, this method is not always applicable. There are many reasons for abandoning this method, these are the characteristics of the soil, and the climatic conditions in the area, and the location of the sewer tie-in into the central pipeline.

Also, consider the fact that the pipes must be laid with a slope. The slope depends on the diameter, for pipes 110 it is 0.02. That is, if the length of the pipeline is 10 meters, then the lower part of the pipe should be 20 cm lower than the upper one, and this will require significant deepening of the septic tank, which is not rational. After all, then there will be difficulties with pumping out the septic tank from sediment

.

When laying sewer pipes to a great depth, do not forget that if the need to repair the pipeline arises, you will have to resort to large-scale earthworks. And this will create significant difficulties, especially in the winter.

The use of insulation materials

This method of solving the problem is perhaps the simplest and most popular. When using it, special heat-insulating materials are used, put on the pipes. However, do not forget that the insulation for sewer pipes does not heat the pipes, but only reduces the rate of their cooling.

That is, in the absence of a constant drain and heating of pipes as a result of the use of hot water, the pipes will sooner or later cool to zero. Therefore, it is recommended to use insulation for sewer pipes only where the sewage system is used regularly.

Heating pipes using an electric cable

This method involves not just thermal insulation, that is, protection against heat loss, but really insulates, providing heating of the sewer pipes. The insulated pipe will be heated by a specially installed heating cable. There are several types of cable used for heating pipes:

- Self-regulating cable. The most convenient and economical option. This type of cable is put into operation only when the temperature drops, moreover, the heating power in different sections of the pipeline will be automatically regulated. That is, in colder places, the heating power will be high, and where the temperature is positive, the resistance will be reduced, and the cable will not heat up.

- Resistive cable. This type of cable is cheaper than self-regulating, but for its effective operation, thermostats and sensors must be included in the system.

- Zone cable. This is a type of resistive cable, but unlike the latter, it does not generate heat along its entire length, but only in certain areas. This type of cable can be cut and redistributed to the desired sections of the pipeline.

As a rule, the heating cable is laid around the outer surface of the pipes, but in some cases it is necessary to heat the sewer pipes from the inside. This installation method is practiced, as a rule, in street pumps. Heating cable fixing methods:

- in a straight line along the pipe - this method is suitable for areas with a mild climate;

- in a straight line along the pipe in several parallel lines, the more lines, the better insulation the cable will provide;

- spiral, the pipe is wrapped in a cable. The more turns will be done, the better the insulation. But with an increase in the number of turns, energy consumption will also increase, so you need to find the optimal stacking frequency.

To perform heating inside the pipe, a tee is additionally included in the pipeline diagram for introducing a heating cable.

Combined method of pipe insulation

As a rule, if the sewer pipes are insulated with their own hands, the best option is to combine several of the insulation methods described above.

For example, the main part of the pipeline can be laid below the freezing point of the soil. And small sections that connect the pipeline to the surface can be insulated using a heating cable or installing an insulating material.

Types of heaters for sewer pipes

Consider what materials can be used to insulate sewer pipes in the ground:

- Glass wool. This material has a low density and low thermal conductivity. However, the material requires careful external waterproofing, and this significantly increases the cost of purchasing the materials and increases the operating time.

- Insulation in the form of basalt fiber cylinders. Such insulation for sewer pipes is very convenient. Installation of insulation is done quite easily and quickly. However, the material also has a significant drawback - a high price.

- Foam insulation. This type of insulation is produced in the form of hollow thick-walled cylinders (shells) for different pipe sizes. Foam shells are applicable both for internal sewerage (in basements without heating) and for external networks. The great advantage of this material is that it can be reused after dismantling.

- Foamed polyethylene. It is almost an ideal material for use on outdoor networks, as it is easy to install and does not lose its qualities over time.However, in areas with a harsh climate, it is required to install this type of insulation with a very thick layer. It is important to choose the right insulation for pipes made of foamed polyethylene, the dimensions of the cylinders must correspond to the diameter of the pipes. It is necessary to put on polyethylene cylinders on pipes before laying, but if necessary, this material can also be used to insulate already laid pipes.

- Expanded clay. A loose type of insulation that fills the trench around the pipe. The main condition for the use of this material is dryness; when wet, it loses its properties. In addition, the effectiveness of this insulation for sewer pipes in the ground is not too high, it is suitable for areas in which the climate is not too harsh.

- Thermal insulating paint. Such thermal insulation is more often used for metal-plastic water supply pipes, but it can also be used for sewage pipes. Paint is applied using a spray gun or manually - with a roller (brush). One layer of paint provides the same insulation as a standard foam shell or one layer of polyethylene foam.

Installation of insulation, produced in the form of rolls, is no less simple. The pipeline is wrapped with one or more layers of thermal insulation, and from above the insulated sewer pipes are wrapped with tape.

The use of heat-insulating paint for pipe material is a very convenient method that provides insulation for the entire service life. As part of this material:

- Insulating fillers - hollow microspheres made of glass, polymer material or ceramics. These are microscopic balls filled with rarefied air. Moreover, the composition of the paint can include spheres made of different materials and having different diameters.

- Binder. The basis of the material is a polymer binder based on latex or acrylic.

- Modifying additives that improve the performance of the paint.

Installation of insulation

Consider how the thermal insulation for sewer pipes, made in the form of cylinders, is mounted:

- Insulation cylinders are selected corresponding to the diameter of the pipes.

- The cylinders are put on the pipes so that the joints of their edges form an overlap with a width of 10 cm.

- The joints of the edges of the insulation are fixed with adhesive tape.

- To insulate the pipeline at the turning points, shaped shells are purchased, made in the form of a branch or tee.

So, the answer to the question of whether it is necessary to insulate sewer pipes is unequivocally positive. Only residents of the southern regions, where there are no strong and prolonged frosts, can neglect the insulation of the pipeline.

How to insulate a sewer in a private house

If it becomes necessary to insulate the sewer plastic pipe in the house, all the above materials can be used. From an economic point of view, ease of installation and aesthetics, the largest number of homeowners prefer isolon. It is simply fixed on the insulated surface through a side cut, can be glued or connected with adhesive tape. An additional advantage of the material is its highest noise absorption among all heat insulators.

Fig. 11 Insulation of the sewage system in a private house with isolon

When deciding how to insulate the sewer in the ground, they proceed from climatic conditions, the convenience of work, the cost of materials. The optimal choice of heaters for underground sewerage with a wide variety is not too large - it can be an electric cable or a shell made of solid materials that do not allow moisture to pass through - foam or foam. Often a combination of heating cable and insulating shell is used for thermal insulation.