If you still do not know how to waterproof a balcony with your own hands, then we advise you to familiarize yourself with useful recommendations from real professionals. There were times when the balcony served as a kind of storage room, where all unnecessary things and other rubbish were kept. Times have changed and people have begun to use balconies and terraces more effectively. A creative approach allows us to turn terraces into great places to relax or even a study. However, having received additional space in the house, do not forget that it should be not only comfortable, but also reliable. Balcony waterproofing prevents corrosion and deterioration of supporting structures. Therefore, it is extremely important when performing work to comply with all building codes and regulations (SNiP).

Why do you need a balcony waterproofing

The balcony is more susceptible to the negative influence of weather conditions than other areas of the apartment. Waterproofing will help protect the space from unpleasant moisture, fungus and dampness. If you use high-quality waterproofing materials and carry out the work correctly, you can provide the walls, ceiling and roof of the balcony with reliable protection.

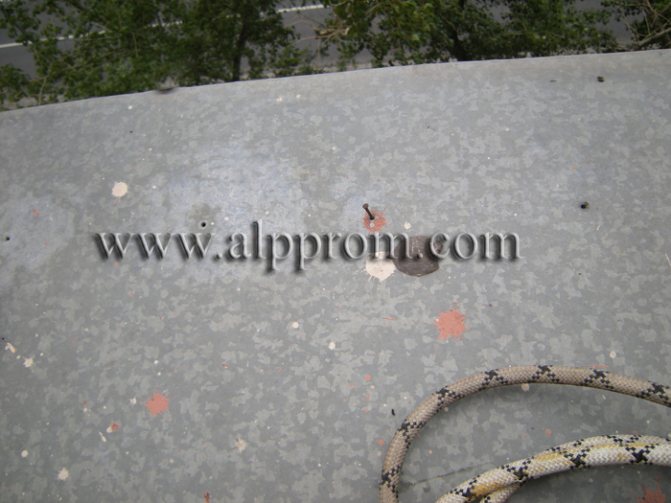

In the overwhelming majority of cases (95%), a concrete slab acts as a balcony base. High-quality waterproofing of an open balcony makes it possible to increase the resource of a structure under the influence of an aggressive environment by one and a half times. If you do not do this, you can incur financial losses in the future.

Because reinforced concrete has a porous structure, and inside it there is an embedded metal element. At subzero temperatures, water enters these pores and begins to chip off metal microparticles. Corrosion sets in and the metal collapses. Waterproofing prevents destructive processes.

It is performed for floor slabs (processing from below and from above), parapet (steam insulation is made at the same time), roof (rafter system is processed).

If you understand the importance of this operation, go ahead and see how to make a balcony waterproofing in accordance with existing technology.

Features of waterproofing

An example of the destruction of a balcony from exposure to moisture

As mentioned above, high-quality waterproofing allows you to cope with many troubles in the future, namely:

- damage to decorative panels;

- damage to finishing materials;

- corrosion of metal parts;

- the appearance and reproduction of fungi and mold;

- deformation of the floor covering.

To make the waterproofing correctly, you need to take into account the design features of the balcony. Depending on this, choose one of the following schemes:

- covering the entire area;

- processing of one balcony slab;

- additional protection using a roof device and canopies.

It is rational to use one suitable type of finish for different balconies. For the open type - terraces, it is quite possible to do with the waterproofing of the slab and the floor. But for a wooden house, you will have to make a complete waterproofing inside and out. For a loggia, you can combine insulation and waterproofing using penofol. Since we started talking about the materials, let's move on to their detailed consideration.

Balcony waterproofing materials

In the beginning, we will deal with the necessary materials.

It all depends on the finish of the balcony structure. If the surface of the balcony is concrete / wood, penetrating compounds are used. If polyurethane / stone / tile is present, a coating material is used.

The types of waterproofing materials are as follows:

- Cast insulation;

- Glued insulation;

- Paint insulation;

- Impregnation.

Any of these materials will perfectly protect the balcony space from the negative effects of water / moisture.

Cast insulation is water-repellent. When choosing it, a heated polymer is used. The floor of the balcony is processed by it. It can quickly become damaged and lose integrity.

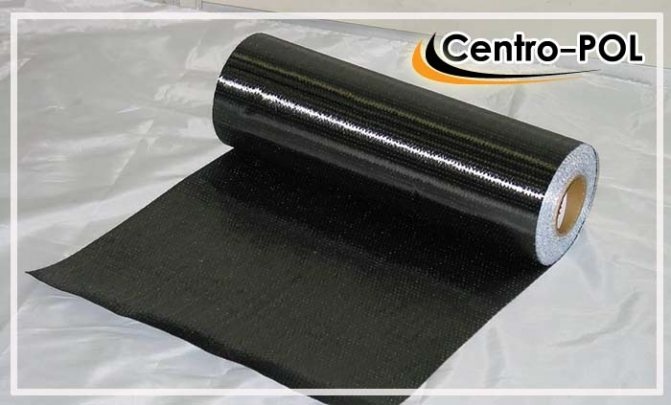

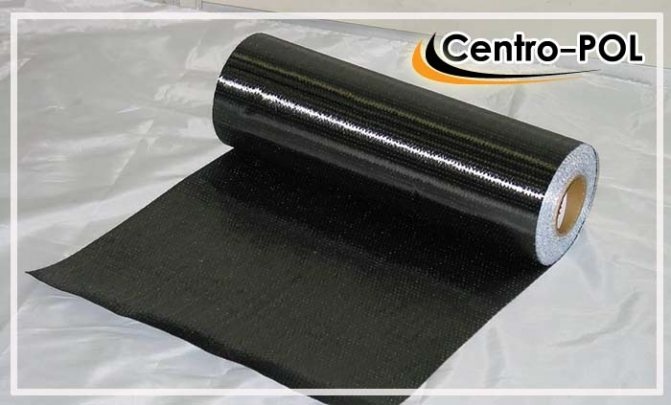

Papered insulation means material in the form of a roll. It is overlapped on all balcony surfaces. The joints are processed with a special mastic. To give the waterproofing strength and effectiveness, it is installed in several layers.

The paint insulation is characterized by ease of use. Another plus is the low cost of the material. However, we do not recommend using it for wooden surfaces. At sub-zero temperatures, it can crack and you will have to update the waterproofing layer.

An excellent material for waterproofing wood / concrete surfaces is impregnation. It penetrates inside and ensures the safety of the structure. However, when treating wood surfaces, warm and dry weather is required. The applied impregnation should dry well.

Types of materials

Waterproofing materials differ in their characteristics and cost. The choice mainly depends on the surface to be treated and the method of application. The following main types of waterproofing materials can be distinguished:

- mastics;

- roll;

- film.

Mastics

To apply the mastic, the surface must be pre-treated with a Primer for better adhesion of materials.

One of the most popular groups of water-repellent materials. Includes plastic adhesives based on bitumen, liquid rubber, polymers, resins, plasticizers and other additives. Ideal for insulating indoor and outdoor terraces.

All waterproofing materials are relatively inexpensive. The average price for rolled and film materials of European quality is about $ 1 per square meter of coverage. The cheapest representative of roll materials is roofing felt, which costs a little more than $ 5 per 10 sq. m. The price of a can of bitumen mastic from branded representatives starts at $ 15. If you need a more economical coating, use an acrylic based mastic. It will cost 2 times less.

Roll

An example of rolled glass roofing material for waterproofing

The most famous materials of this vast group are roofing felt, roofing material and glass-roofing material. Consists of cardboard impregnated with bitumen mixed with basalt chips. This material consists of several layers of polymer membranes that combine waterproofing and thermal insulation properties. They are used for insulation works on floor tiles of terraces.

Film

Also available in rolls. Consist of polyethylene, polypropylene, polyvinyl chloride film. These compounds are widely used when it is necessary to waterproof a concrete floor before creating a dry screed. Like the previous type of materials, they are mainly used for interior decoration of terraces.

Preparatory works for waterproofing the balcony

Having chosen the material, let's get to work. You can entrust it to a specialist, but waterproofing a balcony does not require special qualifications, you can do it yourself and reduce the repair budget.

In addition to the preparatory stage, there are three more: treatment of the floor, the inner surface of the room, the canopy / roof / gutters.

Preparation includes the following types of work:

- We dismantle the old coating;

- We analyze the condition of the concrete base, determining the places of disrepair;

- We remove them with a puncher;

- We clean the surface from debris with a stiff brush and remove the remnants of cement / old glue;

- We process the cracks with a grinder.This is necessary for the new screed to fill all kinds of voids. We expand a small crack, we trim a large one;

- At the exposed reinforcement, we clean the rust with chemical compounds and remove the remnants of concrete;

- We cover the reinforcement with an anti-corrosion compound;

- We prime the floor surface;

- We fill the holes with cement-sand mortar;

- We examine the roof of the balcony and determine the possible places of water penetration;

- We clean the surface of the ceiling / walls;

- We apply a primer with a waterproofing material.

Waterproofing the balcony floor

Waterproofing the floor prevents moisture from entering from below. This is especially important for the owners of apartments located on the ground floors of buildings. Moisture can be from the basement / ground. We clean the floor from debris / dust and create a concrete screed. If the balcony is open, its slope must be 2% so that the water flows freely from the surface. We reinforce the screed with a metal mesh.

For sealing, fill all the seams that have appeared in the process of work by 50% with mastic. We clean the screed from debris / dust and apply WB primer on it to ensure good adhesion. Cover the wetted concrete with several layers of polyurethane mastic.

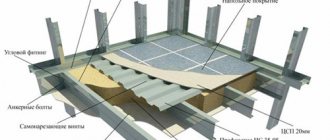

We are waiting for the insulation to dry, and we overlap the vapor barrier material made of foil. This prevents condensation from occurring. We put a wooden frame on top. The OSB plate is attached to it with self-tapping screws. Finishing work - installation of finishing material on the balcony floor.

The thickness of the waterproofing must not be less than 20 mm and must extend up to 200 mm on the walls.

Sealing works for balconies using proven technologies

offers high-quality sealing of seams of balconies and elimination of leaks in seams on loggias, using positively proven technologies for sealing interpanel joints and seams in buildings.

In some cases, in addition to sealing joints, you may need to seal windows on a balcony or loggia, which we also successfully produce.

Installation "Vilaterma"

If the cracks and gaps in the balcony slabs are visually noticeable, we install Vilaterma and then seal the panel joints of the balconies with mastic. As a rule, these are seams less than one centimeter wide. At the same time, we do it "under scotch tape", i.e. we glue the masking tape on the balcony slabs, thereby limiting the width of the seam. This allows you to carefully seal the joints and obtain an aesthetically pleasing seam.

Warm seam system

When waterproofing the floor on the balcony and loggia, sealing joints and seams according to the "warm seam" scheme, we pre-fill the seam with polyurethane foam. The advantage of this technology is that all voids, even those that are not visually noticeable, are filled with foam. Further, if the seam size allows, Vilatherm is installed and the seam is sealed with mastic. In works at height for sealing balconies, we use two-component polyurethane mastic for joints over 1 cm, and silicone sealant for small joints.

IMPORTANT!

If you have mounting foam left open during the installation of the balcony, then we strongly advise you to seal it, since it collapses under the influence of sunlight and this can subsequently cause a leak. In this case, waterproofing of the balcony ceiling from the inside may be required.

Waterproofing the wall on the balcony

Before carrying out waterproofing work with a grinder, we select U-shaped grooves in the interpanel seams and seal them with Germoplast. By doing this, we eliminate leakage through microcracks. Then we fix decorative coatings.

Then we glue the foil polystyrene foam tightly to the wall. The second option is ordinary foam, which is covered with a layer of vapor barrier film. Joints are formed between the foam sheets. We seal them. To reliably protect against moisture, apply 2 layers of mastic.

Partitions

It is possible that there are additional partitions / other structures on your balcony. Then they should also be waterproofed. The principle of operation is similar.

We recommend to additionally cover the walls with expanded polystyrene, and use a coating / penetrating compound as waterproofing.

Waterproofing the ceiling on the balcony

We clean the ceiling slab and treat it with an antiseptic to protect the structure from the formation of fungal mold. Then the surface is treated with a coating / penetrating insulating compound. We seal all the cracks and cracks in the ceiling with silicone.

Fill the joints of the wall with floor slabs with a sealant. When finishing the roof with tiles / metal tiles, each joint is additionally treated with polyurethane mastic. It has good adhesion and is easy to apply to damp ceiling surfaces. We recommend two layers of mastic. The second layer should be perpendicular to the first. After the first layer, the waterproofing layer is reinforced with a mesh. We give the mastic 3 days so that it dries well and hardens. This will create a strong crystalline protective layer.

For residents of the last floors, we recommend laying a layer of roofing material on top of the balcony roof or covering it with roofing mastic. We recommend calling a specialist to waterproof the roof. We do not recommend doing this work yourself. It is life-threatening.

Materials (edit)

In order to strengthen the existing structure, the so-called frame, as well as to install new supporting structures, metal or wood will be needed. It is much easier to make a frame made of wood. When making a metal frame, you will need rectangular pipes or metal corners, and a welding machine. The metal construction is more reliable, but correspondingly more expensive.

The roof of the balcony itself can be made of various materials.:

- Metal tile... It is a double-sided galvanized iron sheet. It is analogous to a conventional metal sheet. It differs from the profile sheet in a more aesthetic look, it can be of different colors. Recently, metal tiles have become very popular. Its advantages are durability and high corrosion resistance. When roofing a balcony with its further glazing, a metal tile will be an ideal option.

- Ondulin - euro slate... Strength and lightness are considered its advantages. This material is environmentally friendly. The advantage of ondulin is easy installation. In addition, it has a sound-absorbing effect. When installing the roof of the balcony made of ondulin, it is worth considering that snow lingers on it much longer, which means that the angle of inclination should be done more.

- Cellular polycarbonate... This material is durable, lightweight and durable. It is produced on the basis of polymer carbonates. The roof of the balcony made of such a material, due to the cellular structure, will have heat and sound insulating properties. The balcony room will be warm and bright. The amount of natural light falling on the balcony will depend on the color chosen, and can range from 20 to 70 percent.

The roof of the balcony, of course, can be made from other materials, for example, from slate, sheet or galvanized iron. Such materials do not have special durability and do not have a very aesthetic appearance, therefore we do not take them into account, because it would be more reasonable to do the work beautifully, and most importantly for a long time.

Having decided on the materials, we will consider one of the most practical balcony roof devices

Waterproofing a wooden balcony

Waterproofing a wooden balcony involves treating the boards with a special antiseptic to prevent strong moisture and the appearance of fungus on the surface. It is allowed to cover the floor with a wall with liquid rubber on the base, followed by processing with a finishing material.

Waterproofing prevents the development of mold and reduces the decorative effect of the tree. The material will begin to lose strength and attractiveness. Deformation of the coating will occur and it will be impossible for it to return to its previous appearance. Waterproofing a wooden balcony will prevent swelling and will not allow cracks to appear, which will lead to the destruction of the structure.

The technology of work depends on the functional purpose of the balcony and its type.

In this article, we examined the process of self-waterproofing a balcony. We hope you can use the above technology.

How to make a balcony in wooden houses

A balcony in a wooden house can be installed with your own hands. First of all, the owner of the house needs to decide on the type of future construction. Often, balconies are installed directly in the roof. If the owner wants to install a gable balcony, then this wish should be taken into account already at the stage of building the building, since it is necessary to make one of the fronts deeper, taking into account the planned width of the future facade structure.

The base plate must be covered with insulation, on top of which a layer of waterproofing is laid, after which a screed is made. At the final stage, a fence is installed, the material for which is selected according to the wishes of the customer: wood, metal, brick.

Design features

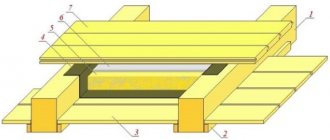

Any balcony, regardless of appearance, decor elements and size, it has three main structural elements:

- base plate;

- parapet or fence;

- visor (roof), windscreen.

The slab is the main structural element... It can be made of wood or reinforced concrete. The advantage of a wooden slab is its low weight, thanks to which the installation of this structure can be carried out on the facade of any house.