When designing and installing sewage systems, great attention is paid to ensuring the safety of their use - removing unpleasant odors, explosive gases, preventing drains from entering the house. One of the effective means for protecting premises from the penetration of faecal waste is a 50 mm sewer check valve.

It is worth noting that sewer check valves are not required in the system. But in some specific cases, they can be useful, preventing the slightest possibility of the appearance of dirty water in the house.

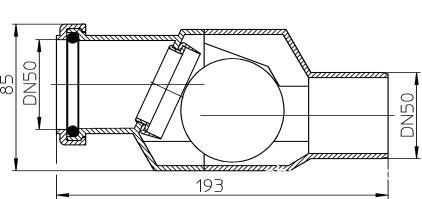

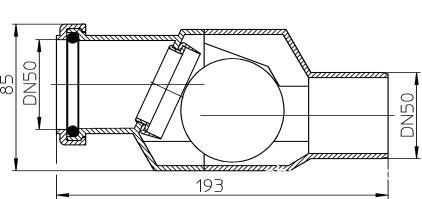

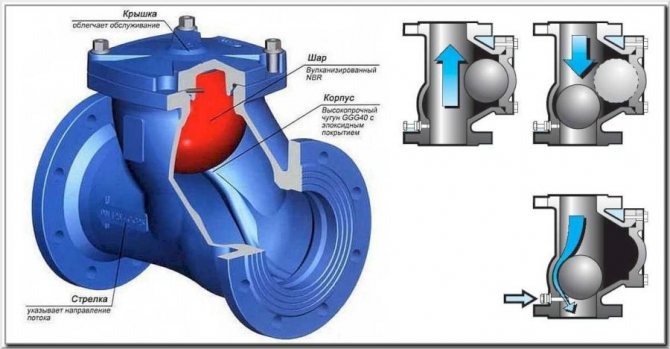

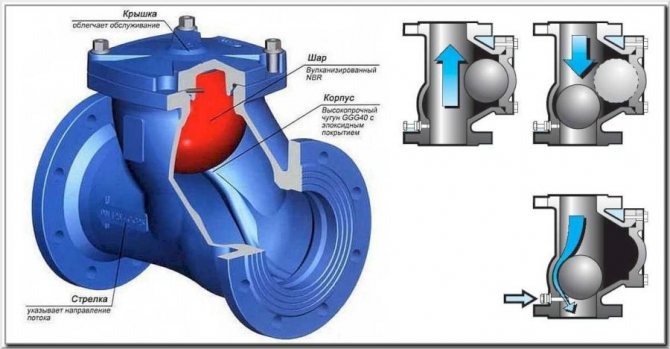

Fig. 1 Sewer check valve 50 mm - exterior

What is a check valve

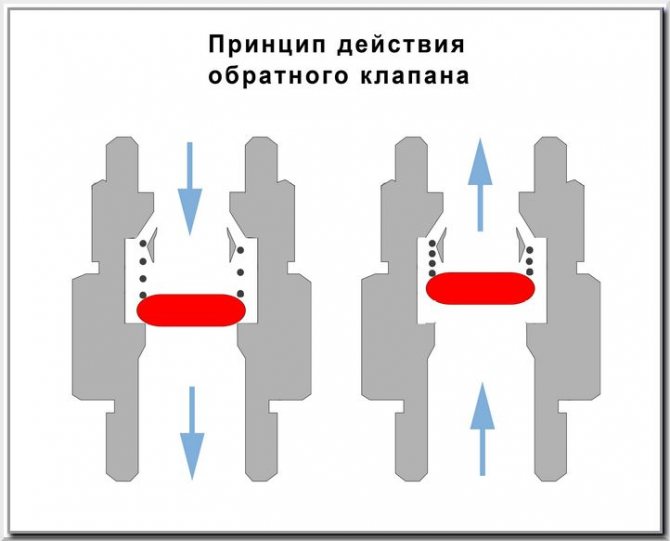

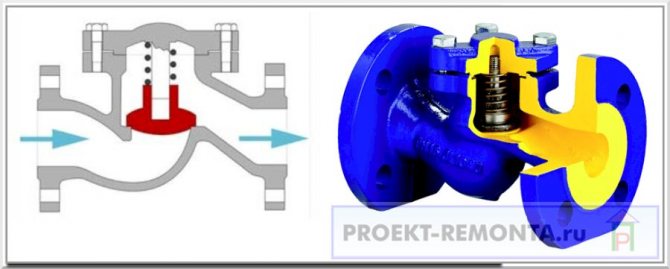

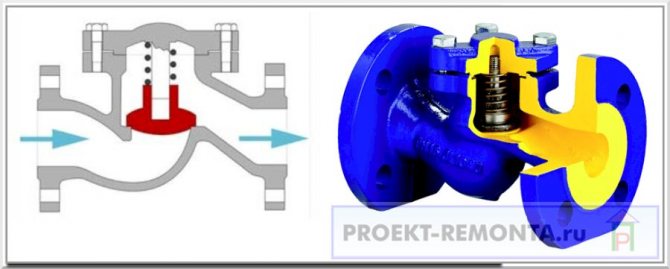

Based on the name, it is easy to guess that this device passes a certain substance in one direction and blocks its movement in the opposite direction. Sewer valve, this is only the most famous option. In addition to the sewage system, there is a similar shut-off valve that is installed on the water supply system, heating, ventilation systems, etc.

Important! A non-return air valve is also installed in the sewer system, it is designed to normalize the pressure in the pipes, the principle of operation is the same, but the device is slightly different.

The liquid and air valve for sewage work on the same principle

Why do you need check valves

A liquid check valve is installed on the sewer system to protect housing from drains. In multi-storey buildings, the sewer system is mostly gravity and if there is a blockage somewhere, all the drains that drain from above begin to fill the riser.

Further, according to the principle of communicating vessels, as soon as the drains reach the level of the nearest toilet bowl, a fountain of everything that has been drained from above begins to beat from it. To block the fetid liquid, a sewer check valve is placed on the outlet pipe.

- In old multi-storey buildings, where the system has already worn out and blockages are not uncommon, residents of the first floors put such fittings.

The check valve in the sewage system in the apartment is especially relevant for residents of the first floors.

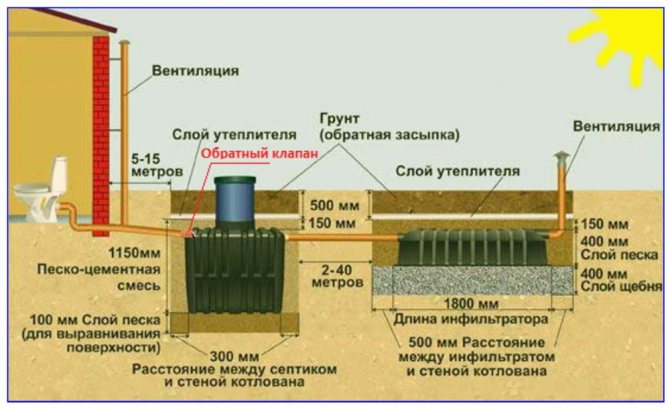

- In private houses equipped with septic tanks, sewer valves are installed at the exit from the basement, so that in case of flooding of the septic tank with groundwater, the drains do not go back.

- A sewage drain check valve must be installed in pressure systems, all these systems are equipped with fecal pumps, and in order to block the return flow of drains when the pump is turned off, a sewer valve is installed. You can find out about pressure systems for apartments, types of septic tanks and other nuances "HERE".

- The sewerage valve is also placed on the central drain pipe in the accumulation tank of the drainage system; without this fittings, water will go back, which can lead to flooding of the site or the foundation of the house. The intricacies of arranging drainage in a private house are shown and told in detail "HERE".

A 110 mm sewage check valve is installed in the storage tank of the drainage system

- Both in multi-storey and in private houses, the problem of rodents periodically arises. Hungry rats can climb quite high through the sewer pipes; the check valve will prevent animals from entering the apartment.

In older homes, rats can enter housing through drain pipes.

Important! Before buying a sewage check valve, pay attention to its color - the external fittings are orange, and the valves for internal installation are gray.

The check valve of the external sewage system is orange, and for the internal one, gray

Sample research

I told where and how sewer check valves are used, but did not mention what they are and how much they cost. I will hasten to correct this defect. As an object for research, I will focus on the products of the Hutterer {amp} amp; Lechner is not the cheapest, but certainly one of the highest quality in the post-Soviet space.

HL3 washing machine shutter.

| Parameter | Value |

| Material | Polypropylene |

| Diameter | 3/4 inch |

| Connections | Union nut with gasket, hose connection |

| Working temperature | 95C |

| Appointment | Prevents drains from entering the washing machine without its own valve |

| Retail price | 664 p. |

50mm HL4 valve.

Device and dimensions of the product.

| Parameter | Value |

| Material | Polypropylene |

| Diameter | 50 mm |

| Connections | Smooth pipe, 50 mm O-ring socket |

| Working temperature | 95C |

| Appointment | Installation in front of a washbasin or bath (works with drains without large suspended matter and faeces), vertical or horizontal |

| Bandwidth | 1.36 liters per second |

| Retail price | 2412 p. |

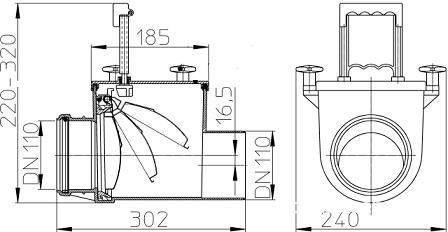

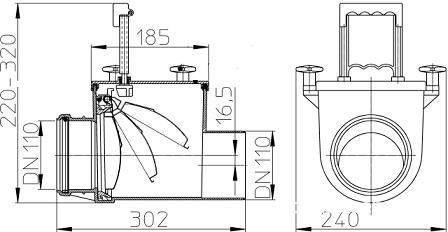

110mm valve HL 710.0.

Device and dimensions.

| Parameter | Value |

| Material | High impact ABS plastic |

| Installation | Horizontal |

| Compound | O-ring flare Ø 110 mm |

| Appointment | Installation in a well on the edge of the outlet |

| Working temperature | 60C (short-term 80C) |

| Working head of counterflow | Up to 5 meters |

| Weight | 720 BC |

| Retail price | 7257 p. |

Straight through HL710.

| Parameter | Value |

| Material | ABS |

| Connections | Smooth pipe and socket with O-ring Ø 110 mm |

| Appointment | Installation in a pipe burst. Designed for effluent without faeces |

| Working head | Up to 5 meters |

| Working temperature | 60C |

| Weight | 2.02 kg |

| Retail price | 7258 p. |

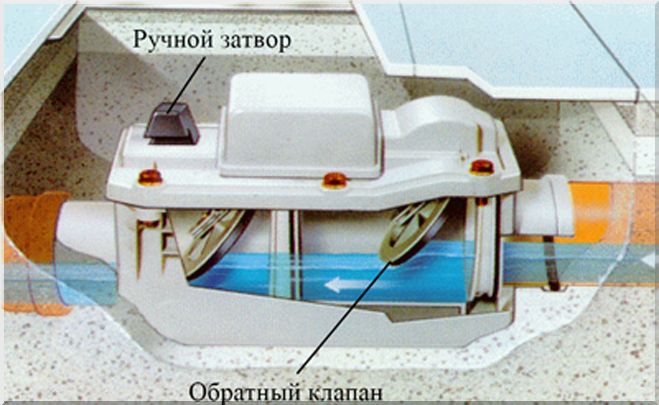

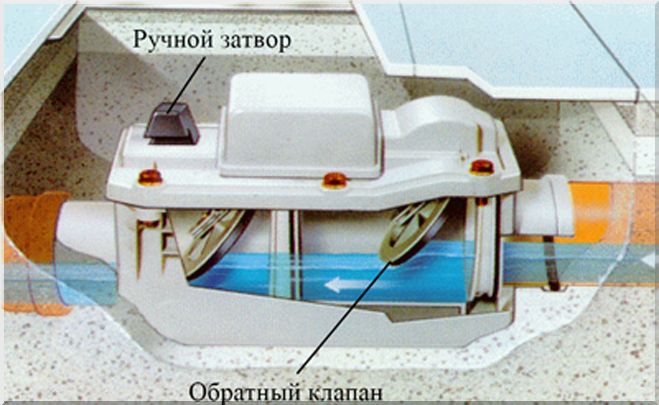

HL710.1 with manual damper control.

The device and dimensions of the shutter.

| Parameter | Value |

| Material | ABS |

| Appointment | Installation in a pipe burst. Not suitable for faecal waste |

| Connections | Smooth pipe and socket with a diameter of 110 mm |

| Working head | Up to 5 meters |

| Weight | 2.18 kg |

| Retail price | 11318 p. |

Double chamber shutter HL710.2.

| Parameter | Value |

| Material | ABS |

| Appointment | Installation in a pipe burst. Works with fecal waste |

| Connections | Smooth pipe and socket with gasket Ø 110 mm |

| Working head | Up to 5 meters |

| Features of the | Two service hatches, manual control of one flap |

| Weight | 3.23 kg |

| Retail price | 15798 p. |

Electrified valve HL710.2 EPC.

The oldest valve in the HL model range is equipped with an electric drive powered from a 220 volt mains and a battery that provides autonomy up to 7 days. Connection - socket, for a diameter of 110 mm. In addition, the manufacturer offers valves with a diameter of 160 and 200 mm.

Here are the most interesting features of the device for the consumer:

- The closing force, thanks to a 300-watt electric motor, reaches 50 kgf. Coarse fractions of effluents trapped between the valve and the saddle cannot prevent it from closing: they are simply grinded;

- The shutter closing time is 11 seconds;

- The control unit with a standard cable can be placed 6 meters from the shutter;

- The damper can be closed forcibly not only manually, but also from the remote control;

- The valve is designed for horizontal installation only.

The retail cost of the shutter is 102,970 rubles.

The cost of the products given by me as samples is, let's say, far from budget. In order not to frighten the reader with the upcoming expenses, I will introduce him to a pair of domestically produced valves.

TP 85.100.

| Parameter | Value |

| Material | Pvc |

| Connections | Smooth pipe and socket, 110 mm |

| Appointment | Internal and external sewerage |

| Installation | Horizontal, vertical |

| Retail price | 1660 p. |

Product with the laconic name "110 mm external check valve".

This Novosibirsk-made valve is also designed for indoor and outdoor sewerage. Like the previous device, it provides for manual locking of the shutter in the closed state and the possibility of servicing through a service hatch.

Unlike TP85, here you will need a tool - an open-end wrench or socket wrench to open the hatch. The cost of the valve is even more attractive: it will cost the buyer only 1,500 rubles.

Types of sewer valves

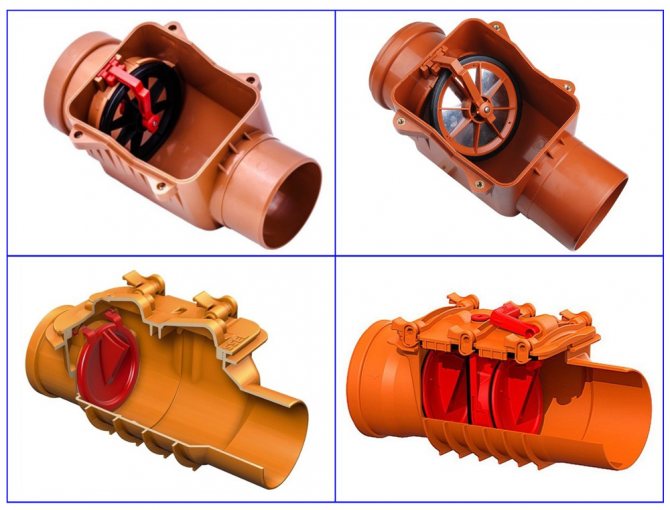

As already mentioned, the principle of operation of such fittings is the same everywhere, but the device can be very different, now 4 types of structures are actively used:

- wafer fittings;

- lifting fittings;

- rotary fittings;

- ball constipation.

Wafer-type sewer locks

The wafer-type check valve is deservedly considered the most compact among all such constipations. The device is mounted inside the pipe between two flanges, therefore it does not require much space. But on the other hand, if such an armature is jammed, then you will have to untwist part of the system to get to the valve.

There are 2 types of wafer fittings.

- Disc constipation. In these models, the passage is blocked by a solid disc, fixed in the upper part. The disc often sinks under its own weight, without any springs, although there are exceptions. These models are considered to be among the most reliable, but they can only work in a gravity system.

Wafer check valves can be made from different materials, but the quality and price depend more on the brand than on the material.

- Bivalve center-stem wafer valves. In these models, an axis is installed in the center, on which the 2 petals are based. The leaves are pressed by a spring, the system is considered universal, the two-leaf horizontal and vertical valves are equally reliable.

Wafer check valve 100 and 110 mm are considered the most reliable

Lifting models

Here, the liquid moves in a curved path, when the drains go in the right direction, the plug is lifted and the liquid flows through. If the direction of movement changes, the spring will press the plug and the flow will be blocked.

Typically, such models are made of cast iron, they are quite powerful, the diameter of the lift check valves for the sewage system is 110 mm and higher, respectively, for private houses, and even more so for city apartments, this fittings are used extremely rarely.

Check valve cast iron - lifting type

Advice! Lifting structures are suitable for clean liquid, but it is better not to put them on the sewer drains, since blockages often occur due to the broken path of movement.

Butterfly valves

In essence, rotary or lobe systems are very similar to butterfly valves, the only difference is that there is a revision window through which the mechanism can be cleaned. There are 2 types of such fittings.

- Rigid systems. In them, the plate closes the passage under its own weight. They work flawlessly, but they are only suitable for gravity systems with a small volume of wastewater, if such fittings are placed under a pump or for large volumes, then when the petal collapses, a water hammer can occur, which is dangerous for pipes and gaskets.

- Soft valves. Without going into technical details, I will only say that the petal in them closes with a delay, as on a door closer, therefore, water hammer is excluded.

Flap check valve 50, 100 and 110 mm for domestic use is the best fit

Ball valves

The ball check valve is considered one of the most reliable, the system is trouble-free, a ball is laid inside, which rolls back in the working position, and closes the main hole during the return flow of the liquid.

Ball check valve is more suitable for industrial applications

Advice! When choosing a check valve for the sewerage of a house or apartment, it is better to give preference to fittings in which there is a manual blocking of the damper. A very convenient option, especially if you need to leave home for a long time, for example, to go on vacation.

Subtleties of installation

Installing a sewage check valve is not a tricky business, plus such work does not require an expensive tool, a home kit, a drill, a hacksaw, a level, a tape measure, etc. is enough. But first you need to decide where to put the check valve.

Seat selection

In this case, it all depends on where the system is most often clogged.

- If blockages usually occur in the first sewer from the house, then a 110 mm check valve is placed after the bend in the basement (before the pipe enters the wall).

Important! In multi-storey buildings, self-installation of such a valve can cause problems with the operating company. The fact is that according to SNiP 2.04.01 - 85, there must be a check valve with an electric drive and an emergency sensor in the basement, so that in case of flooding, the signal goes to the dispatcher's console. Simple fittings are installed only in rooms with round-the-clock duty.

When installed in multi-apartment buildings, the electric check valve of the sewage system may require approval

- The sewer valve in the apartment is best placed on a tee or crosspiece near the central drain into the riser.

- If there is no place near the riser for centralized fittings, then you will have to install a separate check valve for sewage 50 mm to the outlet towards the bathroom, kitchen, etc. And a shutter with a diameter of 100 - 110 mm for the toilet.

Check valve PVC or polypropylene is considered the best solution for an apartment or a private house

Incorrect mounting points

There are 2 recommendations here

- Before installing a check valve on the sewer, think about how you will service it, because every six months such valves need to be revised.

- In a multi-storey building, it is unnecessary to install a vertical check valve on the riser.

About vertical fittings should be said separately, installing such a shutter, you can incur a lot of problems.

- If the riser is cast-iron, then you cannot touch it at all, especially with your own hands, not every master undertakes to repair or replace the cast-iron riser. This is due to the fact that there is a danger of collapse of the entire pillar.

- Whatever the vertical check valve, it will interfere with the movement of drains, respectively, sooner or later a blockage will appear at this point.

- If drains rise from below and the valve blocks them, then in a multi-storey building, they will continue to drain from above, which will make the installation of the shutter useless.

- A sewer riser in an apartment building belongs to public structures. If you, on your own initiative, install a valve on it, then if problems arise with this fittings, you will be obliged to dismantle everything and return it to its original position for your money, plus pay overhead costs, for example, cleaning the basement or repairing neighbors who were flooded after installation valve.

A vertical check valve in apartment buildings should not be installed

Valve installation procedure

It is not difficult to install a check valve for sewage with your own hands. The instruction consists of several simple steps, which I tried to reflect below in the photo and video in this article.

So, it is better for a simple home craftsman to buy a horizontal check valve with a manual interlock function, made of PVC or polypropylene. The pipe diameter does not affect the installation instructions, the check valve 50, 100 and 110 mm is installed the same

- The first step is to simply collect everything as it should be.

- Then measure the distance from the valve to the outlet into the riser.

- Take a connecting adapter pipe of a suitable diameter and set aside the desired length on it, cut off the excess.

- After cutting, the edges of the pipe must be cleaned with a knife from the burrs.

Advice! You should not put a corrugation here, a lot of debris accumulates in it.

Reducer Fitting Diagram

- Now find the central axis of the drain pipe and mark 2 points on it on which the shut-off valves will be fixed.

- Drill 2 holes with a puncher and insert plastic dowels into them under the pins of the clamps.

- Pick up the studs in height and screw in the supporting clamps.

- Then insert rubber gaskets into all grooves and thickly coat all joints with sealants, after which the stop valves are finally assembled.

Installation of supporting metal clamps

- Now you just have to connect the system to the sewer and fix it firmly on metal clamps.

Fixation of shut-off valves on clamps

- Depending on the type of walls and the size of the reinforcement, the system can be fixed in three ways, the photo below shows the principle of fixation.

Three types of reinforcement fixation

How to install the device yourself

Before starting the installation work, it is necessary to determine the model of the check valve and its location (sewer riser or plumbing fixture). When calculating, it is necessary to take into account the following parameters:

- Waste water volume;

- Pipe diameter for installation;

- Site location (vertical or horizontal installation).

To install the unit on the pipeline, you must perform a number of actions:

- Select the location of the device that is available for viewing and maintenance.

- Disconnect the water supply to the riser.

- Cut out a small section of the pipe, which corresponds to the dimensions of the device, if the installation is carried out in an existing riser.

- Mount the device to the pipes.

- Connect the water supply and carry out a test run of the mechanism.

If the check valve is installed during the installation of the entire sewer system, it should simply be located in the designated place. This is the most optimal installation option.

Check valve installation

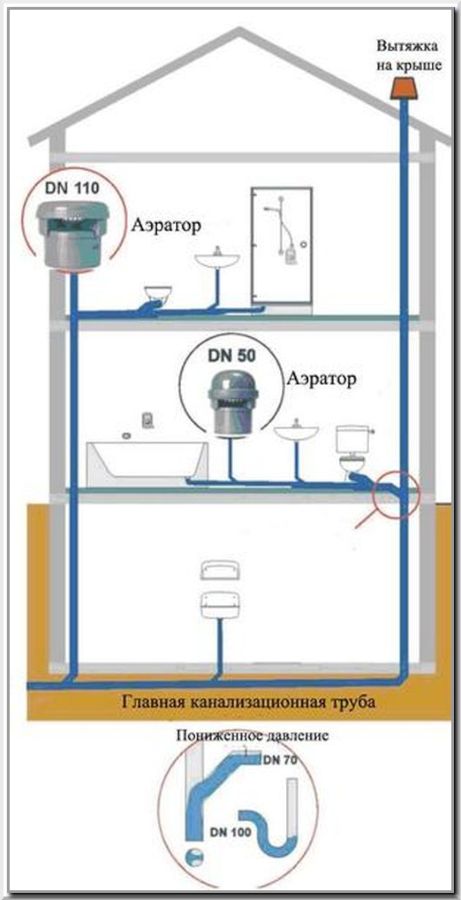

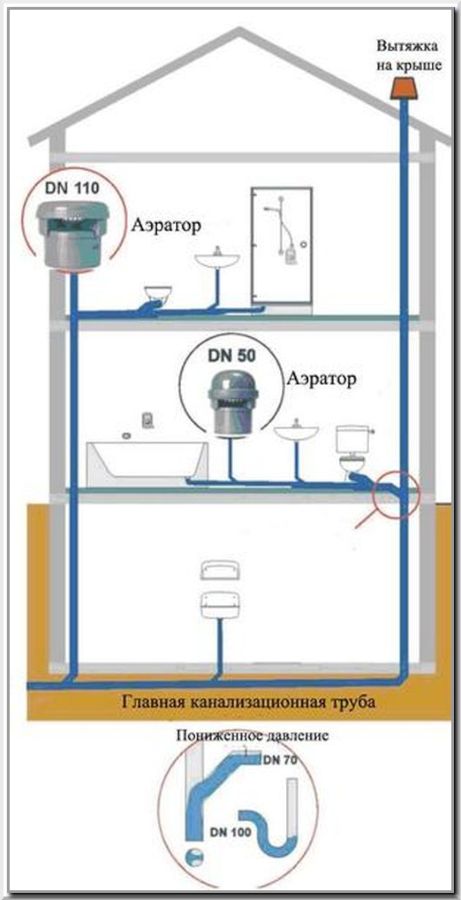

Sewer aerator

If the house has more than 2 floors and there is plumbing on each floor, then the system must be equipped with ventilation. Usually, a free air exchange is provided by a fan pipe, but there are times when it is not possible to install it and then an aeration or ventilation valve is installed.

Important! If the sewer system is sealed and left without ventilation, then when a large amount of water is drained, a pressure drop will occur, as a result of which water will be regularly sucked out of siphons and other hydraulic seals, which will lead to the penetration of sewer gases into the room.

An air check valve is easier to install than a liquid check valve. According to the rules of a valve with a diameter of 100 mm or more, it cuts into the system 30 cm higher, the upper outlet, for example, on the sink, but now there are a lot of small models that are installed next to the toilet or siphon.

How to install the aerator

How does the air sewer valve HL 900NECO and the like work

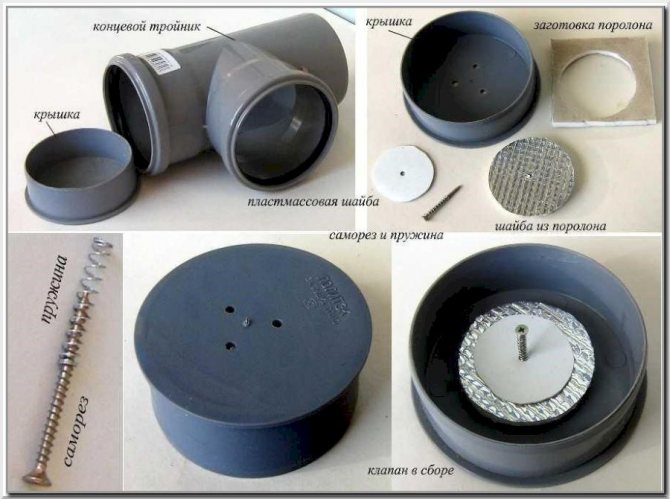

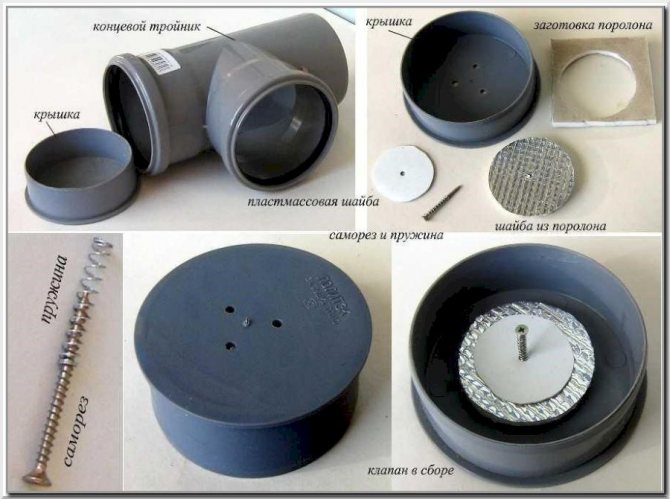

The aeration valve can be made by hand, the photo below gives instructions for making such fittings.

How to make a ventilation valve with your own hands

Professional advice

Although the installation of the fan valve is not particularly difficult, professional plumbers claim that there are several tricks in this matter, the knowledge of which will help to facilitate the work:

- Some of the models of fan constipation are capable of working normally in any position, while for others it is strictly necessary to have a horizontal or vertical position. Before installation, it is necessary to study the instructions for the device in order to know which position is normal for its operation.

- A plastic valve on cast iron pipes can only be installed using adapters.

- In case of failure of any element of the funnel valve, it is not recommended to invent any substitute.If you are unable to purchase a factory-made spare part, it is worth replacing the entire valve, rather than risking that an unsuccessfully repaired device will not be able to prevent flooding.

We also recommend watching a video that clearly shows the device and all stages of valve installation:

The fan valve is just that penny that protects the ruble. If you spend quite a bit of money in a timely manner and install these useful units in the house, you can sleep peacefully without fear of flooding and associated losses and nerve costs.