Layout of the heating stove masonry from two tiers

The device of bunk heating stoves, shown in the photo, is a structure of two parts, located one on top of the other. The parameters of each of them are 165x51x238 centimeters. The heat transfer from the bottom of the furnace is 3200 kcal / hour, and the top is 2600 kcal / hour.

In furnaces for private households, a brick lining with voids is provided in order to lighten the weight of the structure and save material consumption. Both parts of the bunk ovens have exactly the same design. In such heat units, a channelless smoke circulation system is used. According to the scheme of the stove masonry, gases from the firebox enter the upper bell with a nozzle. After cooling down, the gases go down and, at the location of the bottom of the firebox, go through the roll-up into the stacked chimney.

At the lower furnace, the chimney passes through the upper half of the structure. For this reason, the latter has a smaller heating surface. The upper part of the structure has a separate chimney.

The device of a two-tier heating furnace is distinguished by the simplicity of laying bricks, and the scheme of gas movement is simple. The lower half of the unit is cleaned through a door located in the rear wall, and for the upper part, such a door is located in the side wall (in more detail: "Heating stoves for the house - do-it-yourself masonry"). For the functioning of the heating structure, coal or anthracite is used. The pipes for both parts are equipped with two smoke dampers.

Usually, the upper part of the voids in two-tier heating furnaces is covered with solid reinforced concrete slabs, which contributes to the strength and stability of the entire structural array.

The laying of such stoves must be carried out at a high professional level, since their alteration or repair is not an easy task (read: "How to repair a brick stove with your own hands"). Carefully lay out the chimney for the lower part of the heating two-tier structure. If leaks are allowed in the masonry, the wall separating both pipes in the upper part will allow heat to pass even if the two smoke dampers are closed.

In a single array, if desired, you can combine different types of furnaces that have a rectangular or square shape and operate on different types of fuel. The two-tier system has established itself as a good source of heat supply for a country house.

Aren't you afraid?

More recently, even in big cities, and in some places even today, no, no, there are interruptions in heating. There, the boiler room was defrosted by the bunglers, the fuel was not delivered there, because the money was stolen, this accident left the area without electricity (and the boiler room cannot work without electricity - there are pumps all around, blowing air, etc.).

And then, in the frozen city concrete box, the king who managed to build himself a potbelly stove! He brought the tin pipe through the window, gathered up all kinds of combustible rubbish on the street - so he saved his family at least from a cold.

And for a summer residence, or for a country house, a stove is simply necessary! I do not understand those people who, when they brought gas to their village, by installing AGV, break the stoves. Does it bother you, is this stove, or what? She already has a pipe ready, which you still need for the gas apparatus. What is this, frivolity? Why is there such confidence in the reliability of gas supplies? Especially after the just experienced change in the social system and the breakdown of the whole way of life.Aren't terrorists scared? After all, a kilogram of explosives is enough to disable any gas pipeline indefinitely.

Personally, I slightly modified my wood-burning stove, and replaced the door of the firebox with a gas burner. Now I heat the stove with gas. It is very convenient and much cleaner than wood.

But, in case of force majeure, I can downgrade within a few hours and re-fill the stove with wood. This is not to mention the fact that the cost of such a rework is simply ridiculous, completely incomparable with the cost of installing a steam heating. And the walls do not need to be punctured or "decorate" the rooms with batteries.

Furnaces were widely used and applied in all regions of the world, and are capable of using almost any fuel: firewood, coal, gas, peat, oil and its numerous derivatives, straw (or hay), dung (dried cattle droppings), oil shale, woodworking waste ( sawdust) and so on. Therefore, you can heat a house with a stove in almost any area.

I can even say more in confidence, although many will not like it: As you know from the most reliable sources, a few years before the end of the world, the world will face unprecedented cataclysms and disasters. Moreover, these disasters will occur not only in the social sphere, but also simply in nature - hurricanes, floods, earthquakes will reach an unheard-of destructive force. A brief description of these years: The living will envy the dead. These times will even be shortened so that at least some people can survive.

Let me cite several small excerpts from Kir Bulychev's marvelous story "District domino competitions" in order to imagine all this at the everyday level:

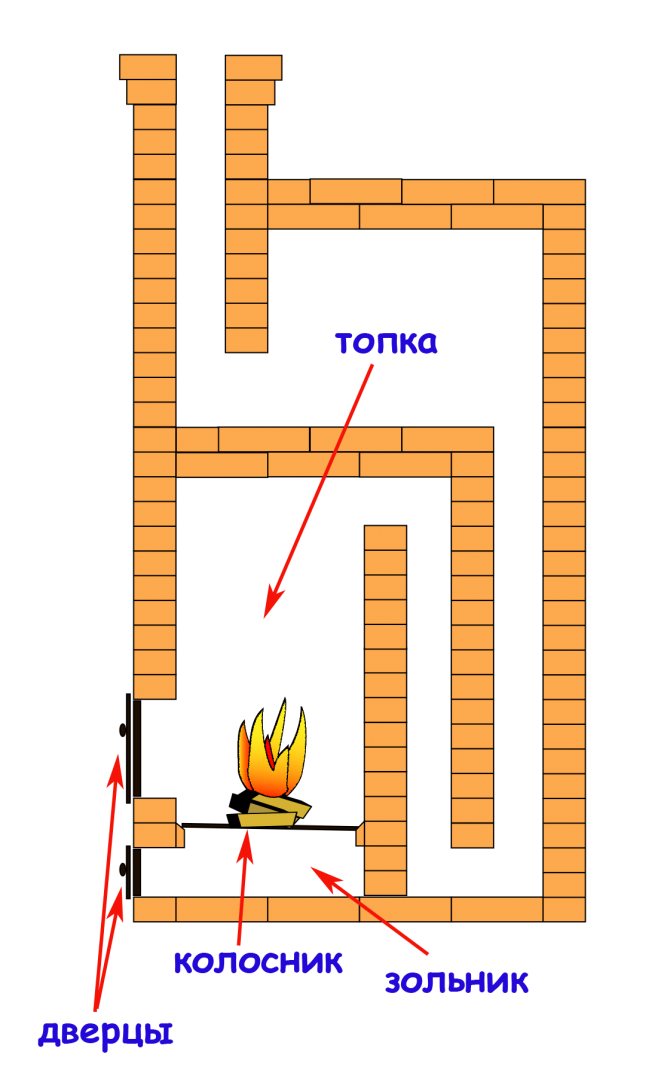

Masonry of a square stove with bottom heating

The stove in the photo is distinguished by a combined or mixed system of smoke circulation. The parameters of this design are 102x102x238 centimeters. Its heat transfer is equal to 4200 kcal / hour.

The device of square-shaped heating stoves with bottom heating assumes that the firebox in it has a relatively high height. Side holes (2 each) located symmetrically on both sides serve to drain gas into the chambers. They are located in the outer side walls of the structure. The gas is then lowered through chambers connected by a channel under the firebox behind the ash compartment.

From the side chambers, gases enter the risers through the lower rolls and go up through them. There, the side chambers all together form the so-called upper dome, which consists of three U-shaped cavities. These cavities are located in parallel. The heated gases are retained in the upper part of the middle and rear of them, and the already cooled waste products pass through the holes into the front plane, which at the top is connected to the stacked chimney and evaporates into the atmosphere. See also: "Heating stoves for mining."

Consequently, the schemes of furnaces for a square-shaped house with a bottom heating have 3 hoods - an upper hood and 2 large chambers. Any type of solid fuel can be used in such a heating structure.

If it is planned that the stove will operate on coal or anthracite, the walls of the firebox should be laid out exclusively from refractory bricks.

Operating principle

The hearth furnace works differently from the classic one. The main property of such products is high efficiency with minimal fuel consumption. The burnout is distributed evenly. Due to the air entering through the firebox door, the firewood is sufficiently oxidized, increasing the quality of its combustion and the level of heat generation.

Firewood is laid on the lower level in the loading chamber. Then the combustion process takes place in the working area. Gases are removed from the upper level and heat exchange takes place.

To maintain high temperatures (about 400 ° C), the furnace body is made of polished stainless steel. The lining is made of fireclay bricks or other fire-resistant material.

Furnace schemes for a house with predominant bottom heating

If the heating structure has a predominant bottom heating, its size, as a rule, is 115x56x231 centimeters with a heat transfer rate of 2640 kcal / hour. In accordance with the smoke circulation system, this stove is classified as a combined channel heating unit with bottom heating.

When a scheme of stove heating of a private house is created using such a design, it is understood that flue gases will first descend from the firebox, and then rise up the riser to the ceiling (

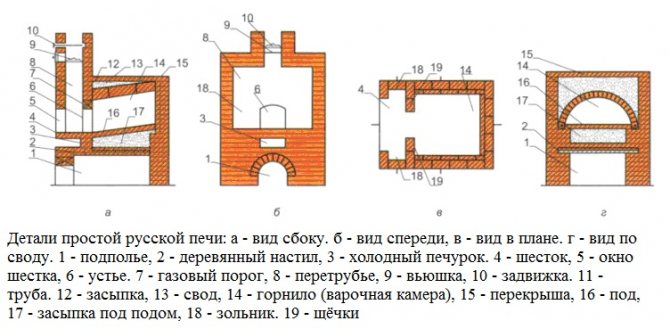

Traditional and modern Russian stoves

One of the characteristics by which Russian stoves are classified is size. Large structures are considered 1500 × 2300 mm, small - 1500 × 1750 mm. There are also furnaces built according to individual projects, their sizes can be of any size. Depending on the characteristics of the device, traditional and modern are distinguished. They differ in the design of the baking oven. In the first, the lower part does not warm up, in the second, heated channels are equipped. Stoves can vary in shape, finish, location, number and functionality of additional elements.

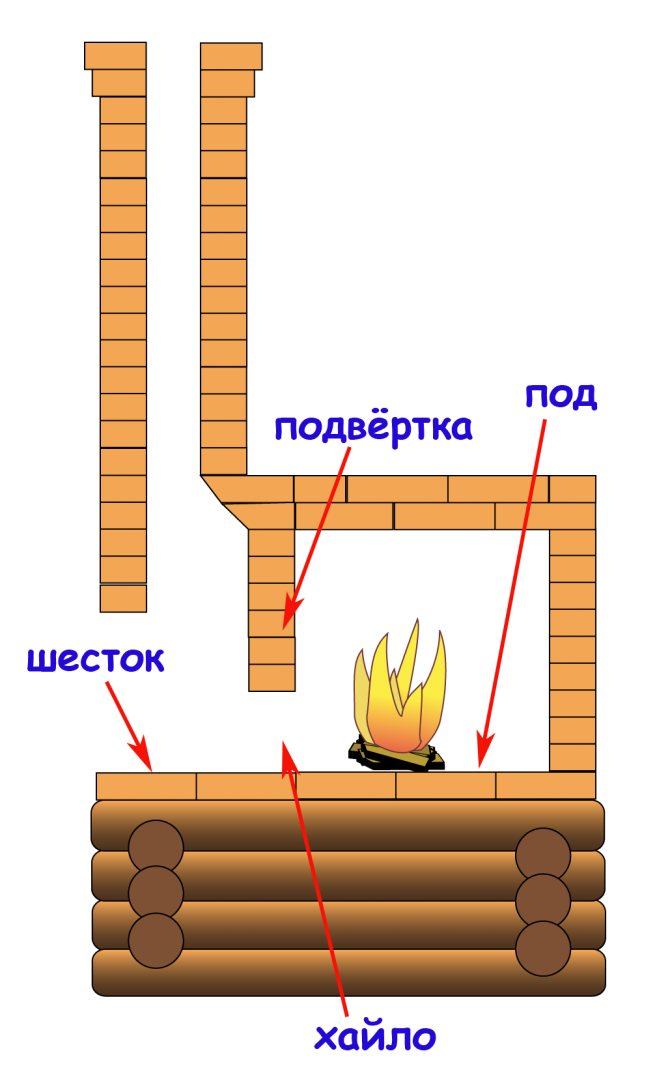

Diagram of the design of a Russian stove with flooding

The world is changing, the needs of people are changing, respectively, new designs of stoves and additional opportunities for the implementation of complex technical solutions appear. So, recently, models with such improvements have become popular:

- Underfloor and stove. The hob is built into the structure of the oven and is a modernized hob. The Russian stove with a flood allows you to cook traditional national dishes, dry mushrooms, berries, fruits.

- Russian stove with a fireplace. The back wall of the stove is led out through the partition into the next room, a fireplace is equipped. A very convenient option for lovers of open fire. At the same time, the dimensions of the furnace itself change slightly, but there is no need for an additional foundation and a chimney system, and warmth and comfort are guaranteed.

- The trestle bed is rude. Initially, a large bed for three people was set up in the Russian stove. Today, ovens are rarely built of such dimensions that allow you to make a large stove bench. Instead, they put an additional trestle bed.

- Side heating. Very convenient for heating adjacent rooms.

- Bottom heating. The improved design allows you to heat large rooms.

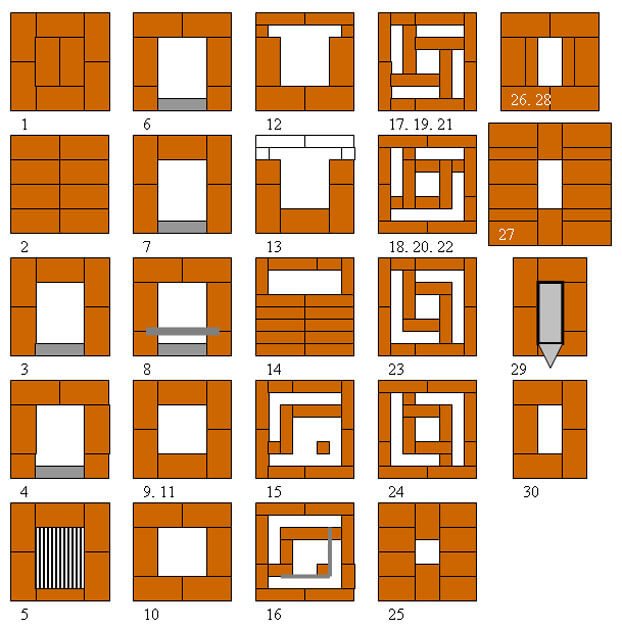

Furnace masonry, designed by V. Grum-Grzhimailo

Shown in the photo, the channelless layout of the heating stove masonry was developed by Professor V. Grum-Grzhimailo. There is no smoke circulation in this heating structure. It has a rounded shape and is housed in a case made of sheet steel. The gases move in the furnace not due to the draft created by the chimney, but due to the force of gravity. As a result, cooled and heavier gases descend to the bottom, and hot light ones rise to the top.

This device of a stove for a house consists of two parts - a firebox is located at the bottom. In its roof there is a small hail (mouth), which ensures the passage of flue gases to the upper part, which is a chamber without smoke circulation.

It looks like an overturned cap, shaped like a glass. Due to this feature, such heating structures are called channelless or bell-type.

The heated gases in them do not enter their mouths into the chimney, since they first go up under the ceiling, and when they cool down, they descend along the walls to the base. From here they enter the chimney and, under the influence of the draft, are carried away into the atmosphere. One vertical cut is located across the firebox, and the second horizontal cut along it.

Along the walls of the structure, from the ceiling in the direction of the vault, there are buttresses designed to increase the internal surface of heat absorption and for a better perception of heat by the brick mass from the exhaust gases. The fins heated by gases allow the stove to retain heat for a longer time.

The efficiency of the structure developed by Grum-Grzhimailo reaches 80%. The iron case allows you to carry out masonry with a thickness of only a quarter of a brick, moreover, the unit heats up quickly enough.

Features of operation and safety precautions

The use of hearth furnaces is not difficult.

Here are the instructions for warming up the product:

- The wood-fired hearth oven is loaded with pallets. Gas and electric is connected to the network or gas pipeline.

- Electric models require preliminary drying of the heating element after a long period of inactivity. Other types of stoves do not require such an operation.

- The required program modes are set.

- The chimney is heated to ensure stable draft (done by opening the damper for 6-7 minutes).

The temperature in the oven must be maintained automatically using temperature controls, as indicated by indicators on the cabinet panel. In the absence of automation on the oven, you will have to independently control the thermostat indicators.

If a hearth-type stove is used for cooking, then after warming up to the desired temperature, open the lid and load sheets with kitchen utensils into the chambers. At the end of the work, it is necessary to turn off the device; it is prohibited to keep it working unnecessarily for more than an hour.

Furnace masonry, created by the Thermal Engineering Institute

Furnace schemes for the home, developed at the Thermal Engineering Institute by engineer Kovalevsky, have a size of 100x85x217 centimeters. They use a mine-type firebox designed for the use of coal.

Through the channel, flue gases enter under the ceiling, from where they enter two side channels. Then they follow to the very bottom and move along the collecting channel to the smoke stack. If the smoke damper is open, then the gases are vented to the atmosphere.

The peculiarity of the furnace arrangement scheme lies in the different thickness of the walls of the smoke circulation channels. The first of them, coming from the firebox, is called the fire channel. It has a 3/4 brick outer wall. The rest of its walls are placed in half a brick.

This heating structure does not fit into an iron casing. Its masonry is simple. The efficiency of the furnace of engineer Kovalevsky is 75-80%. The disadvantage of the heating unit is the possibility of overheating its upper part, since the hottest gases are sent to it. Down the oven, they will fall completely cooled, as a result of which the degree of heating of the lower part is insufficient.

A certain amount of gases from the firebox enters the side channels through the screws, which increases the heating of the lower part of the outer walls (about

Every man has access

In such unusual conditions, only those who have the skills of survival will survive until the second coming. Every man should be able to provide his loved ones with the minimum necessary amenities. One of the main ones is warmth. Even if we ourselves do not have a chance to live in these harsh last times, we must try to pass on the knowledge received from our ancestors to our children and grandchildren.

In practice, I had to get acquainted with the stove business in Karelia, where, living in an abandoned fishing house on an island in the middle of a large lake, I restored a dilapidated Russian stove with the help of homemade adobe bricks found in the attic, left over from thrifty owners. No special skills are needed for this, common sense and clay dug up in the ravine are quite enough.

Subsequently, these skills came in handy many times in life - I had a chance to lay the stove myself in the gatehouse of the church watchman in the village of Poltevo, earn extra money by installing a fireplace in a friend's dacha, and, finally, put and redo the stove several times already in my country house.

There is a sea of literature, both paper and electronic, on stove business. Studying it can help a person who wants to join in many ways. But there is nothing to replace common sense. It is imperative that you understand what you want to get in the end, and be creative and critical in all kinds of recommendations.

Let me explain with an example:

Very often it is quite difficult to find a stove-maker, so you have to be content with those specialists that come to hand. Craftsmen "made in USSR" may not be up to par, but young stove-makers who did not know totalitarianism in stove business inspire more hope.

The fact is that in the years of hard times there was almost nothing - no real stove bricks, no stove accessories, except for the standard set of door, grate, damper, stove; even a trowel or an oven hammer passed from father to son.

And the building of stoves was not allowed everywhere, not always, and with various restrictions, such as the prohibition of stoves in garden associations.

In such conditions, people were forced to get by with what they had, and put stoves from what they managed to get, as a result, a freak was born: a worthless structure with a stove for cooking food, a thin heating shield and an asbestos-cement pipe, which is heated with woods 25 centimeters long. The thickness of the walls is half a brick, coated with clay and whitewashed with lime or chalk. After the first heating, it cracks at all the seams, and after the first winter the stove bursts and the grates burn out. By morning, ice on a bucket of water is already in the room with such a stove.

Alas, such a structure (with various small modifications such as an oven) has become the standard for several generations of Soviet stove-makers. They did not know how and did not want to do anything else. Such masters should be avoided, no matter how experienced they are.

As there are no two identical people, identical houses, the stove must be unique and inimitable. After all, this is not a boiler or TV, but a home. No one will design the stove for you that your home needs. So you shouldn't be lazy here.

And you need to invite a stove-maker who thinks creatively and does not like to repeat himself in his buildings. If you draw up clear and reasonable requirements for the future furnace, and discuss them in detail with the master during construction, then you will get the result.

Stove business is a very creative process and requires talent. Just as not every housewife turns out baking, so not every stove-maker knows how to fold an oven that will not crack. In this matter, you will not be able to inform the master of anything sensible - you will have to rely on him. But in terms of appearance, fuel efficiency, and all kinds of additional options such as a stove bench, samovar, stove, built-in boiler, oven, brazier, and the like, here the decisive word should be yours, and the stove-maker's business is to embody your requirements.

Better yet, roll up your sleeves yourself and start building a home. There is nothing difficult or very difficult here. The maximum weight that will have to be lifted is a bucket of mortar or bricks.

I even had a chance to break my leg at the moment when the old stove was dismantled, and the new one had just begun to be erected. It was impossible to wait several months for the plaster to be removed - the summer was leaving, so I had to continue laying on crutches - and nothing, with the help of my wife I was able to complete the work I had begun. This stove is the center of our home to this day.

In the most severe version, you will not need anything at all, except for a few tools: an oven hammer - picks, and shovels to dig up the clay. Well, another old mortar bucket. Yes, and a shovel can be hewn out of wood - there would be an ax.

In the Russian North, in the Arkhangelsk, Vologda regions, in Karelia - you can still see ovens made of adobe bricks. They stand for a hundred years as if nothing had happened! Each man prepared such a brick himself in the nearest ravine, or wherever he had a clay pit. You can too. My friend and I did, although no one showed us how. It is no more difficult than making sand pies for children.

In the pit, clay is choked with water by feet, sand is added, tamped into a mold and dried. A week later, another brick is ready. It can serve indefinitely until it gets damp. The water will melt the brick in a few days. I have happened to disassemble old stoves and use their bricks to build new ones. I must say that old brick is even better than new one! And from the fragments I made a furnace solution. Something, and the coefficient of thermal expansion of such a solution exactly coincided with that of a brick, and this is a guarantee that the stove will not crack at the seams!

As Gogol wrote: “A Russian person is capable of anything and gets used to any climate. Send him even to Kamchatka, but give him only warm mittens, he pats his hands, an ax in his hands, and went to chop a new hut for himself. "