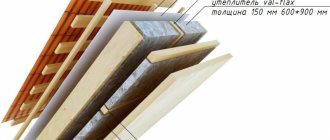

Last time we talked about the insulation of a frame house with mineral wool. Today we will talk about the method of installing a heat-insulating pie of a rafter pitched and flat concrete roof. Roof insulation with mineral wool is impossible without the use of steam and waterproofing. These are materials that prevent moisture from penetrating and accumulating from thermal insulation. At the same time, it is important not only to choose the right materials, but also to correctly carry out the installation.

Selection of material

When purchasing products, first of all listen to the manufacturer.

Very often, when buying a particular roof covering, an instruction is attached to it, which should indicate what materials it is in good contact with. For example, metal tiles or corrugated board, however, like all other metal coatings, become a place for moisture accumulation and you can remove it in two ways.

The first method is to prevent moisture from entering the roofing cake. For this, waterproofing and vapor barrier products are used. As for the second, everything here will depend on the created system of natural ventilation. Understanding what suits you best will help the answer to the question: "what will be your roofing cake?" By design features, the roof can be:

- Cold.

Here, the attic space can only be used as a storage room. By the way, in most cases, the villagers do this. - Warm.

If you decide that the attic space will be insulated, then you can think about a residential attic. The structure of the roofing cake will be much more complicated, more materials will be spent on its arrangement, but all this will be leveled out by additional residential squares.

Once you have decided on the purpose of your attic, you can start thinking about waterproofing products or how to get quality ventilation.

Waterproofing for Thermal Insulation Pie

The membrane is laid from bottom to top.

Waterproofing is a material that retains liquid and allows steam to pass through, another name is a diffusion membrane. They are made from polypropylene, PVC and rubber. Basically, the first two types are used for the roof. Polypropylene membranes consist of three layers. The bottom layer is fleecy, and the top is smooth. The manufacturer's logo is applied to the top layer. When insulating a roof with mineral wool, you need to carefully consider the installation of a polypropylene membrane. By placing it on the wrong side, you will provoke the accumulation of moisture in the insulating cake.

PVC membrane is a high performance single layer material. It is used for insulating flat roofs. There are two types of films available: bottom and top layer. The top layer is lighter, so it doesn't heat up as much in the sun.

How to install waterproofing under a cold roof

Typically, cold roofs are created from a standard set of materials and structures, namely:

- Lathing and counter-lathing. This system can be created both from lumber and from metal, the main thing is that the ventilation ducts do their job well. In the case of using wood, the counter-lattice will create an air gap that will allow gusts of wind to blow excess moisture out of the roofing cake.

- Waterproofing product. For cold systems, it is best to use special membrane films that protect wood and metal products from all types of precipitation.They can be mounted on top of the crate itself, before installing the roofing material or under the crate, so that moisture does not come from inside the living quarters. However, you can combine the two methods and get a closed roofing cake, reliably protected from moisture on both sides.

- Finish coating. In this case, a metal tile or profiled sheet will be used.

IMPORTANT: This kit is often used on outbuildings or on simple roofing systems in private houses. This is a great option if you want to save a ton of money and time.

Metal roof and insulation

Question:

Roof. I am going to make a house from foam concrete blocks, the size of the house in the axes is 10 * 9 m. I want to consider the construction of a roof entirely of metal. How to properly make and insulate under the attic? Siberian region, outside temperature -40 degrees.

Boris, Khakassia, Tashtyp.

Answer:

Hello Boris from Tashtyp!

Traditionally, houses for housing have roofs made of wood. That is, the entire rafter system is made of beams, edged boards, logs or even poles.

After that, a crate is mounted on the rafter system. Also made of wood (edged or unedged boards).

Sometimes plywood or OSBi (oriented strand boards) are laid on top of the crate.

In some cases, all this is complemented by a counter-lattice and various combinations of covering material such as roofing material, glassine, various kinds of moisture-proof and thermo-vapor barrier films. Some other options are also possible.

But after that, the roof itself is laid directly on such bases. It can be in dozens of different options. Starting from such exotic ones as turf, straw, wood chips, shingles and ending with slate, natural or artificial tiles, metal (metal profiles, metal tiles, copper sheets, stainless steel) and many other materials.

If you understood you correctly, then you want to make both the rafter system and the roof completely of metal?

If this is the case, then such things are done more in industrial construction, sometimes in livestock complexes. And very rarely in residential construction. At least I saw something like this only a couple of times in my practice.

This is due to the fact that any metal accumulates cold in itself, especially in regions such as yours, where frosts of about minus 40 degrees are not uncommon.

That is, the metal will be a "cold bridge" between the street and the interior of the house.

In addition, a partial presence of wood is still required in metal roofs. Suppose your roof truss system is made in the form of a farm from an assortment (corner, channel, etc.). In order to attach the same metal tile or metal profile to such a farm, it is necessary to drill holes in the metal sheet itself with self-tapping self-tapping screws, and then in the metal of the corner, channel. But this cannot be done for the reason that the thickness of the same corner can be 5 millimeters or even more. That is, it is necessary to pre-drill a hole in the corner. Considering the number of holes required, this will result in huge time costs, dozens of broken drills and other inconveniences.

Therefore, a crate of wooden edged boards is laid on the farms. A much smaller number of holes and fasteners are sufficient for their fastening.

If we talk about filing from the bottom to the trusses of metal sheets as ceiling attic, then this will be completely nonsense. Then again it is necessary to re-drill the metal corners of the trusses from below, as mentioned above. And the most important thing is that the insulation placed between the metal sheets of the outer roof and the inner metal sheets will have no effect.Since in winter, the cold metal of the outer roof will transfer the minus temperature to the metal of the trusses, and they, in turn, will cool the metal ceiling sheets.

You can, of course, come up with a very complex scheme for insulating metal with a heater, but this is a colossal material and time cost. Because the aforementioned similar options in industrial and agricultural construction are still not efficient enough in terms of heat storage. It is enough to visit such structures in severe cold weather.

Conclusion - you should not get involved with such experiments. And there as you know.

But if you just want to use metal sheets for the outer roof, and a wooden structure as a rafter system, then everything is much simpler. For rafters, then they usually take a 150/50 mm edged board, set it on the edge. A waterproof thermal film is laid on top of the rafter boards (smooth waterproof side up). Then, a 50/50 (millimeter) cranial bar (millimeters) is stuffed onto the rafters, on them a crate (edged board 25 millimeter thick and any available width).

Then they put and fasten a metal roof (metal tiles, metal profiles, etc.)

After that, from below, between the rafter boards, they mount (not very convenient, because above the head) slab or roll insulation of any available brand. Fastened with special "mushrooms" (50/50 mm square plates and self-tapping screws through them) to the crate. The thickness of the insulation layer for your region is 150 - 200 millimeters. (At 200 mm, the rafter boards should no longer be 150/50, but 200/50 mm).

Then a vapor barrier film is attached to the lower surface of the rafter boards. After that, lining, imitation of a bar or other sheathing is usually nailed. Which will be the ceiling of the attic.

In short, everything.

Good luck!

Construction in Moscow and Moscow region

We work with a guarantee! A wide range of construction services. Foundation, walls, floors, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Other questions about roofs:

- House ridge height - CALCULATION

- Gable roof estimate for house 9 by 12 m

- Rebar thickness 6.8 m

- The price of replacing slate with metal roof tiles

- Calculation of the length of the rafters

- How to connect the roofs of two adjacent balconies

- Half-hip (hip) on a chopped pediment

- Temporary roof for log cabins made of banners

- Fastening the rafters of a shed roof and a gable

- Insulation of the attic roof

- Didn't put the film under the roof insulation

- Roof for log house with outriggers

- The roof rafters squeeze out the upper crown of the log house

- Extension of a veranda with a gable roof

- What shape of the roof to choose for a one-story house

- Roof across floor beams

- When to put a roof on a freshly assembled log frame

- Armopoyas for the roof of the house and the extension

- Replacing the roof of an adobe house with room equipment

- Replacing the slate roof with corrugated board or soft

- Shared log roof and garage from a twin block

- How to attach the rafter legs to the sliding valley

- House with mezzanine under the wards for children

- How to fix a chopped pediment

- Insulation of the attic with sawdust

- Brick gables swayed what to do

- Is it possible to put a roof on a log house on the next year

- Roof for a house made of hand-cut logs

- The roof is bursting with walls

- Thermal insulation of the slate roof of an old house

- Which roof to choose on the annex

- Gable roof for a house 10 by 10 m

- Repair of reinforced concrete floor slabs of a soft roof

- How to close the gap between the roof and the top log of a log house

- The roof of the veranda is flowing, it is also the floor of the open terrace

- Slug roof structure on stone gables

- When and from what to make a roof for a fresh log house

- Slate or metal tile

- Replacing the ceiling and roof of an adobe house

- How to close up the junction of a chopped pediment and a roof

- Which roof to choose for a house 14 by 10 m

- Choosing a roof for an annex to a house

- Calculation of joining the roof of the house and the veranda with a step

- Roof of the courtyard with support on the house

- Is it possible to remove bows in the house

- Roof with inspection hatch for caisson

- Soft roof or metal tile what to choose

- The joint of the roof of the porch and the log wall

- Removal of beams in a log house under a canopy and a common roof

- Insulation of the roof if the rafters are made of logs

- Completion of a log house and erection of a roof

- Renovation of the roof of an old village courtyard

- Rafters and log pediment

- Open Veranda Roofing Pie

- Fastening a safety fence to a slate roof

- Living in the house during the roof replacement

- Fastening rafters in a house from a bar

- Convert a gable roof into a gable

- Economical arrangement of gables

- Shed roof rafter system

- Roof annex to a house with a mansard roof

- Roof profiled sheet without a gap and waterproofing

- Completing the roof of the extension and the walls of the house

- Metal profile on old roofing material

- Put ondulin on the old ondulin

- How to fix the balcony roof on the 5th floor

- Roof rafters section

- What to put under a soft roof

- The roof over the old house on supports

- We covered the slate without roofing material

- How to level a fallen roof gable

- Rafter system for a house from a bar 9 x 12 m

- Fastening the lower ends of the rafters

- Connecting the roof of the attached veranda and the house

- House roof height 10 by 10 m

- New roof on an old brick house price

- It jars the roof when the log shrinks

- Old and new house under one roof of the problem

- How to make slant rafters in a log house

- Roof curve installation

- Roof to the attached veranda

- DIY semi-hinged roof

- Carport construction

- An annex from a bar to a brick house under a common roof

- Garage roof lathing 5 by 7 meters

- Step of rafters for logging a gable roof

- Canopy between the veranda and the barn

- Rafter system for a house from a bar 6 by 9

- Sealing the ceiling in the underpass

- Roof geometry

- Waterproofing the floor of an open balcony

- Alternative to roof tiles

- Replacing ondulin with metal tiles

- Insulation of the roof in the production area

- Option of the rafter system for a house 10 by 10

- Roof trusses

- New roof on the panel house

- How to cover ondulin or keramoplast

- How to insulate a slate roof

- How to fix corrugated board Wave to the roof lathing

- Slate for lathing without waterproofing

- Raise the roof and make an attic

- Conversion of the roof to a single slope

- Metal roofing on a not shrunken log house

- Cover the adobe house with slate

- Drainage system and snow holders for the log house

- How to raise slate to the roof

- Temporary roof on the annex

- Does the slate get wet

- Workshop roof 8 by 6

- How to properly cover the roof of an extension

- Canopy project 8 by 14 meters

- Slate - front and back

- Supports for rafter legs

- Mansard roof construction

- Garage roof profile

- How to level a shed roof

- Garage roof repair

- How to fix wave slate on a roof

- Roofing material RPP 300 installation

- Calculation of the length of the rafters for the roof

- Roof - galvanized or painted profiled sheet

- About lumber for floor and roof

- Building up a log house when replacing a roof

- Roof for a log house with a frame veranda

- Roofing material analogs for covering a wooden roof

- Material for the construction of a hinged outbuilding

- Rafter system for a large log house

- Is it possible to put rubemast on rubber

- Barn and gazebo under one roof

- What kind of wood for the roof should be

- How to level a sagging roof

- Alteration of the gable roof

- The slope of the roof from corrugated board to the garage

- Insulation of the abutment of the roof to the wall

- Flat roof for log house

- Roof shape for a garden house 6 x 4.5 m

- Uncovered roof in winter - risks

- Installing a roof on a log house

- How to Increase Roof Trunking Outlets

- Partial roof repair at negative temperatures

- Temporary roof for a house using Canadian technology

- Calculation of the roof to the annex made of aerated concrete

- Roof to the garage - floor beams and rafters

- Roofing on a fresh blockhouse and ridge height

- The rafters are crooked

- How to attach a galvanized windboard

- Roof lathing step for flexible shingles

- Create a terrace and a house under one roof

- Installation of a mansard roof and windows in a log house

- Temporary roof for the winter

- Renovation of an old slate roof

- Shared roof or separate on the annex to the house

- Balcony roof fastening from the inside

- Metal siding as a roofing material

- Arrangement of the roof on chopped gables

- Shed roof for garage made of slabs and rails

- Docking the roof and gutter

- Sudeikin roof

- Docking the roof of the timber extension and the house

- Attach to the broken roof

- Rafter system for a log house

- Conversion of a roof from a hip to a gable

- How to make the roof and cornice of the outbuilding

- How to sheathe the roof on the balcony of the last floor

- Permanent roof for only assembled log house

- How to make a canopy 10 by 8 m without internal supports

- Mansard roof for a house 13 meters wide

- Common roof for a new log house and annex to it

- We made a mistake when laying the film under the roof

- What is a roof profile

- Do I need a counter lattice for the roof of a summer cottage

- Metal roof and insulation

- One roof per house and a new annex

- The device of rafters in a log house

- The height of the mansard roof of the house is 6 by 7

- Solarium on the country roof

- Raise the roof of the house to increase the height of the ceilings

- Blowing snow under the roof

- Condensation in roof insulation

- Installation of a roof on a non-shrunk log cabin with gables

- How to attach a roof adjacent to the wall of a house

- Roof with four gables

- Docking the roof of the house and annex

- Installing the rafter system

- Transfer of crossbars to increase the attic

- Cutting one roof into another

- Insulation of the roofing without a film from the inside

- Whether to remove roofing material when installing a permanent roof

- How to temporarily close the gables after installing the roof

- Cover metal shingles on the broken geometry of the roof

- Replacing roof insulation without removing metal tiles

- Roof for only installed log house

- How to build a roof on an extension and insulate it

- Replacing the roof slate sheet

- When is the best time to install a roof?

- Rumbling galvanized on the roof of the balcony

- How to make a roof on an extension to a house

- Roof above the balcony

- Hip roof lathing

- Roof on the top floor balcony

- How to fix rafters and crossbars in a mansard roof

- How to eliminate the rumbling balcony roof

- The height of the gable roof of the house

- Recreation area on the roof of a foam block house

- Roof repair

- Roof insulation without removing the roof

- Slate roof insulation

- When to cover the roof on a log house

- Installing the wind board

- Repair of an old slab roof in a workshop

- Roof for a bath in oriental style

- About the correct sealing of the garage roof

- Roof to balcony

- Roof roof

- Glassine and metal roof

- Fastening the slate to the nearly vertical side of the roof

- How to cover the roof with rubemast?

- How to properly cover a hip roof with slate?

- Roof rafter system

- Roof above the balcony of the last floor

- How to build a wooden roof 30 m long and 24 m wide?

- Slate roofing

- Questions about arranging a mansard roof

- Installation of rafters and crossbars during roof construction

Construction in Moscow and Moscow region

We work with a guarantee!A wide range of construction services. Foundation, walls, floors, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Arrangement of roofs

Scheme of the roof of the old Slavic hut

Construction in Moscow and Moscow region

We work with a guarantee! A wide range of construction services. Foundation, walls, floors, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Other questions on the topic of insulation:

- What kind of insulation to choose?

- Thermal insulation of interfloor floors made of wood

- Insulation of walls from timber and drywall

- Vapor barrier in a log house

- Vapor barrier of walls in a panel house

- Insulation of the attic floor

- Thermal insulation of a log house with sawdust and lime

- Extension to a panel one-story house

- Insulation of the attic roof

- Thermal insulation of wooden interfloor floors

- Strengthening the cinder block house

- Insulation of a transportable bath from a sea container

- Warming the basement of the veranda

- Thermal insulation of a house from laminated veneer lumber

- Strengthening the columnar foundation

- How to insulate wooden floors in a gas block house

- Insulation of an adobe house with polystyrene foam

- Insulation of the attic with sawdust

- Insulation and sheathing of a log house made of profiled timber

- Sawdust or insulation for interfloor floors

- Insulation of the underground in a private house

- How to foam a brick filling house with polyurethane foam

- Foil insulation instead of vapor barrier

- Insulation of the ceiling from the side of the cold attic

- Foam insulation of stone walls

- Insulation of a floor made of wood from below indiscriminately

- Insulation of the attic with penoplex

- Insulate block walls with a bar

- Insulation of the floors of the first and second floor in a log house

- Warming with sawdust - how to do it right

- Insulation of an unheated veranda

- Insulation of a slate roof from the inside

- Insulation of an existing slate roof

- Insulation of empty walls of a garden house

- Ceiling insulation with clay and sawdust

- How to insulate a panel house after gas conduction

- Insulation of reinforced concrete floors in a log house with expanded polystyrene

- Warming with mineral wool or foam

- Insulation of walls from a bar from the inside

- Filling the ventilation duct with insulation

- Insulation of the foundation from blocks

- Extension to the house and insulation

- Do you need a ventilation gap between the insulation and the film

- Floor insulation in a wooden house

- Eco-friendly insulation of a log house

- Repair and insulation of shield walls of an old house

- Insulation of the ceiling with expanded clay

- Thermal insulation of a house from aerated concrete

- House insulation with foam

- Insulation of an old panel house

- Soundproofing between floors of a log house

- Insulation of a log house from the ground to the roof

- Insulation of an adobe house with brick lining

- Insulation of the veranda wall on both sides

- Insulation with polyurethane foam of the floor in a log house on piles

- Insulation of the basement base

- Insulation of an adobe house with polystyrene foam

- Insulation of the roof in the production area

- Insulation of the attic from the inside

- Underfloor insulation

- Insulation of the house from the outside and plastering of the facade

- Insulation of the floor of the 1st floor in a log house

- Insulation of the floor in the house on stilts

- Thermal insulation of a log house from the inside

- Warming option for the existing foundation

- Interfloor insulation of a two-story bath

- How to insulate a slate roof

- Insulation of a country house outside and inside

- Floor insulation in an old wooden house

- Floor insulation

- Attic insulation

- Floor insulation with foam

- Insulation of the attic with fiberglass plates

- Insulation of an extension to an adobe house

- Soundproofing a house made of rounded logs

- How to insulate the attic ceiling

- How to strengthen the basement

- Thermal insulation of wooden floors 150 mm

- Insulation of an iron pipe

- Thermal insulation of wooden floors with moss

- Insulation of a log house outside

- Finishing floor on an old floor with insulation

- Insulation of adobe walls from the inside

- Strengthening the corner of the crown of a log house

- How to insulate the subfloor

- Insulation of a panel house lined with a floor-brick

- Insulate the aspen blockhouse outside

- Internal insulation and cladding of a country house from a bar

- Which wall insulation is better

- Insulation of the abutment of the roof to the wall

- Isotol with foil between floors

- How to insulate a house from a bar 180 to 180

- Insulation of the basement and foundation

- Thermal insulation of wooden floors

- Insulation of the ceiling with expanded clay

- Insulation of the foundation

- Warming a room when wall cladding

- Insulation of insulated vernade with foam

- Warming of floors using Izospan V film

- Floor insulation on a concrete screed under linoleum

- Siding and insulation of an adobe house

- Warming of a settled log house

- Strengthening and warming the floor from wood blocks

- Thermal insulation with foil insulation for siding

- Thermal insulation of a log house with brick lining

- Liquid wall insulation

- Thermal insulation of brick walls with polyurethane foam

- Insulation of a regularly flooded floor

- Insulation of the floor of the house on sleepers

- Insulation of the ceiling with sawdust in a wooden house

- Insulation of the room attached to the house

- Insulation of the loggia and its boarding

- How and how to insulate a house from a bar

- Insulation of an old adobe house

- Metal roof and insulation

- Thermal insulation of the floor on wooden logs

- How to insulate a panel house before siding

- Insulation of concrete floor slabs

- How to insulate an old brick house

- House insulation under siding

- Sound insulation and insulation between floors

- Moss and birch bark in the vapor barrier of the ceiling of the house

- Insulation of an annex to a slag-filling house

- Insulation of a log house inside

- Insulation of a concrete floor in a house in the country

- Thermal insulation of a log house from the inside

- How to insulate a concrete basement at home

- Insulation with sawdust

- Insulation of the interfloor overlap of the house

- Heat and vapor insulation in the floor pie

- Insulation of the entrance group

- Condensation in an irregularly heated house

- Insulation of an old panel house

- Condensation in roof insulation

- How to insulate a basement in a garage

- Insulation of the roofing without a film from the inside

- Processing and insulation of external walls of a log house from a bar

- Replacing roof insulation without removing metal tiles

- How to build a roof on an extension and insulate it

- Warming a house from a bar

- Insulation of log walls with isover

- Do I need insulation in a panel house under brick lining?

- How to insulate the frame extension

- Remove the resonance and insulate the walls from the gypsum board

- How to insulate a wooden floor

- What insulation for siding to choose

- Again about floor insulation

- Warming a house from a bar

- How to make and insulate the walls of a bath

- Which type of felling is warmer

- Underfloor insulation

- Roof insulation without removing the roof

- Brick wall insulation

- Slate roof insulation

- Insulation of asbestos-cement pipe for a gas boiler

- Balcony insulation and cladding

- Siding installation in November - snow, rain. Installation and insulation of floors and walls.

- Insulation of the ceiling of a two-story bath

- How to inexpensively insulate the ceiling in a bath?

- How to find a good shabashnik and insulate the veranda?

- Insulation of the underground space

- Insulating a doghouse

- How to insulate the ceiling in a bath?

Construction in Moscow and Moscow region

We work with a guarantee!A wide range of construction services. Foundation, walls, floors, roof, turnkey!

+7 (905) 797-20-34

luxurykomfort.ru

Warming

All questions to Semyonich about construction

Semyonich (author of materials)

Our site is regularly updated with interesting and unique materials and articles on the topic of lumber, building materials and works, the author's opinion and knowledge of a real shabashnik with more than 15 years of experience is given. There is a section - funny stories of shabashniki. If you would like to receive information about this, subscribe to the newsletter of our website. It is guaranteed that your address will not be passed on to third parties.

Apartment renovation in Moscow and Moscow region

We work with a guarantee! A wide range of renovation works. Professional craftsmen.

+7 (905) 797-20-34

luxurykomfort.ru

| Country house | Bath |

| For giving | Tool |

| Materials (edit) | Bikes |

| Foundation | Log cabins |

| Roofs | Warming |

| Walls | Siding |

| Floors | Cellars |

| Attic | Window doors |

| Stairs | Outbuildings |

| Wells | Toilets |

| Balconies | Loggias |

| Condensate | Flooding |

| Fences | Kennels |

| Sidewalk | Birdhouse |

| Adobe | Carts |

| Garages | Barn |

| Greenhouses | Bath |

| Swing | Brazier |

| Shower |

| Horizontal bar |

How to install waterproofing under a warm roof

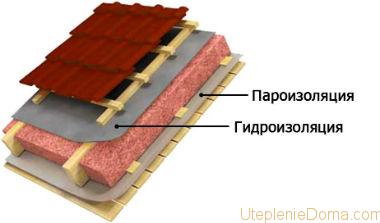

Now, let's take a look at the layers of the insulated roofing cake.

- The lathing and counter-lathing are made of wood.

- Vapor barrier material. If in a cold attic it was not important which insulation product to use, then here its choice should be approached more rationally. When buying a material, first of all, pay attention to its ability to withstand temperature extremes. As an example, we can cite a situation when it will be quite cold outside, but it is hot in the attic and a large temperature difference can be a serious test for a waterproofing product. Next, study its vapor permeability, if it is absent, then it will protect the thermal insulation boards from moisture well.

- After laying the insulation, an additional lathing is created.It is created for an air gap, so small blocks can be used to create it.

- Next comes the thermal insulation material. Since metal roofs collect moisture in the attic, it is best to use hydrophobic materials. They are not afraid of water, therefore, their service life in these conditions will be as long as possible. Foam glass and polystyrene can be considered striking representatives of this category. It is worth noting that if you cannot afford such materials, then you can use proven mineral slabs.

- A waterproofing material is laid on top of the thermal insulation. It will act as a protection against precipitation and condensation.

It is worth noting that it is possible to insulate a metal roof from the inside.

But this way you will reduce the volume of the attic space and complicate the work, since the installation of thermal insulation material will become inconvenient.

Vapor barrier for roof insulation with mineral wool

The right insulating cake.

A vapor barrier is a protective coating that does not allow moisture to pass through in a liquid or gaseous state. When insulating a pitched roof from the inside with mineral wool, two types of films are used:

- made of polypropylene;

- made of foamed polyethylene.

Polypropylene films are very strong, it is extremely difficult to tear them with your hands. This is due to the presence of fiberglass mesh reinforcement. It is either pressed into uncured polypropylene, or laminated on both sides with polypropylene webs. There are aluminum-coated films that emit infrared rays. Polypropylene vapor barrier is available in different colors: gray, transparent, white, blue.

Before insulating the roof with mineral wool, choose a good vapor barrier. The main requirement is that it must be strong and, of course, not let steam through.

The technology of insulating a pitched roof with mineral wool allows the use of foamed polyethylene foam as a vapor barrier. It is a material with a closed-cell structure, therefore, in addition to vapor barrier functions, it also serves as a damper and thermal insulation. One of the most popular brands of foamed polyethylene is Penofol. It is available in thicknesses from a few millimeters to a centimeter. The aluminum coating can be smooth or corrugated. The function of the foil is to deflect infrared rays.

For flat concrete roofs, roll materials and mastics with vapor barrier characteristics are used, as well as polyurea or liquid rubber. Rolled vapor barrier is made on a bituminous basis with reinforcement. Fiberglass or construction paper can be used as reinforcement. Mastics are bituminous and latex, cold and hot applied. Polyurea with liquid rubber are expensive, so they are rarely applied under insulation.

Infrared bathroom heaters will most quickly create a comfortable environment by heating your body, not the air.

You will find instructions on how to make a heater for a summer residence with your own hands here.

Roofing material as waterproofing

For quite a long time, roofing material has been used as a waterproofing product. During this time, he underwent significant changes that only improved his performance. If the old bituminous material could lie on the roof for only 2-3 years, then the modern roofing material will lie there for about 15 years and practically nothing will happen to it.

Despite the fact that this material is used throughout the construction field, it is still not worth using it as a waterproofing product. The reason for this lies in the properties of the bitumen itself. This material does not tolerate severe frost, and it can only be arranged in cold attics. At low temperatures, the material becomes brittle and crumbles at the slightest deformation.Therefore, a bituminous roll product is used as an independent waterproofing layer only in extreme cases.

The bituminous canvas must be placed under the crate without fail. After the laying work is completed, a metal covering is arranged on top of the wooden structure. This is the only way to obtain a relatively high-quality roofing cake that can be left unrepaired for 10 years.

Alternatively, it is best to use a membrane waterproofing, or in extreme cases, a three-layer film. This material consists of a polypropylene material, in which two layers perform protective functions, and the middle one plays the role of reinforcement. Thanks to the micropores of the membrane, moisture does not linger in the attic and is released naturally.

Membrane products can be used in both warm and cold roofing systems. Determination of the direction of micropores can be attributed to the difficulties in laying. If you lay it on the wrong side, then the moist air will flow from the outside, and not vice versa.

Of course, so that developers do not make mistakes, manufacturers indicate the right side in the instructions. When laying material from a roll, the top layer will be insulating, i.e. by rolling out the material, you are already laying it on the right side. If you liked the film waterproofing, then carefully read the next paragraph.

Varieties of material

The main types of mineral wool are basalt wool and glass wool. Each has its own properties, pros and cons.

Basalt wool

Basalt wool is produced from gabbro-basalt rock. Carbonate rocks are specially added to it, which makes it possible to regulate the acidity modulus. The material of higher acidity is more resistant to moisture and more durable. Adding binders to basalt wool: bituminous, synthetic, composite, bentonite clays - bonds the fibers together, helps to give the desired shape.

Glass wool

Glass wool is a mineral material for the manufacture of which raw materials used in the production of glass are used, as well as waste, broken glass. The properties of glass wool are different from basalt, its thickness is 3–15 microns, and the length is several times longer than basalt. Therefore, glass wool slabs are more elastic, have greater strength, and are resistant to vibrations. Glass wool is fire resistant, withstands up to 450 ° C.

Despite all the advantages of glass wool, there is one significant drawback that reduces the popularity of its use. When laying this material, many small particles are formed that are harmful to health. Therefore, the installation is carried out in special clothing, footwear, and a protective mask. It will not work to clean them after work, you will need to throw them away.

Varieties of film waterproofing

For waterproofing roofs on outbuildings or houses with a cold type of roof, the cheapest membrane products are suitable, as for insulated ones, it is most advisable here to use the highest quality diffusion material. Of course, the price tag for such a membrane will be much higher, but this will provide you with a long operating period for the entire roofing system.

The most expensive material in the field of waterproofing is considered to be anti-condensation film. The density of this product is significantly higher than that of its counterparts. It has a rough surface, which is the reason why moisture does not accumulate on this material. Such a film is most often found on complex roofing systems, where the durability of the roof is an important parameter, even if the coating is metallic.

Anti-condensation films have a good degree of fire resistance,

and as tests have shown, it does not burn even on an open fire. Thanks to this, the material can be considered safe and used in public construction.

The choice of mineral wool for roof insulation ↑

The known varieties of mineral wool differ in the type of source (raw) material, according to which they are divided into the following types:

- basalt insulation;

- glass mineral wool;

- slag-based thermal insulation products.

On a note

Mineral wool also differs in the form of the ready-to-use material (usually it is produced in the form of rolls or rigid plates).

Let us consider the characteristics of each of these types of heat-insulating material from the point of view of their compliance with the requirements for the quality of insulation of various types of roofing.

Basalt insulation ↑

Stone or basalt material is well suited for insulating roofs made of metal, ondulin or slate, under which a small dwelling of the "attic" type is set up. The main advantage of basalt insulation, the slabs of which are absolutely inaccessible to moisture, is the possibility of using it in a damp climate.

This material is flexible and durable enough that it can withstand any mechanical deformation that occurs when rafters dry, for example. It is distinguished by excellent indicators of longevity and retains its protective properties for about 40-50 years.

Glass wool ↑

Glass wool is produced from microscopic glass fibers with a thickness of no more than 15 microns and is produced in the form of rolls, mats or rigid plates. Heaters of this class have the following advantages:

- high thermal insulation performance;

- fire resistance;

- reliable protection against mold and mildew.

Glass wool blanks are elastic and durable, which greatly simplifies their independent installation under the roof arches. And the cost per square meter of this insulation is very low (on average, it is 140-160 rubles).

The disadvantages of this material include:

- the danger of microparticles of insulation for the respiratory tract of a person and the need to work with it only in a respirator or gauze bandage;

- significant shrinkage of glass wool slabs or rolls during their long-term operation;

- high hygroscopicity of the material (ability to absorb moisture).

Despite these shortcomings, glass wool is widely used for internal insulation of pitched roofs with such types of protective coatings as slate, metal tiles and others.

Slag-based mineral wool ↑

The material made from blast-furnace slag can be used to insulate soft roofs, as well as ondulin and slate coverings mounted on the rafter crate.

This grade of mineral wool fully meets the requirements for heat-insulating materials and has all their inherent properties. Its advantages include:

- reduced thermal conductivity;

- good vapor permeability combined with a low level of hygroscopicity;

- relatively low flammability index;

- good soundproofing characteristics.

In addition, slag-based insulation material is resistant to deformation and is able to perform its protective functions for a long time (up to 50 years).

With all its advantages, this grade of insulation is noticeably inferior in quality indicators to all the previously listed types of mineral wool and is rarely used.

Insulation of a metal roof

Before installing thermal insulation products, it is worthwhile to understand why it is generally installed and how to make this layer effective. First of all, make sure that the plates do not come into contact with the waterproofing layer, this can lead to a complete loss of all positive qualities.

After the rafter frame is assembled, you can proceed with the waterproofing device. As a rule, it is attached to the base with a stapler and pressed against the crate.It is worth noting that if you use metal products as a coating, then the minimum distance between the insulation and the roof should be 5 millimeters. This will allow the air masses to dry the surface from excessive condensation.

In no case should waterproofing materials be stretched, otherwise it will tear very quickly during operation. When installing roll insulation, loosen the tension and let it sag by a maximum of 2 millimeters, this is quite enough.

An insulated roofing system must necessarily have high-quality natural ventilation. The clean air inlet is usually located under the eaves. The height of such a gap is made different and depends on the volume of the attic space, but the minimum value is 5 centimeters.

Pitched roof insulation technology

The pitched roof can be insulated in the following ways:

- Installation of insulation between the rafters.

- Formation of a continuous layer of insulation on top or under the rafters.

- Combined method.

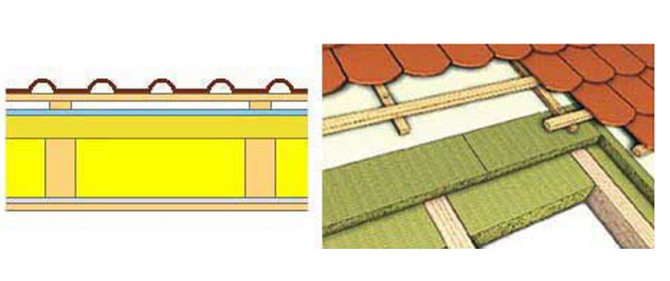

Insulation between the rafters

The easiest way is to install insulation with single-layer ventilation using a superdiffuse membrane. For this method, they buy insulation, the thickness of which is equal to the depth of the cell:

- First, the insulation slabs are cut according to the size of the cells, after adding 2 cm on each side. The allowance is necessary for the slab to sit tightly into the cell.

- In this situation, it is assumed that there is no waterproofing film, therefore it is necessary to fix the superdiffuse membrane. The rafters are enveloped with a membrane and fixed with a stapler to the crate under the roofing material. The edges of the membrane along the perimeter of the room are brought out under the overhang of the roof.

When installing waterproofing, the film passes along all the rafters and tightly envelops them - Then cut insulation is inserted into the cells. If the plates have a foil covering on one side, the material is laid with foil inside the room.

If the insulation boards have a foil coating, it should be directed towards the interior of the room. - If the lower vapor barrier is made of a superdiffuse membrane, then it is immediately attached over the insulation.

- If you are using a regular film, you need to create a lower ventilation gap. For this, the insulation is lined with a thin strip.

- The inner vapor barrier film is overlapped on top of these slats. The joints are glued with tape.

- Stuff the lathing rail for the installation of interior decoration.

Superdiffusion membrane is attached close to the insulation

If there is an old waterproofing film and it is planned to use a film with low vapor permeability (micro-perforated film) for tamping from below, then the gap between the insulation and the film should be on both sides. To do this, it is necessary that the panel is not completely recessed into the cell, but with an indent from the edge by 2–3 cm. The same gap must be left from the attic side. The thickness of the insulation should be 5 cm less than the depth of the cell. The support for the panel can be stuffed strips around the perimeter of the cells or pieces of wire stretched over nails:

- A thin strip (2 cm) is stuffed along the upper edge of the cell, and nails are driven in with an indent of 2 cm from the upper edge of the bar.

- Nylon threads or wire are wound on nails crosswise. Now, when laying the insulation in the cell, the necessary gap will remain between it and the film.

- The exact same operation is performed after the installation of the mineral wool panels. The threads on the bottom side will prevent the material from sagging or shifting in the cell.

To create a ventilated gap, the thickness of the insulation should be less than the depth of the cell between the rafters

Insulation with foam boards must be done in two layers. This is done in order to close the gaps at the joints. In this case, the joints of the slabs of the second row should be shifted relative to the joining of the first row.

It is necessary to select the thickness of the foam insulation so that it does not go beyond the rafters. If the material (or two of its layers) protrudes from the cells, the rafters must be built up with a bar.

Video: laying mineral wool between rafters

The lack of insulation between the rafters is the presence of cold bridges around the perimeter of the cells. Therefore, many owners use combined methods of insulation, additionally equipping a layer on top or under the rafters.

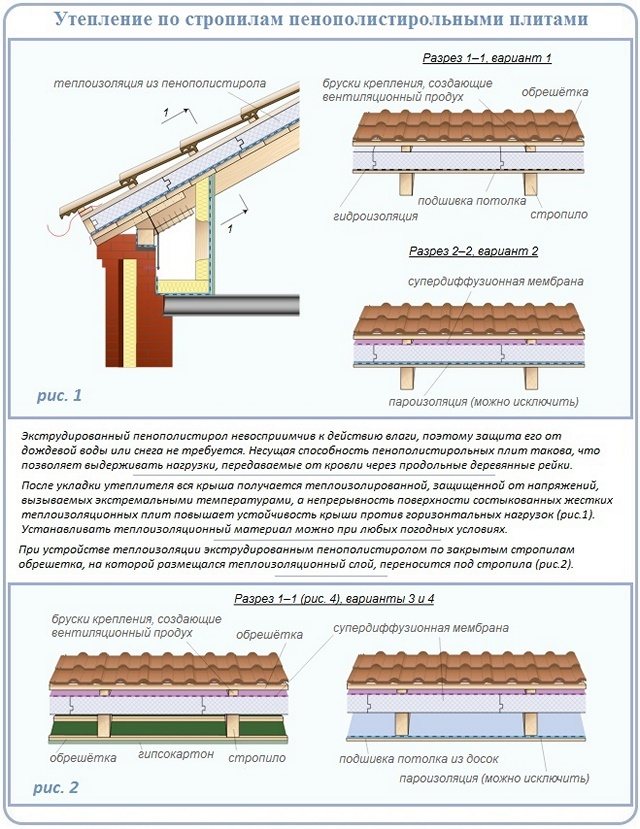

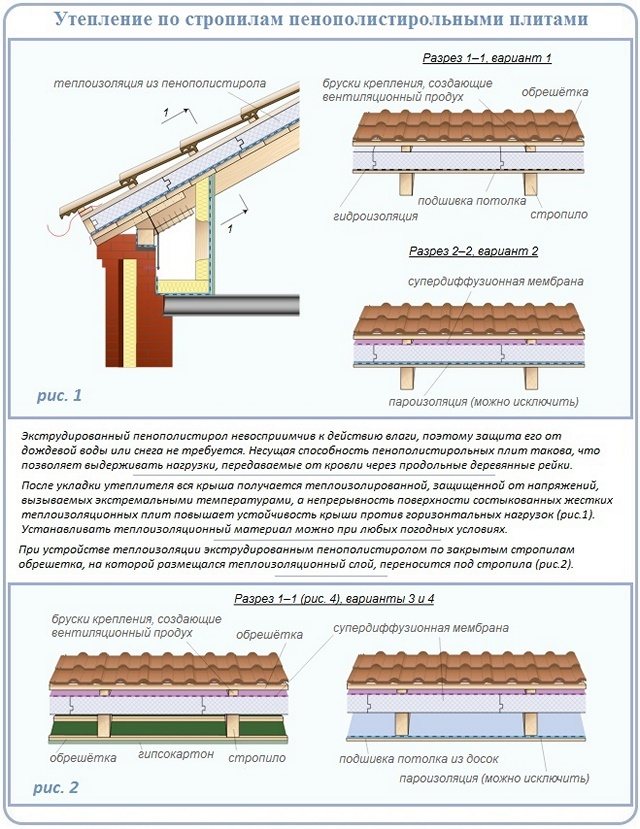

Insulation over the rafters

For insulation on top of the rafters, foam plates are perfect, which have sufficient rigidity. This material copes well with the load that it will experience under the roofing material, therefore, most often in new buildings, a solid layer of insulation is mounted on top of the rafters from the outside. This is much more convenient than screwing the panels from the inside. In addition, interior space can be saved. And if you do not combine the laying of plates with insulation between the rafters, then the open parts of the timber inside the attic will be an original element of the interior.

Foam heaters are not afraid of moisture, therefore, waterproofing of the roof space can be omitted

If extruded boards are used, then there is no need to put a vapor barrier under the insulation and lay waterproofing on top. The work is performed according to the following principle:

- Before installation, a continuous OSB flooring must be made over the rafters.

- On top of it, the insulation plates are attached to the rafters using long self-tapping screws. Self-tapping screws are screwed through the solid flooring. Typically, the foam is laid in two layers overlapping the joints.

Plate heaters are laid in two layers with an offset of the joints - A bar is screwed on top along the line of the rafters, to which the lathing for the roof is attached and which at the same time will create a gap for ventilation.

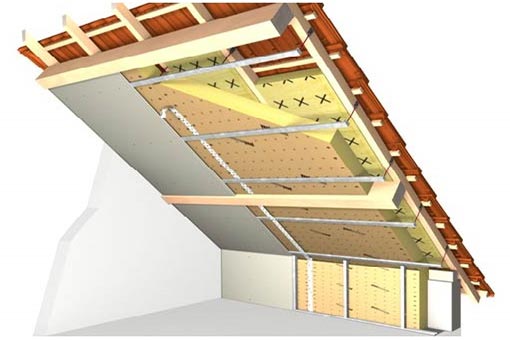

Combined insulation technologies

The most common method of combined insulation during repairs is insulation under and between the rafters. This option is the described method of insulation with one ventilation duct and an additional continuous layer at the bottom.

This technology uses cotton materials:

- First, a superdiffuse film is stuffed or an emphasis is made to arrange the ventilation duct according to the technology described above.

- Then the insulation is cut and inserted into the cells. It is advisable to use material of the same type, but with different density. The thermal resistance of the bottom layer should be 80% less than the thermal resistance of the base layer material. A vapor barrier film will be mounted between them, and if this condition is not adhered to, then condensation will appear on the film.

- For the installation of the second layer of insulation, a transverse bar is stuffed. The cross-section of the timber is equal to the thickness of the insulation.

Insulation fits both between the rafters and from above - Then a rail is stuffed to secure the interior decoration material.

Roofing cake with combined insulation consists of two layers of mineral wool and a vapor barrier film between them

This design is the simplest, most convenient and cheapest. The installation of an additional layer on top of the rafters is most convenient; it is performed with a deep revision of the roof, followed by the replacement of the roofing material. For houses in harsh climatic zones, a combination of all three methods will be the most effective way of insulation.