What materials are there to choose from

To begin with, we will list the common methods of exterior wall decoration, and then we will highlight the options that are relatively inexpensive:

- smooth or textured plaster with and without insulation;

- vinyl or metal siding, corrugated board;

- decorative elements made of wood - lining, house block and the so-called shingle (planks that form a coating in the form of scales);

- panels made of fiber cement and foam with imitation of bricks and other types of facade cladding;

- artificial and natural stone;

- different types of cladding bricks - ragged, figured, bassoon and so on.

Sheathing the walls of the house with artificial stone is not the cheapest option.

If you choose the right colors and sheathe the walls in any of the following ways, then your country house will look beautiful, but not the fact that the work will be cheap. It is not difficult to make sure of this: find out how much it costs to decorate facades with stone or clinker bricks in your city. Since we are interested in inexpensive finishing options, we will not consider the last two.

A little about the best sheathing for different types of buildings. If any house can be upholstered with siding, wood and various panels, then external plaster or a fur coat applied by a wet method is not suitable for wooden walls of log and log dwellings. Plastering is appropriate to do in cottages made of stone, slabs and blocks, and even in old adobe houses. You can get more visual information about the methods of cladding private houses by watching the video:

An important point. The technology of work performance depends on the selected type of cladding. Here the rule applies: water vapor moving from the thickness of the fence structure to the street should not meet obstacles on the way, otherwise it will condense, causing the wall to get wet and as a result a fungus will form.

Since wood, plaster and fiber cement do not interfere with the passage of moisture (it has good vapor permeability), products made from these materials can be attached directly to the walls. Another thing is the upholstery with plastic or metal panels that absolutely do not allow water vapor to pass through. In order for it to go out without hindrance, such a sheathing is mounted using a new technology - on a wooden or steel frame - a subsystem. The latter provides a ventilation gap (air) between the structure and the cladding.

To prevent the structure from being saturated with moisture, all its layers must be vapor-permeable.

Note. The rule also applies to heaters. Vapor-permeable mineral wool is mounted directly to the surface of the structure, and a small air opening is required for foam and foam. Therefore, polymer boards are not covered with a continuous adhesive mixture, as shown in the photo.

How to decorate the facade of a house inexpensively: affordable and practical materials

Building a house is a complex and expensive process that requires a lot of money and time.

Everyone knows that it is better not to save on building materials, but the outer cladding can be made more accessible and cheaper.

How to decorate the facade of a house inexpensively and at the same time get a high-quality, durable finish? Let's consider the most common options.

Among the whole variety of facade finishing materials, the following types are the cheapest and easiest to install:

This does not include decorative stone, sandwich panels, ventilated and wet facades, and porcelain stoneware.And all because these types of cladding are not only expensive, but also technically difficult to install.

Therefore, if you want to save money on facade cladding, then consider only the options indicated above.

Facade plaster and primer

Such cladding will give any home a complete aesthetic look. It is durable, wear-resistant, breathable. Facade plaster allows you to create different textures and volumes when facing external walls, which increases their heat and sound insulation characteristics.

The most popular types of plaster for outdoor use are:

- Cement-sand;

- Decorative (mosaic, fur coat, bark beetle);

- Facade (based on silicone, acrylic, silicate).

The main advantage of plaster is its ability to create various texture imitations for other bases, for example, stone, tile, brick, wood.

To obtain a rich color palette, experts recommend painting the plaster with special facade paints that are resistant to temperature fluctuations, high humidity, UV radiation, while having high vapor-permeable and heat-resistant properties.

The estimated operational life is about 10-12 years.

Facade primer is also one of the cheaper finishes that has become popular lately. It is used for previously plastered facades. For cladding, you can use deep penetrating acrylic or mineral primers, as well as antifungal compounds.

Facade tiles and facing bricks

It is in no way inferior to facing brick or stone, it is also distinguished by wear resistance, practicality, durability, resistance to mechanical damage. The tile is not susceptible to mold, moisture and fire.

A tiled facade will last for decades with proper installation and proper care.

Despite the fact that the material itself is easy to use, its installation creates some difficulties, because it requires a previously prepared surface, evenness of laying the rows and the correct use of the adhesive composition.

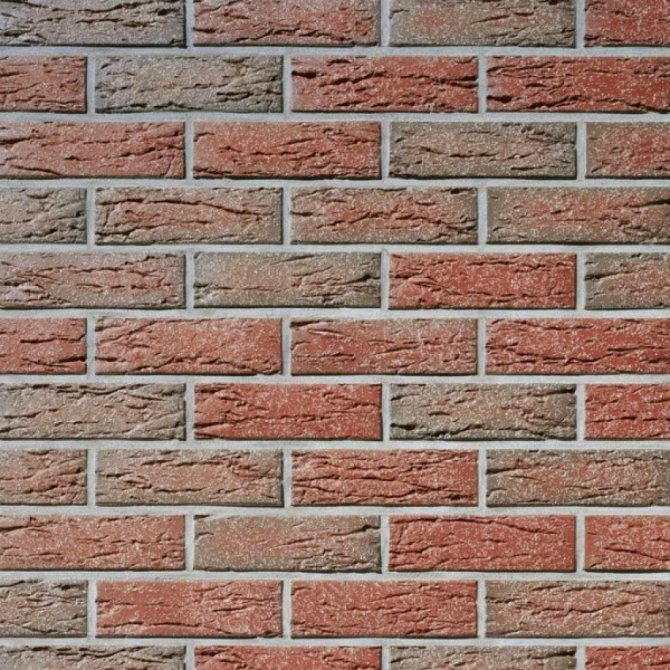

Brick has always been and remains the most demanded facing material for the decoration of building facades.

It is made from natural raw materials, non-flammable, non-toxic, durable, practical, wear-resistant, inert to low temperatures and high humidity. All this means that such it can be used in any climatic conditions.

This type of finishing is the cheapest and most cost-effective, because with a relatively small investment, you get a high result that will delight you for many years.

Advice. Brick cladding should be started at least 50-60 cm from the base of the foundation. This will avoid the accumulation of excess moisture from the soil in the material.

External plastering of walls

The technology for applying smooth plaster has remained unchanged for decades. Self-made or factory beacons in the form of planks are installed on the leveled base, after which the first layer of the building mixture is applied and stretched with the rule. The second layer is a trowel layer, which is made smooth or textured using various tools - graters, curly rollers and stamps.

Reference. The most popular type of plaster is the bark beetle shown in the photo. Grooves resembling wormholes are made due to the round fractions present in the solution, stretched by straight or circular movements of the float. How to do this correctly, see the video:

After the solution has solidified, the surface is painted with an acrylic, silicate or silicone compound, depending on the base of the plaster mixture used.A more progressive, but also expensive option is the application of tinted plaster, which does not need to be painted during the entire service life.

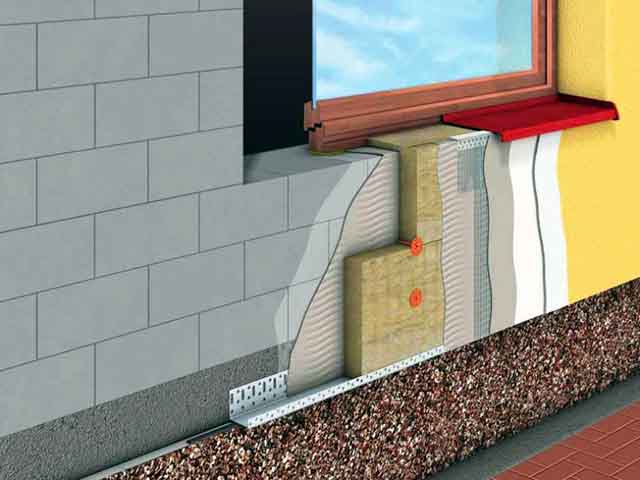

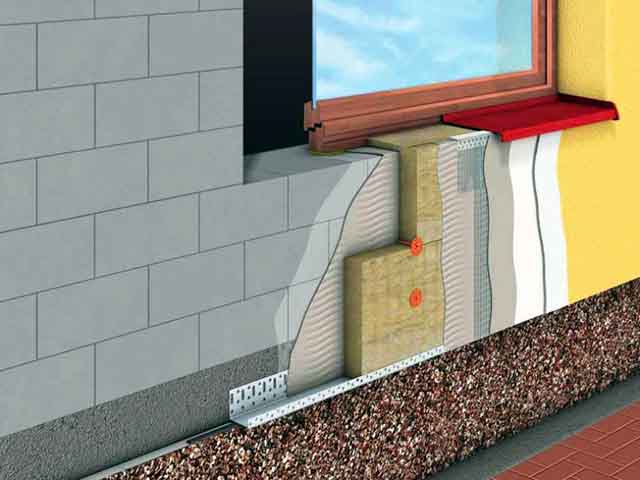

If the wall before facing needs to be sheathed with insulation, then the work is done in the following order:

- The base is impregnated with a primer, after which foam or mineral wool slabs are glued to it. After a day, the insulation is additionally attached to the wall with dowels in the form of umbrellas.

- Next, a waterproofing layer is applied from a special building mixture, where the reinforcing fiberglass mesh is recessed. The canvases are stacked vertically and overlap by at least 10 cm.

- After the waterproofing has hardened, it remains to apply a layer of plaster, as described above.

Insulation cake for plastering

Note. You should not use the described technology for cladding a wooden house, because after a while the cladding will crack and collapse. The reason lies in the properties of wood - it "breathes" (absorbs and gives off moisture), which is why a bar or log changes in size by several millimeters.

Planken

When choosing how to sheathe a wooden house from the outside, many prefer this particular material. Outwardly, the planken is similar to that described above. In this case, the absence of mating grooves is noted. Planken usually has beveled or straight edges. Installation work is carried out end-to-end. However, the process clearances provided must be taken into account. Thanks to them, the facade will be well ventilated. The advantages of the material include practicality, economy and ease of installation. Planken does not imply additional interventions when the structure shrinks or the material dries.

Sheathing with siding and corrugated board

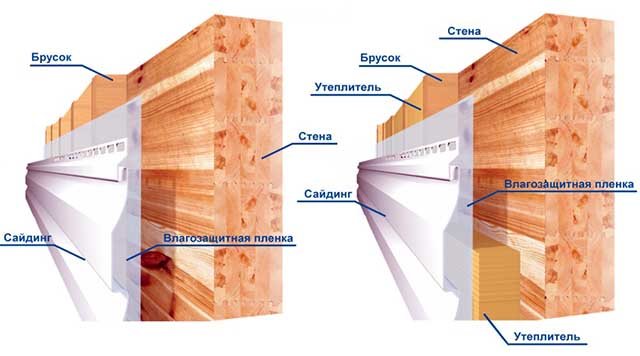

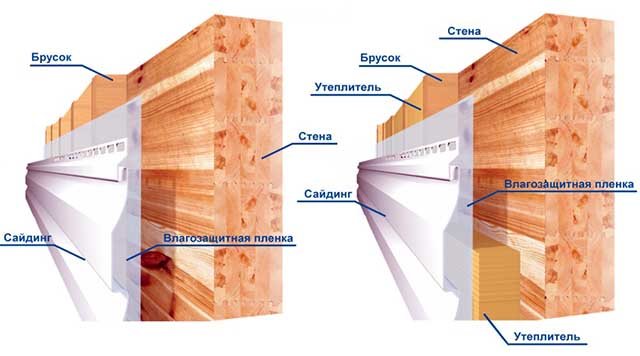

The advantages of these materials are a wide range of colors, affordable cost and quick installation without "wet" processes. This type of exterior decoration of the house involves the construction of a frame made of metal profiles or wooden bars (the latter will be cheaper). If the walls are made of aerated concrete and do not need insulation, then the subsystem serves to create a ventilation gap, level the plane and fasten the sheathing.

The full cycle of finishing works together with insulation looks like this:

- Bars or metal profiles of the subsystem are attached to the walls in increments of 0.5-0.6 m (depending on the width of the slab insulation). Insulating material is laid between them and the dowel is fixed - with umbrellas.

- The entire surface is covered with sheets of a diffusion membrane that allows moisture to pass through only in one direction - from the inside of the "pie" to the outside. It works as a protection against wind and precipitation.

- A counter-lattice is mounted on top, providing a ventilation airflow of 4-6 cm, as shown in the diagram. In the corners, above the plinth and under the roof, additional elements - starting, finishing and corner strips - are attached to the subsystem on self-tapping screws.

- The sheets of corrugated board or siding strips are cut to size, taking into account a gap of 6 mm for thermal elongation, after which they are inserted into the grooves of the extensions and screwed with self-tapping screws. The latter should not tightly press the elements against the crate. How to properly sheathe a house with siding is described in detail in the step-by-step instructions.

Note. Frame profiles are attached perpendicular to the intended position of the siding or profiled sheet strips.

You can sheathe the walls with metal or plastic panels yourself, saving money on the work. Please note that the construction is not interfered with by weather conditions (except for heavy rain) and there is no need to wait until the adhesive and waterproofing layer hardens, as is the case with plaster. And the last point: siding not only differs in an affordable price and looks beautiful, but is also well washed from dust using a regular hose.

Installation of wooden cladding

The wooden cladding of the house looks nice and stands out with its main advantage - environmental friendliness. At the same time, it requires maintenance - antiseptic treatment during construction and periodic painting during operation. A properly made cladding allows excess moisture to pass through and "breathes" along with the wooden walls.

This is how facades sheathed with clapboard look

Reference. Moisture enters the thickness of the enclosing structures in two ways: from inside living quarters and as a result of condensation from the dew point. So the internal vapor barrier solves the issue only partially and the water vapor still needs to go outside, and the pores in the wood contribute well to this.

House block imitates a log building

The choice of finishing method depends on the material from which the building is built. In houses made of SIP panels and erected using frame technology, the lining can be attached directly to the OSB sheets, since they are flat and fairly even. In the same way, dwellings from ordinary and glued beams are sheathed, when there is such a need. Another thing is log cabins with an uneven surface, stone and brick houses. Here you cannot do without a wooden frame device, as described above.

Sheathing with wood products is performed in the following ways:

- The lining and its variety - the house block is installed according to the example of siding - the spike of each subsequent strip enters the groove of the previous one. Fastening - galvanized nails or special clamps.

- Elements of shingles (otherwise - shingles) are stacked with an overlap one on top of the other and nailed with nails, 2 for each piece.

- The original way of sheathing a country house is to use ordinary and unedged boards of approximately the same width. They are mounted in a horizontal herringbone position, superimposing the edge of the next element on the upper end of the previous one, as shown in the photo.

At the end of the finishing, fittings made of wood are placed on the corners, basement and roof junctions of the abutment, after which the facade is covered with varnish or paint. More information about the installation of the lining is described in the following video:

Finishing with finished panels

These types of finishing materials cannot be called cheap, but their use allows, in most cases, to save on the subsystem device. For example, fiber cement panels made using the technology of the Japanese brand Kmew are attached directly to any even walls with several screws or dowels. Clinker panels made of polystyrene with cladding imitating brick, natural stone and other types of finishes are also mounted.

Installation of fiber cement panels on a subsystem of steel profiles

Both types of products are distinguished by their undoubted advantages. The service life of fiber cement boards is equal to the period of operation of the entire building, and they do not lose their appearance over time and are permeable to water vapor. If you want to sheathe the walls with clinker thermal panels, then you will kill two birds with one stone: decorate your house beautifully and insulate it with foam. The installation technology is clearly shown in the video:

If the building is made of bricks

Brick walls can support more weight, which expands the choice of sheathing a brick house from the outside.

Such a facade of the house, in addition to the methods mentioned above, can be sheathed with the following finishing materials:

- Fiber cement siding and slabs. The material is relatively new on the market, it is made from a mixture of different components: cement, quartz, wood fiber, people. The composition may interfere with asbestos and chlorine. Sheets are formed from the mixture, water is drawn out in several stages and fired. With regard to the coating, they are distinguished: panels with photoceramic coating, panels with acrylic coating, panels with hydrofiltered ceramic coating. The cheapest will be panels with an acrylic surface.Fiber cement siding can have different textures and create the illusion of most finishing materials.

- Thermal panels. Such wall cladding is practical in that they combine the properties of cladding and insulation at the same time, thanks to the composition: insulating and outer layer. They imitate various types of natural stones. Unfortunately, due to the recent appearance, such panels do not have accurate data on their application in practice, you will have to check the durability of the material yourself. You can also sheathe the outside of the house with clinker panels.

- Facing brick. It differs from building bricks in the brightness of color, the presence of an assortment of textures, density. This material makes a strong load on the ground, which can provoke its subsidence. Because of this, it will be necessary to harden the earth under it, possibly using reinforcing elements. The brick-faced façade of a private house is a classic.