Table of contents:

- Which side is it better to insulate the foundation

- What materials should not be used to insulate the foundation

- What material to choose for basement insulation

- How is the insulation of the PPU foundation carried out?

- Is it worth insulating the foundation with polyurethane foam from the inside

- Insulation of the foundation of multi-storey buildings

- How is the polyurethane foam insulation of a multi-storey building carried out?

Warming the foundation is an important stage in the thermal protection of a house. The lower part of the building freezes easily in frost, and in spring it gets wet from melt water. The combination of exposure to cold and moisture destroys materials, leading to cracking of the masonry and subsidence of the structure.

Another factor that adversely affects the foundation is frost heaving. The water contained in wet masonry and the surrounding earth freezes during cold weather, turning into crystals. At the same time, it increases in volume and destroys wall materials. If the house is built on the so-called heaving soil containing a large amount of moisture, serious cracks may appear on its foundation after 2-3 cold seasons.

The foundation is often associated with the basement, where the inhabitants of the house store their belongings and winter preparations. In the absence of insulation in the basement, it becomes cold and damp - mold appears on the walls, and an unpleasant damp smell is felt in the air. It becomes impossible to store something there.

After insulation, the basement will become warm and dry. In most cases, it is possible to keep the temperature regime inside the basement at around 5 degrees Celsius throughout the winter, even without heating. But in order to achieve this effect, the foundation will have to be thoroughly insulated.

Foundation on piles

The foundation on piles is one of the most ineffective structures in terms of thermal insulation. Often, houses assembled on a pile foundation have a significant drawback - a cold floor. Especially if the first floor is insulated with mineral wool, the problem of a cold floor becomes very acute. We are often contacted about floor insulation from below, but unfortunately, spraying polyurethane foam on the floor from below is possible only if there is sufficient space for the operator to work.

Insulation with polyurethane foam, in our experience, gives a significant improvement in the situation, but we still recommend that when building a house on piles, insulate a polyurethane foam from the top between the floor log. In this case, the quality of insulation will be the best.

Which side is it better to insulate the foundation

Most experts recommend insulation outside. There are many reasons for this:

- increase in the service life of the foundation... Protection of the material with a heater with waterproofing properties prevents it from freezing, getting wet and cracking;

- prevention of water condensation on the inside of the foundation structures. Dampness provokes the growth of mold and mildew, which destroys the lower part of the building. A fungus that has spread from the basement to all parts of the house is very difficult to remove. Insulation of the foundation from the outside increases the temperature inside the masonry and stops condensation;

- technical simplicity... It is much easier to insulate the foundation from the outside - you just need to dig in the base of the house. From the inside, this can only be done during the construction phase or if a basement is located inside the foundation.

You can insulate the foundation from the outside and from the inside.Modern heaters even allow you to make the basement so warm that it will be possible to place a billiard room, a gym, utility rooms, workshops and much more in it.

What materials should not be used to insulate the foundation

- Good water absorption... No matter how advanced the waterproofing of the foundation is, it will still not be possible to completely avoid contact of moisture with the insulation. As a result, the material will get wet and lose its insulating properties. Therefore, glass wool and other hygroscopic materials are not suitable for this purpose. They will quickly fail and stop protecting the foundation.

- With a short service life... Since the house will stand for more than one decade, it is not worth covering its foundation with material with a service life of 10-15 years. Otherwise, you will have to re-excavate and change the insulation. Therefore, you need to choose materials that serve 40-50 years.

- Attractive to rodents... On the Internet, you can see many videos of how mice and rats pull the insulation to the nests or simply settle in it. If you do not want to become the hero of such a reportage, do not insulate the foundation and basements with polystyrene foam, extruded polystyrene and other materials that attract rodents. Moreover, mice and rats quickly scatter all over the house.

- Heat-insulating paints of the "Re-Term" type... Such materials are effective only in air, since they create a film on their surface that traps warm air. In the ground, this protection is useless, since Re-Term is applied in a layer of several millimeters.

- Roll and slab insulation materials... These options are not suitable due to the need to use anchors. It is impossible to control the fasteners inside the ground, so there is no guarantee that they will not fall off. In addition, the holes from the fasteners make the insulation leaky. Can play a cruel joke and the seams connecting the insulation elements. If the joint turns out to be unreliable, water will penetrate under the insulating material and ruin the foundation.

- Heavy materials, for example, basalt wool, which weighs 15 kg per square meter. Add to this the mass of glue with which it is attached and the plaster layer recommended for protection from water. As a result, the weight of the insulation with fasteners and plastering reaches 25 kg / m². It turns out that the foundation of a house with an area of 100 square meters becomes two tons heavier from such insulation. An increase in the weight of a building can cause soil subsidence, displacement of the structure and other unpleasant consequences.

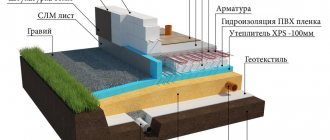

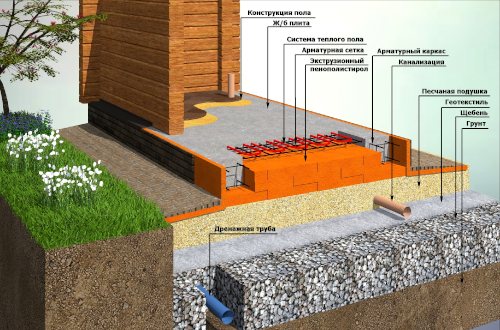

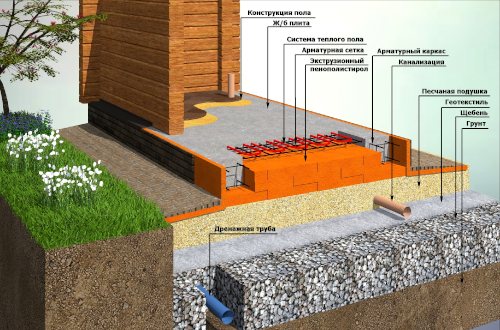

Swedish stove technology

The thickness of the monolithic slab in this structure is only 10 cm. And the entire communication system is concreted into this decimeter, therefore, it is necessary to think about its installation at the same time as laying the foundation.

Operating procedure:

- A pit is pulled out over the area of the future building with a depth of 40 cm.

- A gravel-sand cushion is laid with compaction and laying of intermediate geotextiles.

- The formwork is assembled from expanded polystyrene plates with sides using metal fasteners. The entire area is covered with ordinary polyurethane foam boards 10 cm thick. The side elements are of the same thickness. If ordinary slabs are used along the perimeter, then laminated plywood formwork is additionally mounted along the outer edge.

- The bottom and walls of expanded polystyrene plates are lined with roofing material.

- Lay another layer of expanded polystyrene (also 10 cm).

- Lay communications (water supply, drainage, electricity, etc.) and floor heating.

- Reinforcement mesh is installed.

- Pour everything with concrete using a vibrating machine.

So, in a short time, a super warm foundation structure is obtained. Although there is an opinion that UWB is beneficial primarily for producers of expanded polystyrene.

This technology still has disadvantages:

- A monolithic slab is prone to uneven shrinkage due to shallow deepening, and laying polystyrene foam under it can further aggravate this process. Despite the fact that the manufacturer guarantees the ability of the expanded polystyrene board to withstand maximum loads, this technology is not suitable for heavy and multi-storey buildings.

- In cases where a mistake was made in laying communications, in order to fix poorly performed work, the entire foundation will have to be dismantled. It will be extremely difficult to repair water supply and electrical communications with such a laying.

The Swedish plate technology is more suitable for flat areas; it should never be done on peat soils.

There are many ways to insulate a monolithic slab. In each case, this or that option is most suitable. Each builder must choose an option based on the type of soil, the type of structure and its future load.

What material to choose for basement insulation

The best choice is polyurethane foam. This insulation is supplied in the form of two liquid components, which, mixing with each other during spraying, form a polymer foam. To insulate the foundation, a dense polyurethane foam is used, containing a large number of unopened, closed air bubbles. Such insulation is called closed-cell.

This material has high adhesion, easily sticking to any material. Polyurethane foam is not afraid of moisture, fungus, temperature changes and rodents. Such insulation serves for 50 years or more.

The material consists of 90% of gas released during the reaction, therefore it weighs little and practically does not create additional load on the ground. PPU has a low coefficient of thermal conductivity - 0.020-0.035 W / (m * K) - and keeps heat well.

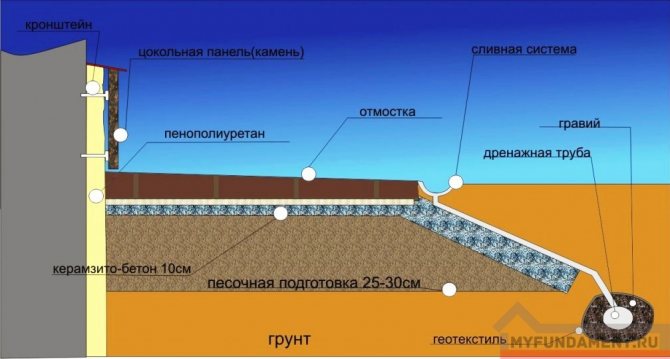

Insulation of the strip foundation

The insulation of the PPU strip foundation is carried out from the outside and protects the foundation from heaving in the cold season. In addition, the insulation of the foundation with a layer of PPU allows you to provide a dry and warm microclimate in the underground of the house, which reduces the overall heat loss of the house. An important distinctive feature of polyurethane foam is its ability to firmly adhere to the bases, while additional measures for attaching the polyurethane foam to the bases are not required.

Unlike PPU, slab insulation must be mounted on glue and fastened with dowels to the foundation, which are cold bridges.

How is the insulation of the PPU foundation carried out?

Initially, preparatory work is carried out. Digging up the foundation, they form a trench up to a meter wide. After that, the soil is cleaned from the underground surface of the house and the surface is left to dry. There is no need to fill up small cracks and cracks - anyway, after spraying, they will be filled with foam. But with significant differences and defects, the surface of the foundation is leveled using plaster mortar.

A 5 cm thick layer of polyurethane foam is applied to the dried foundation. At the same time, not only the entire underground part is insulated, but also 40 centimeters above the ground. This will prevent melt water from entering the masonry.

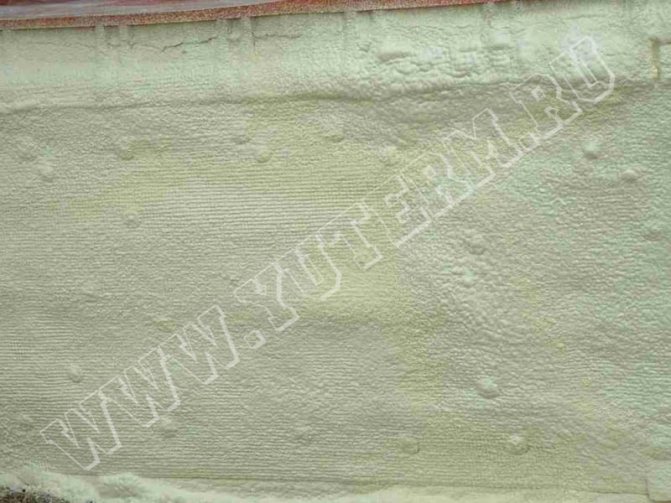

PPU is applied over the entire area from top to bottom using a pistol in several passes. In this case, the polymer significantly increases in volume, turning into a fluffy porous "fur coat". After the material has dried, the foundation must be buried, since the polyurethane foam does not withstand the sun's rays well.

Advantages of thermal insulation of the foundation and basement with polyurethane foam

Thermal insulation of the foundation, as well as insulation of the basement of the house seamless spraying of polyurethane foam (PPU) outside and inside has a number of undeniable advantages, such as:

- the possibility of spraying a layer of polyurethane foam of any thickness;

- after spraying on the surface to be insulated, polyurethane foam forms a single monolithic coating without any joints and joints;

- insulation polyurethane foam is an environmentally friendly and biologically neutral material that does not support combustion;

- work on insulation of the foundation and basement of the house is carried out very quickly;

- after spraying, PPU does not form "cold bridges", since there is no need to install fasteners;

- perfect protection and 100% sealing of cracks and joints;

- insulation of foundations of any even the most complex shape and erected from various materials (block, monolithic, brick, etc.);

- excellent adhesion - adhesion to all known building materials and much more.

Insulation of the foundation from blocks

Insulation of the foundation of a wooden house from the outside

Insulation of the foundation and basement of the house outside

Insulation of the foundation of a wooden house

Thermal insulation of the foundation with polyurethane foam - this is the maximum efficiency of insulation, excellent hydro and vapor barrier, as well as coziness and comfortable microclimate in your room!

Insulation of the foundation and basement of the house with rigid polyurethane foam Is a reliable, high-quality thermal insulation, waterproofing and vapor barrier in one person.

offers its services on a reliable and modern method of insulation and waterproofing of various types of foundations using a high-tech and most efficient material like polyurethane foam. Insulation of the foundation and basement of the house with polyurethane foam from our company is a significant reduction in heat loss and real protection from destruction!

Is it worth insulating the foundation with polyurethane foam from the inside

Yes, it's worth it. This should be done during the construction phase, when there is access to the interior of the structure. With double-sided insulation, the thermal conductivity of the lower part of the house is significantly improved, and the service life of the foundation is increased.

If a basement or cellar is organized under the house, it can also be insulated. In this case, mold and mildew will not appear on the walls, and the room will become much drier and warmer.

But such measures can only be used as a supplement to external spraying. If you insulate the foundation only from the inside, leaving it open on the outside, groundwater and frost will continue to destroy the material. Although the basement is dry, the foundation may crack, causing the structure to shrink.

How to reduce the cost of purchasing material

As you know, any construction work is associated with significant financial costs, because the materials for their implementation are not cheap. But if you wish, you can reduce these costs. To do this, you should purchase material from manufacturers. Such companies often sell their goods much cheaper than dealers.

If you are going to insulate the foundation with polyurethane foam, you can contact the manager of our company. We are the manufacturer of this material and will be happy to advise you on its features. Our managers will tell you in detail how to correctly calculate the required amount of material, what rules and regulations should be followed when using it. We produce polyurethane foam in accordance with all technical standards, our clients purchase it for construction not only in our country, but also in the EAEU states. We do not save on production, therefore our materials are of the highest quality and full compliance with all standards, including environmental ones. Well, very reasonable prices will be another pleasant addition to the purchase.

Get it!

Insulation of the foundation of multi-storey buildings

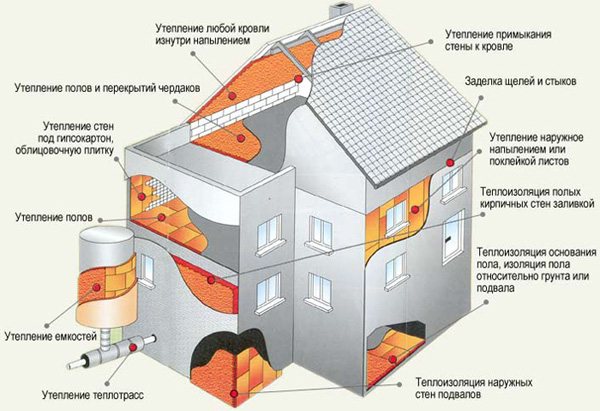

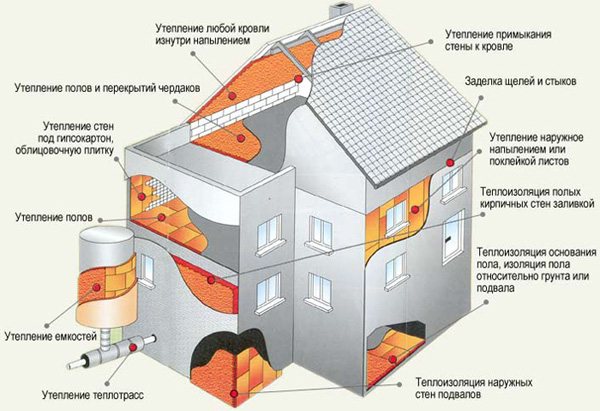

With the help of polyurethane foam, not only private households are insulated, but also apartment buildings. This material is sprayed on any type of foundation for high-rise buildings - slab, pile, tape, combined. Nowadays, this is done already at the construction stage. For such work, only high-density closed-cell polyurethane foam is used.

But buildings built many years ago do not have such insulation, so it has to be carried out separately. Insulation is applied to the outside of the house wall and inside the basements. Dried and hardened polyurethane foam is covered with facade plaster or other finishing materials.

The work is carried out at a temperature not lower than 5 degrees in dry, calm weather. Since the spraying rate is quite high, it is possible to insulate the entire foundation of even a large house in one or two days.

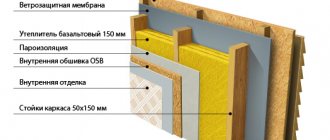

Insulation of the facade of the cottage

Insulation of facades with polyurethane foam is one of the simplest and most profitable ways. This type of insulation is quite simple, it saves space in a residential building, and also prevents the appearance of moisture inside the walls and protects the room from destructive external influences.

It should be borne in mind that such works are seasonal, therefore they are recommended to be carried out in the warm season.

Insulation with polyurethane foam by spraying is especially important. Insulation by spraying polyurethane foam, reviews of which are very good, has its undeniable advantages.

It is sprayed onto the surface and covers it with a film that protects the material from moisture.

In order to carry out such work, polyurethane foam is applied with a layer of up to 50 mm. After that, the facade is covered with special compounds and paints. A curtain wall can also be used. Thermal insulation with polyurethane foam (PPU) is an actual technology for insulation, because quite high requirements are imposed on thermal insulation.

Insulation by spraying polyurethane foam, reviews of which are quite positive, replaces vapor barrier and waterproofing. Such insulation of the facade is not only beneficial, but also very light in weight.

Insulation by spraying polyurethane foam reviews can be replaced in another way, namely by pouring. The material can be poured between the walls of an already built house. In doing so, you will avoid cold bridges.

This method of insulation is very economical and versatile. You will save on heating your home in the winter and on cooling in the summer.

How is the polyurethane foam insulation of a multi-storey building carried out?

First, the building is dug in to a depth of 50-60 cm. The walls are cleared of earth and dried. Sand is poured at the bottom of the formed trench. After that, PPU is sprayed on the entire surface of the foundation, capturing about half a meter above ground level. The dried foam is cut off and plastered. You can use special finishing boards instead of plaster. The polymer, which is above ground level, is trimmed with cladding.

Around the house, a concrete blind area with drainage channels, ebbs and gutters is organized. After such work, the basement of the house becomes dry and warm, and the cost of heating is reduced by 15%. In addition, cracks on the foundation and facade of the house cease to appear, and the basements are not flooded with melt water.

Having insulated the foundation, you don't have to worry about its durability and strength, especially if you have chosen reliable and durable waterproof polyurethane foam as insulation. Since this material is not cheap, for work you need to contact firms that cooperate directly with manufacturers of PU foam components. In such companies, fairly reasonable prices are offered, they have modern equipment and experienced specialists.

We take into account the features of the technology before starting work

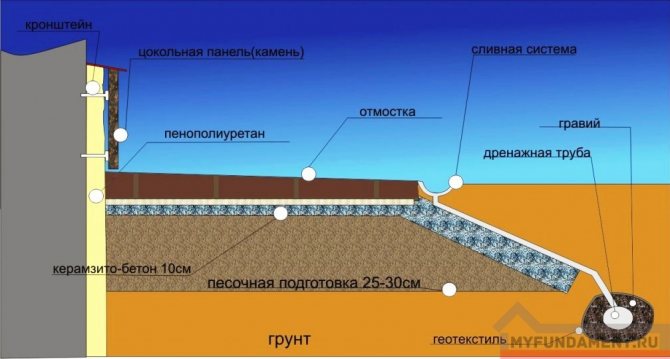

Drawing diagram of the application of polyurethane foam insulation on the walls of the foundation

The technology of spraying with polyurethane foam is suitable not only for warming the foundation, but also for the basement, walls, roofs and floors. If a basement floor is planned, both external and internal insulation are recommended. The internal masters of their craft offer when outside there is no opportunity to work as a "spray". Outdoor is made around the entire perimeter. A layer of 6 cm can be considered reliable.

PPU has its own temperature threshold - +5 C. Therefore, you should not plan work for late autumn and winter.It is not worth insulating with this building material during rain and in strong winds (more than 5 km / h).

To carry out the work, you will need raw materials and a foam generator. For thermal insulation of the foundation, it is enough to choose a rigid polyurethane foam (with a density of 32 kg / m3). As an additional waterproofing, bituminous mastic is useful.