How to insulate the foundation

Insulation of the foundation with polyurethane foam is considered expensive, but it pays off in the near future - the cost of insulating a house with such insulation is minimal.

Insulation of the foundation with extruded polystyrene foam. The material is similar to polystyrene, but stronger than it and contains air cells that increase its thermal insulation properties. It is produced in the form of plates, convenient for installation.

- The foundation is cleaned of dirt and waterproofed with polymer or bitumen mastic.

- Prepare a glue for polystyrene and apply it to the inner surface of the plates. If the foundation is uneven, it is enough to apply glue where it touches the insulation.

- The slab is pressed against the foundation for a few seconds and leveled if necessary.

- The next plate is mounted by aligning the connecting groove.

- It is not necessary to fix the penoplex to the underground part of the foundation - the slab will be securely fixed when backfilled with soil.

- When the glue dries, the material is additionally attached to the foundation using dowels.

Advantages of polyurethane foam for basement insulation

Polyurethane foam has a number of advantages that make it ideal for basement insulation. First, it is worth noting the application feature. Thanks to her, this option of insulation does not have any joints or cracks through which moisture can get to the building. No material can achieve this result without additional layers of waterproofing.

Also, polyurethane foam has the following advantages:

- Resistant to moisture, temperature extremes, plants and insects.

- Low thermal conductivity.

- A structure that does not allow moisture to pass through.

- Tight fit to the building, which prevents condensation.

- High application speed.

- Low material cost.

Polyurethane foam has many other features that only distinguish it from other heaters. It is delivered in cylinders, which can significantly reduce transportation costs. And its application can be carried out even by beginners, if you carefully follow the rules and take into account the recommendations.

Again, this material has a lifespan of decades. Therefore, you do not have to worry about the safety of your foundation, as well as reduce the cost of heating the building. After all, the basement of the house and the basement are a common cause of cold in a building, even in cases where the windows and walls are already insulated.

So this option is ideal for basement insulation. Polyurethane foam can significantly reduce heat loss and increase the life of the base of the building. At the same time, you can apply it yourself, which will be discussed below.

The need for the implementation of external insulation

It is believed that it is the basement that belongs to the most vulnerable part of any building. This happens due to the fact that this part of the building structure experiences significant loads exerted by the weight of the floors and load-bearing walls. This structural element is located underground, which is why it is regularly exposed to temperature changes and high humidity, and in winter it can freeze through, and the soil heaves under the foundation.

The basement is a continuation of the plane of the building's foundation, which rises above ground level, then passing into the outer walls of the house. In other words, this part of the building is an element that connects the foundation with the plane of the load-bearing walls, which start from the plane of the ground floor.The main function of the plinth is to protect the building from high humidity and the penetration of cold air masses inside. In addition, houses with a basement floor have a more well-groomed appearance.

Carrying out work on the external thermal insulation of the foundation of the house allows you to prevent freezing of the basement and the building material of the basement itself. As a result of such measures, the dew point shifts closer to the insulation material, and it is known to be more resistant to high humidity and negative temperatures than the basement building material. Upon completion of the work, the basement becomes a warmer room, and the building itself gets the opportunity to operate longer.

Do-it-yourself thermal insulation

The choice of insulating materials is very diverse. But the above criteria are fully met only by heat insulators in the form of plates and polymer materials applied by spraying. Their main qualities are discussed in more detail below.

Styrofoam

Polyfoam or expanded polystyrene has long been known as a heat insulator and has not lost its popularity for many years. It has the property of perfectly retaining heat, does not absorb moisture and its vapors, is easy to cut and has a low weight, which means it is easy to install. In addition, expanded polystyrene has a low price when compared with other polymeric materials for insulation. All these advantages make the foam popular for arranging thermal insulation over a large area or limited financial resources.

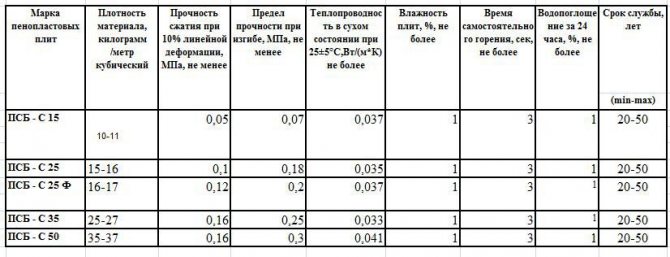

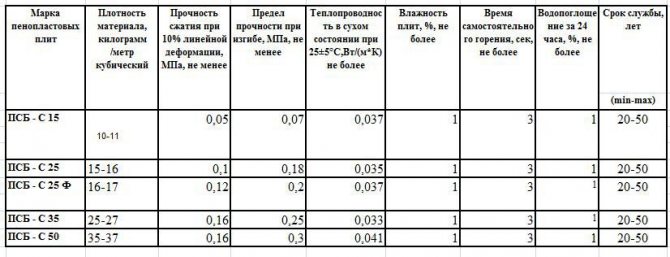

For the production of work on the thermal insulation of the basement, foam is suitable, belonging to the brands PSB-C 25 or PSB-C 35. These varieties have a higher level of density, which means they can better withstand the effects of mechanical stress. The thickness of the slabs can vary from two to ten centimeters.

Depending on the characteristics of the climate in the region of construction, the insulation can be laid in one or two layers. The material is able to withstand significant temperature changes - from -60 degrees to 80 degrees, while its characteristics will remain unchanged. Polyfoam is not afraid of either winter cold or summer heat.

Despite the impressive list of advantages, polystyrene also has its own disadvantages:

- weak level of bending strength;

- high level of fragility;

- attracts mice and rats.

Extruded polystyrene foam has a denser structure than polystyrene foam. Its cells are very small and do not exceed one millimeter in diameter. Due to this, the EPSP practically does not absorb moisture and has significant mechanical strength. The insulation has a high degree of resistance to chemicals, harmful microorganisms, deformations associated with shrinkage.

Expanded polystyrene produced by extrusion is in high demand. the most popular was the material under the brands URSA, Styrofoam, Penoplex, TechnoNIKOL XPS. They are produced in the form of plates with various thicknesses and densities. Standard sheet sizes are 120 * 60 centimeters or 240 * 60 centimeters.

We suggest that you familiarize yourself with Knitting reinforcement: methods, schemes, norms and rules for knitting for beginners

The main disadvantage of extruded polystyrene foam is the high level of flammability of the material. All the main brands of this insulation belong to the G4 or G3 flammability class. When the material smolders, poisonous substances are released into the air.

Polyurethane foam is able to simultaneously provide your home not only with thermal insulation, but also protect against high humidity and the penetration of extraneous sounds from the outside.The material is suitable for use in various parts of the building - roof, attic, foundation, etc. It adheres perfectly to the base of any material.

The task of competently insulating the basement floor in accordance with the necessary standards and technical indicators, with the arrangement of a suitable thermal insulation system, sometimes seems at least difficult, at most impossible. In reality, you do not have to perform any too complex actions.

Among the wide variety of modern heaters, only polymer-based plate and spray materials fully meet the above requirements. Let's consider their characteristics in more detail.

Warming with expanded polystyrene

Expanded polystyrene (polystyrene) has been used as a heater for a long time, and still does not give up its positions. It retains heat excellently, does not accumulate moisture, is easy to cut and is lightweight for effortless installation. In addition, polystyrene has the lowest cost among other polymeric heaters, and this is a weighty argument in its favor for thermal insulation of large areas or a limited budget.

Insulation of the basement with foam

To insulate the basement, it is necessary to choose polystyrene of the PSB-S 25 or PSB-S 35 brand, which is characterized by increased density and resistance to mechanical stress. The thickness of the slabs varies between 20-100 mm, and depending on climatic conditions, the insulation can be laid in 1 or 2 layers. The material withstands temperature drops from -60 ° C to 80 ° C without changing its characteristics, so it is not afraid of the most severe frosts and summer heat. The service life, on average, is 25 years, and with a high-quality arrangement of the heat-insulating pie, it will be 10 years longer.

Styrofoam characteristics

Despite all the advantages, foam also has disadvantages: it has low bending strength, that is, it is quite fragile, and is often damaged by rodents.

The mice gnaw through the insulation

In addition, in the absence of waterproofing, moisture penetrates into the upper layers of the material and, freezing, provokes crumbling of the slabs.

It is easy to insulate the basement part on your own, the main thing is to follow the technology exactly. One of the most important conditions is the high-quality preparation of the base. If the house is new, the basement and the blind area are in good condition, then the work process will not take much time, which cannot be said about old buildings.

The facade of the house before insulation and finishing. In the photo, the base does not need preparation

Plinth close up

The work of cleaning the surface from dirt begins. If the plinth is finished with tiles or facade panels, the cover will have to be dismantled. They clean off the old plaster, knock down the protrusions, the dried solution, and thoroughly process the base with a stiff brush.

In the photo, a way to remove old plaster manually

In a brick plinth, the seams must be carefully cleaned to reveal voids.

Crumbled mortar from the seams must be cleaned

Next, they carefully examine the base, embroider the cracks, treat the areas affected by the fungus with special means.

Cracks need to be well cleaned and expanded before repairs.

If the blind area is old, covered with deep cracks, it must also be completely removed, otherwise it will not be possible to insulate the basement with high quality. Further, a layer of soil about half a meter wide and 10-15 cm deep is removed along the perimeter of the house. If the blind area is in good condition and fits snugly against the wall, it is enough to clean the joint along the entire length with a metal brush to remove debris and dirt.

We offer you to familiarize yourself with the Foundation of expanded clay concrete blocks with your own hands

For a snug fit of the slabs to the base, the walls of the basement should be as flat as possible.If there are differences of more than 10 mm, the surface should be leveled with plastering. To do this, you can use a conventional cement-sand mortar, but it is better to purchase a dry cement-based mixture.

Sand-cement mixture for plaster

Factory mixes are more expensive, but they do not shrink and are more resistant to negative effects. The plaster is applied with a trowel to the wall and spread gently over the surface in a thin layer.

Applying repair mortar

After drying, the walls are treated with a float with an emery cloth, dust removed and covered with a waterproof primer with quartz filler.

Plaster grout

For insulation you will need:

- EPS boards, for example, Penoplex;

EPS plates - fiberglass mesh for reinforcement;

- glue for expanded polystyrene (Titanium, Ceresit ST 83);

- plastic perforated corners with mesh;

- dowels, fungi;

- assembly knife;

- level and tape measure;

- metal spatulas;

- a drill with a mixer attachment and a set of drills.

Construction mixer

It is very simple to calculate the amount of insulation: you need to measure the length of the base around the entire perimeter, multiply by the height and divide by the area of one foam board. The material should be bought with a small margin, since the slabs must be trimmed when joining. In the same way, the amount of reinforcing mesh is calculated, which is necessary when plastering insulation.

Step 1. Slabs are tried on to the surface, if necessary, they are trimmed. The lower edge of the insulation should rest on the concrete base of the blind area or on tightly compacted soil covered with a layer of sand.

Step 2. On the back side of the first plate, glue is applied with a solid line along the perimeter and in the middle.

Glue application

What materials should not be used to insulate the foundation

- Good water absorption... No matter how advanced the waterproofing of the foundation is, it will still not be possible to completely avoid contact of moisture with the insulation. As a result, the material will get wet and lose its insulating properties. Therefore, glass wool and other hygroscopic materials are not suitable for this purpose. They will quickly fail and stop protecting the foundation.

- Short service life... Since the house will stand for more than a decade, it is not worth covering its foundation with material with a service life of 10-15 years. Otherwise, you will have to re-excavate and change the insulation. Therefore, you need to choose materials that serve 40-50 years.

- Attractive to rodents... On the Internet, you can see many videos of how mice and rats pull the insulation to the nests or simply settle in it. If you do not want to become the hero of such a reportage, do not insulate the foundation and basements with polystyrene foam, extruded polystyrene and other materials that attract rodents. Moreover, mice and rats quickly scatter all over the house.

- Heat-insulating paints of the "Re-Term" type... Such materials are effective only in air, since they create a film on their surface that traps warm air. In the ground, this protection is useless, since Re-Term is applied in a layer of several millimeters.

- Roll and plate insulation materials... These options are not suitable due to the need to use anchors. It is impossible to control the fasteners inside the ground, so there is no guarantee that they will not fall off. In addition, the holes from the fasteners make the insulation leaky. Can play a cruel joke and the seams connecting the insulation elements. If the joint turns out to be unreliable, water will penetrate under the insulating material and ruin the foundation.

- Heavy materials, for example, basalt wool, which weighs 15 kg per square meter. Add to this the mass of glue with which it is attached and the plaster layer recommended for protection from water. As a result, the weight of the insulation with fasteners and plastering reaches 25 kg / m².It turns out that the foundation of a house with an area of 100 square meters becomes two tons heavier from such insulation. An increase in the weight of a building can cause subsidence of the soil, displacement of the structure and other unpleasant consequences.

Do-it-yourself thermal insulation

In a building where a heat-shielding layer is installed, the area of frost penetration cannot penetrate the house and touch the surface of the base walls. This has its advantages. The full-height strip foundation, from the base to the basement ceiling, will be in approximately the same temperature regime.

Many people ask a reasonable question - what material to choose for high-quality insulation of the foundation? A couple of generations ago, clay-straw mortar was a popular material for thermal insulation of the basement. Over the past decades, technologies for the production of materials for insulation have changed a lot and have become more advanced. New heaters are produced in a form that simplifies their transportation and installation. The requirements for heat insulators have also changed and are as follows:

- Low thermal conductivity. The lower this coefficient is, the higher the insulating properties of your chosen insulation material will be.

- Low moisture absorption rates. A heat insulator, which is able to actively absorb moisture, cannot retain heat well and gradually loses its valuable, from the point of view of the consumer, qualities. This process poses the greatest danger in winter. Water turning into ice can break the structure of the insulating material.

- High level of resistance to compression processes. Significant soil pressure is exerted on the foundation, and for the insulation it is important that this factor does not affect the change in its properties.

- Immunity to the influence of harmful microorganisms. If the heat insulator is susceptible to the appearance of mold and mildew, then it can quickly collapse under their influence. In addition, the material should not attract rats, mice and harmful insects.

The cost of activities for thermal insulation of the foundation will largely depend on the conditions of the work. In particular, on when the work is being carried out - in the process of building a house or already during the operation of the building. In addition, the variety of the selected material matters. The main ones are:

- polyurethane foam applied to the surface by spraying;

- heat insulator in sheets - foam, mineral wool, foam, extruded polystyrene foam;

- inexpensive insulation applied by filling method - expanded clay in granules;

- thermal panels are a relatively new material consisting of several layers, which includes: finishing cladding - plaster or facing tiles;

- applying "warm" plaster;

- backfilling a layer of clay or soil.

Insulation of the basement with foam

For convenient filling of the foundation with expanded polystyrene, it is better to purchase ready-made slabs from the appropriate material. They are installed using adhesives or mastic.

Expanded polystyrene perfectly retains heat and resists moisture. However, it is often gnawed by mice and rats, which forces them to install a mesh-netting outside the thematic insulation.

«>

Do you need steam and waterproofing for insulation

Isolation of the foundation from moisture is the most important condition for building a house. This measure prevents rain and melt water from contacting the substrate. Otherwise, dampness of the walls, basement and basement of the building will inevitably occur, as well as the accompanying phenomena - the development of fungus and mold, the destruction of concrete.The measure is especially relevant for areas with frequent precipitation, especially if the building is built in a lowland or on soil with a high level of groundwater.

We offer you to familiarize yourself with the oven for a brick house with your own hands

All of them are effective provided that the tightness is maintained.

Insulation of the strip foundation

It is better to insulate a shallow strip foundation with foamed polystyrene or polyurethane foam.

- A trench is dug along the perimeter of the foundation to the level of the pillow. Its width is equal to the thickness of soil freezing 5 cm.

- The foundation is waterproofed with mastic or bitumen-based roll insulation.

- Insulation on top is covered with a film or geotextile. This is to prevent damage to the material when the soil swells.

- Insulation plates are attached to the foundation using glue or the same bitumen mastic. An alternative is to use a burner, with which the material is melted in several places and pressed against the surface of the foundation. The final fixation is carried out using dowels.

About the methods of warming the foundation

All existing methods of insulating the foundation of a private house are divided into two groups:

- performed before pouring the base;

- carried out with an already finished building.

When the house has already been built, it is better to insulate the foundation from the inside.

Since the winters in our country are frosty, it is customary to insulate the foundations both outside and inside. In addition, the concrete used for pouring has practically no thermal insulation. Directly during the construction of a house for insulation, materials are used that are installed in the formwork, or non-removable shields. They are much more expensive than conventional ones, but in the end, the cost of all construction work is lower.

It is much more difficult to properly insulate the foundation of a finished private house. If the owners, wishing to save money on construction, ignored the importance of the depth of its occurrence, there are especially many difficulties, since the ground under the building will freeze harder.

In such cases, the foundation is dug in from both sides, after which insulation materials are laid.

Advice! To exclude freezing of the basement floor, it can be sprinkled with expanded clay. It is also better to insulate the ceiling above the basement, because when the groundwater rises, the ground under the dwelling lets in more cold.

The most common ways to insulate foundations:

- earth insulation;

- insulation with expanded clay;

- insulation with expanded polystyrene.

Insulation of the foundation with earth

The earth is an inexpensive material, therefore, it is possible to insulate the foundation with its help without significant costs. The essence of the method is that the earth is filled up to the level of the intended floor in the house. In this case, the entire foundation of the dwelling is under it.

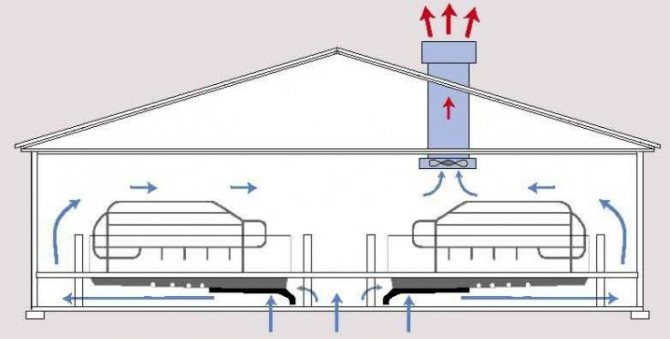

Important! With this method, basement air ducts must be brought up in advance.

An obvious disadvantage of earth insulation is its low thermal insulation characteristics. Nevertheless, if the foundation is buried, freezing of the house through the floor can be excluded by the basement from the inside.

Warming with expanded clay

To insulate the foundation from the outside, choose high-quality materials.

This method is considered traditional. Cheap and quite effective, it is very popular today. In addition, the expanded clay insulation method can be combined with earthen insulation.

Before the foundation is poured with cement, expanded clay is laid inside the formwork. Thus, both walls and floors can be insulated. The uniqueness of expanded clay lies in its porosity, which does not allow the material to pass moisture and cold, retaining heat very well. Its losses arise only because of the cement that gets between the granules. That is why expanded clay is often used for floor insulation with a shallow foundation.

Important! If the foundation of a private house is insulated after pouring it, it is better to use the lightest formwork, since the expanded clay itself has almost no weight.

Slate, which is very easy to install, can be excellent for shields.

The minus of expanded clay is high fragility. To insulate the floor with it, mineral wool and a film are laid on top of a layer of insulation as moisture protection.

Warming with expanded polystyrene

Expanded polystyrene is a truly professional insulation. It is used by those who want to completely eliminate heat loss through the foundation and floor. Expanded polystyrene is sold in whole plates, but little tricks are often used to install it.

Advice! Before fixing the slabs to the surface of the foundation of the house, waterproofing should be applied to the touch points and its side parts. Its thickness is determined by the type of foundation, its depth and thickness.

Expanded polystyrene boards are laid from the bottom of the foundation to the level where the floor begins. The seams between them are filled with polyurethane foam.

Advice! In order to better insulate the base, it is better to place the plates as close to each other as possible.

Important! The surface insulated with expanded polystyrene should be covered with a cladding to exclude the harmful effects of ultraviolet radiation.

Step-by-step instructions for insulating the basement with polyurethane foam

The key difference between this insulation technique is that there is no need for an additional waterproofing layer. Read the procedure carefully.

- When insulating the basement with sprayed polyurethane, the surface must be treated with an antifungal primer. The material is applied to the concrete surface in several layers, the thickness of which is from 50 to 80 millimeters.

- The drying process of the polyurethane foam takes only a few seconds.

- Coatings that have been treated with sprayed insulation on top must be additionally processed. This need is due to the peculiarity of the heat insulator to tolerate poorly the effects of direct exposure to ultraviolet rays.

- It is recommended to cover the insulated surface with a layer of reinforcing mesh, plaster and then finish with the final finishing material.

Watch our video on choosing thermal insulation

Thermal insulation keeps the base from freezing and mechanical damage

Such a structure will last much longer without major repairs. Condensation does not form on the walls of the insulated basement, this saves building materials from premature destruction.

Internal insulation has a similar function. As practice shows, external and internal insulation has the same result. The difference between them is only external.

Insulation of a columnar foundation

To insulate such a foundation, a zabirka is created - a special type of base in the form of an interlayer between the ground and the foundation, which protects against moisture and temperature extremes. A pick-up is created in several stages:

- They dig a trench 20-40 cm deep.

- The trench is covered with rubble or sand by one third.

- Beams with grooves are attached to the pillars of the foundation.

- Special thin boards are inserted into the grooves.

- The lower part of the structure is filled with expanded clay.

In what cases is PPU insulation preferable?

In terms of energy efficiency, polyurethane foams are better than polystyrene, but the low cost of the latter makes it possible to compensate for the properties due to an increase in thickness. On the other hand, there are some technological factors that make the use of PU foam advisable.

Unusual foundation relief

There is a main disadvantage of polyurethane foam insulation, namely the formation of voids between the mounting surface and the insulation. There is a high probability that moisture will enter these voids and create unaccounted cold bridges. In addition, large differences in plane do not give a chance to make facing of certain surfaces without installing complex battens. These objects include stone foundations in old buildings.The issue of insulation is of particular importance if the building belongs to architectural monuments.

Preparation before application

To do insulation with polyurethane foam, a number of preparatory work is required. They will help to significantly increase the efficiency of insulation and extend the life of the insulation. It is necessary to determine in advance which ones and where the insulation work will be carried out. Remember that insulation is carried out not only in the above-ground part, but in the depth, on average, they take about 1 meter of the underground part and 0.5 meters from the top.

After that, it is necessary to make a trench around the building so as to make room for work. It should be 1 meter deep and 0.7 meters wide. The second indicator is individual, as it is necessary to free up space for work.

After that, you will need:

- Remove plants and dirt from the foundation.

- Repair or remove crumbling foundations.

- Dry the work surface.

Yes, first you need to get rid of the fungus, dirt and plants that are on the surface of the foundation. After that, check the foundation for cracks, crumbling parts and chips. Although polyurethane foam can be applied to any surface, the reliability and uniformity increase the material's life.

After that, dry the foundation well. To do this, leave it for 3 days, provided the weather is good and there is no precipitation. If this requirement is not met, you will have to use special equipment.

Please note that polyurethane foam is poorly taken on a damp surface, which can give a bad result in the form of a thin layer of air between the insulation and the foundation, and this, in turn, will contribute to the formation of condensation.

At the top of the foundation that you will be insulating, make a frame for the cladding. Since it is not possible to apply facing materials to polyurethane foam, a metal crate is required, on which the panels will be installed afterwards.

Life hack: since the insulation is associated with digging the soil and drying the foundation, such work is best done in the summer.

Now all significant irregularities will be even. Sometimes it makes sense to do a full recovery before starting. This will make it possible to use insulation more efficiently and increase its service life.

After preparation, cover the foundation with a protective compound. This will remove microorganisms, improve adhesion, and extend the service life. After that, cover the foundation with bitumen in two layers. Although the insulation itself protects well from moisture, a layer of bitumen does not hurt.

Insulation of the pile foundation

Many are interested in how to insulate the pile foundation of a wooden house. A feature of buildings with this type of foundation is the presence of an air gap between the base and the soil, which, in the absence of thermal insulation, leads to significant heat losses. Therefore, the insulation of the pile foundation from the outside is a necessary measure, on which the comfort of the residents of the house depends.

- Before insulating the pile-screw foundation, waterproof the grillage.

- Install the insulation of the screw foundation.

- Finish the outer insulation layer.

Insulation of the base of the pile-screw foundation is carried out mainly with foam. Also, when insulating the pile-screw foundation of a wooden house, great attention is paid to high-quality waterproofing.

Insulation of the foundation of multi-storey buildings

With the help of polyurethane foam, not only private households are insulated, but also apartment buildings. This material is sprayed on any type of foundation for high-rise buildings - slab, pile, tape, combined. Nowadays, this is done already at the construction stage. For such work, only high-density closed-cell polyurethane foam is used.

But buildings built many years ago do not have such insulation, so it has to be carried out separately. Insulation is applied to the outside of the house wall and inside the basements. Dried and hardened polyurethane foam is covered with facade plaster or other finishing materials.

The work is carried out at a temperature not lower than 5 degrees in dry, calm weather. Since the spraying rate is quite high, it is possible to insulate the entire foundation of even a large house in one or two days.