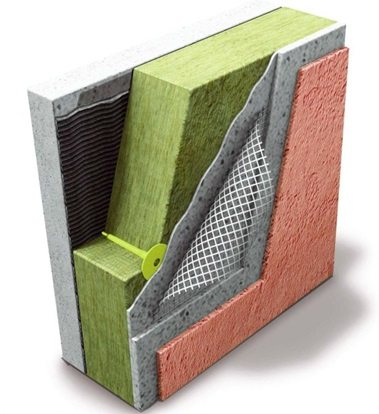

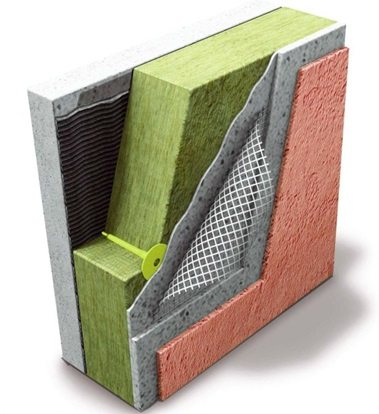

Plan of stages of work on the system of facade insulation with a thick plaster layer

- Preparatory work

- Installation of scaffolding

- Removing attachments

- Preparation of window openings

- Installation work

- Mounting fixing system

- Installation of mineral wool boards

- Installation of metal tiles

- Base coat application

- Application of a leveling plaster layer

- Applying a decorative layer

You can start cutting the expansion joint after applying decorative plaster. Cutting occurs along the corners of the building at a distance of 250 mm, along the surface in squares of 15 * 15 m.Produced by an angle grinder with a diamond disc

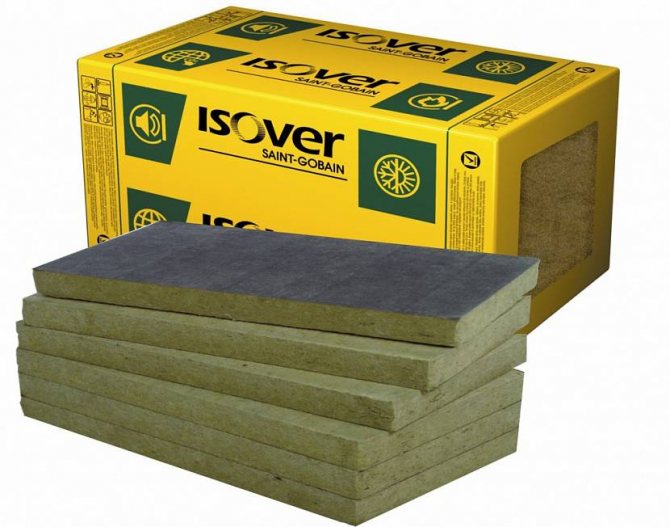

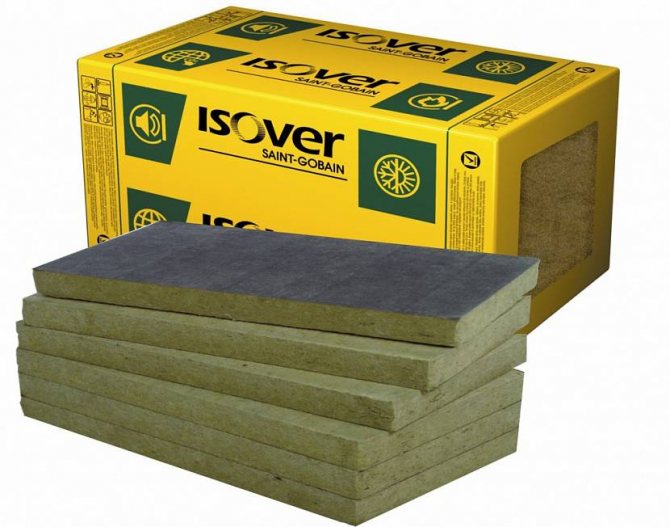

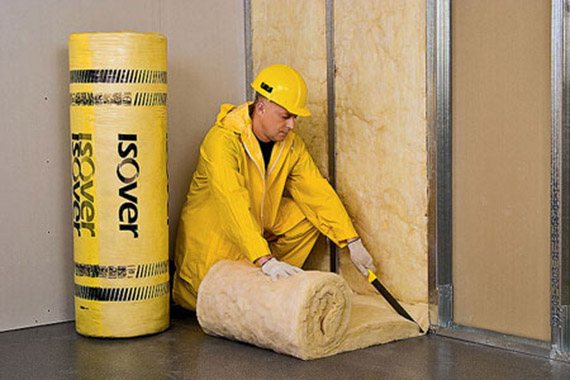

Isover. Which insulation is better: in slabs or in rolls?

Isover. Which insulation is better: in slabs or in rolls?

In this video you will find out which insulation is easier to work with: in slabs or in rolls. The main characteristic showing the quality of the insulation material is its recoverability. High-quality material has the ability to recover to the declared size after opening the package, which was demonstrated in the video. The thickness of the Isover insulation both in slabs and in rolls after opening the package was restored to 50 mm. To install the insulation in the slabs, it is necessary to measure the distance between the frame posts. Plates are ideal for wall insulation with a standard distance between the frame posts - 600 mm. When installing the slabs, joints are formed, which must be covered with a second layer of slabs. It is better to use insulation in rolls with a non-standard step between the frame racks. First, the distance between the posts is measured, then the unpacked roll is cut to the required size and rolled out along the entire length of the wall. When insulating with rolls, no joints are formed. All Isover materials are highly resilient and adhere to the structure.

Isover: How safe are thermal insulation materials?

Stamps

Isover thermal insulation product lines have several dozen items and are designed to solve specific problems. All of them differ in the form of delivery, thickness, density and size.

For general construction works

Isover Profi. A versatile material with increased elasticity. Provides the highest level of thermal insulation among the brand's retail materials.

Supplied in rolls, board thickness - 50, 100 and 150 mm. It does not require additional fasteners during installation; a raspor can be installed. Has earned positive reviews from builders.

It is used for insulation and sound protection:

- external walls from inside and outside the house;

- pitched roofs;

- interfloor ceilings;

- frame walls;

- internal partitions;

- ventilated facades.

Classic. Supplied in rolls, material thickness - 50 mm. A surprise can be set.

Application area:

- insulation of suspended ceilings;

- interfloor floors - the material lies between the lags;

- attic rooms.

Izover Classic stove. The shape of the mineral wool is a plate. Size - 610 * 1170 mm, thickness 50 and 100 mm. Packaged 5 and 10 m2.

Application area:

- insulation of frame walls;

- wall insulation from the inside;

- insulation of ventilated facades.

Izover kl 34. The form of release is a plate with a thickness of 5 and 10 cm. Does not require additional fasteners during installation.

Application area:

- ventilated facades;

- frame walls.

Izover kl 37. Release form - plate.It is used for insulation and sound protection of roofs and floors.

Izover kt 40. Two-layer roll material. Thickness - 10 cm, each layer 5 cm. It is used for insulation of horizontal surfaces.

Isover Sauna. Supplied in rolls, mat thickness 50 and 100 mm. The main feature is the presence of a vapor barrier layer. Suitable for rooms with high humidity. Refers to medium combustible materials. It is used for insulation of walls, floors and ceilings in baths and saunas.

Izover Uteplyaev. Universal mineral wool, available only for Siberia and the Far East.

Special solutions

In the Isover product line, there are special insulation materials with characteristics optimized for specific tasks.

- Izover Pitched Roof. Has increased moisture resistance.

- Sound protection. Provides a high level of noise protection.

- Frame P32. Designed for thermal insulation of frame houses. Provides heating cost savings of up to 25% compared to the base product.

- Frame M40-Al. Mineral wool with one-sided aluminum coating. Designed for wet rooms, can be used without additional finishing.

- Izover Plaster Facade. High density material with low vapor permeability.

- Vent Facade Top and Vent Facade Bottom. They are used for two-layer thermal insulation systems for ventilated facades.

- Floating Floor. Designed for insulation and sound insulation of the floor. Has increased elasticity and density. It is made using the thorn-groove technology.

- Izover OL-P. Special solution for flat roofs. Has ventilated grooves for moisture removal. It is made using the thorn-groove technology, which increases the tightness of the mineral wool layer.

Isover: How safe are thermal insulation materials?

In this video, you will learn how safe the use of mineral wool is for your health and the health of your family. The safety of mineral wool has been confirmed by ecolabels, as well as studies in large scientific centers, such as, for example, the Institute of Hygiene named after Sysina. In addition to these guarantees, Isover provides an environmental declaration for its products. Thermal insulation based on mineral wool is used in all buildings and structures, including kindergartens, schools, hospitals. Another sign of the absolute safety of mineral wool is its incombustibility and fire safety, which is confirmed by certificates of compliance with fire safety requirements.

Isover: Which insulation is better: stone wool or fiberglass?

Isover: Which insulation is better: stone wool or fiberglass?

Isover is the only Russian company that produces mineral wool based on fiberglass and stone wool. The basis of stone wool insulation is molten rocks, and the basis of fiberglass insulation is sand and cullet melted at 1000 ° C. Materials based on stone fiber are denser than materials based on fiberglass, which is primarily due to the length of the fibers in the production of the base for the insulation. But density is not a determining parameter when choosing a heater. The main characteristics are thermal conductivity and mechanical characteristics. If we compare materials by field of application, insulation based on both types of mineral wool is divided into three types: Light grades are used in frame structures, for insulation of walls, pitched roofs. Such insulation does not take on any load. Rigid grades are used in plaster facades, flat loaded roofs. Highly specialized materials are used for soundproofing partitions and for insulating saunas and baths.Materials based on fiberglass are lighter than materials based on stone wool. Due to the length of the fibers, they have greater elasticity, which allows filling all irregularities and voids of the insulated surface, eliminates the formation of "cold bridges" and ensures reliable fixation in the structure. Both types of materials are non-combustible materials, do not spread or sustain combustion. Now that you know the differences between the two types of mineral wool, you will make the correct and objective choice of thermal insulation material for your home.

Isover: Is the density of insulation materials important?

Characteristics and scope

The material is produced in slabs and rolls and is characterized by high thermal efficiency, elasticity, density and light weight. Refers to non-combustible materials.

The main competitors in the mineral insulation market are Ursa, Izovol, Rockwool, Park, Knauf. Isover mineral wool has a wide range of applications in general construction works. For industrial work, the Izover company produces insulation under the Izotek brand.

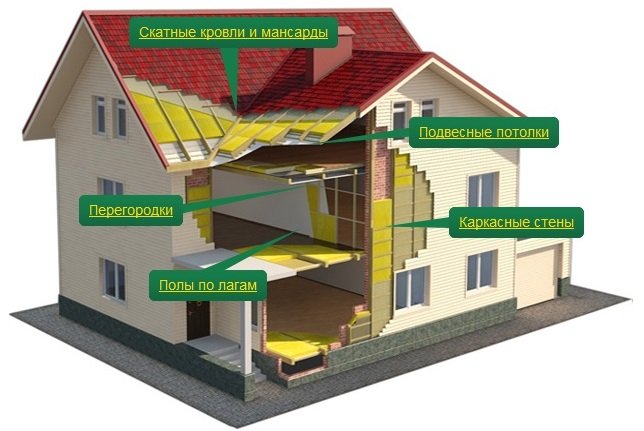

Isover is used for the following types of work:

- thermal insulation and sound protection of external walls;

- insulation of roofs;

- ventilated facade systems, multilayer walls;

- for sound insulation of internal partitions;

- in industry - for thermal insulation of pipelines, ventilation, etc.

Izover, like other insulation, has its own advantages and disadvantages.

The pluses of Izover include:

- Convenience of transportation and storage - the manufacturer compresses the insulation 5-6 times when packing it. Izover 100% restores its shape.

- Product lines with different technical characteristics, designed for different areas of construction. For example, Isover Soundproofing or Isover Pitched Roof.

- High elasticity. The insulation surpasses other mineral wool in this indicator, thanks to the special TEL technology, according to which it is produced.

- High energy efficiency - 5 cm of mineral wool is equal in thermal conductivity to 1 m of brickwork.

- Refers to non-combustible materials. The use of mineral wool for thermal insulation of a house does not increase its fire hazard class.

- Noise protection. Due to the fact that there is air between the fibers of the insulation, it does not transmit sounds well.

- The manufacturer's declared warranty period is 50 years.

- Resistant to biological and chemical attack.

- Light weight - 28-60 kg / m3.

- It is convenient to work. To insulate the surface, you just need to roll out the roll.

- Does not shrink during use.

- Environmentally friendly material. Holder of EcoMaterial Absolute ecolabel and ISO 14001: 2004 International Environmental Management Certificate.

- Heat resistant.

- High density and stiffness, which allows you to mount the insulation without additional fasteners.

The disadvantages of Izover include:

- The soft structure of cotton wool limits the scope of its application.

- Absorbs moisture well. A ventilation gap is required during installation. If it is not done, cotton wool can become saturated with moisture and lose its technical characteristics, and even freeze completely in winter.

Isover: Is the density of insulation materials important?

Is the density of mineral wool insulation a decisive characteristic when choosing a heater? You will find the answer to this question in this video. The density of the insulating material affects the coefficient of thermal conductivity, strength characteristics and other parameters. But this relationship is not linear. The dependence of the thermal conductivity coefficient on the density of the material is the same for fiberglass and stone wool. For fiberglass-based insulation, the range of optimal density that provides the minimum thermal conductivity is 25-35 kg / m3. For insulation based on stone wool - 45-55 kg / m3. Thus, stone wool is able to provide the same thermal insulation characteristics, but at higher densities.Remember that by purchasing thermal insulation materials, we acquire the thermal insulation qualities of the product, not its density. Even a lightweight fiberglass insulation board with a density of 60 kg / m3 is able to withstand heavy loads without deformation. Therefore, when choosing a heater, first of all, pay attention to the coefficient of thermal conductivity, durability, incombustibility and environmental friendliness.

Basalt heat-insulating plate of the Optimal 50 series, as deservedly received this name. This is really the best option for solving most of the problems with the insulation of various buildings, structures and their individual elements.

This insulation balances between good insulation efficiency and the comparative cheapness of the material itself (the Ventfasad series also has similar characteristics).

Heat insulator "Izover Optimal

«

And for those buyers who find the scope of application of the Optimal 50 series too narrow, the manufacturer has provided a modified and more efficient version with the name Isover Ruf N Optimal 50. However, it is the classic insulation "Isover Optimal" that has gained immense popularity.

Main operational characteristics of Isover Optimal slabs

- Resistance to stress and deformation. The density of the material is in the range of 28–40 kg / m³. Due to this, the plates retain their geometric shape throughout the entire period of operation.

- Excellent thermophysical parameters. The insulation has a low thermal conductivity - no more than 0.042 W / (m * K). This significantly reduces heat losses.

- Low water absorption - no more than 1 kg / m² at partial immersion in 24 hours.

- Fire resistance. The material belongs to the group of non-combustible insulation materials.

- Noise absorption. The fibrous structure effectively traps sound waves.

Isover for roof insulation

The number of materials for thermal insulation is constantly growing. More and more consumers are realizing the need to insulate walls, roofs and foundations of private houses and other buildings. The technical characteristics and advantages of Isover insulation induce some to use this particular material. What he really is? What are the advantages and properties?

What is Isover insulation?

This insulation is represented by mineral wool - a fibrous material that is made in the form of slabs, rolls and mats. The thickness of the glass fibers is 4-5 microns, and the length is 100-150 microns. For production, only natural ingredients are used, so there is no need to worry about the environmental friendliness of the material.

Plates can be rigid or semi-rigid. Insulation is mounted both horizontally and vertically, both during interior work and when arranging facades.

Isover

It is made from sand (quartz) and broken glass. To improve certain properties, soda, borax, limestone and other components can be added to the material. The entire mass is poured into a special hopper. The process of melting the ingredients takes place there. When molten glass is ejected from the centrifuge, it forms strands due to the blowing of the steam. When hitting the rolls, the aerosolized filaments flatten out and form a carpet. Then, at + 250 ° C, the polymerization process takes place. When the material cools down, it is cut into rolls, mats and slabs.

What is isover

Isover is a material that is used to insulate flat surfaces. It is produced by the French. The name of the insulation comes from two French words "isolation" - isolation and "verre" - glass. It explains what it is made of. There are two forms of French insulation on the domestic market. There are slabs and rolls. They are formed with fiberglass and basalt wool. Each variety has its own specifications. They define the scope of use.

The basis of the material is fiberglass and basalt wool fibers.When making slabs or rolls, recycled soda, limestone and sand are added. The use of recyclable materials allows you to reduce the cost of the finished product, so French insulation has a very affordable price.

Insulation in the form of slabs Source obustroeno.com

Isover manufacturing technology is extremely simple:

- The listed Components

recyclable materials

are mixed

among themselves, to them

are added

others

minerals

, mix

heats up

up to 1300C and

convertedinto plastic mass

similar to

liquid glass

. - She is poured into the tank

... Within its walls there is

microscopic holes

. - Capacity unwinds

how the drum spins

with high speed

... Centrifugal force pushes the loaded substance through microscopic holes. In this manner

the finest threads are formed

. - The threads are mixed with a special adhesive composition

... A viscous mass is formed.

- She goes to drying oven

.

- There the workpiece goes through the rollers

... With the help of them

formation is forming

. - At the finishing stage, he is cut into the required

dimensions

... The maximum possible dimensions are 610x1170 mm, the thickness of the slab can vary from 5 to 10 cm.

Specifications, advantages and disadvantages

Since insulation is the main role of Izover, it is worth paying attention to its thermal conductivity. The coefficient of thermal conductivity is within 0.038 W / (m * K). Other advantages include the following factors:

- Good soundproofing. Using mineral wool in the interior partitions, you can achieve a good effect.

- It is not eaten by rodents and insects. Therefore, using such material for the facade, you can not be afraid that subsequently holes from rodents will appear in it.

- Ease of installation. This material is produced in various forms, so you can choose the one that will be optimal for the work being done.

- Long service life - 50 years.

- The material does not deform in compression and has tensile strength. Thanks to its good compressibility, it is easy to transport.

- Resistant to extreme temperatures.

- The insulation is not flammable, therefore it meets the high fire safety requirements.

Ceiling insulation

Disadvantages of the material:

- The need to use protective equipment during installation work. Although over time there will be no harm from mineral wool, when installing thermal insulation, it is necessary to protect the respiratory system.

- High moisture permeability. When wet during operation or during installation, heat-shielding properties will be lost. Therefore, when doing facade work, the mineral wool must either be covered or covered with a layer of plaster as soon as possible after installation. This will prevent the harmful effects of rainfall.

Safety precautions when working with mineral wool

Existing varieties and scope

The French concern "Saint-Gobain" produces various types of insulation. Nine types of isover are most popular on the Russian market:

- Thermal insulation

isoverKL34

- unpressed plates, which have a very wide range of applications, are used to insulate any

vertical

and

horizontal surfaces

... For installation, it is being constructed

wooden lathing

... Plates are inserted inside it without additional fastening. - Isover

KL37

- pressed plates laid in

packaging

... Used for insulation

slabs

between two

adjacent floors

,

interior walls androof slopes

.

Important!

When installing, the slabs must be pressed tightly against each other.

Scope of use of different varieties of isover Source www.tproekt.com

- Isover

CT 37 -

roll thermal insulation. It is used for insulation

horizontal

surfaces. Isover of this form of release can also fit on the walls, but only if it is necessary to insulate

internal partitions

. - Isover

CT 40

- two-layer rolls used for insulation

ceiling and floor

. - Isover

«STYROFOAM» 300A

the material to which the structure was added

expanded polystyrene

... These are slabs

increased rigidity

... They are attached to the surface using plastic dowels or special adhesives based on bituminous mastics. - Isover

«VENTITERM»

- plates, processed additionally

water repellent

... This is a new product, it is still conquering the market. Its scope is insulation

facades

, carried out using the installation of one-layer or two-layer systems. - Insulation

isover"Pitched roof"

- material intended for insulation

rooftops

,

to improve sound insulation

premises. It is produced in the form of plates with dimensions 610х11700 mm, 10 cm thick. The material has high elasticity and elasticity, therefore

Warming plus sound insulation Source e-teplo.kz

On our website you can find contacts of construction companies that offer a roof repair service, installation of windows and doors, house insulation. You can communicate directly with representatives by visiting the Low-Rise Country exhibition of houses.

- Isover

"Sound protection"

- material intended for soundproofing premises. It is produced in the form of plates with a thickness of 5 cm, can be used in any climatic zone. With it, you can improve the sound insulation of the roof, internal and external walls. - Isover

"Ventfasad"

- two-layer plates intended for insulation

ventilated facades

.

The choice of French insulation has its drawbacks. They must be taken into account when buying insulation. Since it contains fiberglass, it is possible to work with the material only with the use of protective equipment. Gloves should be on the hands, long-sleeved pants and a jacket on the body, glasses on the eyes, a gauze bandage on the face. If this safety precaution is ignored, any contact with mats or rolls will cause severe skin irritation.

Safety regulations Source bg.decoratex.biz

During operation, dust may be emitted from isover. Particles of fiberglass will certainly be present in its composition. Their ingress into the human body can provoke the development of diseases. Therefore, when carrying out internal insulation, it is important to cover the material before laying the topcoat (lining, drywall) with a vapor barrier film.

Isover cannot boast of high mechanical strength, it is not able to bear the load, therefore, improper installation often leads to deformation of the finish. Such defects are often used by insects and mice for colonization.

If the boards have not been additionally treated with water repellents, they will absorb moisture well. It lingers for a long time in the inner layers, which is why the properties of the material change.

On a note!

With an increase in the moisture content of fiberglass by 1%, the thermal insulation decreases by 10%.

Isover slabs laid inside a metal lathing Source tues.ru

It could beinteresting!

In the article at the following link, read about front thermal panels with insulation for exterior decoration of the house: types and prices.

Isover laying technology from inside the walls

For laying the mats, it is necessary to construct a crate. This can be done using a wooden beam or metal profiles used for laying drywall. The step of the lathing should be one centimeter narrower than the width of the insulation. Due to their high elasticity, the boards can be easily inserted into the space between the two guides and adhere very tightly to the surface.

From above, the insulation must be covered with a layer of vapor barrier. The film is overlapped, the joints are additionally fastened with a special vapor barrier tape. From above, such a structure can be sewn up with drywall or immediately mount the lining.

Types of Izover

Due to the wide variety of forms, Isover mineral wool is used in various fields.When building a house, it can be used to insulate ventilated facades, attic, floors, ceilings and internal partitions. Each model has its own purpose and is used in a specific area, so it is difficult to give a general description of the material. You can still consider each species separately.

Isover Optimal

Its density is 28-37 kg / m 3. It comes in the form of slabs. It is used for a frame house. They can insulate the roof, floors, and walls. It is used as sound insulation for interior partitions and floors between floors. The dimensions of the slab are 60 * 100 cm, the thickness is 5 cm or 10 cm. One package contains 4 slabs (10 cm) or 8 slabs (5 cm).

Isover Roof V Optimal is produced in a thinner thickness of 3 or 5 cm. In most cases it is used for flat roofs. Despite the small thickness of the material, its structure is homogeneous. It can withstand a load of 7 tons per 1 m 2.

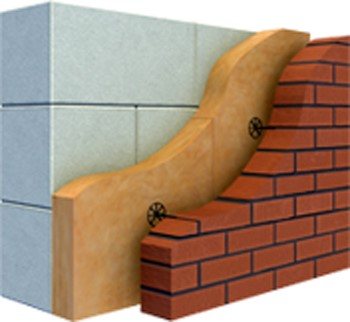

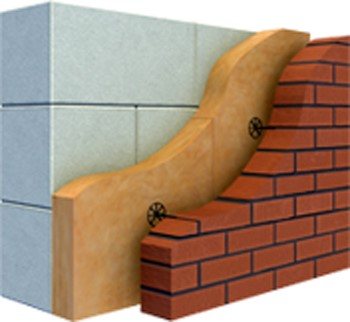

Isover Standard

This model is used for thermal insulation of facade walls before cladding with siding or facing bricks. They are also sheathed with frame structures. They are produced with the same dimensions as the Optimal series mineral wool. Among its characteristics, it should be noted low compressibility under a specific load of 2 kPa - 10%. The density of the Isover Standard slabs is 50 kg / m3.

Isover Venti

This product is intended for thermal insulation of ventilated facades, and there is no limitation on the height of the building. This is achieved by the fact that this material has a high mechanical strength. It is also produced in slabs of 60-100 cm in size with a thickness of 5 or 10 cm. The density of the material is 85 kg / m3. Due to its high vapor permeability, moisture effectively escapes from the structure. Like other mineral wool materials, Izover Venti does not burn.

Izover for ventilated facades

The model range of Izover Venti Optimal has slabs with a thickness of 3 to 20 cm. This allows you to choose the most suitable solution for each insulated facade.

Izover Facade

This range is used to insulate plaster facades. If stone plaster is chosen as the finish and the insulation will need to be covered with a thin layer of plaster, then this option must be chosen. The thickness of the produced slabs ranges from 5 to 20 cm, width - 60 cm, length - 100 cm.

Density characteristic of Izover Plaster Facade - 145 kg / m 3. For a simplified and accelerated installation of such plates on the surface of the walls, this material is produced with other geometric dimensions - 60 * 120 cm.

Isover for plaster facades

Isover Light

It is used in various fields - interior partitions, suspended ceilings, ventilated facades and frame structures. Izover Light has increased elastic properties of the slab. The density of the material is 38 kg / m³. During operation, it does not undergo shrinkage or deformation.

Isover Classic

It is used for thermal insulation of floors and ceilings and is laid between the joists. Isover Classic is produced in rolls, and during transportation the mineral wool is compressed 6 times. Density - 11 kg / m 3. The width of the roll is 122 cm, in it the material is folded into two layers of 5 cm each, so during installation it is easy to choose the required thickness of the insulation. Since the width between the joists can be 60 cm, the mats are cut lengthwise into two pieces of 61 cm wide and fit tightly between the boards.

Thermal insulation of floors

Isover Sauna

This model also has a vapor barrier. The presence of a foil layer makes it possible to save the high temperature of the sauna for a long time. It will also save time on installation work, since two stages are performed at once and there is no need to install additional films or membranes. The thickness of Izover Sauna is 50 or 100 mm. It is used to insulate not only walls, but also ceilings in baths.

Isover Master of Acoustics

It is used wherever acoustic insulation is required.It comes in the form of stone fiber based mineral wool slabs. It is used for external walls, interior partitions, floors and ceilings, that is, wherever high-quality sound insulation by Izover Master may be needed.

Isover Flor

Such insulation is used to protect against impact noise. It reduces the noise level by 35 dB. Isover Flor is produced by the manufacturer in the form of rigid slabs with dimensions of 60 * 120 cm and a thickness of 3-5 cm.

Isover Profi

This is the warmest material among analogues. It is produced in rolls and is used in many inclined structures, for example, for roof insulation, plasterboard partitions on a metal frame. Izover Profi is also used before finishing the facade with siding or facing bricks. The thickness of the rolls is 5, 10 or 15 cm. The roll length is 4-5 meters.

There are other varieties of this insulation. Thanks to this variety, you can choose the most suitable material for high-quality performance of thermal insulation work. You can also choose the thickness and dimensions of the insulation. Correctly carrying out all the work, you can significantly save heating costs and provide comfortable conditions in the room.

Today, isover optimal insulation is very popular among a huge layer of people. People are going to buy isover optimal insulation, as it has an amazing number of well-known features, among which it is necessary to emphasize the ease of installation, low price and effective protection from the cold. Isover optimal insulation is simply irreplaceable in the design and creation of heat-insulating coatings for walls and roofs of premises. It does not get wet and does not rot, and is not able to absorb moisture. Mold and rot are also not terrible for such a material as isover optimal insulation, since it has the necessary impregnation.

Insulation isover optimal: application and use

Where can Isover Optimal be used? Walls, roof slopes, ceilings - all these parts of buildings and apartments simply cannot be effectively insulated without the described material. It has good flexibility, and installers can easily change its size and shape, depending on the wishes of the client. Floor slabs are also often protected with this material.

Advantages and disadvantages - isover optimal insulation

Let's designate the greatest distinguishing features that the isover optimal insulation can boast of. Of course, the main quality, which is why isover insulation is optimal and is known, is its efficiency in keeping warm. Complete sealing of the building with heat loss is an obvious result of the use of isover optimal insulation. In addition, the isover optimal insulation is completely environmentally friendly: it is non-flammable and does not form harmful substances. During production, to achieve these goals, certain types of additives are used that make the isover optimal insulation safe. In addition, this material completely deprives you of sounds from the street. You are also not in danger of mold because of the water-repellent qualities of this material and its structure. In addition, the isover optimal insulation is coated with bactericidal additives that prevent fungi and mold from appearing.

Characteristics

The basis for the production of all thermal insulation materials of the brand is the patented TEL technology, which uses fiberglass in the production and gives the Isover insulation unique operational and technical characteristics that allow the thermal insulator to be used as a heater in professional, private construction, as well as for pipes.

The group of basic properties includes:

- low coefficient of thermal conductivity (0.041 W / m * K), which does not increase over time when compared with other types of heat insulators, because the fiberglass of the insulation perfectly retains air, and therefore heat; 5-6 cm of insulation can be compared with one meter of brickwork;

- high sound insulation, achieved again due to air interlayers between the fiberglass, therefore, in a room insulated with an appropriate thermal insulator, the penetration of noise from the street is excluded;

- flammability degree; whether the insulation burns can be determined from the corresponding GOST, as a rule, materials with a density of less than 30 kg / m3 belong to the NG class;

- resistance to moisture is one of the most important indicators of any thermal insulator, the certificates of conformity indicate a value of 25-40 m / m * cPa with the correct arrangement of the air gap during installation;

- moisture absorption is no more than 1 kg per square meter of insulation, provided that it is placed in an aquatic environment for one day;

- different density of materials of the manufacturer's line; this property makes it possible to insulate various parts of the premises using the product differentiation method;

- environmental safety, since the production does not use components hazardous to humans and the environment; this fact was repeatedly confirmed by various medical commissions, the composition of which consisted of doctors from different countries;

- low weight of the product gives additional advantages during its transportation and installation; can be easily used to insulate building structures made of insufficiently strong materials, which means that they are not able to withstand a large mechanical load;

- prevents various effects of a chemical or biological nature;

- impressive (up to 50 years) operational life; having insulated the room with this heat insulator once, you can forget about heat loss through the walls, ceiling or floor for many years;

- various form of release, so for each specific case it is very easy to select the appropriate type of material

All of the above general characteristics apply to each brand of insulation in the assortment line, but there are differences between them. Below is a little more detail about each "representative".

Isover Optimal

Belongs to the category of universal materials based on basalt fibers. Isover Optimal is widely used for thermal insulation of individual structures of frame houses, with the exception of the foundation. This brand perfectly combines high elasticity and low thermal conductivity, incombustibility, ease of installation and the possibility of multifunctional use.

Insulation Isover Optimal

Isover Profi

It is made of fiberglass in the form of mats, but rolled into rolls. Similarly to the previous brand, it is a universal type of insulation, which means that it can be used to insulate various elements of the building frame: roofs of various geometries, walls, both inside and out, floors, attic ceilings, ceilings, even suspended ones, as well as for additional sound insulation of partitions between separate parts of the premises.

Insulation Isover Profi

It has the lowest level of thermal conductivity of all heaters presented in the brand's line. In addition, special markings are applied to the boards to facilitate cutting during installation. The dimensions of the material allow for insulation with a minimum amount of waste.

Isover Classic

Due to the fact that this insulation is also universal, it is widely used as a heat insulator for various parts of the house. The only exceptions are the foundation and / or basement, as well as elements, the surfaces of which do not withstand heavy loads.

Insulation Isover Classic

Isover Classic is a fiberglass insulation, produced in the form of mats, which have a pronounced porous structure, which means they perfectly retain heat. But at the same time, it does not have sufficiently high indicators of strength and rigidity, therefore it is not advisable to use it under a screed or for walls that will subsequently be plastered.

Insulation Isover Extra

Product produced in the form of mats with increased elasticity with a 3D effect. This allows the insulation to unclench easily after compression and fill all the free space between, for example, wooden beams or metal profiles.

When insulating vertical surfaces, the material adheres tightly to the walls and at the same time connects to each other at the joints, which excludes the appearance of "cold bridges" that significantly affect the quality of insulation. It is worth noting that the 3D effect inherent in this product makes it possible not to additionally level the surfaces before starting installation work, since it has an excellent property - a snug fit.

It is in demand for internal insulation, roofing of various shapes, as well as for the facade, the finish of which will be siding, lining or decorative plate.

Isover Master

In production, basalt fiber (stone wool) is used as a basis, and it is supplied to the shelves of building stores in the form of slabs with different thicknesses. Izover Master is mainly used for thermal insulation of facade surfaces, the height of which is no more than 16 m, and thin-layer plaster is used as finishing.

Insulation Isover Master

Standard

Mineral wool of this series is intended as a heat insulator for surfaces that cannot withstand heavy mechanical loads. Isover Standard will be an excellent solution for do-it-yourself insulation of facades and walls made of various materials (brick, wood, foam blocks, concrete, etc.)

Isover Ruf

It is a two-layer insulation system. The mineral product Isover Ruf is able to significantly reduce heat transfer rates in a room for any purpose due to its two-layer structure. It has a balanced combination of physical and mechanical properties, is non-combustible materials, and is able to perfectly withstand significant operational loads.

Isover KT 40AL

Lightweight roll material made of fiberglass and additionally covered with polished aluminum foil, due to which it has increased heat-saving and vapor barrier properties. Isover KT 40AL is excellent for thermal insulation of baths, saunas, swimming pools and other rooms, the internal climate of which has a high level of humidity.

During packing and packaging, a roll of mineral wool is compressed five times, which greatly facilitates its transportation and storage, while it restores its original dimensions after unpacking in a matter of minutes.

Summarizing the description of all brands of the above brand, it is worth noting that Isover heaters are in no way inferior, and in some parameters even surpass the products of such companies as Knauf and Izorok (Isovent).

Pros and cons

Like any other building material, Isover heaters have a number of their pros and cons. The undoubted advantages of the product include all its technical and operational characteristics described above. And of the shortcomings, only the soft structure of cotton wool can be noted, narrowing the scope of application.