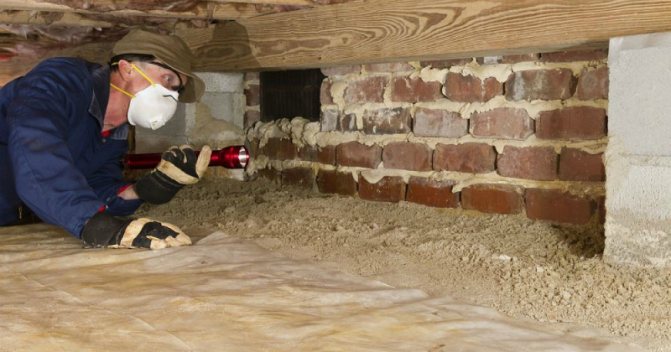

Basement waterproofing is one of the most important measures that can be carried out both at the stage of building a house and after its completion. The basement part is a kind of connecting link between the foundation and the rest of the building. Therefore, its strength, stability and non-susceptibility to various influences will determine the durability and reliability of all structures of the house. During the operation of the building, in particular, with the help of the plinth, the internal premises are protected from moisture penetration.

It should be noted that it is the outer part of the basement floor that is most exposed to moisture, therefore it is very vulnerable. The plinth takes on the influence of upstream water, groundwater, rain and other precipitation. There must be a reliable waterproofing and heat-insulating layer between the foundation and the upper structure of the building. This is how you need to make the basement of your house. Additionally, it is recommended to organize drainage of the site.

Insulation types

In order to reliably protect the base from moisture, it should be taken into account that the structures will have to be protected in two planes at once:

- Vertically. It is necessary to apply moisture-proof material on the outside of the walls.

- Horizontally. Moisture-proof materials are laid between the foundation and the outer part of the basement.

The horizontal waterproofing of the basement floor from the outside will exclude the penetration of moisture into the interior of the house. The waterproofing device in this case involves the use of roll materials, among which roofing material and roofing felt are more popular. It is best to choose roofing material, because roofing felt cannot provide long-term protection of the basement from moisture penetration.

The modern roofing material offered on the market is quite effective. It is made from bitumen, so it is perfect for waterproofing the outside of the building and between the foundation and the walls of the house.

Vertical waterproofing is more variable than horizontal, therefore (depending on operating conditions and other factors), you can choose a more suitable option:

- Bituminous mastics and analogues. The thick liquid mastic allows you to create on the outside (on the outside of the basement floor) powerful protection that will have excellent performance and operational characteristics. Of course, there is no need to talk about the strength of the material here, because the hardened mastic is easily exposed to mechanical stress. Experts recommend preferring liquid glass.

- To paint the base, you can use special protective varnishes, which are distinguished by an affordable price and ease of application. These varnishes have no more advantages.

- With the help of synthetic resin or liquid polymer waterproofing materials, you can create a more or less high-quality waterproofing layer. But if effective drainage of the site is not provided, these materials will remain useless.

- The plinth from the outside can also be pasted over with roll materials. In principle, the option is good, but again, a lot here will depend on the operating conditions.

When choosing the type of waterproofing, it is necessary to take into account what materials the basement is built from, as well as what building materials are supposed to be used in the future for finishing. The horizontal waterproofing of the basement deserves special attention.

Protection of the foundation from freezing

When constructing the foundations of houses, measures should be taken to protect the foundations of the foundations from freezing.The depth of freezing is influenced by the climate (temperature, snow depth), the type of soil and the internal temperature of the house.

Non-freezing types of foundations are rock, coarse sand, gravel. It is clear that foundations on freezing soils should be laid below the depth of soil freezing.

Deformation of foundations: a - the amount of subsidence; b - the amount of heaving; c - the amount of lateral shear; W.P.G. - the level of soil freezing; 1 - foundation subsidence (A> B); 2 - buckling of the foundation when its sole is laid above the U.P.G. (BUT

The mistake of many individual developers is the belief that the deeper the foundation is laid, the better, and that such a solution in itself ensures its reliable operation and stability. Indeed, when the base of the foundation is located below the level of freezing of the soil, the vertical forces of frost heaving cease to act on it from below, however, the tangential forces of frost heaving acting on the side surfaces can, in this case, pull the foundation together with the frozen soil or tear its upper part from the bottom. Such cases are most likely when constructing foundations made of stone, brick or small blocks, especially under light buildings and structures.

In order to prevent deformation of foundations on heaving soils, it is necessary not only to place their soles below the level of freezing of the soils and thereby get rid of the direct pressure of the frozen soil from below, but also to neutralize the tangential forces of frost heaving acting on the lateral surfaces of the foundation. For this purpose, a reinforcing cage is laid inside the foundation to its entire height, rigidly connecting the upper and lower parts of the foundation, and the base is made widened, in the form of an anchor support platform, which does not allow the foundation to be pulled out of the ground during frosty heaving of the soil.

Such a constructive solution guarantees the stable operation of the foundations with any vertical deformations of the soil, however, in practice, it is possible only when using reinforced concrete. If the foundations are built of stone, brick or small blocks without internal vertical reinforcement, it is necessary to make their walls inclined (tapering upwards). This method of constructing foundation walls and pillars, with careful alignment of their surfaces, significantly weakens the lateral vertical impact of heaving soils on the foundation.

Additional measures that reduce the influence of frost heaving forces can be:

- covering the side surfaces of the foundation with a sliding layer (used engine oil, plastic wrap);

- warming the surface layer of the soil around the foundations (slag, expanded clay, polystyrene), which reduces the local depth of soil freezing. The latter measure can also be applied to previously built shallow foundations that need protection from frost heaving.

In areas with a high location of groundwater, the forces of frost heaving act on the foundations of low-rise buildings. In heavy heaving soils (water-saturated clays, loams, sandy loams, fine and silty sands), these forces reach 100.150 kPa (10.15 tf / m2) and, acting on the foundation from the bottom up, often exceed the loads of the structures located above. At the same time, seasonal vertical displacements of the surface layer of the soil when it freezes by 1. 1.5 m is 10.15 cm. Skewed porches, terraces, verandas, and sometimes walls of houses - in the overwhelming majority of cases are the result of the action of the forces of frost heaving of soils.

Penetrating waterproofing

The main advantage of penetrating waterproofing is that it penetrates deep enough into the concrete. The mixture will gradually move along miniature cracks into the concrete, clogging up all capillaries and pores through which moisture can flow.In addition, the penetrating waterproofing enters into a chemical reaction with the concrete itself, becoming a "single whole" with it.

Penetrating waterproofing will significantly increase the strength of concrete (the manufacturer notes that the strength increases by about 20-30%). In addition, concrete becomes inert to chemical attack.

The work technology is as follows:

- Penetrating insulation is presented in the form of a dry powder, which must be diluted in water and the resulting mixture is stirred to the required density.

- The mixture is applied to a damp concrete surface.

- Apply layer by layer. It is recommended to use special synthetic brushes for this.

- Processing the basement floor with these materials from the outside is allowed only at a positive temperature outside.

Technology of penetrating waterproofing of joints and seams

It is used for the treatment of seams, joints, cracks in conjunction with a liquid penetrating waterproofing. It can also be used to restore damaged concrete surfaces.

- The concrete surface is cleaned of dirt and dust, washed with water. Cracks are embroidered, removing the remains of cement mortar, at the joints, strobes are made in size 2.5x2.5 cm using a grinder or a perforator.

- Cracks and grooves are abundantly wetted with water using a brush or spray bottle. Cracks are treated with a liquid solution of penetrating waterproofing and kept for 2 to 6 hours.

- Mix the required amount of dry mixture with water to the consistency of plasticine. Put the mixture into cracks and seams, with your hands or with a spatula. If large cracks are to be repaired, fine gravel must be added to the mortar. When waterproofing concrete structures with traces of destruction, the mixture is applied with a spatula in a layer of up to 13 mm, in several layers.

An hour after the setting of the waterproofing solution, it is necessary to treat the seams with a liquid waterproofing solution.

Roll waterproofing

Roll waterproofing (aka bituminous, polymer, synthetic) is applied to all basement structures of the building. As a rule, the outer parts of the walls are covered with 2-3 layers of roll waterproofing for reliability. If the building is located on an area where there is a high level of groundwater or active perching, then it is recommended to make 4-5 layers of waterproofing in order to exclude the possibility of moisture penetration into the house.

The roll insulation for the plinth is glued with an overlap, therefore, the protection of the foundation from moisture in this case is at an extremely high level. Additionally, all joints can be covered with liquid waterproofing, which will provide a very high result.

Rolled waterproofing is not resistant to mechanical stress, therefore it is recommended to additionally protect it. Despite the use of waterproofing, good drainage of the site is necessary if the groundwater is located high enough.

Insulation of the foundation with expanded polystyrene

Installation technology consists of sequential stages:

- preparation of the workplace. It consists in the excavation of the foundation. The minimum trench depth should match the basement depth. Ideally, excavate the soil to the full height of the foundation. As for the width, it is determined by a simple addition of the thickness of the insulation and the width of the space necessary for comfortable work.

Advice. It is advisable to fill the bottom of the trench with expanded clay or lay a sand-crushed stone pillow. If it is expensive, then you can limit yourself to filling the space under the insulation.

- preparation of the base. The open foundation must dry out. In the warm season, it takes about a week. Cool - up to 2 weeks. The term depends on the weather and humidity of the foundation. Dry surfaces may require additional treatment. So, large cracks should be repaired with mortar, and small ones should be blown out with foam.A seriously deformed foundation must be leveled. This will reduce the consumption of material and eliminate the possibility of unwanted air gaps between the insulation and the base;

- foundation priming. You shouldn't ignore this step. Firstly, the primer protects the foundation from moisture, and therefore from destruction. Secondly, it increases the adhesion of the surface. Thus, the adhesive for extruded polystyrene foam will adhere more strongly to the surface.

- waterproofing of the foundation. Papered insulation (bitumen, geotextiles), coating (mastics), plastering (based on polymer-cement mortars) are used as materials. Examples of their use in the photo.

- fastening of expanded polystyrene. Installation is carried out using glue or foam glue for expanded polystyrene.

Advice. Additional fixing of the sheets with umbrellas is not required if the foundation is hidden by the ground. If the basement floor is insulated, then this is a prerequisite.

- finishing. To protect the insulation from the harmful effects of ultraviolet radiation and other environmental factors, you need to close it with a finishing material. Or cover it with plastic wrap or roofing felt, and only then cover it with earth.

Protection of a brick base from water

The device of a brick basement is a traditional solution for many types of country houses. You can isolate it from moisture using the following simple technology:

- Before you start laying, you need to purchase a brick that has been pre-treated with special impregnations that protect the material from moisture (of course, such bricks are more expensive, but when using the basement and the entire building, the costs pay off).

- On the surface of the masonry, after cleaning it, it is necessary to apply bituminous mastic in 3-4 layers (or any other analogue of coating waterproofing).

- Further, the surface is necessarily covered with roll waterproofing (you can take a regular roofing material or any modern material).

- Penetrating waterproofing can also be applied if desired.

It is recommended to consult with specialists about the use of certain materials in specific climatic conditions.

Once again, we note that in any case, when installing high-quality waterproofing, effective drainage of the site is required. It is drainage and its entire system that are the key to the absence of large volumes of water in the area around the house.

Roll, coating and penetrating waterproofing, drainage and high-quality performance of all work - these are the main components of high-quality protection of the basement from moisture penetration.

Chief editor of the site, civil engineer. Graduated from SibSTRIN in 1994, since then he has worked for more than 14 years in construction companies, after which he started his own business. The owner of a company engaged in suburban construction.

Special cases

It cannot be said that something new has been written here, but those cases are listed in which the freezing of the foundation can lead to significant consequences.

1. Freezing of the foundation walls in the presence of heating system pipes inside the perimeter

At the junction of warm and cold, condensate always evolves, therefore, in such cases, the middle part of the foundation thickness suffers (shifts inside the middle part occur taking into account changes in the ambient temperature and an increase / decrease in the temperature of the coolant in the heating system).

Such a case of constant freezing threatens the appearance of cracks inside the foundation, which, in principle, weakens the structure and entails the subsequent crumbling of concrete at the joints of the blocks (FBS, gas and foam concrete).

2. The foundation is higher than the freezing depth of the soil with an external facing

This is usually ceramic or siding (vinyl or metal), but no insulation. Or with the wrong styling.Freezing of the lined foundation most of all affects in the places of fastening of the lining (profiles) with their subsequent loss. And with an incorrectly mounted layer of insulation, mold will also be added to all troubles.

3. Freezing of the foundation of the house with obvious icing of the surface

It occurs in 0.1-0.5% of cases, while almost never - 2-3 years in a row. This is due to certain weather conditions - a small amount of snow and severe frosts.

Polyurethane mastics for foundation protection

From time to time, TV channels tell us how a whole house or part of it suddenly collapsed somewhere. We do not want to scare you, as idle TV people do. But let's say that there is no "sudden" in the case of the destruction of a building. Any structure starts from the foundation and rests on it. If it is not strong enough and moisture resistant, then the house will not stand for a long time. The most common causes of foundation destruction are dampness, moisture, loose and water-saturated soil, heterogeneous soil, the beginning of the construction of a new house or a road nearby. It only seems that the foundation is heavy and will withstand everything. No, it is, first of all, a movable structure that is sensitive to any stress and changes in the environment. Polyurethane mastic will help protect the foundation from destruction.

How to understand that your foundation is in danger

There are several signs that can help you identify the problem in the first step. Usually, thin cracks, spots, mold on the walls inside the house, distortions of door and window structures appear on the foundation, then the external finish begins to collapse, the floor deforms, some parts of the building collapse, the soil falls along the structure. If you notice cracks, it is worth checking the stability of the base.

The most common problem in Russian latitudes is excess moisture. Usually concrete is used for the foundation. It is a porous material that can take in some water. But if there is too much of it, then the concrete will not cope. In addition, moisture can linger inside, freeze and thus destroy the material.

Which waterproofing to choose

There are several main types of waterproofing. To choose the best option for you, you need to understand what type of soil you are dealing with, how deep the groundwater goes, at what depth the foundation is located, what it is made of, what size the building is.

There is one simple way to check how deep the groundwater goes. In the spring or fall, dig small holes where you plan to build your house. And look to what level the water reaches in them. This will determine how deep the foundation can be set.

If you notice that there are many marsh plants and sedges near the site, then the water is close.

We decided to arrange a basement or basement, which means that waterproofing is needed for sure.

Very often in such cases, vertical insulation is used together with bitumen-based roll materials. Another option is coating insulation. In this case, polymer compositions are applied to the surface of the foundation. Some recommend using both for maximum protection.

Impregnation, antiseptic, water repellents to protect concrete, stone, brick from moisture, mold, fungus

We try to suggest what you need to pay attention to when choosing the impregnation necessary for the consumer, with which he will protect his house or its constructive elements. That is why we recommend using and using recommended and specially developed impregnations and antiseptics in the construction of houses and baths made of logs and beams, houses made of brick and concrete, foundations, basements and other structures and structures, which will help to achieve long-term and easy operation of the entire building. Build your home WITHOUT ERRORS.Treat all its structures in advance with special antiseptics and impregnations for concrete, brick, stone or wood. It is better to prevent the possible beginning of the destruction of the structure and the deterioration of its characteristics during the operation of the building, than then to constantly struggle and resolve issues of restoration and correction of emerging problems. If you make a choice in favor of the recommended impregnations and antiseptics for concrete and brick and prefer to buy them, then most likely for a long time you will not need to solve such problems as choosing and buy antiseptics against mold and mildew for brick and concrete, you no longer need you will need to think about how to process the foundation. We have tried to offer you tested and certified concrete wall treatments that can work and are suitable for both indoor and outdoor applications. In our assortment, you can choose, order and buy with free shipping impregnation for concrete, impregnation for bricks, antiseptic for concrete, antiseptic for bricks, impregnation for stone, water repellent for concrete, water repellant for bricks, water repellant for stone, impregnation of concrete from dampness , getting wet, rain, mold and mildew spread.

← to products in this category

Polyurethane mastic or bitumen?

There are many types of waterproofing compounds on the market. With the development of the chemical industry, these products are becoming more and more perfect. Whereas previously it was possible to rely only on bitumen, now there are more durable alternatives to it.

What is the difference between bitumen and polyurethane mastic? Bitumen is one of the oldest building materials available and cheap. Polyurethane mastics appeared on the market not so long ago, but they are distinguished by their strength and elasticity, which persists for many years. Bitumen loses these properties very quickly. Its strength is enough for several years, then the physical and chemical properties of the material weaken. Polyurethane mastics can last more than 40 years.

Polyurethane mastic from "Khimtrast"

has developed its own polyurethane mastic, which can be used not only for waterproofing foundations, but also for roofs, swimming pools, tanks, basements, terraces, balconies, tunnels, as well as under screeds and tiles, for repairing old bituminous insulation.

Mastic "Chemtrast PUMA (1k)" is available for purchase in wholesale and retail volumes. If the surface for waterproofing is not so large and you need to make minor repairs, then you can buy a liter or three-liter jar of mastic. You pay for the purchase through the online store on the company's website, then the product arrives at your home. You save your time on trips to hardware stores, markets and queuing.

You can also order the color of the mastic that best matches the color of your home. In this case, the indicator of moisture resistance will remain unchanged. High adhesion allows you to protect almost any surface from external influences.

How to work with polyurethane mastic

The concrete foundation on which you plan to apply the mastic must be clean, without tears or cracks, without sharp joints. If you notice bubbles on the concrete, then its surface must be sanded and then cleaned of dust and dirt. It is also necessary to get rid of moisture from the foundation. The best time for work is a sunny dry day without precipitation.

How to check if the surface is dry enough? A few hours before applying the mastic, place a small piece of polyethylene on the surface of the concrete and check for condensation. If it is not there, then you can start work.

For better adhesion, the company's specialists recommend applying a primer to concrete - "Chemtrast Primer-PM (1k)". One coat of primer should be sufficient. An hour after that, you can start applying the mastic.Before use, the material must be mixed using a mixer with a spiral nozzle.

Then take a roller or paint brush and apply the first coat of polyurethane mastic from top to bottom. The layer should not be thick, literally 1-2 millimeters. After a day, you can add a second layer of thicker mastic. Use aliphatic mastic to protect the surface from UV rays.

When working with polyurethane mastic, observe safety precautions, work in a gas mask or protective mask, in special clothing that will cover all parts of your body.

After work, rinse all brushes with acetone, and store the mastic in a tightly closed container so that polymerization does not occur.

Experts are always ready to tell you which polymer is best for your purposes. Our warehouses can be found in Novosibirsk, Irkutsk, Yekaterinburg, Krasnoyarsk, Voronezh, Yaroslavl, Nizhny Novgorod, Moscow, St. Petersburg, Samara and Ufa.

The plinth protects the walls of the building from the penetration of ground moisture into them and, as a result, their destruction. But what will the base itself protect? Surely this is done correctly. finishing the basement of the house, which only in the second place performs decorative functions, and in the first place - a protective role. It is this issue that we will deal with in the current article, in which, together with the site stroisovety.org, we will deal in detail with how to properly coat the basement of a building so that it is completely protected from aggressive environmental influences and, moreover, has an attractive appearance.

Vertical waterproofing

Insulation of the vertical type is the treatment of the walls of the finished foundation. There are several ways to protect the base, which are possible both during the construction of the building and after construction.

Table. Strengths and weaknesses of the most popular waterproofing options

| Material | Operational period | Ease of repair | Elasticity | Strength | Cost, per m² |

| 5 to 10 years old | ★★★☆☆ | ★★★★★ | ★★☆☆☆ | About 680 rubles | |

| Polyurethane mastic | 50 to 100 years old | ★★★☆☆ | ★★★★★ | ★★☆☆☆ | About 745 rubles |

| Rolled bituminous materials | 20 to 50 years old | ★☆☆☆☆ | — | ★☆☆☆☆ | About 670 rubles |

| Polymer membranes (PVC, TPO, etc.) | 50 to 100 years old | — | ★☆☆☆☆ | ★★★☆☆ | About 1300 rubles |

Inexpensive and simple, and therefore the most popular way to waterproof the foundation. It implies a complete treatment with bituminous mastic, which penetrates into all cracks and voids and prevents moisture from entering the house.

Important information! When choosing one or another bitumen mastic, pay attention to the marking - this will help you find out the heat resistance of the material. For example, mastic labeled MBK-G-65 has a heat resistance (within five hours) of 65 ° C, and MBK-G-100 - 100 ° C, respectively.

Advantages of bituminous mastic:

- ease of use (you can do it alone);

- affordable cost;

- elasticity.

Disadvantages:

- low speed of work (several layers are required, which takes a lot of time);

- not the best water resistance (even a high-quality application does not guarantee 100% protection);

- fragility (after 10 years you will have to re-process the foundation).

The process of applying the mastic itself is extremely simple and consists of several stages.

Stage 1. Surface preparation.

Below are the basic requirements.

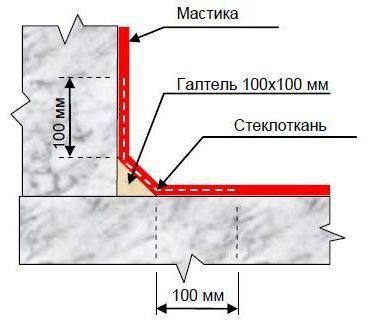

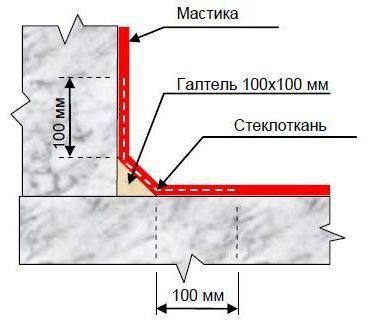

- The surface of the foundation must be solid, with beveled or rounded (ø40-50 mm) edges and corners. Fillets are made in the places of transitions from the vertical to the horizontal - so the abutting surfaces will be mated more smoothly.

- For bitumen, sharp protrusions that appear where formwork elements are joined are extremely dangerous. These protrusions are removed.

- Areas of concrete covered with cavities from air bubbles are rubbed with fine-graded cement mortar based on a dry construction mixture.Otherwise, bubbles will appear in the freshly applied mastic, which will burst in 10 minutes after application.

Also, dirt and dust should be removed from the surface, and then dried thoroughly.

Important information! The moisture content of the substrate is very important and should not exceed 4%. At a higher value, the mastic will swell or begin to flake off.

It is quite simple to test the base for moisture: you need to lay a piece of PE film 1x1 m in size on the concrete surface.And if after a day there is no condensation on the film, then you can safely proceed to further work.

Stage 2. In order to increase adhesion, the prepared base is primed with a bituminous primer.

You can go the other way and prepare a bitumen primer yourself. To do this, bitumen grade BN70 / 30 must be diluted with a rapidly evaporating solvent (for example, gasoline) in a ratio of 1: 3.

One layer of primer is applied over the entire surface, two at the junction. This can be done either with a brush or with a roller. After the primer has dried, the actual mastic is applied.

Stage 3. A block of bitumen is broken into small pieces and melted in a bucket above the fire.

It is recommended to add a small amount of "waste" there during heating. Then liquid bitumen is applied in 3-4 layers. It is important that the material does not cool down in the container, since with another heating it will partially lose its properties.

The total thickness of the waterproofing layer depends on the depth of the foundation (see table).

Table. The ratio of the thickness of the bitumen layer to the depth of the foundation

Stage 4. After drying, the bitumen should be protected

as it can be damaged when backfilled with soil containing debris. To do this, you can use rolled geotextiles or EPS insulation.

Video - Thermal insulation of the EPPS foundation

Reinforcement

Bituminous insulation needs reinforcement for:

- cold seams;

- junction of surfaces;

- cracks in concrete, etc.

Often, fiberglass and fiberglass are used for reinforcement.

The fiberglass material must be sunk into the first layer of bitumen and rolled with a roller to ensure a tighter adhesion. As soon as the mastic is dry, the next layer is applied. It is important that the fiberglass material is laid with an overlap of 10 cm on both sides.

Reinforcement will provide a more even distribution of the load over the entire insulating strip, minimize the elongation of bitumen in the areas of cracked openings and, as a result, significantly extend the service life.

It can serve as both the main protection and addition to the applied bitumen mastic. Usually roofing material is used for this.

Among the advantages of the method should be highlighted:

- low cost;

- availability;

- good service life (about 50 years).

As for the shortcomings, this can only be attributed to the fact that it is impossible to cope with the work alone. The algorithm of actions should be as follows.

Stage 1.

Unlike the previous method, there is no need to carefully apply the material, since the mastic is needed exclusively for fixing the roll waterproofing to the base.

Stage 2.

With the help of a burner, the roofing material is slightly heated from below, after which it is applied to a layer of hot bitumen. Roofing material sheets are joined with an overlap of 10-15 cm, all joints are processed with a burner.

Stage 3.

After fastening the roofing material, you can fill up the foundation, since additional protection is not required here.

Important information! Roofing material can be replaced with more modern materials that are fused onto the base. These can be polymer films or canvases with bitumen-polymer spraying (for example, Isoelast, Technoelast, etc.).

Video - Waterproofing with roofing material

This method is extremely simple to perform and is used for the purpose of waterproofing and leveling the surface of the foundation. Here advantages of plaster waterproofing:

- simplicity;

- high speed of work;

- affordable cost of materials.

Disadvantages:

- low hydraulic resistance;

- short operational life (about 15 years);

- possible cracking.

There is nothing complicated in the application process. First, with the help of dowels, a putty mesh is attached to the foundation, then a plaster mixture with hydro-resistant components is prepared. The mixture is applied to the foundation with a spatula. After the plaster has dried, the soil is poured.

Essentially, it is a dispersion of polymer-modified bitumen particles in water. The composition is sprayed onto the base, providing high-quality waterproofing. Dignity

this method is as follows:

- high quality waterproofing;

- no need for special skills;

- durability.

But there is also limitations

:

- high cost of the composition;

- low speed of work in the absence of a sprayer.

In addition, liquid rubber is not widely available. For the foundation, a composition of the same type, which is of two types, is quite suitable.

- Elastomix - applied in 1 layer, hardens for about 2 hours. It is not subject to further storage after opening the package.

- Elastopaz is a cheaper option, but it is applied in 2 layers. Tellingly, Elastopaz can be stored even after opening the package.

Stage 1.

The surface is cleared of dirt and debris.

Stage 2.

The foundation is covered with a special primer. Alternatively, you can use a mixture of liquid rubber and water (ratio - 1: 1).

Stage 3

... An hour later, when the primer is dry, a waterproofing material is applied (in one or two layers, depending on the type of composition). It is advisable to use a spray for this, but a roller or brush can be used instead.

Video - Treatment of the base with liquid rubber

Penetrating insulation

On the base, previously cleaned of dirt and slightly moistened with water, a special mixture (Penetron, Aquatro, etc.) is applied with a sprayer, which penetrates into the structure by about 150 mm. It is important that the solution is applied in two to three coats.

The main advantages:

- effective protection;

- the ability to process surfaces inside the building;

- simplicity of work;

- long service life.

Disadvantages:

- insignificant prevalence of such solutions;

- high price.

Making a clay castle

A simple yet effective way to protect the substrate from moisture. First, a pit 0.5-0.6 m deep is dug around the foundation, then the bottom is covered with a 5-centimeter gravel or crushed stone "pillow". After that, clay is poured in several stages (each layer is carefully compacted). The clay itself will act as a moisture buffer.

The only advantage of this method is its ease of implementation.

The clay castle is only suitable for wells and household objects. If we are talking, for example, about a residential building, then this method can only be used as an addition to the already existing waterproofing.

This method of protecting the base appeared relatively recently and consists in the following: mats filled with clay are nailed to the cleaned surface of the foundation using a mounting gun or dowels. The mats should be laid with an overlap, about 12-15 cm. Sometimes, instead of mats, special clay-concrete panels are used, then the joints in this case must be additionally processed.

Overlap - photo

In principle, screen insulation is an improved version of a clay castle, therefore it can only be used for utility structures.

Finishing the basement of the house: how to make waterproofing

Oddly enough, but before proceeding with the immediate finishing plinth foundation at home, you need to execute it waterproofing... For what? The answer is still the same - protection from moisture, which can seep not only through the soil, but also through the seams of the facing material.In general, the waterproofing of the basement should be carried out at the stage of building the foundation, but, as a rule, everything is limited to insulating only its underground part, which is mainly performed with roofing material or bitumen mastic. In fact, these materials interfere with further finishing the basement of the house, and they seem to be ignored, or, at best, released 10-15 cm above ground level. In principle, this is quite enough to protect the foundation from destruction, but not the basement of the structure.

Finishing the basement of the house do-it-yourself stone photo

FROM waterproofing the basement of the house things are a little different - roofing material, bituminous mastic and similar materials will not work here. Almost all materials for finishing the basement of the house require a different type of base - therefore, the requirements for waterproofing the basement of the building are slightly different.

Types of insulation for foundations - characteristics and properties

Various materials can be used to insulate the foundation. We offer to rank them by cost:

Sand

Warming takes place during the construction phase of the house. This is the cheapest way to insulate. Unfortunately, its effectiveness tends to zero. Because sand is incapable of retaining heat.

Expanded clay

This material is not able to accumulate moisture. The technology of warming the foundation in this way has two directions.

Firstly, expanded clay can be poured into the middle of the formwork, even at the installation stage. This method simplifies pouring, reduces concrete consumption, and increases the thermal insulation properties of the foundation. But it makes it more fragile.

Secondly, expanded clay is poured inside the strip foundation. Thus, a lot of it is poured, and the result is a decrease in heat loss not only through the foundation, but also through the floor of the house or basement.

Styrofoam

In the language of professionals, it is called PSB (non-pressed suspension expanded polystyrene) or PSB-S (self-extinguishing suspension suspended polystyrene). This is reflected in the labeling of the material. It is a sheet of balls. There is air inside the balls, which ensures the thermal insulation properties of the material. Insulation of the foundation with foam can be attributed to the most popular type. This is due to such characteristics of the material as low coefficient of thermal conductivity, absolute non-hygroscopicity. As well as cheapness, availability, and ease of use.

Penoplex

The scientific name is extruded polystyrene foam. As you can see, the names of penoplex and polystyrene are similar, and reflect the technology of their manufacture. At the same time, the technology of its manufacture is more complicated. But penoplex can be called more progressive compared to polystyrene. Because it is devoid of its major drawbacks. The material is denser, which means it has greater mechanical compressive strength. It does not sustain combustion. The period of its disintegration in the ground is at least 100 years. The groove-comb system simplifies installation and eliminates the presence of seams.

Of the minuses, one can name the fact that insulation of the foundation with foam is more expensive than foam.

Polyurethane foam (PPU)

The most expensive, but also the most effective way to insulate the foundation today. Warming the foundation with polyurethane foam is simple. This sprayed insulation is simply sprayed onto the wall. The use of polyurethane foam avoids many steps. For example, sealing joints, leveling the base. In addition, when using this heat-insulating material, insulation and waterproofing of the foundation can be carried out at the same time.

Based on the popularity of both types of expanded polystyrene, let us dwell in more detail on how to produce thermal insulation with extruded polystyrene foam.

How to decorate the basement of the house: materials for finishing the protruding part of the foundation

Materials with which modern builders can perform finishing the basement of the house, quite a lot - they include natural and artificial stone, siding, special facade panels, tiles, clinker bricks, bassoon and even ordinary or decorative plaster. In principle, this list can be continued and continued, but there is little sense in this - all the same, the finishing of the base with these materials is almost identical.

By technology finishing the basement of the house all materials can be divided into two groups - which require a frame for their installation and which do not need it. Frame materials include all kinds of siding, fiber cement and other panels, for the installation of which you will need to arrange a metal frame. If we talk about such materials in more detail and consider their installation technology, then we can note one feature concerning the preliminary stage of waterproofing - here the choice of insulating materials is not limited. Bitumen, roofing material, and similar materials are suitable.

The disadvantage of this option finishing the basement of the house is the high cost of the materials themselves and the work associated with their installation. For example, fiber cement panels are one of the most expensive materials today, and their main advantage is durability.

Finishing the basement of the house Photo

In financial terms, the most profitable material for a basement is all kinds of tiles, clinker bricks and stone of artificial or natural origin. The advantage of these materials lies in a fairly simple installation technology - for example, finishing the basement of the house with artificial or even natural stone, it is quite simple to do it yourself. The same can be said about tiles and clinker bricks - knowing the technology of working with tile material, revealing the foundation with any such products will not be difficult.

Materials for finishing the basement of the house

Warming the base of the porch

Fig. 5

- sand or gravel bedding 400 mm thick; extruded polystyrene foam; sand layer 50-100 mm thick; stairs

Seasonal deformations of the porch and stairs at the entrance to the house deliver a lot of trouble to the owners of country houses. The reason for this is the frost heaving of the soil, causing the relatively light structure of the stairs to bulge.

In addition, the base of the porch or staircase is located at a depth shallower than the base of the foundation, so the forces of frost heaving cause especially strong deformations of these structures. The most radical way to protect the porch from bulging is to protect its base from freezing (Fig. 5).

To do this, make a recess 700 mm deeper than the sole of the porch or stairs. At the bottom of the excavation, a sand bed is arranged with a thickness of at least 400 mm from washed sand or gravel.

Plates of extruded polystyrene foam are laid on the compacted base, the thickness of which is taken in accordance with the above table. A layer of sand of at least 50 mm is poured over the insulation, on which a flight of stairs or a porch is installed. To protect the base from freezing, the insulation should protrude 1.2 m beyond the porch.

Additional protection for the tiled basement of the house

As they say, there is a silver lining - having protected the basement of the building, it is also necessary to protect the cladding itself from the ubiquitous moisture. No matter how ridiculous it may seem, but such a situation really takes place. The fact is that rain and melt water, flowing down the walls of the house, can flow and be absorbed into the solution or adhesive composition, with the help of which the basement was finished with natural stone or something else.

As a rule, either the same finishing material or special cornices made of painted galvanized steel are used as such protection. If you deal with the quality of such protection, then it is better to give preference to galvanized steel - it is more reliable.If moisture can still seep into the seams between the finishing material, then, in principle, it is not able to penetrate under the cornices.

Cornice on the basement of the house photo

The eaves are attached as follows - first, a slot is made in the wall 1.5–2 cm deep to the width of the grinder's disk, into which the bend of the eaves is inserted. After that, the cornice itself is attached to the wall with dowels, and the cut slot is sealed with a sealant. If you correctly do the docking of individual cornices, then finishing the basement of the house artificial stone (or whatever you use there for these purposes) will be reliably protected from rain and melt water.

In general, be that as it may, but finishing the basement of the house is a necessary construction activity that must be carried out in conjunction with other means of protection of the foundation (drainage of the foundation, its waterproofing and the device of the drainage system).

Warming of the foundation of different types

Having dealt with the heaters, he will briefly characterize the insulation of the foundation by its types, the main of which include:

- Tape

- monolithic tape; - shallow tape. - Columnar

- Pile

- Pile-screw

- Plate (floating)

- deeply buried slab; - shallow slab.

In addition, the depth of laying affects the choice of insulation and the technology of its installation: strong, shallow and not buried. It is important to take into account such a parameter as the material from which the foundation is made: brick, wood, iron. The different properties of these materials lead to the fact that they conduct different amounts of heat.

Insulation of the strip foundation

This type of foundation is used in multi-storey construction or the construction of heavy structures. It is clear that only a monolithic concrete wall can withstand the weight of the structure. However, concrete is not able to retain heat inside a building. It is advisable to insulate the strip foundation at the stage of arrangement. Because digging a deep, wide and long trench is long and troublesome. The technology of insulation of a monolithic foundation of a tape type depends on the type of insulation and is given above.

The insulation of shallow foundations is somewhat different.

This is due to the depth of their arrangement. In order to prevent heat loss through a shallow foundation, it is necessary not only to insulate it vertically, but also to insulate the floor in order to exclude the possibility of freezing of the soil and the base of the house. Most often, vertical and horizontal insulation is performed using expanded clay, filling it into the pit between the foundation.

Insulation of a columnar foundation

It is considered the most reliable type of foundation. It is used in low-rise construction. In terms of the manufacturing method, it is similar to tape. But, to give it strength, concrete pillars are used. They are installed in the corners, along the perimeter of the load-bearing walls and at the junction of the internal walls. Before proceeding with the insulation of such a foundation, it is necessary to eliminate the voids between the supports. For this, foundation pickups are arranged. Wooden or metal structures that connect the supports.

Expanded clay is poured into the middle of the formed cells. Which in itself is a good insulation. Outside, the zabirki are waterproofed and pasted over with expanded polystyrene. Or polyurethane foam is applied to them. Further, the insulation is covered with a film and covered with earth or covered with a finishing material.

Insulation of the pile foundation

The specificity of this type of foundation is that the structure is erected on piles - vertical supports, covered with a concrete slab. It is irreplaceable on soils characterized by special instability. Then it becomes necessary to deepen the piles and install them on a solid foundation. On piles, a grillage is equipped, on which the building is actually being built.

The grillage can be made of various materials (see photo).

Based on the design, it is impractical to insulate the foundation on piles. However, protecting the grillage will reduce heat loss.

Warming of the foundation grillage is carried out using any heat-insulating material that meets the requirements of reliability, strength and durability.

Insulation of the screw foundation

It would be correct to call this paragraph of the description "insulation of the pile-screw foundation"

Its specificity is in the use of screws acting as a pile. The popularity of this type of foundation has led to the simplicity and high speed of installation of screw piles. It is used in unstable soils and in the construction of temporary buildings. Further, the arrangement of the foundation is identical to the pile one. And, consequently, the insulation of the pile-screw foundation is carried out according to the same scheme. And it consists in warming the grillage. Insulating temporary buildings is most often impractical.

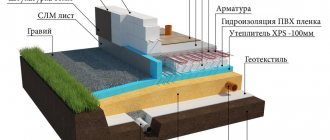

Insulation of the slab foundation

The essence of the slab foundation is in arranging a single monolithic slab under the entire building. This leads to a specific approach to its insulation. Namely, the entire surface of the slab must be insulated during construction. Moreover, preferably in several layers due to the proximity to the ground. The sequence of work is as follows: sand is poured onto the ground, then geotextiles, a layer of concrete, and a layer of waterproofing are laid. Styrofoam is laid on this pillow or expanded clay is poured. Closed again with waterproofing. Only then can you equip the slab - the concrete base of the building. The technology of insulation and the sequence of work is illustrated in the photo.

The grandfather's method of warming the foundation of a house with straw