Winter colds always come unexpectedly. It is more pleasant to meet them in a circle of loved ones behind warm walls than under a warm blanket, turning off the heating at night in order to somehow save some money.

Mounting foam for wall insulation will quickly cover residential and non-residential buildings. It is sprayed onto surfaces of any inclination with pneumatic devices or pistols. The most popular type of such insulation is foam rubber.

Features of insulation

To carry out insulation with liquid polyurethane foam, you need to wear a protective suit. Polyurethane foam is often used as a material. Next, you will spray the foam all over the facade. The material needs to be filled in the void between the rafters, the wall and the beams.

Advantages of wall insulation with foam:

- the ability to increase volume;

- the upper temperature limit is within +80 ° C;

- vapor permeability;

- resistance to mechanical stress;

- refractoriness.

Tip: Residual foam with a polyurethane component can be used to seal the gaps left by reinstalling plastic windows.

To insulate which objects you need to use a pneumatic gun:

- window;

- insulated external walls;

- foundation;

- balconies outside;

- loggias;

- pipes.

The facade after insulation with foam will remain without seams, joints. One cylinder contains 600-700 ml of insulation, it is enough for one square meter for a layer 4-8 cm thick. To start insulating walls with polyurethane foam, you need to insert the cylinder into the gun, pull the trigger, pointing it at the wall. The setting time is 24 hours.

The video shows the insulation of the hangar PPU.

Features of work on the insulation of facades with polyurethane foam

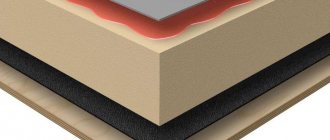

Insulation of the facade with polyurethane foam is carried out by spraying. Liquid PPU It is poured into the tank and, using a pneumatic spray gun connected to the compressor, the mixture is applied to the facade under pressure. As it cools, it turns into foam, which fills in all the cracks on the facade and then hardens. To ensure good adhesion, the walls must be cleaned of dirt and dust before application. Since the foam does not form a uniform surface, after the end of the polymerization process, the master carefully cuts off the excess so that you can make the plaster facing.

Material analysis in comparison with analogues

Modern technologies offer many options for facade insulation. Compared to other thermal insulation materials, liquid thermal insulation PPU has a very high level of thermal conductivity. For example, a layer of 1 cm of polyurethane foam has the same thermal conductivity as 5 cm of mineral wool or 30 cm of reinforced concrete.

Types of foam insulation

Foam is distinguished by its composition and structure, regardless of the field of application. There are the following varieties:

- Penoizol - contains aldehydes, which is why it is potentially hazardous to health, which is denied by manufacturers. Due to its structure, it dries longer than polyurethane - up to three days. It is used for insulating load-bearing structures, walls, attics. Available in liquid form, in the form of finished slabs;

- Foam concrete and ecowool are produced in liquid form for pouring the facade. Practically not used in the decoration of the facade due to the large weight, which gives a strong load on the walls, and the high price;

- Polyurethane foam is inferior to previous types of foam in terms of basic characteristics. It is intended only for sealing holes, joints and seams, as it cannot pass steam, moisture, which is critical for insulating material.Interaction with air increases the volume twenty times with a minimum amount of air bubbles inside. Produced in small cylinders;

- Polyurethane or PU foam is the most common type of foam due to its versatility. Polyurethane insulation is recognized as the most effective insulation for the facade. Its structure is a polyurethane compound of two components, which are machine-mixed before application. Expansion of foam based on polyurethane occurs 30-40 times from the initial volume, forming small balloons inside. Thanks to this, polyurethane performs well at home insulation.

Technology advantages

- Roof insulation with polyurethane foam does not imply the dismantling of the old coating, which will save money, effort and time.

- Polyurethane foam can be applied to any surface configuration, since the material has high adhesion rates.

- High speed of insulation, which reaches up to 500 square meters per day.

- Low coefficient of water absorption, which is extremely important for the roof.

- The structure of the material allows air to pass through well, which contributes to the normalization of the indoor microclimate.

- Polyurethane foam is not a medium for the development of insects, rodents and pathogenic microorganisms.

- Low coefficient of thermal conductivity, allowing you to keep cool inside the house in the warm season, and warm in the cold season.

- The porous structure further enhances sound insulation.

- The possibility of insulating both the outer and inner sides.

How to choose from all varieties

The choice of the type of insulation depends on the situation, as well as the area of application, we will consider some common cases in which foam insulation is used:

- You can use polyurethane if you need to repair cracks or other defects on the walls. Do not expose it to direct sunlight.

- To fill a large volume, use Penoizol. In this case, it is necessary to purchase a special high-pressure apparatus, since a conventional cylinder will not be enough for this.

- To seal cracks and insulate a small surface area, select mounting specimens in cylinders. It does not ignite when interacting with fire, does not support combustion, has an ecological composition and hardness after solidification.

Remember! For insulation of the entire building, polyurethane foam is categorically not suitable, since it does not have the appropriate characteristics.

To eliminate defects that were found outwardly, foam, which contains polyurethane, is applied using direct technology, using an apparatus or a special balloon. Errors within the layer that creates the foam insulation require a long hose to push the material through. To fill the air spaces inside the insulation, holes are made in the wall.

POLYURETHANE FOAM FLOATING

Polyurethane foam (PPU) foams on any surface, increasing in volume and filling all voids and irregularities. After spraying, the polyurethane foam increases in volume up to 100 times and turns into billions of hollow cells filled with air. Freezing, it becomes so tough that an adult can calmly walk on it. Simultaneously with the insulation, the structure is waterproofed. Wood, brick, concrete, metal - any materials are suitable for applying polyurethane foam. As a result of high-quality "adhesion" (adhesion) of the foam to the surface, a reliable yet lightweight seamless coating is formed. The guarantee of the preservation of the thermal insulation properties of the material is 25 years.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE >>>

APPLICATION

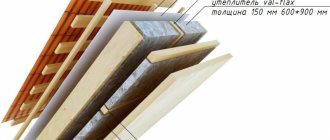

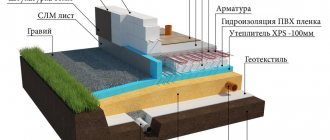

Polyurethane foam is used for insulating attics, walls and facades, repairing damaged roofs with any angle of inclination, and reconstructing old houses.It is an ideal means of insulating floors, foundations, basements: the material does not rot or decompose. PPU is applied with a layer of 50 mm several times (the thickness of each layer is 18-20 mm). For wall insulation, polyurethane foam with a density of 40-60 kg / cubic meter is sufficient. m. If spraying on the ceiling, a material density of 40-50 kg / cubic meter is sufficient. m.

8 PLUSES OF SPRAYABLE POLYURETHANE FOAM

- low thermal conductivity (0.019-0.03 W / mK)

- low weight and no load on the structure

- lack of "cold bridges",

- seamlessness

- simultaneous waterproofing

- vapor permeability

- soundproofing

- incombustibility

- high pace of work

Pros and cons of the warming process

The advantages that you get if you insulate your house with this material:

- Insulation speed, regardless of the surface.

- It is not subject to biological effects, fungus and mold are unlikely to appear on such a wall.

- Hardly flammable material, but it can melt when exposed to temperatures over 80 degrees.

- Does not need to fasten the frame to the facade, membranes, films, steam and waterproofing.

- Forms a monolithic surface without seams, excluding cold bridges.

- When insulating pipes and other metal elements, it creates a dense layer, excluding the penetration of moisture, the appearance of corrosion.

Among the disadvantages that foam insulation creates are:

- Impossibility of constant interaction with water.

- Do not expose to direct sunlight.

- The high cost of the material requires the purchase or rental of special equipment for application before insulating the building.

- An insufficient level of vapor permeability of the insulation requires installation inside artificial ventilation.

- To carry out the warming process, you must wear a respiratory mask with goggles, a canvas suit and gloves that not every owner has, so you will have to buy them too.

Despite the fact that people have been insulating houses with foam for a long time, the perfect ideal means for this has not yet been invented. The owner of a private house, who opted for foam insulation, will not deny its effectiveness. The main thing is to buy materials and equipment for installation, and the process itself will not take much time and effort.

Attention! Be careful, if you do the insulation with your own hands, be sure to use protective equipment. After application, treat your facade with a special coating. It is designed not only to protect the insulation, but also your health.

Price and technology of roof insulation with polyurethane foam

Polyurethane foam is a universal means of thermal insulation, on the basis of which elastic, semi-rigid and rigid materials are made. Polyurethane foam is processed by different methods: pressing, extrusion, casting, spraying or pouring. On the basis of this substance, a large number of common materials and products are obtained: filled, reinforced, foamed, laminated and many others in the form of plates, sheets, profiles, blocks, films and fibers. It is also worth noting that products and structures based on this material are used in almost all areas of the industry. Let's talk about insulation with polyurethane foam, how polyurethane foam is applied to roofs.

The content of the article about the technology and the price of roof insulation with polyurethane foam

- Elastic polyurethane foam

- Roof insulation technology with polyurethane foam

- Heat transmittance for PU foam roof insulation

- Advantages of roof insulation with rigid polyurethane foam

- The effect of polyurethane foam on human health

- The cost of thermal insulation by spraying polyurethane foam

- Additional material on this topic

- Return to Yandex search

- or write a comment

Elastic polyurethane foam

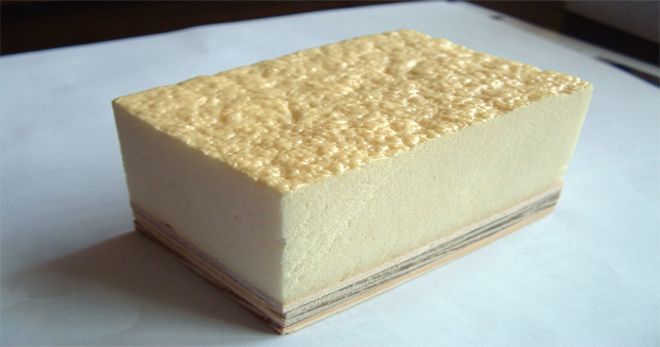

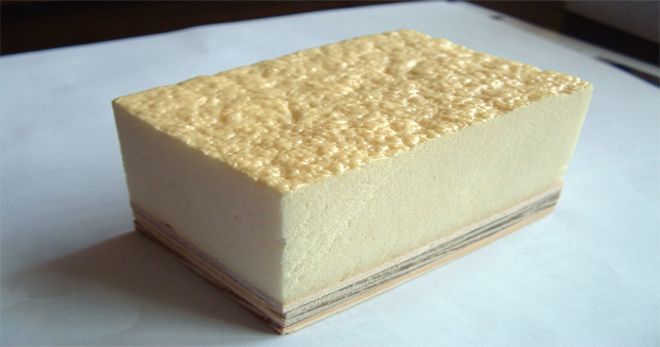

Elastic polyurethane foam is a foamed polymer. Among natural and synthetic materials used for the production of upholstered furniture, car seats for cars, etc. he is in a leading position.Polyurethane foam can be molded (the casting of the part is done individually) and block (the final product is represented by large rectangular or cylindrical blocks, cut into blanks of the required length and width). For pouring and spraying polyurethane foam, special equipment is used.

Roof insulation technology with polyurethane foam

Roof insulation with polyurethane foam is carried out in 2 ways:

- by spraying;

- by filling method.

What method is suitable for roof insulation, the builders will tell you, or you can figure it out yourself.

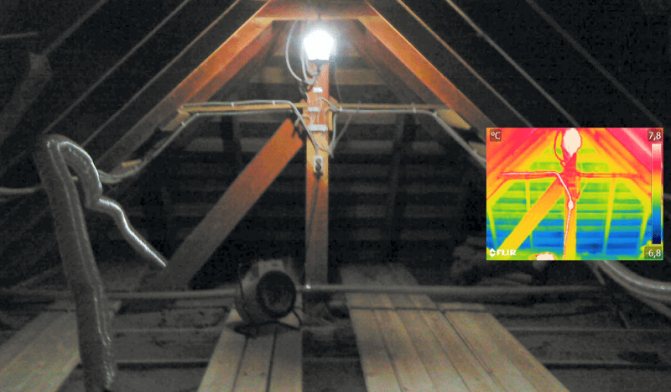

Roof insulation with polyurethane foam by spraying

The spraying method consists in the fact that a liquid is poured into a special equipment for polyurethane foam, after which it is sprayed over the surface, forming a light warm coating and filling all possible gaps.

The density of application of polyurethane foam on the roof is 30-60 kg per m3. If it is necessary to provide a better level of thermal insulation, an additional layer is applied, exceeding the first layer (120-150 kg per m3). Double spraying is done when insulating complex roofs and for soundproofing an apartment. The method of layer-by-layer spraying of polyurethane foam is used for the construction of seamless waterproof surfaces.

Video: Insulation of the roof, roofing with polyurethane foam

Roof insulation with polyurethane foam by pouring

This method is suitable for surface treatment of any relief and complexity. It is used in the presence of arches, ledges, columns, etc. Pouring is done when carrying out work on the roofs of old houses, during their restoration. The layer thickness is easily adjustable.

Heat transmittance for PU foam roof insulation

The thickness of the polyurethane foam layer depends on the required level of thermal insulation. Consider the heat transmission coefficient for different roof structures. This is important information when insulating a roof with polyurethane foam.

| Roof structure | Heat transmittance W / (m2 * K) | ||||

| Without PPU | 40 mm | 60 mm | 100 mm | 120 mm | |

| Monolithic reinforced concrete floor | 4.49 | 0.61 | 0.42 | 0.26 | 0.22 |

| Corrugated board | 6.83 | 0.64 | 0.44 | 0.27 | 0.23 |

| Wood cladding 19 mm | 5 | 0.61 | 0.46 | 0.31 | 0.27 |

| External wood covering 21 mm | 4.39 | 0.58 | 0.41 | 0.26 | 0.22 |

Advantages of roof insulation with rigid polyurethane foam

Can be applied to any surface

Rigid PU foam is widely used in the construction industry. This is the highest quality insulation used for thermal insulation of facades, internal walls, walls, roofs or other elements. Thanks to the spray function, the insulation is easily applied to any surface. The increased adhesion of raw materials allows architects to design and insulate elements of complex shapes: protrusions, columns and arches. Note that PPU spraying is used to repair damaged roofs with different angles of inclination, to insulate old buildings. As practice shows, saving time during spraying is 80%, and money costs - 50%.

At the present time, the most common is waterproofing and insulation of roofs of buildings using this material. Over the past several decades, thermal insulation of PPU roof structures has been actively used in America and Western European countries. It was these states that were the first to raise the issue of the need to save heat consumption for heating buildings. Experts have found that the level of heat loss and the power of heating systems can be reduced by insulating the roof of residential buildings and other structures.

The roof, insulated with polyurethane foam, is airtight

A positive feature of the insulation of the roof structure using polyurethane foam - the imposition of one layer of material guarantees the complete tightness of the roof. It is believed that it is this material that provides the highest level of heat, moisture and vapor insulation. In addition, a lot of money is saved on the installation of insulation.

Thermal insulation of the roof with polyurethane foam using polyurethane foam spraying allows you to permanently get rid of the problem of icicles arising from the low level of thermal insulation of the building. To get rid of this negative phenomenon, it is enough to apply a layer of 30-50 mm.

Wide scope of application

Due to its easy application and providing a high level of protection against heat loss, polyurethane foam is used for:

- insulation of the foundation;

- hangar insulation;

- insulation of the garage;

- thermal insulation of pipelines;

- insulation of the basement;

- thermal insulation of the attic.

The effect of polyurethane foam on human health

The wide scope of application of polyurethane foam gave the idea to scientists to test this material for environmental friendliness. After conducting research, it turned out that polyurethane foam does not pose a health hazard, since it does not contain harmful free volatile compounds.

Today, volatile ester fractions are not used for the manufacture of polyurethane foam. The resulting products are free of formaldehyde, asbestos, freon and other harmful chemicals. After the attic, roof, floor and walls are insulated with polyurethane foam, harmful microelements do not accumulate in the premises.

You might be surprised to learn that you come across this material every day. Upholstered furniture consists of a frame and elastic polyurethane foam with finishing with special materials. In addition, bed mattresses are also made using polyurethane foam. In the automotive industry, the material is used to produce a wide variety of seat or door elements. Many farmers make hives from it - houses for bees. All items made in this way are subject to serious control, so there is no need to worry about your health.

The cost of thermal insulation by spraying polyurethane foam

Roof insulation with polyurethane foam - price

The cost of insulation with polyurethane foam is determined by the layer thickness, density and complexity of the work. Prices for roof insulation work with polyurethane foam, depending on the layer thickness, are shown in the table below.

| Type of work | Thickness, mm | Price, rub / m2 |

| Spraying polyurethane foam | 25 | 450 |

| 50 | 530 | |

| 100 | 580 | |

| 150 | 850 | |

| 200 | 1150 | |

| Filling by volume | 10000 per m3 | |

| UV protection | – | 80 |

What determines the price of roof insulation with polyurethane foam?

Insulation by spraying polyurethane foam is not a finished product. You cannot order it or buy it from a store. The peculiarity of such insulation is the creation of thermal insulation on a certain object. In all cases, the price is individual, calculated taking into account the labor intensity, thickness and fatness of the applied layer, location, and the total amount of work. Note that the price of thermal insulation with polyurethane foam, taking into account all possible losses, is lower in comparison with thermal insulation with mineral wool. Unfortunately, there is an opinion among the people that PPU spraying is available only to elite buildings, but this is not the case. Thermal insulation with polyurethane foam, made in accordance with all the rules, will last up to 30 years without losing its original properties and without repair work.

- Equipment for insulation with polyurethane foam, price, ...

- The cost of insulation with polyurethane foam

- Insulation of the garage with polyurethane foam, price, technology

- Attic insulation with polyurethane foam, technology, video

- Wall insulation with polyurethane foam, technology, ...

- Balcony insulation materials: polystyrene, ...

Tags: Thermal insulation of buildings