Benefits of Application

The popularity of roll materials among the owners of houses and apartments earned primarily for the ease of installation. You can make high-quality moisture-proof floor cladding with their use with your own hands. Another advantage of this type of hydro-insulators is their low cost. At the same time, despite the fact that such materials belong to the budget group, they protect floors from moisture very effectively. A long service life is also what the roll-on waterproofers received good reviews from the owners of apartments and houses.

Waterproofing methods

The building materials market and the unflagging interest of developers and manufacturers in this direction give the consumer a wide range of moisture-proof coatings:

- polymer, polyethylene and anti-condensation films;

- membrane systems;

Bipol TechnoNICOL surfacing roll waterproofing

Continuous innovation and development leads to an increased demand for progressive coatings with a longer service life.

Varieties of material

Roll waterproofing for floors is classified mainly by the method of attachment to surfaces. In this regard, materials are distinguished:

- Sticky. This type of waterproofing agent is usually attached to the floor surface using bitumen mastic or special adhesives.

- Fused. This type of roll material is fixed to surfaces with a gas burner. A thin bituminous layer is applied to the back surface of this group of waterproofers already at the production stage.

- Mechanically fixed. Such materials are fixed to surfaces using nails or staples.

Roll-up waterproofers can also differ in the type of materials used for the manufacture. The cheapest varieties are made on the basis of ordinary cardboard. This is how, for example, a well-known budget roofing material is made. In more expensive materials, the basis can be fiberglass, fiberglass or polyester.

Insulation requirements

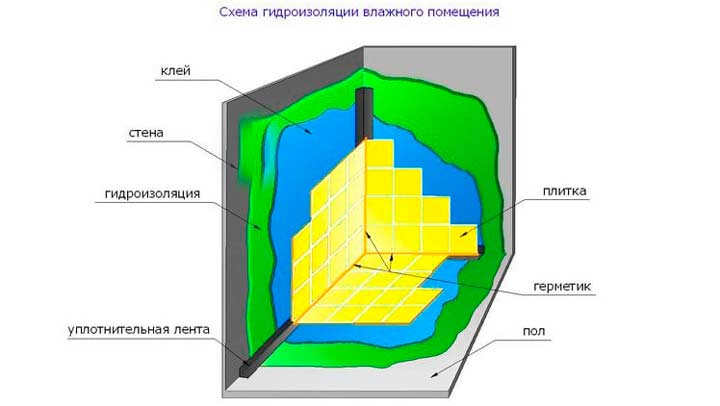

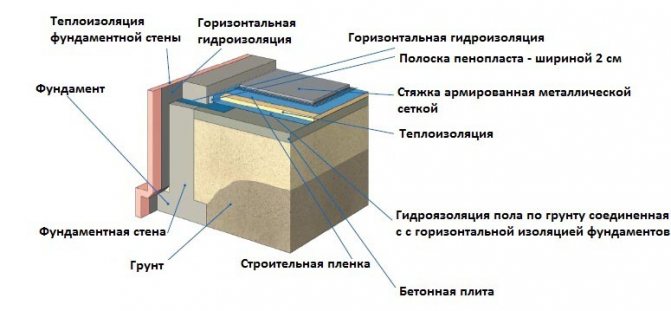

General layout of the floor and various protective barriers

According to SNIP, waterproofing of the floor is required for arrangement with a medium and high degree of exposure to wastewater and penetrating moisture.

Under the medium and high degree of impact intensity is understood as the periodic ingress of moisture on the floor surface, water flowing down the walls of the room, constant or frequent wetting, and the presence of water on the surface of the floor covering.

That is, waterproofing works in bathrooms and toilets are carried out at the finishing stage without fail.

The thickness of the insulating layer, according to building codes and regulations, is determined by the type of work and the material for waterproofing the floor. The choice of a specific work technology depends on a number of factors and requires an assessment of the condition of the floor covering, a visual inspection of the floor slab, the floor, the cost of work and the volume of the room.

Products

There are several brands of roll-on waterproofers on the domestic market. But most often floors and other surfaces are protected from moisture using the materials manufactured. Waterproofers of this brand are distinguished by simply remarkable performance characteristics. Basically, two types of materials from this manufacturer are suitable for finishing floors - glued "Technoelast Prime" and fused "Technoelast Thermo". Also on sale there is a special self-adhesive membrane of this brand, intended for indoor use.

Good quality at not too high cost - this is what distinguishes TechnoNIKOL, roll waterproofing. The price for a self-adhesive membrane from this manufacturer, for example, is only about 1300-1500 rubles. (10 / 0.75 m). The materials of this particular manufacturer are considered a good alternative to a less durable and durable budget roofing material. Their guaranteed service life is 25-30 years.

Floor waterproofing TechnoNIKOL 10x0.75 m

The roll is rolled from top to bottom, the top edge is secured with a metal edge strip.

Installation instructions >>>

TECHNONICOL floor waterproofing

Rolled baseless self-adhesive bitumen-polymer waterproofing material.

TECHNONICOL floor waterproofing is obtained by applying a self-adhesive bitumen-polymer binder to an anti-adhesive film, followed by covering the binder from the front side with a protective layer (Spunbond).

Application

Waterproofing of floors of internal premises. It is possible to use in the system both with a protective screed, and without it, in the system without the use of a protective screed, ceramic tiles are laid on the material with cement glue. It is possible to use where it is forbidden to use an open flame, laying on combustible bases is possible.

Price

TECHNONICOL floor waterproofing (10x0.75m) - 169.00 rubles / m2

Manufacturing jobs

Installation is carried out on a base primed with a bituminous primer.

Installation instructions >>>

TECHNONICOL flat roof waterproofing

Self-adhesive bitumen-polymer roll roofing material.

TECHNONICOL flat roof waterproofing is obtained by impregnating a strong polyester base with a bitumen-polymer binder, followed by applying a self-adhesive layer to the underside of the canvas. As protective coatings, coarse-grained dressing is used on the front side and an anti-adhesive polymer film on the lower side of the web.

Application

One-layer waterproofing of flat roofs of unexploited buildings (garages with concrete and wooden bases, outbuildings, change houses, etc.), repair of roofing.

Price

Waterproofing of a flat roof TECHNONICOL (8x1m) - 209.00 rubles / m2

Manufacturing jobs

Installation is carried out on a base primed with a bituminous primer.

Installation instructions >>>

Waterproofing system

TechnoNIKOL self-adhesive waterproofing floor is a baseless bitumen-polymer material of the latest generation, used for the production of insulation works on wooden, metal and concrete floors. It is supplied with a special adhesive layer, which greatly simplifies its installation, allowing it to be insulated without preliminary preparation (including in emergency mode).

Floor waterproofing from TechnoNIKOL is supplied to consumers in original packaging, in the form of rolls. The dimensions of the material they contain are standard:

• strip thickness 1.5 mm;

• strip width 0.75 m;

• strip length 10 m;

• the weight of one roll does not exceed 7.5 kg (the weight of one square meter of material is only 1.5 kg).

The price of TechnoNIKOL floor waterproofing is relatively low, providing this truly unique waterproofing material with wide popularity among builders. They use it in the construction of both residential buildings and industrial structures, getting a rare opportunity to save money without sacrificing reliability.

It is also popular among non-professionals, because it is easy to use like no other roll-on waterproofing agent.

Floor waterproofing TechnoNIKOL: installation instructions

In terms of its chemical composition, TechnoNIKOL floor waterproofing is a bitumen-polymer composite protected from above by spunbond with a wide range of operating temperatures. Its only installation limitation is the need to pre-treat the base with a bituminous primer, which improves adhesion and, as a result, the service life of the waterproofing coating.

If you're curious, here's the sequence installation of waterproofing floor TechnoNIKOL: buy, bring to the place, print, glue.As you can see, no special skills or any additional equipment is required. After that, both a sand-cement screed and any type of floor tiles can be laid on the waterproofing. Installation is done without waiting, immediately after gluing.

Floor waterproofing, produced under the TechnoNIKOL trademark, and this should be emphasized, has a long service life, reaching 45 years.

Floor waterproofing materials: bikrost

It is also a very popular type of waterproofers on the domestic market, perfect for protecting against moisture, including the floor. Bikrost can be manufactured both on glass cloth and polyester. Its advantages, among other things, include the ability not to lose its properties at an air temperature of -15 to +80 ° C. Polymer additives are not used in the manufacture of this type of roll waterproofing. Therefore, bikrost does not differ in too good adhesive qualities. However, it costs less than glass-insulating glass and even Technonikol waterproofers.

Types of penetrating waterproofing

According to the method of application and the principle of operation, the following types of penetrating waterproofing for foundations are distinguished:

- injection materials (injection waterproofing);

- damping cements (cement waterproofing);

- sanitizing plasters (coating waterproofing);

- water repelling materials (water repellents);

- materials for protecting concrete from capillary moisture;

- different formulations to make concrete water-repellent;

- anti-salt, anti-fungal impregnation;

- many other types of materials.

A huge advantage of penetrating waterproofing lies in the possibility of its application from the inside of concrete structures, basements and foundations, which ultimately significantly reduces the cost and time of the work performed. Formations from crystals of the waterproofing mixture penetrate deeply into porous concrete up to 60 cm deep and become an integral part of the concrete, which guarantees its water resistance.

During operation, upon contact with water, the chemical reaction continues along with the sealing process. The result is a double waterproofing effect: waterproofing of the outer layer of the floor and crystallization of pores inside the concrete. When using this technology, the walls remain vapor-permeable.

Features of penetrating waterproofing:

- can be applied to both dry and damp surfaces;

- work can be carried out without exposing the outer walls;

- waterproofing is possible after basic construction work;

- does not need protection during the installation of reinforcement, backfill, etc .;

- does not require preliminary surface treatment with a primer;

- improves the frost resistance of concrete, protects it from weathering;

- penetrating waterproofing resistant to chemicals;

- provides protection against corrosion - prevents oxidation of the reinforcement.

Polyethylene film

This type of waterproofing is also often used to protect the floor from moisture. Technical polyethylene film is best suited for this purpose. Its thickness is slightly greater than that of the usual one, and therefore, it is somewhat stronger. In terms of transparency, such material is inferior to the greenhouse, but in this case, of course, it does not play any role. Polyethylene technical film is cheaper than usual. In particular, such a roll-up waterproofing is well suited for a wooden floor. On top of it, a not too thick concrete screed is usually arranged or plywood is stuffed.

Materials from popular manufacturers

In the Russian market, roll waterproofing of the Technonikol and Rizolin companies is popular. Using the products of these manufacturers as an example, we can consider the characteristics of self-adhesive tapes and roll waterproofing. We will also get acquainted with the preparatory work.

TechnoNIKOL

This company has in its assortment both rolled and bitumen-polymer products. They are perfectly adapted to the climate of our country. Among the presented products, one of the most effective products is a self-adhesive bitumen tape. It serves as a sealant for joints, seams and cracked areas.

Why are floors waterproofed in city apartments?

Most often, the floors are protected from moisture, of course, on the basements of private houses. Indeed, in this case, there is a very real threat of groundwater penetration into the room. But sometimes the floors are also waterproofed in city apartments. In this case, this procedure is carried out mainly in order to completely exclude the possibility of flooding of neighbors from below. Also, roll material for waterproofing the floor in an apartment is usually laid before laying such expensive coatings as parquet and solid board. In this case, the main purpose of the operation is to protect the flooring from warm water vapor rising from the lower floor.

Roll waterproofing TechnoNICOL

Rolled waterproofing, produced under the TechnoNICOL brand, occupies a leading position in the ranking of building materials on the international market. The reasons for the popularity of TechnoNICOL brands are:

- high degree of reliability and effective protection against moisture and condensation formation;

- biological and chemical resistance, maintaining flexibility and elasticity at low temperatures;

- the ability to withstand a significant breaking load;

- long-term service life - from 35 years;

- ease of installation, cost-effectiveness.

The strength of TechnoNICOL waterproofing agents is due to the use of a multi-layer structure consisting of a polyester base, two layers of bitumen-polymer filler and a protective film. All coatings are manufactured in strict accordance with GOST and applicable building codes.

New models of roll waterproofing are being developed under the TechnoNICOL brand, taking into account various climatic conditions and production capabilities of the consumer. Baseless self-adhesive roll coatings are widely used for waterproofing floors and foundations.

In addition to protecting against moisture, waterproofing coatings from TechnoNICOL are capable of protecting premises from noise, dust, and harmful gas.

Roofing and insulation materials are used both in the construction of new buildings and in repair and restoration work. The scope of application of TechnoNICOL waterproofing agents includes:

- strengthening of foundations under industrial structures;

- construction of high-rise buildings;

- hydroprotection of private households from the damaging effects of dampness and moisture;

- construction of tunnels, viaducts and bridges using reinforced concrete slabs.

Modern roll materials for waterproofing are able to effectively and reliably protect a building or structure from groundwater, freezing and atmospheric precipitation. The correct choice of waterproofing agent, strict adherence to the recommendations of specialists and installation technology are the basis for the successful installation of roll waterproofing and the durability of the structure.

Preparatory activities

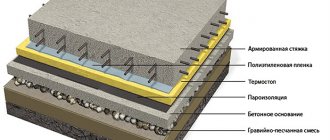

Floors in urban apartments in most cases consist of the following structural elements:

- concrete floor slab;

- cobbled logs;

- floorboard.

In order to perform the highest quality waterproofing of the floor in the apartment, it must be disassembled down to the concrete base. This is especially true for residential premises in old buildings. Wood has a limited lifespan, and the condition of the floors in apartments in such high-rise buildings usually leaves much to be desired. In any case, you should not put a new tie on them.

Installation of waterproofing should only be carried out on a carefully leveled concrete base. Also, the stove should be thoroughly vacuumed and wiped with a damp cloth. If the coating has a lot of defects, a special self-leveling mixture should be applied to it before laying the roll material.

Material selection

The process of choosing a waterproofing material consists of several aspects that influence the final decision.

- The volume of the treated surface. Large areas of coverage will require significant (but one-time!) Financial investments.

- Working hours. Some insulating materials have a very long drying time, which is not always appropriate for a particular construction project.

- Operating conditions. The waterproofing material must correspond to the climatic conditions of the environment, otherwise the dismantling of the coating and re-waterproofing are inevitable.

- The type of building material. Different types of building and structural coatings have their own characteristics that determine the choice of insulation.

Based on financial capabilities, many make a choice in favor of popular roll types of waterproofing materials, positioned in terms of strength and availability.

Roll materials for waterproofing are available to everyone

Price for roll materials for waterproofing

How to make waterproofing correctly?

In a city apartment, any of the materials described above can be used to protect the floor from moisture. But most often in this case, membrane materials "TechnoNIKOL" are used. Ease of installation is what, among other things, distinguishes such roll waterproofing. For the floor in a city apartment, it fits just perfect. It is not recommended to use this material only under tiles and cardboard-based floor coverings.

It is best to mount the membrane film across the room. First, it is advisable to cut the material. The cut strips must be rolled up. For installation, simply remove the bottom protective layer from the membrane. Spread the self-adhesive strips on the floor in the direction from the center to the edges. They should be laid with an overlap of approximately 30 cm. This will provide reliable protection.

Thus, "Technonikol" is very good for a city apartment, roll waterproofing. The price for it is low, but the quality is excellent. But you can, of course, save even more and buy an ordinary roofing felt for the floor in the apartment. It is best to stick it on a concrete slab using a special compound. Of course, you shouldn't heat bitumen in an apartment.

Hardfaced waterproofing for floors in urban dwellings is rarely used. Covering floors with the use of such material is only worthwhile if you have the skills to work with a gas burner. Otherwise, the production of such an operation in a city apartment can become a very dangerous enterprise. In any case, an unpleasant smell with this method of installation will certainly spread throughout the entire entrance, which can cause discontent among neighbors.

Sometimes ordinary roofing felt is also used for waterproofing floors in city apartments. This material is attached to concrete using special adhesives. When performing floor cladding using any of the waterproofers described above, it is imperative to make allowances for the walls.

Styling options

Among roll waterproofing materials, the following types are distinguished:

- lining (bitumen-polymer, polymer and polyester) materials that do not require the use of adhesives;

- film coatings glued to the primed base with special mastics and adhesives;

- deposited materials based on mastic.

Depending on the selected coverage, the method of performing the work can be one of the following:

- flooring (used mainly on wooden bases);

Some installation methods require compliance with safety measures, fire regulations and constant ventilation of the work area. Craftsmen recommend to carry out installation work in dry, warm and calm weather.

Video - Waterproofing. Types and application

Features of work in the bathroom

Roll waterproofing for the bathroom floor is laid using a simpler technology. After all, you usually don't need to dismantle anything in such a room. The floors in the bathrooms of urban apartments are most often originally made of concrete. Therefore, the preparatory work in this case will most likely consist only in their alignment. All cracks and chips in the concrete coating must be sealed with a cement-sand mortar. You can start waterproofing the floor about two weeks after this procedure. In this case, the gluing of the roll material is carried out in the same order as in ordinary rooms. For better adhesion, concrete can be pre-primed with a deep penetration agent.

If you intend to later lay tiles in the bathroom, it is best to use a roll material based on fiberglass or fiberglass to protect the floor from moisture. Since this waterproofing option is more durable, it can be leveled with a hard roller.

Waterproofing materials for the floor

On the construction market there is a huge amount of the described materials that are suitable for creating insulation in the house. The most demanded of them are:

- mastics, lubricants;

- pasting or roll insulation;

- intended for the insulation of plaster;

- bulk mixtures;

- penetrating mixtures;

- bulk mixtures;

- spray-on polymers.

In the case of independent work, it is better to choose plastering or coating options. An order of magnitude more difficult and more complicated in processing roll insulation, which must be connected and laid in a special way. If, nevertheless, the choice is made in favor of a penetrating component, you can work with it at home, but you must strictly adhere to the rules indicated in the instructions.

If waterproofing of the floor screed is assumed, then it is better to choose bulk compounds. They are presented in special small-sized granules - reacting with water, they turn into a gel-like paste and prevent moisture leakage.

Self-leveling floor

Self-leveling or 3D floors, as well as sprayed-type polymer coatings are difficult to work with, it is better to entrust their creation and finishing to specialists.

Floor tiles are often used as waterproofing, but they are common finishing materials. The tile, even if it is connected with silicone grout, does not guarantee complete insulation, and in the event of a flood, it will quickly let moisture to its neighbors.

How is the basement work carried out?

The technologies for waterproofing the basement floor are similar to the methods for laying roll materials in the bathroom. The only difference is that in this case, several layers of material are usually used. After all, the protection in the basement of the house should be as reliable as possible. Otherwise, soil moisture will surely penetrate the basement.

First, clay is poured onto the floor in the basement, and then a layer of sand. Next, a concrete screed is poured. Its thickness should be 8-10 cm. It is possible to start waterproofing the floor only after the concrete has gained sufficient strength. That is, not earlier than two weeks after the screed is poured.

Waterproofing roll floor materials in the basement is usually done with a gas burner. Lay the strips of the deposited material with an overlap of 20 cm. Also, the waterproofer should go 20 cm onto the walls of the basement floor. The deposited material is laid in two layers. You can close the floor on the basement with ordinary roofing material.But in this case, it is better to put three layers of waterproofing. The joints of the roofing material strips in the basement are sealed with a gas burner.

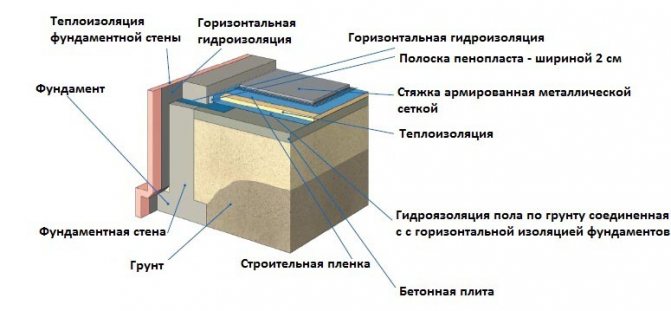

Roll waterproofing for foundation

The durability of the structure and the safety of people depend on the strength of the foundation. In order to avoid premature destruction under the influence of groundwater, the foundation must be carefully treated with waterproofing materials.

Roll insulation is the most common option for waterproofing buildings and structures. In the processing of the foundation, all existing types of isolates are used - glued / welded and membrane.

The waterproofing of the foundation with the help of roll roofing is carried out at any stage of the work - both before pouring the concrete solution, and after the foundation is already ready.

Waterproofing at the stage of concrete pouring

If the roll-up waterproofing is installed before the concrete is poured, then it should be laid using the "overlap" method into the existing formwork. Each panel should overlap the previous one by 15-25 cm. The joints between the panels are glued together using double-sided adhesive tape (tape). After that, the reinforcement is installed and the concrete is poured. For greater reliability, several layers of waterproofing are used, each of which is coated with bitumen mastic.

Vertical laying of waterproofing

The vertical method of installing an insulating roll coating is used on ready-made foundations. With this technique, glued or welded waterproofing materials are glued to the surface of the base.

Before proceeding with the insulation of the foundation, it is necessary to carry out preliminary processing - thoroughly clean the concrete surface from protrusions, dust and dirt. The smoother the foundation at the point of contact with the waterproofing compound, the more reliable the moisture protection will be.

Those parts of the foundation that will be located underground are carefully processed with glue or bitumen mastic. After that, the roll waterproofing is pressed against the coated surface. If the material to be welded is used, the lower layer is heated by the propane burners until softened and after that it is also pressed against the surface of the foundation. The joints and edges of the panels are subject to additional processing with mastic / glue or a gas burner.

For more effective protection of the foundation, roll waterproofing should be laid horizontally so that water does not penetrate into the joints between the panels. If a basement is provided in the building, then the waterproofing is carried out in two stages - at first, the walls are processed, which will be located underground, and then additional waterproofing is laid for the floors of the basement and the first floor.

In waterproofing the foundation, proven types of materials are used - roofing material, filisol, hydrostekloizol.

Recommendations for surface preparation

Before starting waterproofing work, it is necessary to inspect the surface for the presence of an angle of inclination, cracks, chips, potholes, etc. Builders remove large debris from the surface manually. Small crumbs and dust are blown off with a vacuum cleaner. For maximum effect, it is better to walk with the vacuum cleaner on the surface twice.

Modern self-adhesive waterproofing materials would lose in many ways if there were no self-adhesive bitumen tape among them. This tape is used as a joint sealant and for repairing defects. The sealant tape is endowed with the following characteristics:

- excellent manufacturability;

- moisture protection;

- excellent adhesion to all types of surfaces;

- environmental Safety.

Aluminum foil is added to the multipurpose tape, which gives the material tremendous strength. The membrane is formed by the adhesion of the sticky layer to the surface. The sticky layer owes its qualities to the bituminous mixture.

Almost all self-adhesive waterproofing material that is on the market today does not require professional installation skills. Even a beginner can cope with the task, the main thing is to follow the manufacturer's recommendations. Also, before applying self-adhesive waterproofing material, you need to thoroughly prepare the surface - walk over it with a metal brush or sandpaper.

When choosing a waterproofing material, experts pay attention to the following indicators: thickness, tear strength, heat resistance, water absorption, vapor permeability, temperature during operation.

Installation of waterproofing

Installation of waterproofing

Self-adhesive waterproofing with a sticky base must be in the room for 24 hours before starting work. The rest of the materials must be unrolled and left for 24 hours to eliminate strong folds. To make the waterproofing more elastic, it is wiped with diesel oil.

Before laying, it is necessary to mark the location of future strips. It should be borne in mind that the edges should overlap each other by 20-25 cm. When the waterproofing does not have a self-adhesive coating, it is laid with a flooring. To fix the material, use special screws. In some cases, no fixation is needed. Regardless of whether a wooden floor or a concrete floor is waterproofed, its moisture content should be no more than 5%.

For gluing waterproofing, special mastics or glue are used. They are preheated to a temperature of + 25 ° C and applied to the surface of the floor and panels. Then they are pressed to the base and rolled out with special rollers. The edges of the waterproofing, which go over the previous layer, are additionally coated with mastic for better adhesion. This is especially true for the bathroom floor, where the humidity level is constantly high.

When fusing, a burner is used, the flame temperature of which is maintained in the range of + 140 ... + 160 ° C. At lower values, the material may peel off from the floor surface. When laying the waterproofing, both surfaces are heated, and then the panel is pressed tightly with a roller. The joints are also warmed up and fixed tightly. This installation method is unacceptable for a wooden floor.

The canvas should overlap the wall by 6-7 cm in order to provide high-quality waterproofing. If the roll is deformed and bent, it is cut, leveled and continued to be laid. In this case, you should step back 20-25 cm so that an overlap is formed. Experts recommend laying 2-3 layers of waterproofing, placing them perpendicular to each other. If air bubbles form on the surface of the material during installation, they are carefully cut and covered with mastic.

What is waterproofing for?

Waterproofing

All materials are designed to solve the following tasks:

- Protect concrete or wood flooring from moisture.

- Prevent liquid from entering from the basement side. This will ensure the durability of the ground floor floor.

- In case of an accident, prevent water from flowing from the upper floor to the lower one. This is especially true for apartment owners.

- For a private house, it is important to protect the supporting structures. The absence of excess moisture will ensure the durability of the materials and the service life of the structure.

- Normalize the humidity level in the room. This will prevent the development of microorganisms that destroy the material and harm human health.

The waterproofing of the floor provides a better quality concrete screed, as it does not allow moisture to quickly evaporate. The cement-sand mixture hardens gradually, creating a durable coating. The use of high-quality water-repellent materials allows you to make a sauna even in an apartment in a multi-storey building.