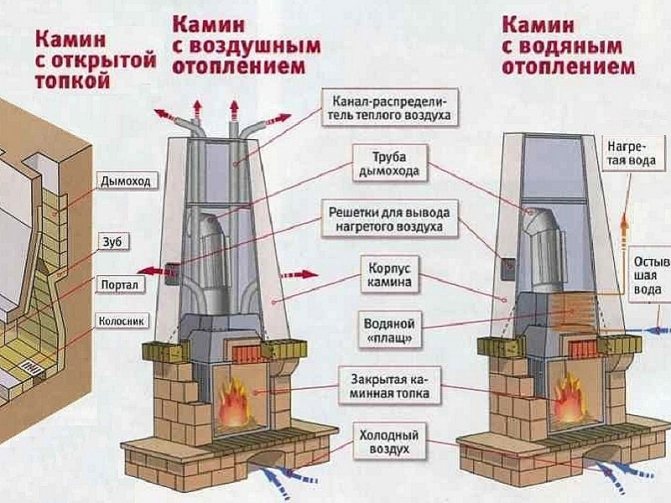

Not every person knows that all types of fireplaces, represented by a huge number of models, have quite definite, established standard indicators for some technical parameters. These parameters include the dimensions of the main nodal elements. When erecting a fireplace, these values should be adhered to, since deviations can lead to a violation of the functions of the device. Any fireplace should cope with the same tasks:

- remove the heat obtained as a result of fuel combustion;

- ensure the removal of combustion products;

- provide oxygen supply to the furnace.

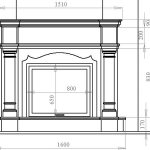

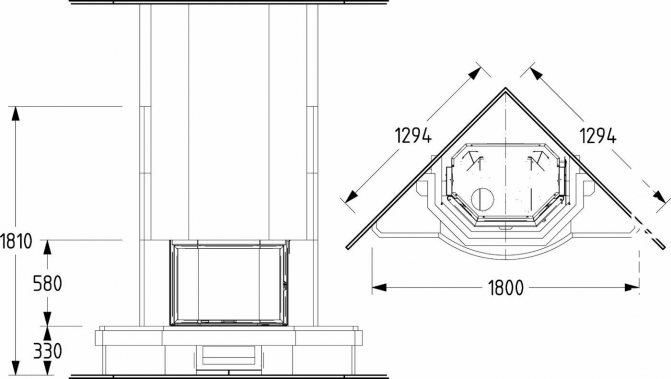

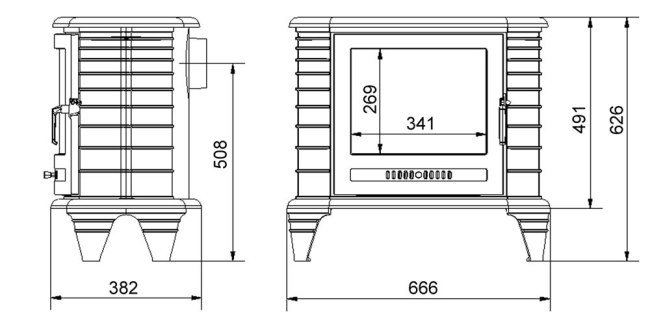

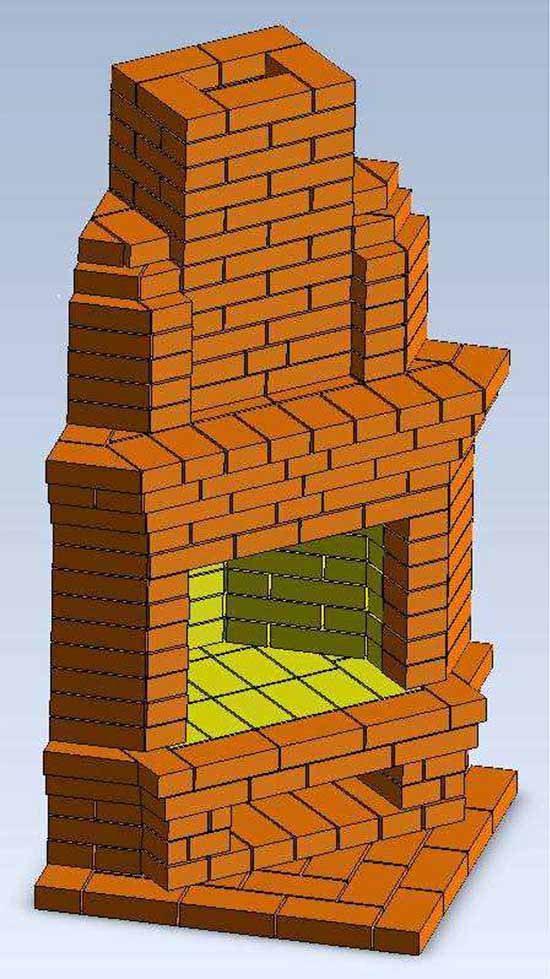

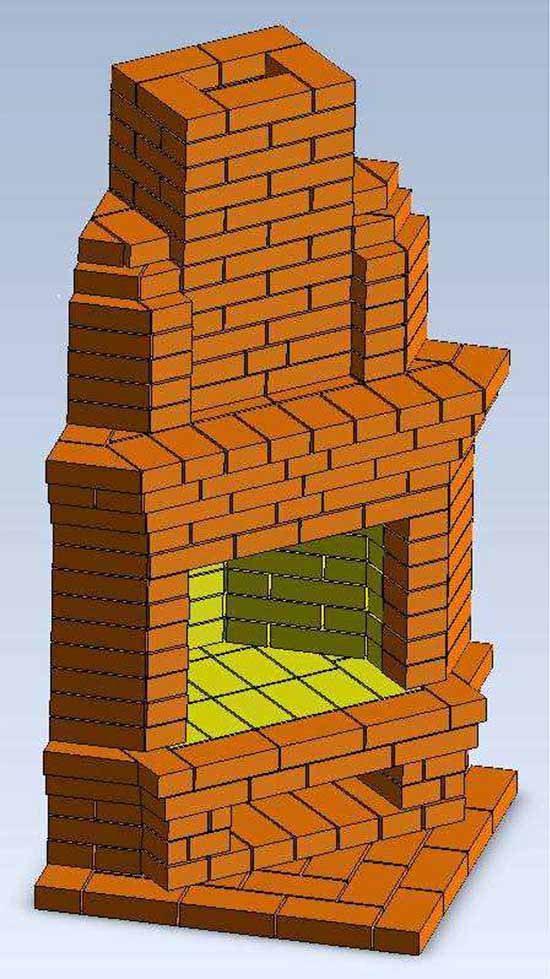

Wall-mounted fireplace drawing

The history of the construction of fireplaces is rich in experimental discoveries that were accumulated in the form of experience that was passed on from the master to his student. Today, many professional stove-makers do not even think about why the chosen standard project has exactly fixed dimensions. His knowledge is reduced to memorizing indicators for different types of ovens. Meanwhile, there are pretty good reasons for standardization. Let's take a closer look at the dimensions of the fireplace, its main characteristics, which are an indicator of its correct operation.

Conditions for normal traction

Everyone has heard of the term cravings. Even without knowing the definition, one can intuitively imagine what it is. There are opinions that this is the pressure difference or temperature difference between the upper and lower points of the chimney.

However, this representation is not entirely correct, because with a small pressure difference, the thrust can be increased due to other factors. Therefore, draft should be understood as the speed of movement of air masses through the section of the chimney. It can be enlarged, reduced, or normal. The average speed should be 0.25 m / s.

It is impossible to measure the speed of movement of combustion products at home. Before lighting the fireplace, it is recommended to make sure that there is a draft. To do this, you should observe the behavior of the flame of a burning piece of paper, and you can already estimate the magnitude of this thrust by the behavior of the fireplace itself after kindling.

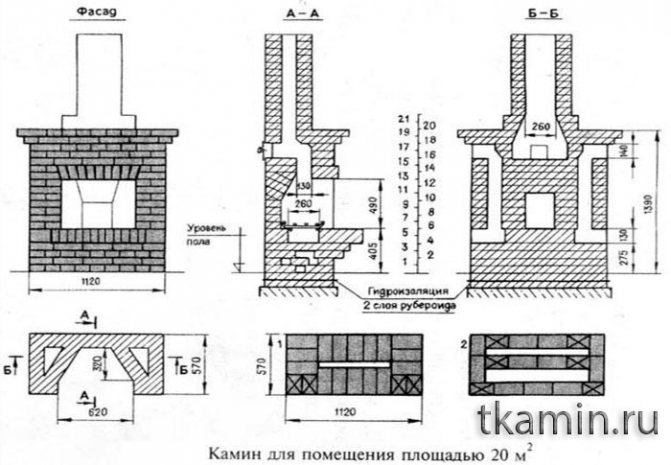

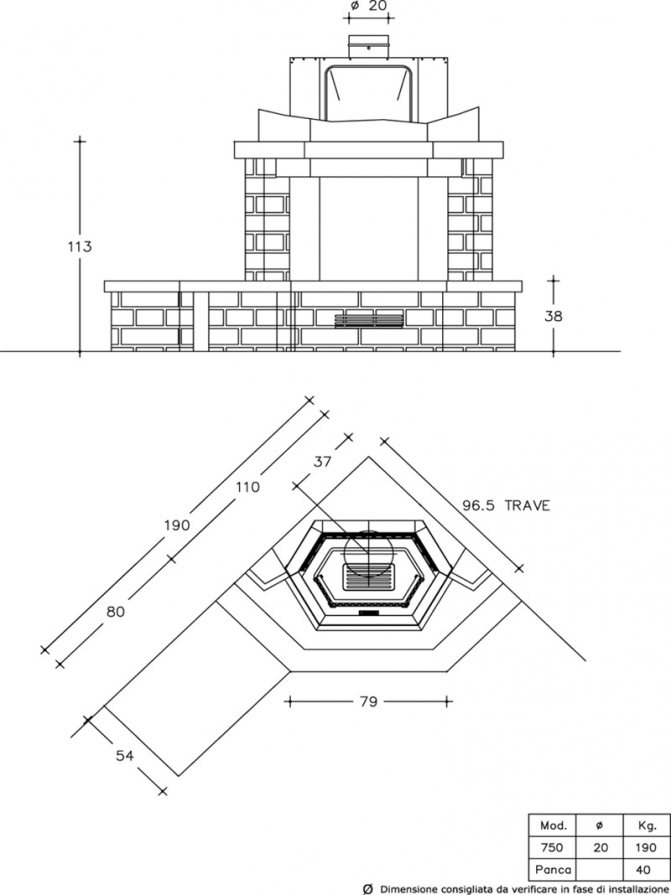

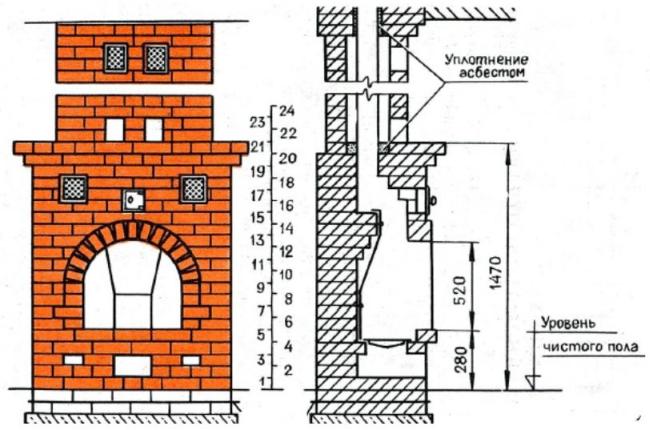

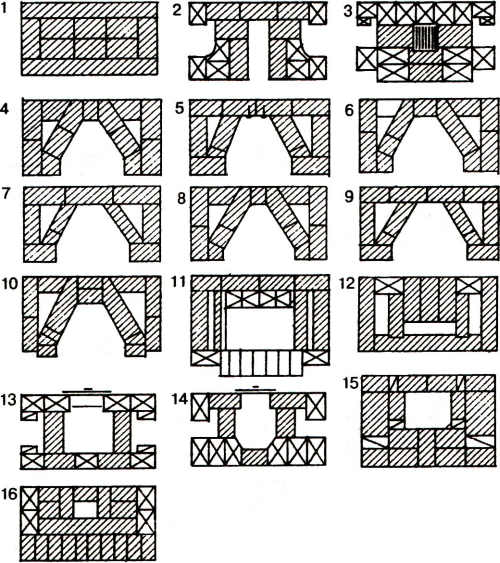

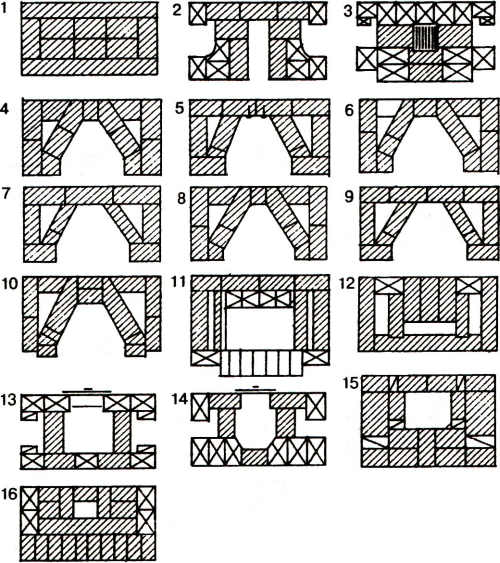

Bricklaying scheme

In order not to rely on chance, all factors affecting the magnitude of thrust are carefully studied. Among them, there are dynamic (atmospheric pressure, precipitation, wind, damage to the chimney) and statistical, depending on what dimensions of the fireplace were chosen during construction, what is its width, height.

Good to know: How to make a fireplace with your own hands, step-by-step instructions for work

How to make sandwich chimneys and connect everything correctly?

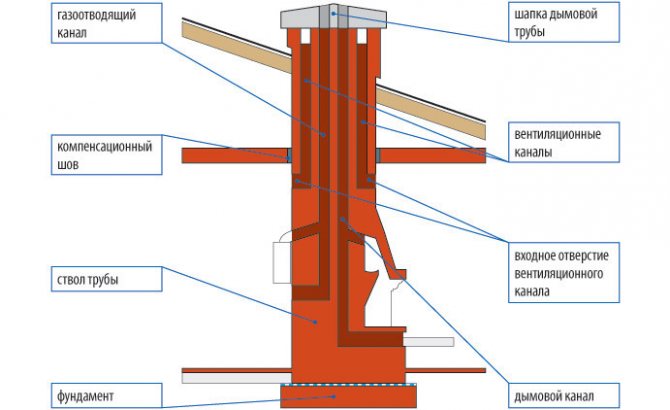

It so happens that one chimney is used for the simultaneous removal of combustion products from several heaters. In this case, the calculation of the chimney will need to be made, taking into account all the heating devices that will be connected to the system.

Sandwich chimney diagram.

In this case, it will be necessary to take into account their type, power, fuel option and its consumption. For example, in a building with a single chimney, several different heaters are installed, these are stoves, and fireplaces, and boilers. It is clear that such a system will differ sharply from the previously described option, because the diameter of the chimney to the fireplace will not correspond to the diameter of the pipe from the boiler, since fireplaces mainly heat rooms with wood fuels, while boilers run on natural gas.

Figure 2. Chimney with two outlets.

At first glance, it is impossible to combine these different systems, but experts have found a way out in which the correct placement of heating devices will not only eliminate possible problems, but also make them so that they will successfully complement each other. This can be achieved in the following way. A chimney for the fireplace and for the boiler is arranged separately. In the course of its operation, the boiler turns off from time to time and goes into standby mode.

At this very moment, another heating device is used - a fireplace. This allows you to maintain a normal temperature inside the pipe, so that it will not cool down and, therefore, condensation will be excluded. But the chimney for the fireplace should be much larger than for the boiler.

Some people mistakenly believe that infrequent use of the fireplace will in no way harm the system, but even the slightest deviation of the chimney from the norm will lead to serious consequences - even equipment failure. Therefore, the only correct solution in this case will be a two-way chimney with two separate outlets (Figure 2).

Basic fixed sizes

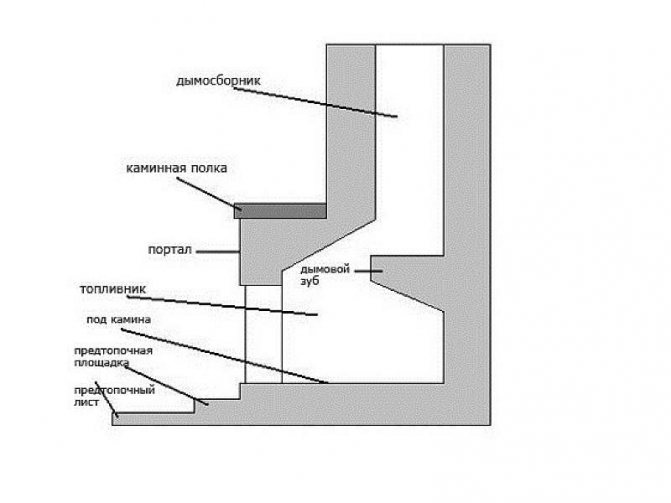

Standardizing sizes does not mean that all fireplaces have to be cloned from one. The fact is that among all the dimensions are determined by those that affect its functionality. It is these dimensions that must be respected. Among them, the linear dimensions of the furnace, the area of the smoke channel, the distance from the floor to the lower edge of the fireplace window, the position of the smoke tooth relative to the fireplace bottom, and the width of the channel in the area of the tooth overlap are distinguished.

The rest of the dimensions do not affect the operation and play a decisive role in the difference between the models from each other. For example, the size of the portal is chosen depending on the size of the firebox and on the space allocated for the fireplace.

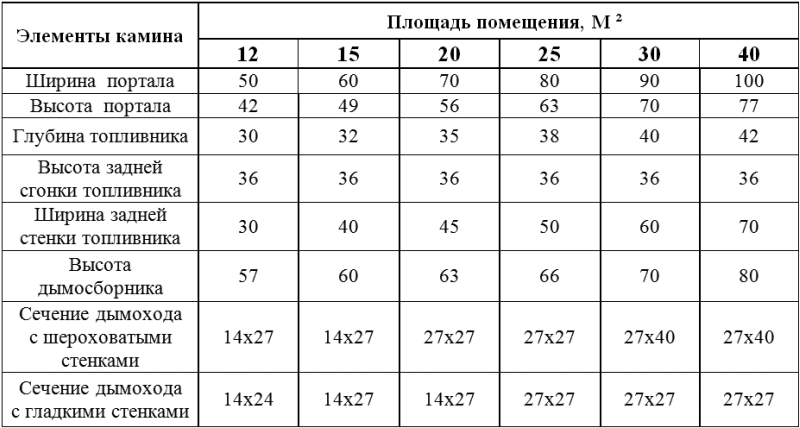

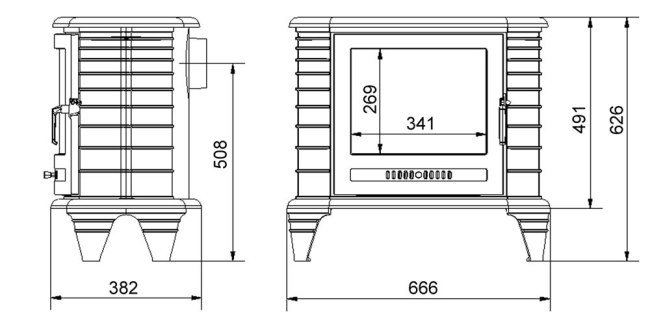

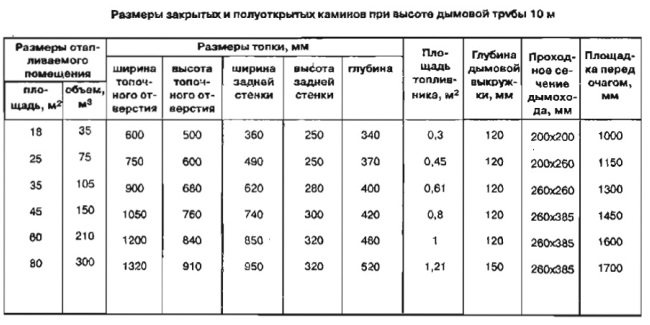

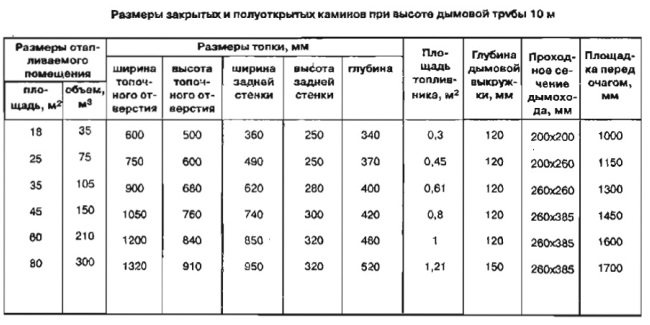

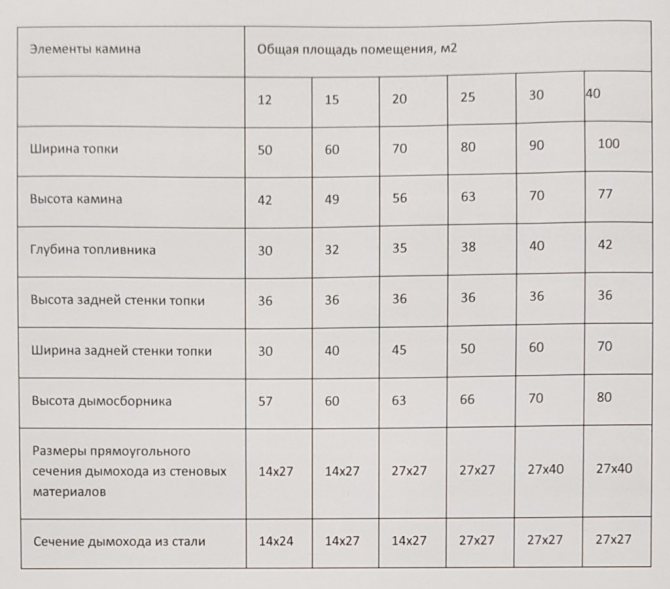

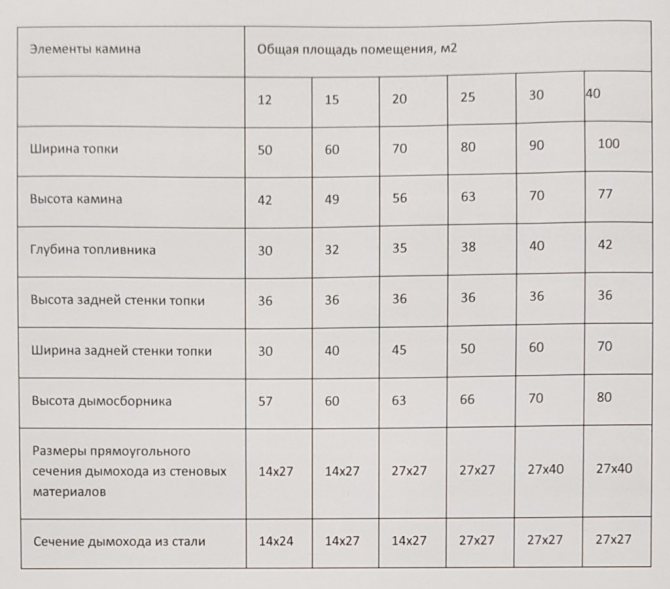

Fixing dimensions does not mean setting them to an absolute value. The listed dimensions depend on the volume of the room that will have to be heated. But a mathematical relationship has been established between them, which cannot be violated. When creating a project, you can use one of the many ready-made tables, which contains all the values necessary for these conditions. Such a table is an everyday tool for any craftsman.

Dimensions of fireplace elements

Despite the fact that similar tables can be found in any source, every master, even a beginner, should have an idea of how to generate this data.

Internal section of the chimney

Chimney chimney.

Better the usual cylindrical shape for the construction of a chimney yet. Considering the uneven upward movement of combustion products, which move in a circle along the axis of the chimney, the cylinder looks like the most acceptable shape, which is capable of providing the strongest draft. In a rectangular pipe, vortices will form at the corner parts, which prevent the normal thrust level from being achieved. However, it is noted that a rectangular pipe can be successfully used with thermal devices that do not require high thrust.

Such fireplaces and stoves include options that heat rooms with wood. If, for example, the cross-section of the chimney is rectangular and the chimneys in it are correctly arranged enough, this will allow you to maintain the temperature to which the heater was heated. Compared to pipes with a circular cross-section, this looks ideal, since all the heat will quickly evaporate from the cylindrical chimney. New generation fireplaces are increasingly equipped with cylindrical chimneys. They work according to a rapid heating system - when the system heats up to a predetermined temperature, the boiler shuts down on its own and goes into standby mode, thus saving energy.

Calculation of parameters

The starting point for calculating the structure can be the volume of the room or its area.To determine the area of the fireplace window, which is the front of the firebox, you need to divide the area of the room by 50. All the necessary measurements for the house can actually be carried out without special devices. Knowing the area of the furnace hole, you will have to solve a small problem in mathematics. The ratio of the width to the height of the window is expressed as a fraction of 2/3. Based on these conditions, the first specific dimensions are determined.

Theoretically, the gas flow rate should not depend on the depth of the furnace. But practice shows absolutely opposite results.

- Excessive depth leads to increased speed. Such an outcome is considered unfavorable, since the heat will not have time to be transferred into the room and, together with the warm air, will leave the room through the chimney.

- Shallow firebox depth is a direct cause of poor draft. The room will gradually begin to fill with combustion products.

Good to know: How to build a corner fireplace with your own hands, a simple instruction for beginners

The standard depth is tied to the height of the window. It is 2/3 of the value of the latter. The selected proportions have been tested over the years and are the truth, to which there is no need to select a theory.

Finished cast iron version

A complete calculation of the fireplace implies the calculation of parameters for the chimney. But here the main indicators depend on the shape of the smoke channel. In cross-section, the channel can be a circle, square or rectangle.

Convection currents rise along the chimney along a complex trajectory that looks like a spiral. As a result, air masses practically do not encounter obstacles in the circular channel. In the other two types of channels, microflows are formed at the corners, which, with their swirl, impede the movement of smoke. In such chimneys, it is advisable to talk about an effective channel, with an area much smaller than the area of the smoke hole.

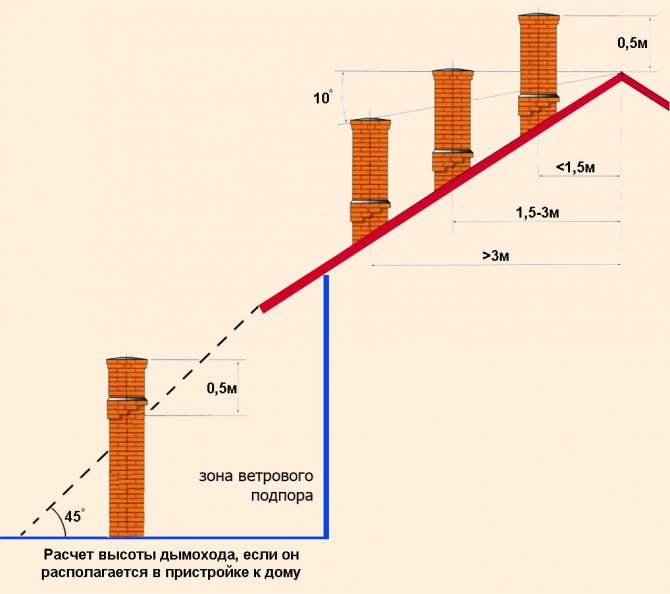

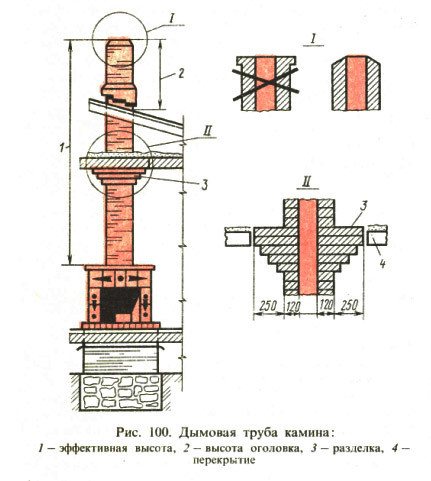

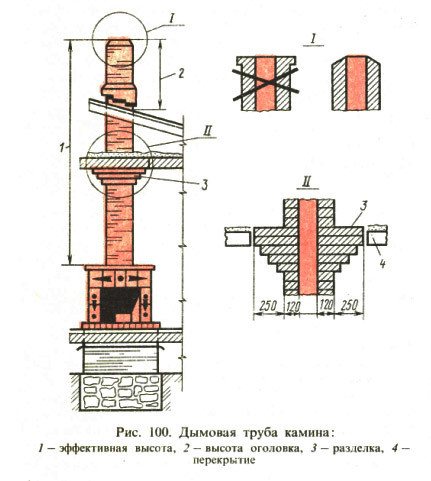

This theory is proof of the fact that with the same chimney height, the thrust value depends on the shape of the channel section. The averaged parameters of the chimney can be set and adhered to during construction. The length of the pipe will be affected by where it exits through the roof. It is not the proportions that are important here, but the distance from the pipe to the ridge. If it varies within 1.5 m, then the pipe is erected 0.5 m above the top of the roof.

Chimney dimensions table

The next range of distances, limited to three meters, corresponds to the equality of the levels of the pipe and ridge. If the distance from the pipe to the ridge exceeds 3 m, it is necessary to apply geometric constructions. Mentally, you should draw a horizontal line through the highest point of the roof. From it, count the angle of 10 ° degrees and draw the beam. Our pipe should end at the intersection of the beam and the axis of the smoke channel.

Do not forget about the area of the channel. It should be 10 times smaller than the area of the fireplace window. If you run a channel with a larger area, then this will not lead to an increase in thrust, as it might seem at first glance. Too large an area promotes the breakthrough of cold air flows from the atmosphere into the room. This phenomenon is called reverse thrust.

Good to know: Installing a fireplace in a wooden house, the main stages of work

Interior decoration

Bio - fireplace.

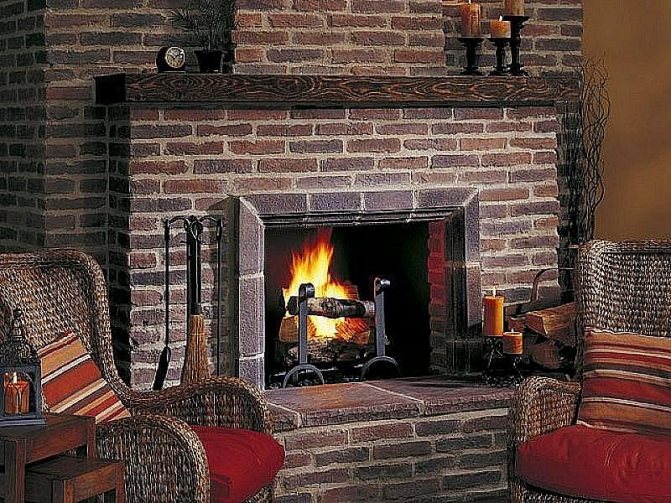

Nowadays, fireplaces have become very popular, they are installed not only in a private house. Modern biofireplaces have made it possible to use this unit in ordinary apartments. But such structures are intended primarily for decorative purposes, but today we want to talk about real ones, working on wood fuel, for the installation of which it is required to build a foundation.

Both heats and dries

In a country house.

Regardless of what kind of fireplace is installed in the house, many perceive it as an attribute of decorating the room and do not think why this unit has survived almost unchanged from ancient times to the present day. But he is an excellent ventilation device at home.

With its help, you can ventilate and dry the room, while this operation is performed in a very short time, during which more than one heating device cannot cope with this task. This unit is very good to use in rooms where there is no central, constant heating.

For example, having lit a fireplace in a private house used for occasional living, you will very quickly dry and warm up the dacha. (See the fireplace stove for a summer residence)

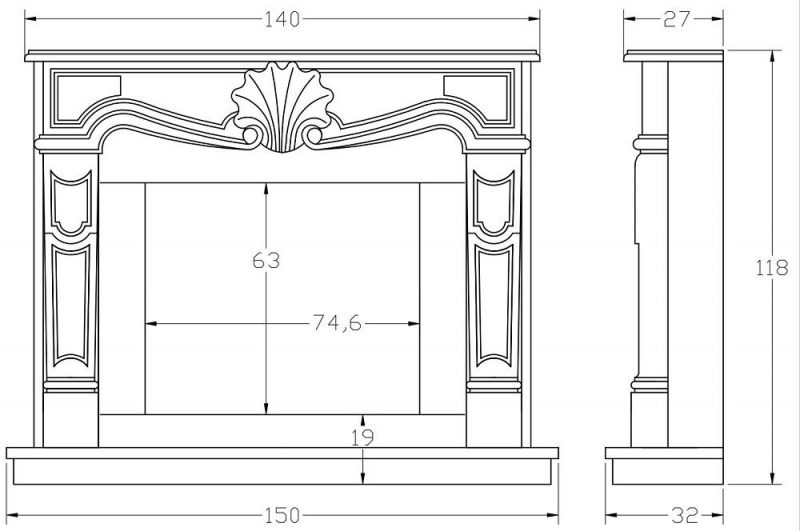

Size matters

But we must understand that all these advantages are effective only if the sizes of fireplaces for the house are chosen correctly. After all, it is no secret that when arranging it, many care first of all about the appearance, location in the room. And only in the last place they turn their attention to such an important fact as the size of the fireplace.

Today we will just talk about how to correctly calculate a fireplace for a house and make a design drawing based on the existing tasks in order to ensure maximum efficiency.

Important aspects: what needs to be considered?

Smooth under.

When you start designing a fireplace for a home, make a drawing (see Drawings of corner fireplaces) and perform calculations based on the size of the room. Firewood can be burned both in a special metal basket and on the grate, or, perhaps, just on the bottom of the firebox.

Grate.

Our regular readers know that for normal combustion, in addition to fuel, a sufficient supply of air is required.

- in the case when the fuel will burn on a flat hearth and the dimensions of the fireplace inserts are the same, combustion on the grate will be much more efficient;

- however, in both cases, the dimensions will be identical.

The fact is that the use of a grate provides additional air flow, in this case it is possible to reduce the size of the furnace without losing efficiency.

Double effect - warmth plus ventilation

Since we started talking about air supply and the possibility of taking it in in different ways, it should be added that in some cases air can be taken not only from the room in which the fireplace is located, but also from the next room or even from the basement.

Such a device allows you to simultaneously achieve several positive aspects:

- By taking air from the basement, you will significantly increase its ventilation, which in itself is a good result.

- If air is taken from another room in the house, no vacuum is created in the room where the fireplace is located, and its absence does not allow cold air from outside to enter the heated room. The effect is obvious - the room heats up very quickly with minimal fuel consumption.

- If it is necessary to ventilate the heated room, the external air intake is simply shut off. In this case, combustion air begins to flow from the room where it is located, the room is ventilated.

What have not been considered yet

All dimensions that have been listed above are in a certain dependence on each other. We suggested taking the area of the room as the starting point for the calculation, which is a well-founded decision. However, in some cases the problem has to be solved from the end. For example, if the house has a chimney that meets the requirements for fireplaces in terms of its functions. Then all calculations will have to start from the area of the channel.

There are certain indicators that are not mathematically related, but are decisive for the normal operation of the fireplace.

- The height of the fireplace window from the floor can be about 0.3-0.4 m (depending on the presence of a niche for storing firewood).

- The podium for the portal protrudes from its borders in front by 0.5 m, and on the sides by 0.3 m.

- The angle of the smoke tooth is 20 ° degrees.

- The side walls of the furnace taper towards the chimney, forming an angle with the normal from 45 ° to 60 ° degrees.

Now you know everything about the formation of the geometric dimensions of the fireplace. Is it more convenient to use this knowledge or ready-made tables to understand what the width of the fireplace should be, its height? Each master gives a personal answer to this question.

Chimney - special attention

When designing, it is important to correctly calculate the size of the chimney for the fireplace. It is calculated based on the area of the portal and should be in 10-15 times smaller than it.

Advice: knowing the size of fireplace inserts, you can, of course, calculate the size of the chimney, but you should know that this is a very responsible event. If you do not have a lot of experience in this area, it is better to entrust it to a professional, because no one has canceled such a concept as reverse thrust. Carbon monoxide poisoning is deadly! Remember this!

You can get more detailed information about chimneys by reading the corresponding articles on our portal. There, various chimneys are described in detail, including chimneys for fireplaces.

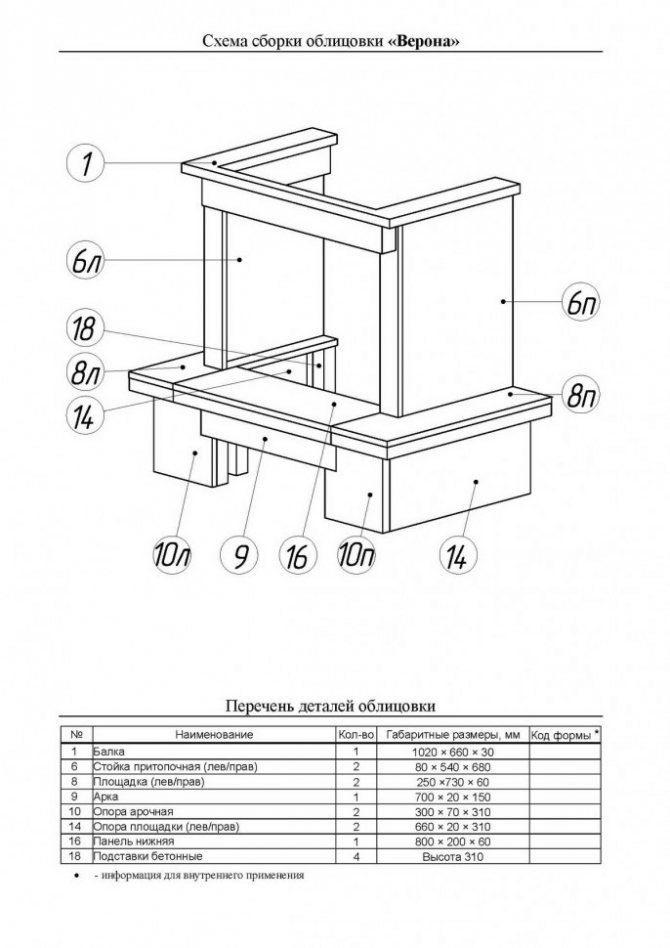

Dimensions and material - direct relationship

When setting up a fireplace, the dimensions of the chimney and firebox are not the only ones you need to know. For example, someone is more interested in the question - how many bricks do you need for a fireplace? The question is not idle and quite understandable.

But before answering it, we want to add a little to all of the above. In our article, considering the methods of calculating and determining the size of this or that part, we did not mention the materials. Why are we talking about this just now? Because this is directly related to the question of the number of bricks.

Choice of location and dimensions

Previously, we calculated the furnace dimensions, the fireplace and its dimensions directly depend on the material from which it will be made. Knowing the material, you can fairly accurately calculate the dimensions and determine the place for the future fireplace.

On our pages, we have already described how to choose a place, so we will not repeat ourselves. The only thing that needs to be added: knowing the placement rules and correctly calculating the dimensions, you can install this unit in the best possible way.

Foundation

After determining the dimensions of the firebox and chimney, you should calculate what the foundation should be.

A foundation is built based on the weight of the future structure. If the weight of the fireplace is less than 700 kg, then the foundation can be omitted, however, often, the weight of the structure is significantly higher, so the foundation is necessary.

When building a medium-sized fireplace, as a rule, a foundation is made with a depth of 0.75 to 1 meter. These figures are true if it is planned to live in the house permanently and the soil under it will not freeze. When building a fireplace in a summer cottage, the foundation must be buried to the depth of freezing of the soil.

Please note: it is extremely important that the foundation of the fireplace and the foundation of the house do not have bandages, since these structures can give different settlements, which will lead to the formation of cracks.

Major mistakes

Unfortunately, this is not always the case. In some cases, one or several rules are violated:

- The correct size fireplace for a particular room.

- Correct placement in compliance with its dimensions for a particular room.

Knowledge is power

This knowledge is optional in the case when you will be engaged in construction with your own hands, they will be useful to you when you hire outside workers for construction.

Nowadays, there are "specialists" who are able to build something that at first glance looks and works well, but on deep examination turns out to be another flaw. The knowledge will help you to exercise the right control over the construction work in your home.

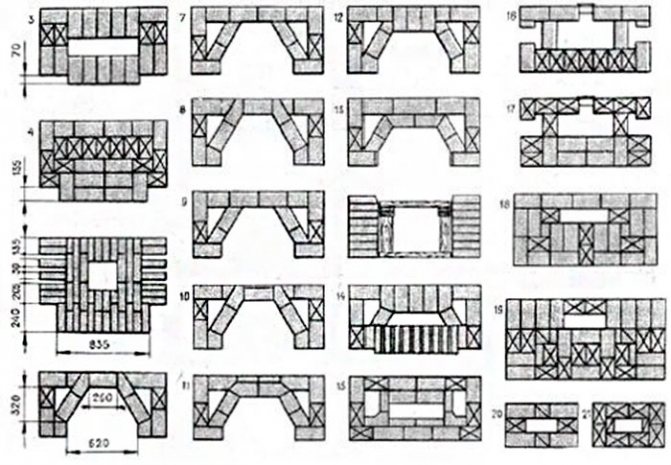

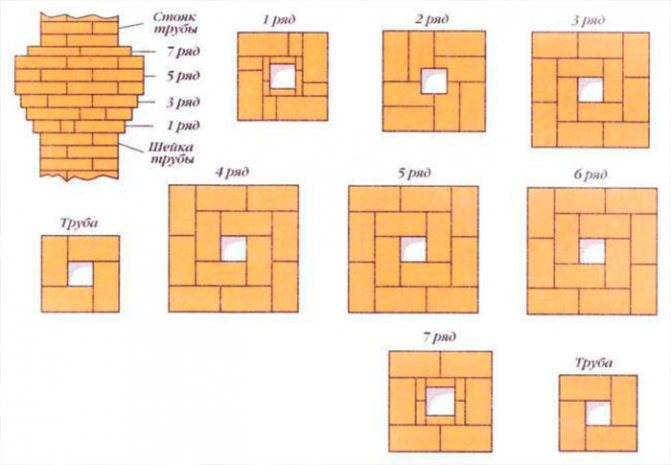

The number of bricks - count the orders

Masonry.

As for the number of bricks, we will not give detailed calculations for one simple reason - they will not be useful to you at all. Indeed, for each specific case, a completely different calculation is required.

Nevertheless, we will try to explain in a nutshell how you can roughly determine the number of bricks. Knowing the size of the fireplace, the dimensions of the brick and the thickness of the seam, you can fairly accurately calculate its amount.

Ordering.

- In any case, when arranging fireplaces, its dimensions are transferred to orders.

- Having orders on hand, use them to count the number of bricks.

- Don't forget about the seams. The thickness of the seam plays an important role in this case.

We have already described how to properly arrange the seams in the articles on masonry on our resource, so we will not repeat ourselves. By adding the number of bricks in all orders, you get the total. If the base is made of bricks, do not forget about it.

Our advice: add more to the amount of bricks obtained 10%.

Size and shape matter

This rule applies entirely to the size and shape of the chimney. A straight-through channel with a gate of approximately the same area of circular and rectangular cross-section removes combustion products and smoke in different ways. And this difference is very significant, since in a chimney with a circular cross-section, the rise of smoke is carried out by a spiral flow, which completely occupies the entire cross-sectional area. In a rectangular channel, in addition to the central flow, small flows and eddies are formed at the corners, which significantly reduces the flow rate.

That is why, when calculating the area of the chimney, the ratio of 1/10 is taken in relation to the area of the furnace window for rectangular chimneys. And the ratio is 1/15 for round chimneys.

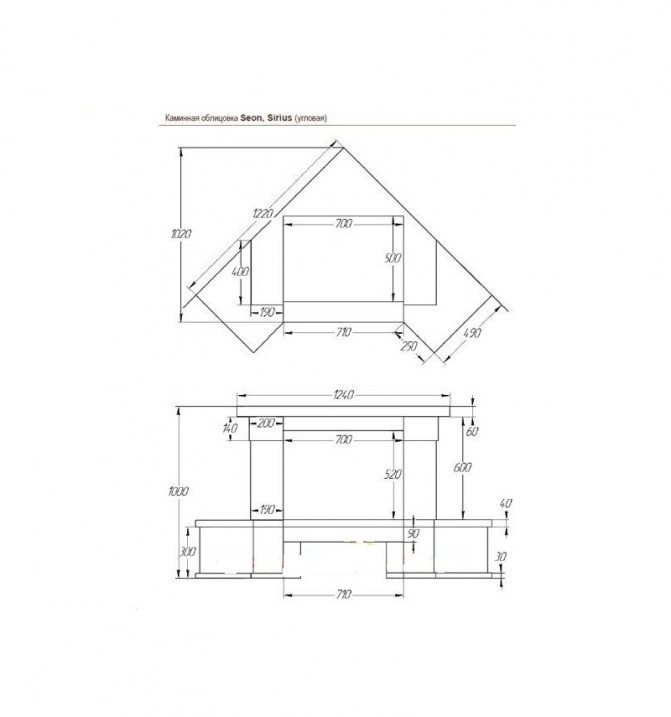

Mini fireplace drawing

This heater is recommended to be installed in a room of at least 16 m 2. It is built into a partition to heat two rooms. To increase heat transfer, the firebox is laid out without refractory bricks. Thus, ceramic brick heats up much faster, because it retains the heat capacity of the array less than refractory bricks.

- In this case, in order to protect the firebox from high temperatures, the master stove-maker uses a metal sheet 3 mm thick instead of a stone tooth.

A drawing of a brick fireplace is attached below in the description. If the master has little qualifications in this direction, then instead of the portal arch, a horizontal overlap can be built. To do this, you need 2 metal corners of the required length.

The positive characteristic of this fireplace is that by purchasing materials for its construction, you spend as little money as possible.

For the construction you will need:

- ceramic bricks 235 pieces;

- clay - 0.12 m 3;

- sand - 0.3m 3;

- cleaning door - 1 piece;

- stove valve - 1 piece;

- - 1 piece;

- strangles - 2 pieces;

- steel sheet thickness - 3 mm and size 0.25 m 2;

- roofing material - 1.5 m 2;

- cement - 15 kilograms.

Fireplace "mini" and its ordinal scheme of masonry

To maximize the efficiency of this structure, the side walls of the firebox are laid out at an angle of 25 degrees.

The back wall is laid out in 10 rows in the usual way, that is, horizontally. Starting from the 11th row, the brick moves out a quarter at an angle of 30 degrees into the inside of the firebox. By this action, a pass of the chimney tooth is formed, metal pins are inserted into the seams between the bricks, then a sheet of metal will be attached to them.

Below there is a metal drawing for the firebox.

Due to the absence of fireclay bricks in this structure, the space in the room heats up much faster, since the side air channels are lined.

In the lower part there are openings through which cold air enters, and hot air heated from the fireplace insert through the "chokes" located in the 13th and 14th rows, goes into the interior of the room with hot air. Thus, its efficiency increases by 15, 20%

Fireplace construction according to the order

To prevent the brick walls of the future hearth from dampening, absorbing moisture from the foundation, the base area must be covered with roofing material in 2 layers. Without waterproofing, the building will crack pretty soon and start to smoke into the room.

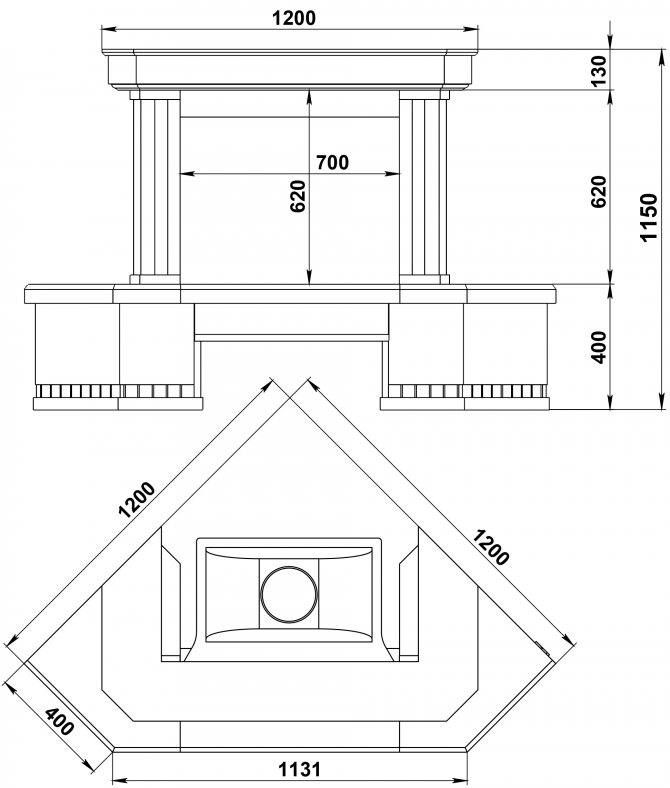

This is how the corner hearth "Annushka" looks like

The brickwork of a corner fireplace is carried out according to the orders in the following sequence:

- Prepare a clay-sand mortar from a dry masonry mixture, following the instructions on the bag. Lay out the first solid row of 1020 x 1020 mm bricks in the shape of a square platform. This design makes it possible not to place a pre-furnace metal sheet in front of the portal.

- Lay the bricks of the second tier, starting from the far corner of the landing, to form a triangular base of the hearth 890 x 890 x 1260 mm. For cutting and shaving off stones, use a grinder equipped with a concrete circle.

- In rows 3-4, a niche is laid out for storing and drying firewood. From above, it is covered with a sheet of metal laid on the lintel from the corner. The next 5th tier is solid, it plays the role of a capital overlap.

- On the 6th row, the hearth part of the firebox is formed, consisting of chamotte stone and framed outside with red brick. Further, up to the 13th tier, the side and rear walls of the fuel chamber are placed. A chimney tooth is formed from the 12th row, for which the refractory stones of the back wall are cut obliquely and moved forward (30 mm on each row).

- On the 13th tier, a horizontal portal lintel is placed from two steel corners, deployed with shelves towards each other. From the 14th to the 16th row, the overlap of the firebox and the chimney tooth are simultaneously formed.

- Rows 17-21 make up the walls of the smoke collector, gradually turning into a rectangular channel, and the 18th tier is made with a protrusion of the bricks of the frontal part. The remaining rows 22-30 form a chimney with curly side walls. Install the valve on the 28th tier.

The order of construction of a corner fireplace with the romantic name "Annushka" is displayed in the following video:

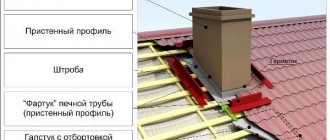

The chimney channel crossing the timber floor and the roof structure must be laid with a fire cut (thickening of the pipe in the place of passage). The top of the chimney is removed from the leeward zone and rises to a height that provides normal draft, which is reflected in the diagram.

Features of masonry fireplace

Before starting the construction of such a useful invention as a fireplace, the dimensions of which were determined by us earlier, waterproofing should be provided. This will require roofing material, laid in 2 layers. Laying should start at the corners. In this case, you need to constantly monitor the level. To give the structure an original look, you can lay the bottom row on the edge, and all subsequent ones - flat. Outside solid rows require the use of a trowel or trowel. The smoke collector or firebox should be carried out manually, as this facilitates the detection of small stones in the solution.

It is important to remember that when erecting a smoke collector and a firebox, the fireplace stove requires the removal of excess solution with a damp cloth. We must not forget that the inner wall is not plastering

The seam must be thin, otherwise it can quickly crack. Modern fireplaces need to tie the seams on half a brick in each row.

The lining of the firebox and the outer wall should not be connected, otherwise, due to frequent temperature changes, the masonry may be disturbed.

Facing the finished fireplace

If you wish, it is quite acceptable to leave the "front" part of the fireplace without finishing, especially if you used a nice red brick. It is worth thinking about this even during the laying, if no further finishing is envisaged, it is better not to put the mortar end-to-end to the very edge, leaving characteristic slots between the bricks. To make them, then it is problematic and threatens with a violation of the integrity of the masonry. In case you nevertheless decide on cladding, make a choice on one of these materials:

- Stone (any variation, even natural.)

- Tile (better tiled).

- Drywall, do not forget that it must be fire and temperature resistant. In addition, it will require a special frame (only made of metal).

- Classic plaster.

Here are some tips to help you keep your fireplace intact. For example, if you use stones, tiles, it is better to immediately varnish. This will make it easier to treat dust wiping.

By the way, one more thing, if you chose plaster as a finish, remember an important rule, plastering is allowed only after complete shrinkage. Otherwise, huge cracks will go along the entire plane, which will definitely not add grace.

The plaster itself, at first glance, is a simple way of finishing, however, taking into account the variations in different shades and design styles, you can create a prettier and more expressive cladding, even better than that of natural stone. A variety of ornaments and patterns can be applied with plaster, which cannot be done with any other finishing material.

Types of corner fireplaces

An electric fireplace can be installed in an apartment

The classic corner fireplace consists of a portal (body), a firebox, an ash pan, a grate, and a smoke exhaust system. Today there are several types of heating facilities.

Electric fireplace

Floor-standing and back-to-wall models are installed in apartments without permission. The device looks like a standard heater with simulated flames and embers. A corner electric fireplace is inexpensive and easy to operate.

Fireplace stoves

They support long-term burning, work on solid fuel. The facade is semicircular, which provides an extended view of the fire. At the moment of combustion, heat is reflected from the walls and evenly distributed throughout the room. The following brands are included in the user rating of fireplace stoves:

- Teplodar wood-fired. The difference between the structure is its compact dimensions, the efficiency is 95%. Suitable for baths, combined with steam generators;

- Bavaria with the upper outlet of the smoke ducts. A slightly elongated device has a power of 9-12 kW and is designed for a room volume of up to 180 cubic meters. A decorative look is created by a heat-resistant tile cladding, and functionality is created by a high-quality hob;

- Eurokom, which maintain a long burning mode. The Polish cast iron apparatus is equipped with a hob;

- Godin with futuristic or classic designs. French products are manufactured in cast iron, steel, with a tile lining. Thanks to the secondary afterburning system, the living room, kitchen or the entire home is heated qualitatively;

- Neva from a Russian manufacturer. Firewood is used as fuel. The cast-iron stove has small dimensions (0.87x0.64 m), but it will warm up the house by 60 m2 with high quality.

Bio fireplaces

Brick fireplace stove can be equipped with an oven, hob, water circuit

They run on alcohol fuel, therefore, they require compliance with the operating rules. The mixture for ignition is poured only into a special compartment, and then ignited. The biofireplace is economical - you only need to refuel once every 3-7 hours. Manufacturers offer a modern way to control the intensity of combustion - from a smartphone or remote control.

Brick models

To consider the device and features of brick modifications is the example of the Annushka model, designed by E. Doktorov. The structure is mounted at the outer or inner wall of the building.

In the classic project, the furnace hole was 0.2 m2, and the width was 2/3 greater than the height. For good heat transfer and no smoke, the depth and height of the firebox are correlated as 1: 2 or 2: 3. The chimney is 8-14 times smaller than the firebox. Other features of the author's fireplace include:

- the presence of a foundation is 15-20 cm more than the fireplace space;

- arrangement of screening made of galvanized iron. Its size is 100x200 cm;

- the protrusion of the upper edge of the screen 35-36 cm from the firebox and 7-8 cm from the walls;

- use of ceramic insulators;

- the presence of a heat-resistant layer near wooden walls - asbestos or fire-resistant drywall is used;

- primary laying of materials dry;

- thermal insulation of the chimney exit point to the attic or second floor

- outlet of the pipe head 50 cm from the roofing.

Gas devices

A gas fireplace requires a permit and a working chimney

The structures are connected only after obtaining permission from specialists. Installation takes a long time, but the finished product almost does not emit combustion products, does not require frequent cleaning from soot or soot.

Metallic options

You will need wood-burning fuel for the bookmark. Similarly, brick ones require the construction of a chimney, but the foundation is made in the form of a layer from below. The factory door made of fireproof glass allows you to view the flame.

Standard fireplace sizes

The choice of a fireplace project, its design, and additional elements depends on many indicators. But most often, during the initial selection of construction options, it is proposed to use the standard dimensions of the fireplace.

This concept is used for the selection of basic materials for construction and structural analysis during construction. Standard dimensions indicate the functionality of the fireplace - its external dimensions, the size of the firebox, the amount of fuel needed to heat the room. The calculation of these parameters is based on the ability of the firebox to heat the room most efficiently. If a fireplace with a small firebox is installed in a large room, then naturally the power of the fireplace will not be enough to heat the room.

The standard dimensions of the fireplace, in their contextual understanding, imply the use of certain ratios of its nodal structures. So, first of all, this concept concerns the height of the fireplace. It is from the height of the furnace that all calculations are made. This indicator is one of the components of the proportion of the "height / width" ratio of the furnace window - 2/3.

This section is standardized with other important parameters - the dimensions of the chimney section and the flow section. The height of the fireplace is also taken into account when calculating the depth of the firebox, which determines the productivity and safety of the building. Also, the standard dimensions are calculated for the height of the protrusion from the lower level of the firebox and to the height of the installation of the upper tooth (protrusion).

When calculating the size, shape and materials for construction, experienced craftsmen use special calculation formulas. And for those who are trying to calculate the parameters on their own, it is recommended to use the standard dimensions of the fireplace, given in the table.

We calculate a fireplace with an open hearth: important aspects of creation

When organizing the construction of any fireplace, one should not forget about the important recommendations of specialists. The most important thing is to follow all sizes, since they play an important role in the characteristics of the fireplace. When you start preliminary calculations, follow all formulas and take into account possible factors and aspects.

The fireplace should harmoniously fit into the interior in color, shape and size.

Among the important aspects, the following can be highlighted:

- The size of the insert of almost any fireplace should not be less than 25 cm, and not more than 40 cm. Such dimensions are considered optimal for household type fireplaces with an average power. These varieties are the most common. If we talk about a stove for a bath, then here the width of the firebox can be slightly more than 40 cm.

- If you doubt the correctness of the calculations for your fireplace design, you can check them in a simple way. The width of the firebox must necessarily match the width of your firebox door.

- Please note that the difference in size will significantly reduce the heat flux, and the fuel will burn much more slowly than it should be. In any case, the wrong dimensions will reduce the use and efficiency of your fireplace.

Experts always try to pay special attention to the firebox, because its parameters are the most important indicator. The minimum size of the firebox should be 80 cm, the maximum 100 cm. Very often, when constructing a fireplace, it is impossible to achieve such an indicator, and the way out of this situation is to increase the level of the afterburner. If the size does not match, then all the flammable gases that were formed in the process will not burn.

Finishing the finished fireplace

The finished fireplace is decorated with facing materials or left as it is: the brick gives the room a special charm and authenticity.

How to make the right jointing

It is performed if the facade of the fireplace is not planned to be faced.

- We use a clay solution: we bring the clay pulp to readiness, and then pour the cleaned and dried sand into the mass, stir the mixture until a homogeneous thick composition is obtained, which is easy to form.

- To make the jointing more convenient, when laying brick blocks, we do not bring the cement mortar to the outer edge of the wall by 5 mm.

- We regularly check the geometric parameters of the structure using a level.

Facing the fireplace with various materials

There are many options for decorative finishing of fireplaces:

- The finished fireplace structure can be plastered without affecting the inner surface of the firebox and smoke box. This is the easiest method for finishing a heating structure. With the help of special spatulas and special techniques you can create interesting decorative effects. In addition to plaster of the usual color, you can use colored compounds.

- Another common method of decorating a fireplace structure is to decorate it with drywall sheets. The material is cut and attached to a steel frame. In this case, it is necessary to strictly check the geometry of the walls and corners using a level.

- Also, the fireplace can be faced with refractory tiles or elegant tiles, overlaid with synthetic, wild stone or marble. To improve the aesthetic characteristics and facilitate the maintenance of the fireplace, decorative stones should be coated with a special fireproof varnish.

- To make the fireplace even more aesthetically pleasing, it is worth installing a special screen in it. For the manufacture of fireplace screens, a metal mesh and elements of artistic forging are used. In accordance with fire safety regulations, a steel sheet must be laid in front of the fireplace.