It is known that a large amount of heat is emitted through door slots. If the door is made of steel and has an empty internal cavity, then it becomes an additional source of heat loss. Wood, like metal, is also not able to maintain the required temperature regime in the house. Therefore, door insulation (wooden or metal) is not a whim, but a necessity, allowing you to maintain a comfortable microclimate and significantly save on heating.

What is felt insulation for doors

What a pity that this superb, natural material with excellent performance is almost forgotten. Today felt is used to insulate doors and window openings. In ordinary houses, this is where it ends, but if we are talking about wooden structures or a bathhouse from a log house (timber), then it is also used as a mezhventsovy heater and for sealing cracks. And, probably, no one even knows that felt insulation can be different:

- technical fine-haired - manufactured in accordance with GOST No. 288-72;

- technical semi-coarse wool - manufactured in accordance with GOST No. 6308-71;

- technical coarse-haired - manufactured in accordance with GOST No. 6418-81;

- yurt - manufactured in accordance with GOST No. 16221-79;

- Firth - made from the finest fibers of six rabbits and goats.

Felt insulation has a fairly low thermal conductivity, the coefficient is 0.03-0.07 W / m * K and depends on the density of the material. The latter varies in the range from 10 to 400 kg / m. cub.

The material is produced both in panels and in rolls. The dimensions of the panels are 2000 x 2000 mm, rolls are up to 1800 mm wide and up to 200 m long. It is made from both natural and synthetic raw materials. Synthetics is already a trend of modernity, you should not take it seriously, but natural materials deserve attention.

This is a seal for the crowns, 15% made of felt.

In addition to the fact that the felt is produced in its pure form, it can be a part of other natural insulation materials. For example, felt jute, where impurities make up up to 15% of the total mass of the material. It is produced in strips and is used for laying between the crowns of buildings made of logs or beams, as well as for sealing gaps between logs and in corners (bowls).

Felt insulation for doors was originally used to make felt boots. The very name of this shoe tells us about the method of its production. Felt boots are made from natural sheep wool by dry or wet felting. As a result, the villi bind together in such a way that a monolithic carpet is obtained. Whoever spent at least one winter in felt boots knows firsthand about their qualities. Accordingly, felt insulation for doors has all these characteristics:

- repels moisture, but still gets wet;

- when it gets wet, it does not lose its thermal insulation qualities;

- excellent sound insulator;

- not harmful and non-toxic;

- does not burn in the natural environment - to maintain combustion, more oxygen is needed than is contained in the atmospheric air;

- harmful bacteria do not grow in it.

It would seem that felt door seal is just the perfect material, but no, there is one drawback. Moth loves to eat it very much and if it is already started, then it is extremely difficult to remove it. In this regard, the material in production is treated with a 3% solution of sodium chloride.

The question of which heating for the house is better has been raised more than once, and there is still no definite answer.Each of the methods has both advantages and disadvantages.

If you need a working plan for heating a one-story house, then take a look at this article.

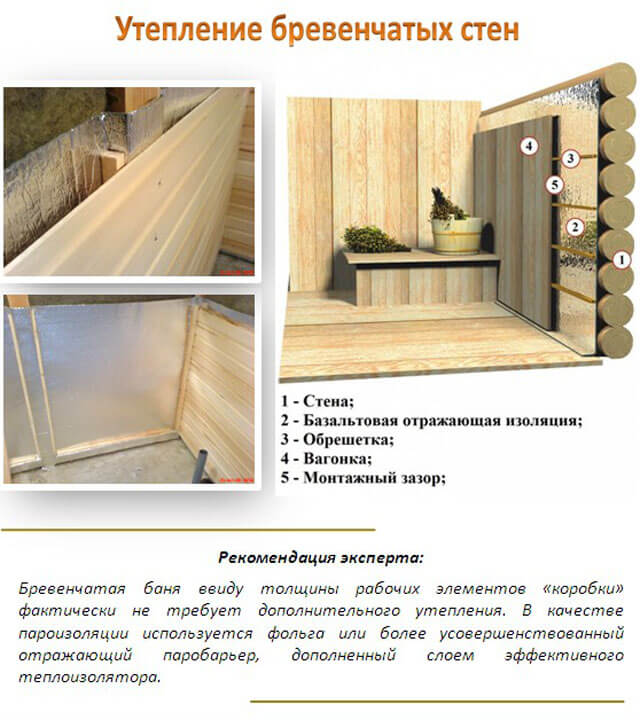

Features of warming the walls of the steam room

After the ceiling is insulated in the steam room, you can start processing the walls. The rough surface must be specially prepared for this procedure. Any joints, crevices and other cavities must be plastered or sealed with sealant.

- First, the aluminum foil is fixed using wooden blocks of 4 × 4 centimeters in size, placed horizontally.

- Heat-insulating material is laid between the beams.

- Then the foil is finally fixed with a construction stapler. It is important to stretch the material, but at the same time to prevent the formation of gaps, cracks or foil tears.

- All joints of the structure are glued with a special aluminum tape.

- On top of the tape, bars are attached longitudinally for laying the selected facing material.

- The work is completed by laying the topcoat.

When finishing, materials of low density should be used, since the insulation of the steam room in the bath requires from all structural elements the main thing - the preservation of heat in the room. It is best to look for pine, linden or aspen wood materials with low plank thickness. They not only reliably protect the steam room from heat loss, but will also look aesthetically pleasing in the photo and during visual inspection.

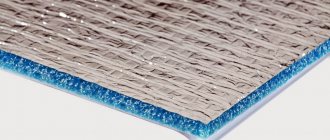

The installation of the material should be carried out horizontally in order to reduce the total load distributed over the main structural elements. Penofol, which is gaining popularity in the construction market, should be chosen as an insulating material.

How to insulate a door in a bathhouse with felt

Most often, felt is used for insulating door and window frames, as well as for external door insulation. The fact that the material is environmentally friendly and the fact that it breathes allows it to be used even in baths at high temperatures and humidity. Consider the insulation of a door in a bath with felt from two angles. The first will be the insulation of the box.

This technique is applicable to both the front door and the entrance to the steam room. In both cases, felt insulation for doors is laid along the perimeter of the box at the junction with the movable part. For this you need:

- roll the felt into a small roll;

- the side where the edge is visible, the roll is laid along the perimeter of the box;

- fastened with nails or a stapler.

No additional protection needed. If it is necessary to insulate the front door with felt, then you need to take the cloth and fix it on the outside. Then, using furniture nails with beautiful hats, fix the material you like (usually a leather substitute) over the insulation. The main thing is that the finish is resistant to atmospheric aggression.

The two-pipe heating scheme of a two-story house can be both vertical and horizontal. In this case, there can also be several methods for routing horizontal contours for each floor. Some of them: hitchhiking, dead-end, collector.

Heating a country house is somewhat different from the main housing. You can read about the best way to heat a summer cottage in winter in this article.

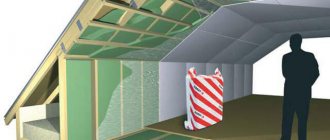

The importance of insulating ceilings in the steam room

There is a greater amount of insulation material on the ceiling compared to wall ceilings. The reason for this is air convection: as it heats up, it rises to the ceiling, and cold air descends in its place. The same thing happens with water vapor. In this regard, heat-insulating materials in the ceiling are laid in two layers, which will reduce the level of heat energy losses.

Ceiling thermal insulation of the steam room is carried out in stages:

- The rough surface of the ceiling is covered with paper rolls.The sheets are overlapped with each other with a sufficient overlap. The sheets are fixed with wood blocks measuring 5 × 5 centimeters.

- The empty spaces between the beams are lined with heat-insulating material.

- Then all ceiling segments are covered with aluminum foil, which is fixed with adhesive tape. It is important to avoid the formation of gaps and crevices in this layer. It is the foil surface that maximizes the safety of water vapor in the steam room and prevents condensation from forming. In the absence of aluminum foil, the ceiling of the steam room can be insulated with paper or cardboard impregnated with special compounds. It is worth finding out in advance how to insulate the ceiling in a bathhouse is best in your case.

- From above, the coating is once again knocked out with bars measuring 2x3 centimeters. This allows for improved ventilation of the ceiling.

- On top of these bars, the selected facing material is mounted.

Where else is felt insulation used?

Felt-based linoleum - insulation and soundproofing.

In addition to the above purposes, this material can be used for thermal insulation:

The methods, of course, are rarely used, but they are still discussed on the forums. Although felt for floor insulation is used very often in the form of a substrate for linoleum. Considering the hypothetical possibility of laying insulation under finishing materials, for example, as wall insulation with foam, you need to immediately cut off possible problems:

- moisture - although the material does not absorb moisture well, it still happens;

- mole - you need to impregnate the material with some means, but then you can forget about environmental friendliness;

- rodents - will not miss the chance to pull soft bedding into their burrow.

As you can see, it is quite problematic to use felt for wall insulation, and the price bites. It is sold by weight and per kilo they ask from 200 rubles, depending on the density. Such insulation will cost almost gold. A felt seal is suitable as a local thermal insulation, but even the technology has not been developed for the insulation of large areas. What to do in such a situation when there is no one to even turn to for practical advice? You will not find practitioners on the forums on this issue in the daytime with fire - some theorists are skeptical.

Honeycomb insulation

This material is essentially a standard cardboard, pressed in a factory way into an accordion or in the form of a honeycomb.

The honeycomb filling of the door is considered a cheap option for insulation, but the least effective in terms of insulation from noise or cold air. It is used as a filler that deprives the door of its hollowness.

Fastened as standard, on the entire surface of the door, avoiding obvious gaps.

The cost of the material is from 29 to 125 rubles per sheet. If you buy material in a roll, then the price is 2100-3800 rubles.

Warming a house with felt is a harsh reality

Despite all the positive aspects of this material, the complex warming of the house with felt is not possible for a number of reasons:

- it absorbs moisture;

- a mole starts up in it;

- mice feel great in it;

- it is too expensive;

- there is no methodology for such work.

How to insulate a door with felt can be told from two sides:

- insulation of the box (joints);

- complex insulation outside.

Also, this material is used for caulking mezhventsovy slots. In addition, felt insulation for the walls of wooden houses is used as a spacer between the logs (timber) during the installation of the structure. It can be used both in pure form and as part of other materials (jute). It is better to leave attempts to completely insulate the walls of any buildings made of any materials. Yes, there is a sturdy yurt felt that has high insulating qualities, but it still won't work. It is not designed to be enclosed by the body of the walls, because you are not going to insulate it without finishing.Felt floor insulation is widely used, but only as a substrate for linoleum. It does not apply to laminate flooring.

Read also: What fruits are obtained from a melon tree

Insulation of entrance doors is relevant both for a private house and for an apartment in a multi-storey building, since heat loss through a doorway in the cold season can reach up to 20%. The easiest and cheapest way to eliminate drafts is to fix door insulation in problem areas of the opening. The traditional material for creating a barrier to the penetration of cold air into the house is an ordinary building felt, but, besides it, there are a lot of modern synthetic insulation, and about the whole variety of these materials - below.

Felt tape for insulating doorways

Benefits of using a seal

The purpose of the material lies in its name. The main advantages of the seal include a number of the following qualities:

- It protects the housing from the penetration of cold and hot air from the outside, dirt, dust and foreign odors.

- Significant reduction in heat loss.

- Increases sound insulation performance, so that when the seal is fixed, it is possible to reduce the level of extraneous noise and significantly block their penetration into the premises from the entrance or street.

- High degree of sealing of the door frame due to the tight fit of its components.

- Increase in fire safety indicators, since the material acts as a kind of barrier to the spread of smoke and fire.

- A high-quality sealant does not change in size and eliminates the formation of gaps under the influence of sharp temperature fluctuations.

Note! The material also provides a shock-absorbing function, which is expressed in a softer contact between the door and the frame, thereby eliminating the occurrence of loud bumps and squeaks.

Types of doors and methods of insulating them

No matter how tightly the doors are fitted to the frame, over time, gaps appear between the door leaf and the frame, and the frame itself may skew. Therefore, the factory seal is broken, allowing cold air to freely enter the living quarters of the house. Completely changing the door is a costly and not always acceptable way out, and fixing felt insulation on the ends of the door or opening is a cheap and quick solution, which often completely eliminates the blowing of the door. But, in addition to the time factor, there are other reasons for the occurrence of a draft in the opening of the front door:

- Installation with errors, oversized door leaf;

- Loosening of awnings (hinges);

- The old house has crooked walls.

Elimination of draft on the front door

The door leaf and frame made of wood warp and wear out much more often than metal structures, since wood absorbs moisture well, and it is not always possible to protect it from this with high quality. Moisture impregnation creates cracks and twisting of fibers in the wood, and such deformations are potential places for draft penetration. Due to periodic moistening and shrinkage, doors can sag, loosen, dry out, crack and deform, which will certainly affect the density of contact between the canvas and the frame.

Therefore, wooden doors are not installed as often as before, and the appearance of doors made of other, more modern and reliable materials - plastic, metal, glass or a combination of the above components - contributes to this.

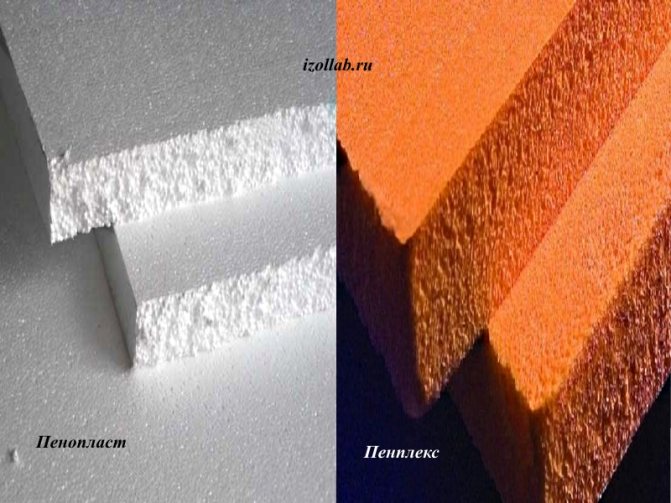

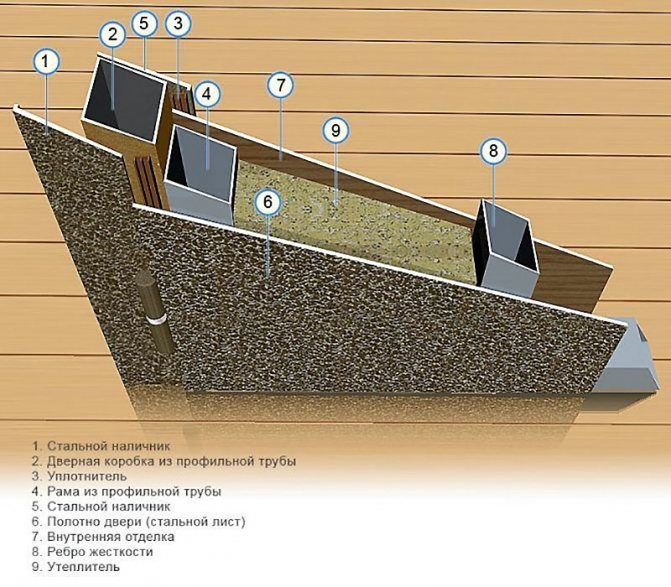

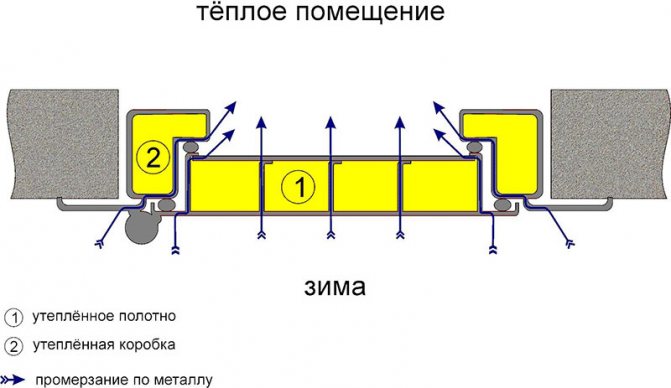

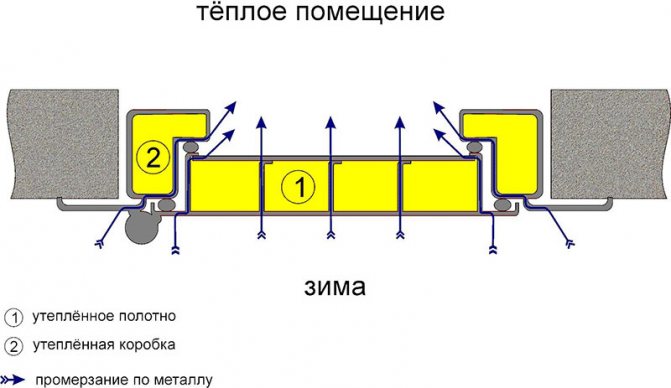

Metal entrance doors are the most reliable and warm, despite the fact that metal conducts heat well. The fact is that a high-quality insulation is laid inside the structure of the canvas, and often it is a felt seal or synthetic materials such as polystyrene foam, polypropylene foam or synthetic wool.In addition, the high precision manufacturing of the structure ensures minimal gaps between the door and the frame, which means that the insulating gasket will be dense and durable. The cost of metal doors is higher than wooden structures, but their reliability is much higher. The same applies to doors made of plastic or glass.

Internal structure of metal doors with insulation

»Alt =» »> Structures of wooden doors are made of solid wood, from panel assemblies, with glued or paneled sheets.

Of all the above structures of entrance doors, plastic ones withstand subzero temperatures worse than others and poorly keep cold air flows. Therefore, to insulate doors made of plastic, you will have to try, and the best way out is to hire a specialist. But the most reliable, albeit expensive, option is to install a second front door. However, it, like the first door, will also have to be insulated.

And, if for the installation of at least the first, at least the second entrance door you need the help of professionals, then in order to attach a felt seal on the door, you only need your desire. When carrying out this simple operation, you first need to check the box (door frame), canvas, fittings, lock, and even platbands for their correct attachment, absence of cracks and loosening. To prevent such an examination from giving negative results, it is recommended that the following set of measures be carried out regularly:

- Seasonal prophylaxis: lubrication of moving mechanisms (except for the lock secret), checking fasteners, replacing hinges, etc .;

- Elimination of subsidence or sagging of the canvas;

- Wooden doors must be covered with varnish, paint, water-repellent impregnation, and the coating must be renewed annually;

- Checking the strength of the fastening of the door frame, if necessary - its additional strengthening;

- Check the existing insulation, if necessary, install a felt insulation for the doors.

Freezing points and places of insulation

Types of felt seals

The production of the material is localized in regions that traditionally produce wool products. Classical technology is rooted in the distant past and has secrets. Not all developed countries know how to make felt. In Russia, production secrets have not been lost, and the products enjoy well-deserved respect. Despite the fact that the manufacturing process is traditional, the quality of products is regulated by state regulations. The consumer can choose the desired felt of the following types:

- GOST 288-72. Fine-haired technical felt. The inclusion of synthetic substances is allowed. Found the main application in technology. Gaskets, oil seals from this material are used in mechanical engineering;

- GOST 6308-71. Semi-coarse technical felt. Excellent performance in terms of wear resistance. Used in mechanical engineering and in small volumes in construction;

- GOST 6418-81. Coarse technical felt. It is used in many areas of economic activity. From mechanical engineering to construction;

- GOST16221-79. This type of felt is called yurt felt. The name corresponds to the purpose of the material. Available in rectangular cavities. There is no single standard. The length is from 2 to 6 m, and the width is from 1.4 to 2 m;

- Felt. It is used for technical purposes and in the production of household items and clothing. An expensive kind of felt. Produced in thicknesses from 2 to 10 mm. Felt gaskets are made from old items such as hats or an impact-resistant layer removed from packaging, which is used to transport fragile, valuable devices and devices.

Car Sound Insulation Felt

Any felt is used as a door seal. Consider the minimum required thickness. Felt has a limited dynamic compression ratio. For this reason, the difference in the gap width should not exceed 2-3 mm.Otherwise, the baffle of the door leaf will not be airtight, the seal will be partial and the protection will not become effective.

Advice! If the slot width is uneven, it is possible to pre-fill areas with a large gap with pieces of felt of the desired thickness. It is easy to cut longitudinally. After preliminary alignment, a finishing strip of felt is installed. Another option involves the installation of a felt seal with the end side relative to the plane of the door. It is effective in this case to form a cushion.

Materials for door insulation

The functional range of materials that create a hermetic sealing of the gap between the canvas and the box, prevent the penetration of moisture and cold air currents from the street, is quite wide, but traditionally it is: thick foam felt tape, batting, mineral wool, foam plastic, synthetic winterizer, expanded polystyrene, NPE ( foamed polyethylene), rubber band seals. To insulate the gaps, it is recommended to use synthetic seals that do not deteriorate from temperature and moisture changes, and to insulate the door leaf, it is preferable to mount natural materials from felt, felt, etc. Such thermal insulation will be protected from harmful atmospheric influences by the door body.

Since insulation can be combined with decorating the canvas, leatherette or synthetic leather with a layer of insulation is best suited for this purpose. Natural finishing materials are expensive, and they are usually ordered individually. For self-insulation of the door you will need:

- Thick line or soft, thin wire;

- Screwdrivers, screwdrivers and screws (for wood or metal - depending on the material of the door);

- A cutter attachment for a screwdriver or drill to make grooves in a wooden sheet for sealing tape. In such grooves, you can insert felt insulation, synthetic winterizer, soft rubber, foam rubber;

- Construction foam for sealing gaps between the frame and the wall of the entrance doorway;

- Construction stapler and staples 14-16 mm, level, tape measure.

Materials and tools for door insulation

Features of the choice of door insulation

The reasons for heat loss are different: from the skewing of the door leaf and insufficient sealing, to insufficient quality of the material. If the replacement of the door is not included in the plans, then the only correct solution that will help to save 25-30% of heat energy is the door insulation, the nuances of which will be discussed.

In order to reliably insulate the entrance or balcony doors, use the following materials: mineral wool; cellular insulation; liquid insulation; polypropylene; felt insulation (including self-adhesive); polyurethane, anti-draft.

The nuances of installing a door insulation

You will have to tinker with the insulation of a metal door.

Algorithm for installing heaters on a metal door:

- If the door is collapsible, it is untwisted, after removing it from the hinges and dismantling the locks with handles. In the case of welded seams, they are separated using an angle grinder.

- Laying insulation in an empty box (if necessary, blowing with polyurethane foam).

- Assembling the door frame.

In the case of a wooden door, first align the jamb and reinforce the hinges.

Stages of fixing insulation on a wooden door:

- The doors are removed from the hinges, the fittings are untwisted.

- Lay the canvas on a flat surface, after which a heater is attached to it with liquid nails or glue.

- The upholstery is reinforced with a nail spacing of 30 cm.

Each material has design and installation criteria that help to choose the insulation correctly.

Insulation works

Immediately before warming the canvas and sealing the gaps, gaps, distortions, loosening, subsidence, and other visible door defects should be eliminated. The cracks are covered with wood putty, the gaps and skew of the canvas are regulated by awnings. On a wooden door, you can seal the holes for the screws for the hinges, so as not to outweigh them in a new place. An extreme measure to eliminate a loose closing of a wooden door or its distortion is the use of a plane.

The choice of a seal for any door is a serious matter, since different materials will behave differently:

- Foam seals are usually made with one self-adhesive surface, and they are not reliable and durable. Their advantage is cheapness;

- The rubber seal is a narrow tape with a sticky surface. The tape is sold without an adhesive surface, and then it can be glued with ordinary rubber glue, after cleaning the work surface. On a wooden door, a rubber seal can be nailed with small nails;

- A felt gasket in the form of a tape is nailed to the frame of a wooden door or glued to metal (plastic) with rubber glue. The thickness of the felt tape depends on the gap - if the tape needs to be made thinner, it is cut with a carpenter's cutter;

- Sealing tape and plastic or silicone is much more elastic than rubber or felt, it does not press well under the pressure of the web, so it will last longer. Both silicone and plastic do not crack from frost, do not deform and do not stretch, they make tight surface joints.

Felt door sealing

»Alt =» »> The tape is attached and placed along the perimeter of the frame without gaps, the length of the tape can be longer than necessary, but not less, so that you do not have to make an additional connection, which will reduce the seam tightness. The thickness of the tape is set with a piece of plasticine - it is glued to the frame, the door is closed, and after opening it, you will see how thick the seal is needed.

Replacing the seal on the front door

Any tape seal must be fastened if the thickness of the factory seal is already insufficient to prevent drafts, and the combination of decor with insulation is the most reliable measure.

We use foam rubber

If you have a wooden door installed, use this material outside. For this you will need:

- Remove the canvas and place it on a flat surface, preferably on stools. Next, you need to dismantle the locks, handles, peephole and other details.

We insulate the doors with foam rubber

- Now we proceed to the preparation of the rollers, which are needed to fill the space inside the box. If it swings outwards, then it is necessary to mark and cut 3 leatherette strips 140 mm wide, and the length of one strip should coincide with the length of the door, and for the other two, equal to the width of the door. Fasten with small nails along the perimeter of the opening, stepping back 1.5 cm.Only the side on which the hinges are located remains without upholstery. For a door that opens inward, 4 strips are cut: 2 long and 2 short - and nailed on all sides.

- Further, twists of cotton wool are formed in the form of bundles, with a diameter of about 3 cm and are wrapped in leatherette, fixed from below. Everything is rolled up and secured.

- After that, we begin to place the foam rubber sheets along the entire door leaf.

- Cut out one large sheet from the upholstery material, adding 10 cm from 4 sides. Distribute it evenly over the insulation material and nail it in with nails. Please note that the side parts are fixed first and only then the top and bottom.

- We finish the 3 cotton bundles that are needed for the door that opens outward. They are attached in such a way that the top of the canvas covers the bottom.

- After all the stages, we nail everything over the entire surface, leaving the edge with the loops for last.

- The last step will be cutting out all the necessary holes for the door fittings in the material: locks, a handle and a peephole. We place the product on the hinges.

What is felt insulation for doors

What a pity that this superb, natural material with excellent performance is almost forgotten. Today felt is used to insulate doors and window openings. In ordinary houses, this is where it ends, but if we are talking about wooden structures or a bathhouse from a log house (timber), then it is also used as a mezhventsovy heater and for sealing cracks. And, probably, no one even knows that felt insulation can be different:

- technical fine-haired - manufactured in accordance with GOST No. 288-72;

- technical semi-coarse wool - manufactured in accordance with GOST No. 6308-71;

- technical coarse-haired - manufactured in accordance with GOST No. 6418-81;

- yurt - manufactured in accordance with GOST No. 16221-79;

- Firth - made from the finest fibers of six rabbits and goats.

Read also: Tiles for the hallway on the walls under the stone

Felt insulation has a fairly low thermal conductivity, the coefficient is 0.03-0.07 W / m * K and depends on the density of the material. The latter varies in the range from 10 to 400 kg / m. cub.

The material is produced both in panels and in rolls. The dimensions of the panels are 2000 x 2000 mm, rolls are up to 1800 mm wide and up to 200 m long. It is made from both natural and synthetic raw materials. Synthetics is already a trend of modernity, you should not take it seriously, but natural materials deserve attention.

This is a seal for the crowns, 15% made of felt.

In addition to the fact that the felt is produced in its pure form, it can be a part of other natural insulation materials. For example, felt jute, where impurities make up up to 15% of the total mass of the material. It is produced in strips and is used for laying between the crowns of buildings made of logs or beams, as well as for sealing gaps between logs and in corners (bowls).

Felt insulation for doors was originally used to make felt boots. The very name of this shoe tells us about the method of its production. Felt boots are made from natural sheep wool by dry or wet felting. As a result, the villi bind together in such a way that a monolithic carpet is obtained. Whoever spent at least one winter in felt boots knows firsthand about their qualities. Accordingly, felt insulation for doors has all these characteristics:

- repels moisture, but still gets wet;

- when it gets wet, it does not lose its thermal insulation qualities;

- excellent sound insulator;

- not harmful and non-toxic;

- does not burn in the natural environment - to maintain combustion, more oxygen is needed than is contained in the atmospheric air;

- harmful bacteria do not grow in it.

It would seem that felt door seal is just the perfect material, but no, there is one drawback. Moth loves to eat it very much and if it is already started, then it is extremely difficult to remove it. In this regard, the material in production is treated with a 3% solution of sodium chloride.

The question of which heating for the house is better has been raised more than once, and there is still no definite answer. Each of the methods has both advantages and disadvantages.

If you need a working plan for heating a one-story house, then take a look at this article.

Ventilation gaps

When insulating the walls of a bath building, many owners create a system of ventilation gaps - special spaces located between the insulating material and the outer wall. These are very narrow slots required to drain excess steam and air from the interior. Moreover, such ventilation does not in any way affect the microclimate of the bath from the inside, since excess moisture goes into the ventilation gaps very slowly, gradually, through microscopic pores in the insulating layer of the walls.

Even at a minimum speed and invisibility for the internal atmosphere of the bath, ventilation to a significant extent protects the entire building from premature destruction due to increased dampness, rotting and the formation of mold. Narrow air gaps can be left in the thickness of walls, foundations and ceilings, and can be equipped with special branch pipes.

Thus, using all these nuances - the correct choice of insulation materials, the use of suitable vapor barriers, the creation of a multilayer insulation structure, the abandonment of ventilation spaces - you can create an excellent source for rest, healing and relaxation - a Russian bath.

A good insulation for a bath is the most important thing to pay attention to when arranging it internally. Indeed, the safety of bath procedures, and their comfort, and the durability of the walls themselves, especially in the steam room, directly depend on its quality. But how to figure out which insulation is better for a bath, when almost a dozen of their types are offered on the modern market? Our article will help you with this.

So, back in Soviet times, civil engineers made the following discovery: any homogeneous thick wall does not guarantee effective heat retention - because it itself will necessarily absorb some of the energy. But the multilayer structure, in which there are materials of different technical characteristics - in terms of density, porosity and thermal conductivity - prevents heat loss well, and a half-meter such "cake" can be compared in its performance with a wall of one and a half meter thickness. But the effectiveness of the "pie" itself depends precisely on what kind of heater was chosen for the bath.

How to insulate a door in a bathhouse with felt

Most often, felt is used for insulating door and window frames, as well as for external door insulation. The fact that the material is environmentally friendly and the fact that it breathes allows it to be used even in baths at high temperatures and humidity. Consider the insulation of a door in a bath with felt from two angles. The first will be the insulation of the box.

This technique is applicable to both the front door and the entrance to the steam room. In both cases, felt insulation for doors is laid along the perimeter of the box at the junction with the movable part. For this you need:

- roll the felt into a small roll;

- the side where the edge is visible, the roll is laid along the perimeter of the box;

- fastened with nails or a stapler.

No additional protection needed. If it is necessary to insulate the front door with felt, then you need to take the cloth and fix it on the outside. Then, using furniture nails with beautiful hats, fix the material you like (usually a leather substitute) over the insulation. The main thing is that the finish is resistant to atmospheric aggression.

The two-pipe heating scheme of a two-story house can be both vertical and horizontal. In this case, there can also be several methods for routing horizontal contours for each floor. Some of them: hitchhiking, dead-end, collector.

Heating a country house is somewhat different from the main housing. You can read about the best way to heat a summer cottage in winter in this article.

Vapor barrier

As steam insulators for a bath, means are needed that can withstand temperature extremes. Such materials include plastic wrap, glassine, aluminum foil and others. The vapor barrier layer should be, first of all, environmentally friendly, since in a warm and humid environment it will inevitably undergo evaporation, and then harmful substances can penetrate from its surface into the air of a bath or steam room if the owner made the wrong choice.

The best material for moisture insulation is aluminum foil. It can withstand high temperatures up to 150 degrees, is absolutely harmless, resistant to decay, mold and very durable.Often, heat-insulating materials are used to insulate the walls of a bath, which already have a layer of aluminum foil on one of the surfaces intended for the interior space. For example, prefabricated expanded polystyrene or fiberboard often has a foil surface on one side.

In addition, seams and joints between insulation should also be sealed using foil tape, which often has a double-sided adhesive surface. Thus, the walls of the bath are covered from the inside with a continuous layer of heat and moisture insulation, which helps to create an appropriate atmosphere for wellness procedures to the maximum extent.

In addition to the foil vapor barrier, kraft paper is also successfully used. It is good to use it for a steam room, as it creates an excellent sealing of the room and at the same time insulates it in addition to other thermal insulating means.

Usually, a special frame made of wood material, the so-called lathing, is superimposed on top of the insulation inside the bath. It is necessary for further finishing the walls of the bath, because it is to the crate that the finishing materials are fixed - panels, plates, interior fittings, shelves and others.

Where else is felt insulation used?

Felt-based linoleum - insulation and soundproofing.

In addition to the above purposes, this material can be used for thermal insulation:

The methods, of course, are rarely used, but they are still discussed on the forums. Although felt for floor insulation is used very often in the form of a substrate for linoleum. Considering the hypothetical possibility of laying insulation under finishing materials, for example, as wall insulation with foam, you need to immediately cut off possible problems:

- moisture - although the material does not absorb moisture well, it still happens;

- mole - you need to impregnate the material with some means, but then you can forget about environmental friendliness;

- rodents - will not miss the chance to pull soft bedding into their burrow.

As you can see, it is quite problematic to use felt for wall insulation, and the price bites. It is sold by weight and per kilo they ask from 200 rubles, depending on the density. Such insulation will cost almost gold. A felt seal is suitable as a local thermal insulation, but even the technology has not been developed for the insulation of large areas. What to do in such a situation when there is no one to even turn to for practical advice? You will not find practitioners on the forums on this issue in the daytime with fire - some theorists are skeptical.

Expanded propylene

The main advantages of this insulation are environmental friendliness, light weight, insulating characteristics, resistance to fire, moisture, chemicals and atmospheric agents. Polypropylene foam withstands loads, does not absorb water.

Available in the form of air plates, which can be easily cut to the required dimensions and easily attached to the door using special glue or liquid nails.

The material costs from 1100 r and above for 1 package, which differ in size or number of sheets.

Expanded propylene

Warming a house with felt is a harsh reality

Despite all the positive aspects of this material, the complex warming of the house with felt is not possible for a number of reasons:

- it absorbs moisture;

- a mole starts up in it;

- mice feel great in it;

- it is too expensive;

- there is no methodology for such work.

How to insulate a door with felt can be told from two sides:

- insulation of the box (joints);

- complex insulation outside.

Also, this material is used for caulking mezhventsovy slots. In addition, felt insulation for the walls of wooden houses is used as a spacer between the logs (timber) during the installation of the structure.It can be used both in pure form and as part of other materials (jute). It is better to leave attempts to completely insulate the walls of any buildings made of any materials. Yes, there is a sturdy yurt felt that has high insulating qualities, but it still won't work. It is not designed to be enclosed by the body of the walls, because you are not going to insulate it without finishing. Felt floor insulation is widely used, but only as a substrate for linoleum. It does not apply to laminate flooring.

Mineral wool

Minvata is made from silicate rocks. High noise and heat insulation characteristics of the product are determined by the fibrous structure. Minvata is environmentally friendly, non-flammable, resistant to moisture penetration, the influence of temperature fluctuations, is not afraid of the effects of chemicals, and besides, it is characterized by a moderate cost.

The main disadvantages of the material are subsidence under its own weight, as a result of which voids are formed. The installation of additional stiffeners that can keep the insulation from slipping helps to avoid this.

No related posts

Felt and felt - what kind of materials?

The main material for making felt or felt is animal wool, mainly sheep. The upper layers of hairs have a scaly layer, which, under the influence of steam or hot water, adhere to each other. However, the wool of wild sheep does not have such a texture, therefore, it is generally accepted that felt was first made no earlier than 5-6 centuries BC, and the original material was still the wool of dogs and horses, which were domesticated at that time.

Horses, dogs and sheep were first domesticated by nomadic peoples. The horse helped to carry the heavy load, the dogs guarded the flock of sheep. The most ancient felt items were found on the territory of modern Bashkiria and Altai. Gradually, the technique of making this material passed to other nomadic pastoralists of Central Asia and the Caucasus.

And in this online store of our partners you can buy very high quality felt at low prices

With the increase in skill, the Bashkirs acquired the opportunity not only to make products for themselves, but also to sell them to other peoples, for example, a non-woven felt carpet. In general, the Bashkirs widely introduced felt products into their everyday life. They were also used as insulation for yurts, as a canopy from rain and sun. Bags and prayer rugs were made of felt. Felt products were necessarily included in the bride's dowry. There is still a custom to put a small white felt rug under the bride's feet at the moment of her arrival at the groom's house. The groom's mother invited the bride to enter and sit on the felt bunks. It was believed that this would help the future family to have many children.

Healing properties were also attributed to felt. Felt belts were used to treat people from sciatica and arthrosis. The strips of felt fabric were used for massage, which, according to the ancient nomads, has a beneficial effect on blood circulation and also helps to relieve back pain. This was especially true for nomads - people who are constantly in the wind.

Read also: What kind of lamp is needed for plant growth

Manufacturing technology

The felt technology is one of the most ancient. It involves exclusively manual labor and appeared long before the advent of looms and even knitting tools. It is surprising that this technique has come down to our times, and has not sunk into oblivion, like many others. Moreover, products made of felt and felt are very popular not only in Russia, but also in Europe. In its manufacture, wool is used, and the best is sheep wool.

So, sheep wool is laid in thin layers on the fabric. Rub the soap on a grater. Pour soap with hot water and shake until completely dissolved. The resulting hot soapy mass is applied to the wool. Patting with a palm, the hairs gradually fall off.To increase the density of the fabric, you can apply one or more layers of wool and repeat the felting procedure. When laying wool, it is advisable to make sure that the wool does not lie parallel, it should be applied in different directions. This will give strength to the resulting material. It is necessary to dry the resulting material for about a day.

When felting wool, it is also worth mentioning a special direction in felting technology - felting. It is often called dry felting. When felting, a special felting needle is used as a working tool, on which notches and notches are applied at different angles. These notches help to snatch individual hairs from the total wool mass and slowly entangle them, forming a felt material. Often, using the felting method, not material in its usual sense is made, but small objects - toys, decorative crafts, small parts for women's and men's accessories. This method is ideal for making and shaping bulky items, while you can help yourself with your hands, pulling any element if necessary.

The felting method is also often used when it is necessary to create a pattern on a ready-made felted material. To do this, a felted cloth is laid on a dense object. A drawing is carefully laid out on it. Often this pattern is fixed, for example, with a thin packaging film, although experienced craftswomen can do without it. Then, with neat and quick movements with a felt needle, the pattern is, as it were, driven in, imprinted into the felt.

The technology for making felt is practically no different from felt, with the only difference that thinner types of wool are used in the manufacture of felt. Synthetic fabrics are often added to felt. The outer finish determines the type of felt - pile or smooth. Pile, in turn, is subdivided into "suede", short-haired, "velor" and long-haired. Felt is often used to make items of clothing that are in direct contact with the body, such as a hat or scarf, because the texture of the felt is pleasant to the body and does not create a slight tingling effect, as sometimes coarser felt.

Felt and felt in the modern world

Felt and felt, as a kind of felt, are extremely flexible and versatile materials. Despite their ancient history, they attract more and more fans, because felt and felt are environmentally friendly, and modern society prefers natural objects and fabrics. Felt products can look quite appropriate in the image of a modern girl and even add some zest. Felt products are often chosen by people who prefer folk or eco-style in the interior.

And it is simply impossible to describe the entire list of manufactured products. These are shawls, scarves, tops, and jackets. Felt slippers are very popular. These materials are often used as a decoration for women's accessories - hairpins, brooches. The popularity of felt is only reviving, and this “hand-made” material has a great future.

The art of making textiles is one of the most ancient skills of mankind. Vegetable fibers were used as raw materials for it among agricultural peoples, and wool, mainly sheep's wool, among cattle breeders. The first woolen materials were non-woven, they were obtained by dumping fibers into a homogeneous mass. This was facilitated by the structure of the sheep fleece, the hairs of which have scales on the surface and are coated with lanolin. In Iran, Mongolia, Kazakhstan and other regions, various types of felt were produced, and the methods of their manufacture have survived to this day. At the same time, relatively recently, new types of this material were invented. Synthetic felt created from polymer fibers is used both for technical purposes and for artistic creation.

Manufacturing methods and varieties

The oldest method of producing these non-woven textiles is to spread the wool in a thin layer, expose it to hot water or steam, and then seal it in one way or another.

Currently, felted fabric is made using the following sequence of operations:

- loosening of raw materials using pinching and scutching equipment;

- oiling and mixing;

- combing with a carding machine;

- compaction of the base;

- acid solution impregnation;

- rolling away on felting devices;

- drying.

A special type of felt is felt, which is obtained by rolling from wool with the addition of fluff. Thick or thin felt made from natural raw materials has the following properties:

- tear and abrasion resistant;

- warms, while letting in air;

- protects from high temperatures, splashes of molten metal, from electric shock;

- absorbs sound waves;

- well absorbs moisture and other liquid and gaseous substances;

- plastic;

- can be draped;

- relatively inexpensive.

The positive qualities of this felted material also have their downside. First of all, wool fibers are usually coated with lanolin, which causes allergic reactions in some people and gives the material a specific smell. The presence of lanolin attracts moths, which irreparably damage natural felt. However, high quality wool materials do not smell and are supplied with a special pest repellent impregnation. It should also be remembered about the high hygroscopicity, due to which a wet felt dries up for a long time and can be deformed.

Modern varieties of felt are subdivided into technical, household, and fine-woolen felt. A separate group is felt, which is obtained by the method of heat pressing. Technical material is most often made from coarse dark wool up to 25 mm thick and is used for:

- various insulating, heat-insulating and vibration-damping gaskets, filters, substrates, oil seals, etc .;

- overalls, safety footwear, protective devices;

- electrical insulation (thin up to 6 mm);

- horse harness and when transporting expensive products (saddlery and saddlery).

For household and household needs, shoe felt, thin fabric for bath accessories, traditional woolen fabrics of various thicknesses for yurts, carpets, and national clothes are produced. In the manufacture of modern wardrobe items, warm and home shoes, hats, as well as various accessories, felt material, including synthetic, is often used.

Areas of use

Ancient cattle breeders used felted woolen material for their versatility: the walls of temporary dwellings were made from it, it protected in battle, warmed in winter, was used for decorative purposes, and our ancestors could not imagine themselves without comfortable and warm felt boots and hats. From the middle of the last century, felt, felt and other traditional materials began to be gradually replaced from everyday life, but they were still widely used in production, in agriculture and even in various sports.

However, in recent decades, there has been a real boom in all kinds of felt products. Instead of reliable but awkward felt boots, beautiful and waterproof shoes are produced, which quickly became fashionable for all ages. Consumers also appreciated the comfort and healing effect of felted room slippers, the convenience and reliability of bath accessories, the stylish look and warming properties of clothes for the cold season. Finally, felt has become a popular material for making bags, decorative covers, various art products, and toys.

Popular publications:

Features and advantages Insulation is a low-density porous material, the granules of which are produced by firing foamed raw materials ...

Drawing up a diagram The complexity of manufacturing and installation largely depends on the type of visor. It is the configuration of its coverage ...

Preparing for installation Before starting installation, remove the old door. We must do it carefully, trying not to ...

Caution polynor CAUTION POLYNOR. We go to the official website of the so-called “revolutionary insulation POLYNOR”, looking for contacts. ...