Ecowool work without vapor barrier

In the case of interior cladding with plasterboard or fiberboard, it is not recommended to install a vapor barrier if there is cellulose wool in the walls. This is due to the unique property of the insulation to control air convection due to the low air permeability of the material. The main consequence of this is the absence of a dew point. The main mechanism of moisture transfer in insulation is convection. In fact, air carries up to 98% moisture in isolated cavities. It is easy to conclude that limiting air movement is a fundamental principle of thermal insulation and elimination of the dew effect. Vapor barrier in the walls is not only optional, but also harmful in all buildings in any climate, as it creates an insurmountable barrier to moisture movement, eliminating the possibility of moisture control. The American Society of Heating and Air Conditioning Engineers ASHRAE, for example, warns against using vapor barriers in any building. In cold climates, a vapor barrier installed inside the room to control the movement of moisture outward during the heating season will collect moisture from the warm summer air in summer, causing the insulation to get wet and create an area for fungal growth.

We argue that the absence of vapor barrier does not impair the quality of cellulose wool (ecowool) and the quality of building structures.

Where is a vapor barrier needed?

Vapor barrier is still necessary in buildings and rooms with high levels of humidity, such as swimming pools. A constant level of high humidity at high temperatures creates a significant concentration of water vapor in the air, which can exceed the moisture transfer capacity of cellulosic insulation. To prevent increased moisture in the insulation and, as a result, deterioration of the building's performance, we recommend using vapor barrier in rooms with high humidity levels.

Home humidity control

High levels of indoor humidity can lead to serious winter problems in cold climates, ranging from mold in the corners of walls and closets to condensation on windows and rotting in walls or in the underlayment of the roof. A low level of humidity leads to drying out of wooden structures, accelerated dehydration of the human body and plants. A moderate indoor humidity level is essential for human health and comfort. By understanding the basics of moisture balance, you can achieve the right moisture level.

Humidity in the house

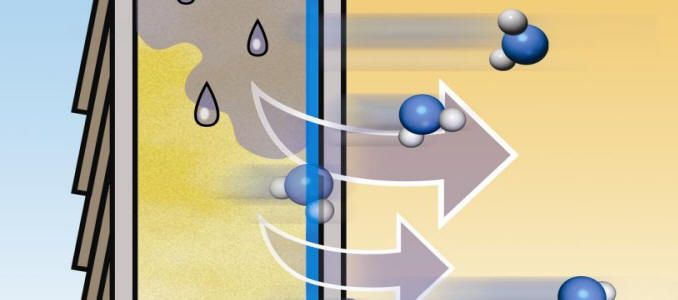

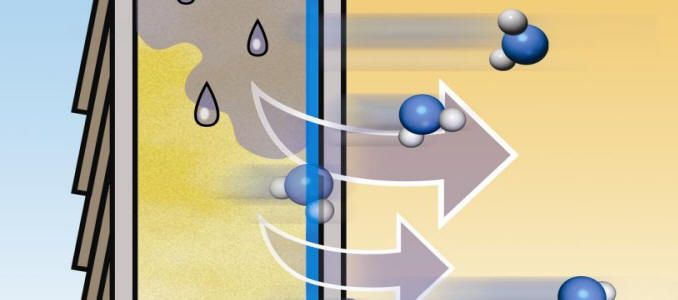

In the home, moisture comes from several sources. People, plants and pets, as well as washing, showering and cooking, increase the amount of moisture in indoor air. A damp basement, narrow spaces, and a leaking roof also increase humidity. Typically, a family of three evaporates up to 10 kg of water vapor daily, while the air in a 100 m2 house can hold 5-8 kg of steam. Water vapor is removed from the house in two ways. The first is convection: water vapor is removed from the house through open windows, chimneys, ventilation ducts and crevices. The second way is diffusion through walls and ceiling from areas with high concentration in areas of lower concentration of water vapor, due to the difference in portional vapor pressures.Energy efficient homes are more prone to moisture problems than conventional homes, as the ventilation of the premises by convection is limited for energy saving purposes. Signs of high humidity in the house are stuffiness in the premises and condensation on the windows. If steam continues to condense on the windows, the window may fail over time and mold may develop in secluded areas. In such cases, the humidity of the premises should be reduced.

How ecowool helps regulate humidity. In the cold season, outdoor air can retain very little moisture (1-4 g / m3), while the optimal humidity for humans in the house is 9-13 g / m3. When ventilating the premises and warming up the air to room temperature, the relative humidity can drop to an undesirable level of 20-25%.

The ecowool contained in the walls and ceilings is capable of releasing moisture into the dry air of premises and absorbing it when the air humidity rises, smoothing out the drops. This is its fundamental difference from other types of thermal insulation and one of the reasons for the absence of the need for a vapor barrier in the walls.

Thermal insulation from the inside with mineral wool - mistakes with serious consequences

Insulation from the inside with mineral wool is similar to sabotage in order to cause maximum damage to the structure and people. Standards require, experts recommend insulating only outside the building.

And insulation from the inside is an extreme forced measure, and it must be carried out according to certain rules. Can this be done using mineral wool with special measures to protect the structures?

Let's decide in order - how to properly insulate, how mineral wool should be used, what are the common mistakes and opinions on this matter.

Lack of insulation from the inside - freezing

When insulated from the inside, not only with mineral wool, but also with any heat insulator, the wall turns out to be protected from heat, so its temperature decreases.

Moreover, with a sufficiently large amount of insulation, the wall can freeze through. Freezing a structure is always bad, because for any material there is a finite number of freezing cycles before it breaks down. It is even worse if the wall freezes in a damp state. In this case, it will be so.

Humidification, dew formation

Dew point - the temperature at which dew falls out of the air, will be located directly on the wall. More precisely, condensation can begin to fall out in the insulation, but the cold surface of the wall will also condense water on itself.

Vapor barrier and ecowool - can you do this?

I read this wonderful forum for a long time, learned a lot of useful things for my construction site, for which many thanks to everyone!

I am going to insulate the attic roof, basalt wool is prescribed according to the project, but ecowool is very interested. There is one BUT - the builders put a non-vapor-transparent film isospan D under the metal tile. The structure looks like this: - metal tile - lathing - bar 50 × 50 - film - rafters 150mm

If ecowool is blown out between the rafters to the entire height of 150 mm, will it not get wet due to condensation? If you still make a vapor barrier from the side of the room, it certainly will not get wet, but then it turns out that the rafters will be sealed between two non-vapor-transparent films, which is also bad - they can rot without ventilation?

- Registration date: Dec 2008

- Posts: 156

Answer: Vapor barrier and ecowool - can you do this?

researcher added 1/27/2009 at 09:14 AM

I read this wonderful forum for a long time, learned a lot of useful things for my construction site, for which many thanks to everyone!

I am going to insulate the attic roof, basalt wool is prescribed according to the project, but ecowool is very interested. There is one BUT - the builders put a non-vapor-transparent film Isospan D.The construction looks like this: - metal tiles - lathing - bar 50 × 50 - film - rafters 150mm

If ecowool is blown out between the rafters to the entire height of 150 mm, will it not get wet due to condensation?

if you beat it off from the inside with a vapor barrier, it will not get wet.

ecowool, incl. includes boric acid and borax - this prevents wood from rotting.

but in your case (as in mine) there is a snag: blowing in ecowool - in fact, its packing is quite tight throughout the volume of the cavity. blowing ecowool into the cavity between the two films will lead to protrusion of all non-solid surfaces. those. the hydrofilms will stick out in big bubbles. if from the inside you can form a solid surface with the help of a black ceiling, then it is more difficult with the outside - the belly can easily reach the ends of the roofing screws (surely the ends through the battens?) and - goodbye waterproofing along with insulation.

I have not yet figured out how best to act for myself. Actually, I see two options: 1 - under the external hydraulic film from the inside on the rafters, attach the fitted plywood sheets to the rafters (at the same time, when blowing out, some of the wool will blow into the inevitable cracks, but in general the issue will be resolved) and this is quite costly and hemorrhoid. 2 - still use basalt. 3 - fill in by method AS06

those. do not blow out but simply pour without pressure.

Comment

- Registration Date: Jun 2008

- Posts: 2037

Answer: Vapor barrier and ecowool - can you do this?

I read somewhere on the Internet that a semi-wet method of blowing is used to avoid tummies. ". and we make the ceilings and the attic on site (already during the installation process) - here we often use the semi-wet method (first we make a wet surface (nozzle for spraying mod. 349 - see the description on the previous link), and then we supply the raw materials ) ". As far as I remember, the idea is this - a polymer mesh (cell 2x2 or 3x3mm) is pulled onto the rafters, wet it, blown out ecowool with a low density, tomorrow a dense crust of dried ecowool will form on the grid, catch up with the backing density to the required one. One of the practitioners posted a photo. On which site I saw this I do not remember, sorry.

At the expense of the films: from the bottom, para-insulation (i.e. ordinary PE or PP tape, preferably metallized from the bottom side), from the top there is a wind shield (i.e. vapor-transparent).

Why does mineral wool get wet

The thermal conductivity coefficient of mineral fibers is 0.031-0.042 W / m 2 * K. This means that a 5 cm thick layer of glass wool is equal to the thermal effect of a meter-long brick wall. But the insulating properties are lost when moisture penetrates into the fibers.

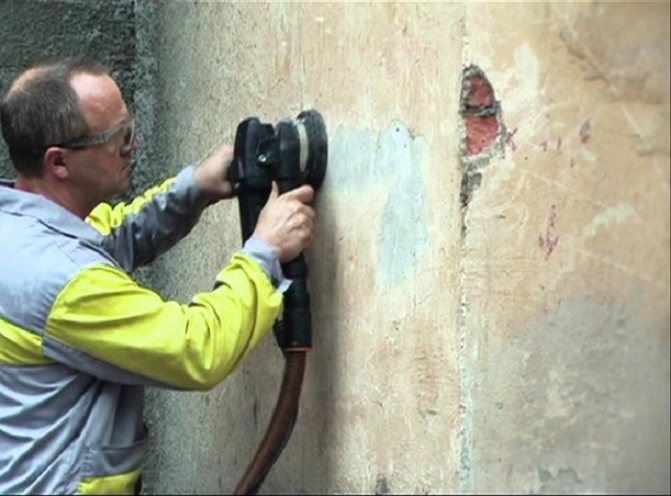

Reasons for getting wet:

- Damaged the waterproofing membrane when laying the insulation. They pulled the canvas too tight, accidentally pierced it with a nail or self-tapping screw.

- The joints of the film were not glued. As a result, condensate penetrates into the fibers of the mineral wool.

- The waterproofing was not fixed tightly enough near the ventilation and chimneys.

- A low-quality diffuse membrane was used.

The risk of getting wet: what is the danger of raw insulation

Wait to get wet roof insulation

dries up on its own - a dangerous delusion. Wet mineral wool does not retain heat. In addition, it becomes a source of unpleasant odors, the spread of mold and bacteria. Well, the "cherry" is in the troubles of the roofing pie: wooden rafters are destroyed, metal structural elements rust at an accelerated pace. The result is a major overhaul of the roof.

To avoid problems, check the condition of the insulation:

- if streaks or drops appear on the walls of the attic;

- cracks appeared on the roof, the roofing elements do not fit tightly;

- in places where snow accumulates, the roof caved in.

Disputes over vapor barrier

Some debate is still going on over the need for vapor control, but the consensus is getting closer. Most professionals now agree that vapor barriers are important under certain conditions, and not required for every home. In environments where conditions inside a home or office are very different from outside conditions, water vapor is likely to move through wall cavities and may be trapped inside, in which case a well-installed vapor barrier is recommended. Vapor barrier may also be required in some areas where humidity levels are particularly high.

Benefits of Using a Windproof Membrane

Let's consider the main advantages of this product:

- The product is an absolutely environmentally friendly material. The film does not cause any harm to human health, as well as to the surrounding world.

- The film has a high level of fire resistance. Fire resistance is formed by specially designed additives in the composition of the product. These additives prevent combustion from occurring.

- This material is easy to use. Installation can be carried out in any season, and the material does not need to be individually protected.

- Technical properties. This includes unique resistance to ultraviolet rays, moisture resistance, elasticity, resistance to various mechanical damage and sudden temperature changes.

- Huge operational life. The product does not lose its high technical characteristics even after several tens of years.

- The membrane can be attached to various parts of the house.

How the correct vapor barrier should work

Note that a poor vapor barrier installation can be worse than no vapor barrier at all.

The main purpose of vapor barrier is to prevent moisture build-up and deterioration of building materials. An improperly installed vapor barrier can actually trap moisture inside the wall, while a more porous wall can breathe efficiently and be less susceptible to long-term exposure to moisture. This condition is especially problematic where vapor barriers are installed on both the inside and outside of the wall.

Do I need a vapor barrier?

Once considered essential throughout a home or office, vapor barrier installation is now highly recommended only for certain conditions, and vapor barrier installation methods must be adapted to the climate, region and type of wall construction. For example, the recommended vapor barrier in a brick-built house in a humid southern climate differs significantly from creating a vapor barrier in a cold climate in a house built with wood siding.

Most experts recommend vapor control in certain situations:

In areas with high humidity — such as greenhouses, spa or pool rooms, and bathrooms.

In very cold climates, the use of polyethylene plastic vapor barriers between the insulation and the inner wall can be helpful if all air gaps in any cavity of the wall and ceiling are also insulated. The outer surface of the wall or floor cavity must remain permeable in order to dissipate moisture entering the wall cavity.

In very hot and humid climates, you can also benefit from an external vapor barrier that prevents moisture from entering the external wall.

Walls and floor slabs transfer ground moisture through concrete walls or slabs. It is generally recommended to install a vapor barrier against a specific surface prior to installing wood materials.

If the vapor barrier complies with building codes, rules and guidelines, remember the following rules:

We install mineral wool

For installation of insulation on any surface, a working frame or additional partitions is required.The simplest and most effective mineral wool partition is best made from plasterboard sheets. Builders and ordinary people, depending on their preferences, lay mineral wool in one of two existing ways. In the first case, it is placed behind the drywall, in the second, the insulation is placed in the partition. We will now consider how this is done specifically in each case.

The first way

On the wall, special fastening brackets are installed under the profiles to which the drywall will be attached. They are positioned vertically with a distance of about 50-60 centimeters between themselves and screwed to the surface. Almost on the same line, four or five fastening brackets will be installed, which is quite enough for both the CD profile installed for the frame assembly, and the fastening of mineral wool sheets. Bend the screwed brackets in the shape of the letter “P”. Ultimately, on the entire surface there will be some kind of horns ready to receive mineral wool. We dissolve the roll or take out the layers of mineral wool from the bale (depending on the form of the material) and measure the desired fragment, depending on the need. In this case, we give some tolerance. For example, for a wall with a height of 2.6 meters, a stock of ten centimeters should be thrown over - after all, this is not a rigid material, cotton wool can deform, therefore, in the absence of a stock, it may happen that some part of the space will not be covered with insulation.

We place the prepared strip of cotton wool on the fastening brackets sticking out of the insulated surface. Given the properties of cotton wool, it will easily break through with a bracket and will hang securely in an upright position. Similarly, we carry out the adjustment and installation of the material in a horizontal position. The next band is set like an accordion. Having completed the installation of mineral wool in the recommended way, you will inseparably and tightly cover the entire planned surface with insulation.

After completing the installation of the thermal insulation material in the inner surface, it should be remembered that we still have to install the profile for the installation of drywall sheets, and mineral wool, despite the fact that it is already on the wall, continues to be a source of danger to humans - it continues to be present in its composition a certain concentration of carcinogen and formaldehyde. So you should not relax and all further work must be done with extreme caution and in compliance with the above safety measures.

So, we stopped at the stage of installing profiles for sheathing mounted mineral wool with gypsum plasterboard sheets. The profile LED is installed according to the usual method (it is described above), however, in this case, again, we protect our hands with gloves from the effects of material particles. If we use mineral wool without foil, then first we mount a waterproofing barrier over the insulation and profiles (there is a large selection of waterproofing materials on the construction market). Thanks to this, the room will receive additional protection from the side effects of mineral fibers. To complete the insulation of the wall according to this option, it remains to cut out the necessary fragments from the drywall sheets and fix them to the profile.

Second way

We make a working frame on the wall surface for fixing drywall. In the usual, previously described way, we mount metal profiles. Now you can fill the space of the frame with mineral wool. But since we have already used the fastening brackets, the insulation strips should be laid in a different way. In this case, it is assumed that the distance between the profiles does not exceed 40 centimeters, and the width of the strip of mineral wool is within 50-120 centimeters. Thus, you can use the often used "accordion" method - the insulation should be passed under the profiles one strip after another.With a small distance from the profile to the wall, cotton wool can be stratified to the desired size. Passes should not be made, the entire surface should be tightly covered with insulation! Even the smallest gaps in a designed, albeit very warm, blanket can significantly reduce the thermal insulation of a room.

When carrying out work on pulling strips of mineral wool under the profiles, be careful not to spoil the insulation with the fastening brackets placed on the surface.

After completing the installation of mineral wool, some ordinary people are in no hurry to close the insulation with drywall, and on top of the mineral wool, in order to provide additional protection against carcinogens and formaldehydes, a layer of dense cellophane film is applied and only after that they close the structure with drywall.

Do not use impermeable vapor barriers.

Construction methods that allow interior wall materials to dry are considered better than those that seek to prevent moisture ingress.

Steam barriers are usually best installed on the side of a wall that experiences hotter temperatures and more humid conditions: the inner surface in colder climates and the outer surface in hot, humid climates.

Under existing conditions, oil paints or vapor barrier latex paints provide an effective moisture barrier.

Avoid installing vapor barriers on both sides of the structure. Walls and ceiling cavities should ideally be able to dry in one direction if the other side is built to prevent moisture ingress.

Seal all cracks in the walls and holes in the wall. Use special sealing tape to join the sheets if polyethylene sheets are used.

Use sealant or sealing tape to seal around electrical boxes on outlets, switches, or ceiling lights.

Areas of use for the windproof membrane

Let's take a look at each area separately:

- This material is used for thermal insulation of the roof, attic and attic floors. The windproof membrane protects the thermal insulator during the installation of the roof covering (s). Thanks to this, condensation does not penetrate into the "cake" during operation.

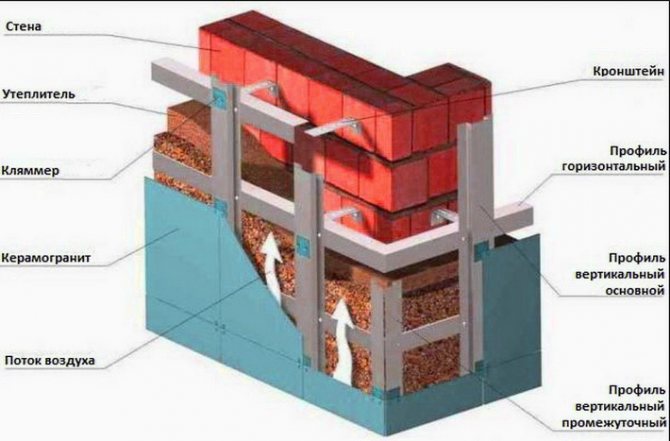

A windproof film is used for the walls and facades of the house. Here the main role is played by the function: vapor diffusion as well as hydrophobicity. The windscreen creates ventilation so that the surface can "breathe".

It is used for floors and floor joists. In this case, films that are capable of passing only steam, not water, are suitable.

Hydro-windproof film is used for frame partitions. This material helps to prevent the mineral wool particles from spraying. A protection against condensation accumulation is also formed. The efficiency of the air impermeability of the partitions is increased.

Types of materials for vapor permeability:

To help builders apply vapor barrier correctly, various building materials are classified according to vapor permeability.

Impermeable materials:

- Glass

- Sheet metal

- Polyethylene sheet

- Rubber membrane

- Vapor barrier paints

- Outdoor plywood

- Foil Rigid Insulation Board

Semi-permeable materials:

- Foamed or extruded polystyrene

- Laminated plywood

- Bituminous coated paper

- Drywall painted with oil or moisture resistant latex paint

Vapor barrier for ecowool is needed or not

Construction of the Church of St. Sergius of Radonezh is nearing completion in the north of Moscow

30.06.2017 07:20:19

In the northern district of Moscow on the Khodynskoye field, work is being completed on the commissioning of the church of St. Sergius of Radonezh.This was announced by the curator of the program for the construction of Orthodox churches in the capital, State Duma deputy Vladimir Resin.

The government may pass a law on remote provision of medical care to patients

30.06.2017 07:18:50

The State Duma Committee on Health Protection recommended the lower chamber to adopt in the first reading the draft law on telemedicine, which provides for the provision of medical assistance remotely.

A contractor for the construction of a gas distribution pipeline is being sought in Gatchina

30.06.2017 07:17:08

In the town of Vyritsa, Gatchinsky District, Leningrad Region, a tender has been announced to find a contractor for the construction of a distribution gas pipeline. The starting cost of the auction is estimated at 38.8 million rubles.

Almost $ 3 billion will be allocated for the construction of roads in Kazakhstan

30.06.2017 07:15:35

This year, $ 1.8 billion of borrowed funds and $ 1.1 billion of own funds will be allocated for the development of the road infrastructure of Kazakhstan. This was announced by the Chairman of the Committee for Roads of the Ministry of Investment and Development of the Republic of Kazakhstan Mereke Pshembaev.

The space elevator will be a real breakthrough for humanity

30.06.2017 07:13:41

According to world scientists, the idea of building an elevator to Space no longer looks fantastic. Thanks to technological progress, this project can be implemented by 2050.