A lot of cheap counterfeit products have appeared on the construction market, unscrupulous manufacturers care little about compliance with GOST standards, the goods do not meet either technical specifications or environmental safety standards. More expensive samples from reliable manufacturers are not available to many consumers in this time of economic downturn.

The population of the country, looking for cheaper solutions in the field of insulation of their houses, and, more importantly, more environmentally friendly for health are increasingly beginning to make insulating mixtures with their own hands, one of the components of which is sawdust.

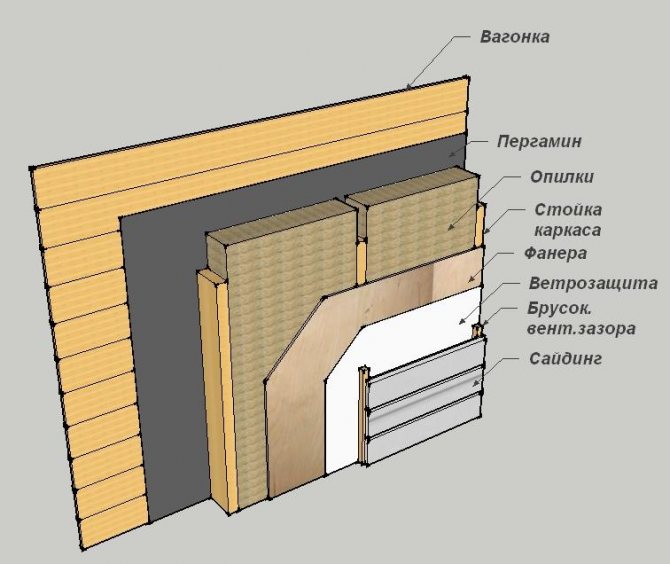

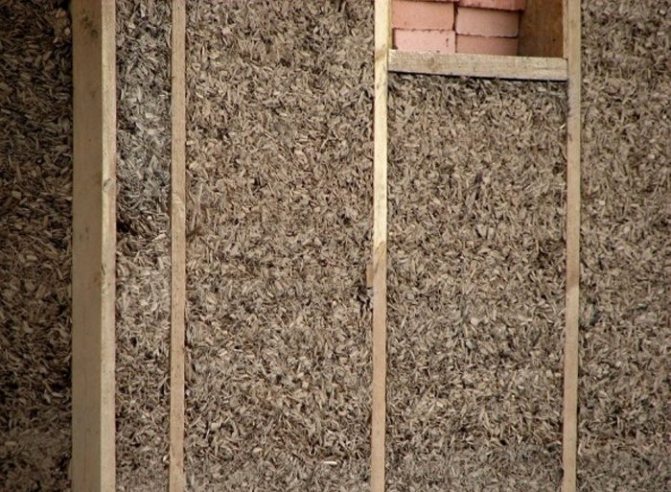

Sawdust as a reliable insulation of the surface of the walls of frame houses

Why is sawdust not used for insulation in its pure form?

Clean, only received sawdust for insulation of premises is categorically impossible to use for the following reasons:

- sawdust walls are a wonderful place for arranging dwellings for rodents, as well as the appearance of various kinds of microorganisms;

- after a while, the wood raw material cakes, voids appear in its mass - it begins to rot and a greater amount of thermal insulation properties disappear.

Undoubtedly, sawdust is a good solution in the issue of insulation - they have a low heat transfer value. However, they must be used wisely, correctly, and only in combination with other astringents. This will avoid the appearance of the negative consequences discussed earlier, and then such a heater will compete with industrial means.

The use of pressed sawdust

Pressed sawdust is suitable not only for heating, they are also used as insulation in private buildings and baths. Special boards made from wood fiber and compressed sawdust exceed standard sawdust in terms of efficiency. Antiseptics or fire retardants are always added to the material for their creation, which increase the resistance of the plates to negative influences. Their installation is carried out in a few hours, but additional coating is required for such plates.

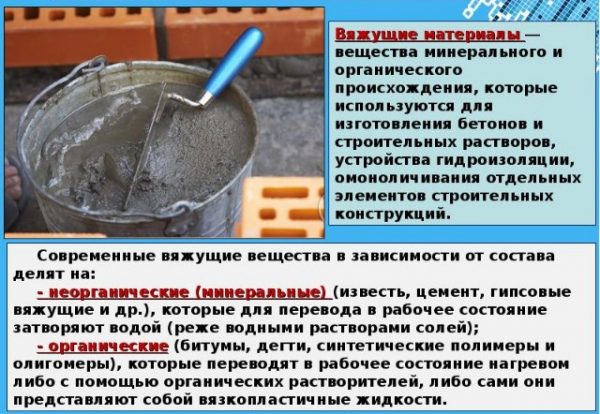

The most popular types of binders

Known to many, such substances as Portland cement, clay, gypsum mixtures, PVF glue, and cow dung can act as binding connectors for wood chips.

Astringents in construction

- Clay is the most inexpensive material, and with access to nature, it is completely free. It is a completely natural substance, therefore it is environmentally friendly - no chemical reactions are present during the drying process, only moisture evaporates. Clay is lightweight, strong enough, but fragile, durable. The only drawback is the fact that unbaked clay is not resistant to excessive moisture - it starts to deteriorate.

If we compare the clay composition with sawdust with others: gypsum, cement, then it is practically not inferior to them.

- Portland cement is the most common binder used in professional construction. The only drawback is a long time to set hardness (standing up).

Cement with the use of wood shavings is excellent for thermal wall plastering, both indoor and outdoor. The embedded cement is excellently resistant to high humidity. Backfill walls are a profitable and reliable way to keep your home warm.

- Gypsum - for interior wall decoration, ideal for “speedy” construction. Such a composition rises almost instantly, and gains strength similar to cement. The cured mixture is durable and environmentally friendly.

- Polyvinyl acetate - hardened PVA glue, insoluble in water, very strong, even tough.

For this reason, PVA is used in places with high humidity, as well as in places with direct contact with water. The hardened glue has one remarkable property - it allows water vapor to pass through - so that the treated walls will not only be insulated, but will also “breathe”. It should be noted that with strong heating of the insulation, moisture will come out of the sawdust, and they will dry out, but PVA deformation is sufficient to hold the shrunken wood particles, without losing shape and overall strength.

- For lack of anything better, cow dung will do. It was widely used until the 19th century. The house was insulated using this natural glue. Today, few people insulate their homes with them, but it is quite suitable for a barnyard. Its strength is certainly lower than that of all of the above means, but placed in the inter-wall space of an outbuilding, it will work for many years.

Sawdust as insulation - an easy way to insulate a house with your own hands

Sawdust is not used in its pure form, without adding any impurities, since they have a high flammability. But sawdust is used in materials such as ecowool or wood concrete, which are excellent for floor insulation.

If the temperature in winter reaches 20 degrees, then the insulation is applied with a thickness of 15 centimeters. Sawdust is an economical material, since it has a low cost, it is used as insulation for roofs, interfloor ceilings, floors, and ceilings. First, the solution is sprayed onto the wall.

Such a question may arise even at the stage of design work or when the purchased house requires some modifications to make living in it comfortable. Why is the air temperature not always comfortable inside the dwelling? This is due to the presence of the following factors: You can insulate your house in one of several ways. Experts strongly advise to insulate the walls from the outside; it is recommended to carry out such work from the inside in extreme cases.

You need to work quickly, but carefully. Everything that falls to the ground can no longer be used for its intended purpose.

The use of various auxiliary components

The principle of operation of heaters is the same - the wood base, which contains small inclusions of air in its structure, is mixed with a binder mass, which, after drying and gaining strength, forms a monolith.

Each composition has its own properties: getting up time, viscosity, elasticity, which can be transformed with the help of additional substances. Each team has its own nuances and solutions for specific tasks.

- So for floor insulation, sawdust is used instead of mineral wool. To increase the service life and reduce the decay process, they are knitted with PVA glue with the addition of an antiseptic solution.

- A small amount of Rotbant or TG is added to the cement-bonded mixture, if it needs to be poured into a mold, to speed up getting up, so if you add a glass of gypsum to the bucket of the mixture, the cement will rise within 1-2 hours.

- The same method works with lime compounds.

Primary Menu

Research and production association

Unique sawdust plaster

I finished building my own suburban house two years ago, the house turned out to be good and very good-quality, living in it in summer is simply amazing, but with the advent of cold weather it is just a nightmare how cold it is. I reviewed a huge number of insulation options for personal houses, but many of them are ineffective, some of the new unique insulation options have not yet been tested as needed, and a number of heat insulators require quite a lot of money. For a long time I thought about how it is better and cheaper to insulate my own house, until my new neighbor in the dacha recommended me a good and cheapest option for insulating all the walls.This version of insulation has been strong for many years, and it was used by our distant forefathers when they did not even hear about the unique ultra-fashionable heat insulators of the walls. Many of the readers have probably heard about this heat insulator of the walls, this is an ordinary solution of sawdust, if you plaster the walls with this substance, then such a decent thermal insulation comes out. Moreover, its price is low, and it can be prepared quite simply and quickly, our forefathers prepared this mixture from ordinary sawdust, which they simply combined with such an astringent as clay and lime. This is the most common and most affordable heat-insulating old plaster, which does not differ enough from modern complex heat insulators, both in terms of efficiency and durability.

We make a solution of thermal insulation plaster

This plaster is perfect for finishing facades and internal walls, for insulating the slopes of door and window blocks, while the sawdust plaster also has good sound insulation properties. Such plaster is made quite easily and quickly, instead of the clay that our forefathers used earlier, I used ordinary cement with the addition of an insignificant amount of lime and clay. Such an insulating mixture is simply applied to virtually any walls that do not even need to be prepared, you just need to clean the walls from dust and dirt earlier and you can start plastering right away. It is believed that a solution based on sawdust is more suitable for interior work, and such warm plaster is also suitable for facade insulation. Also, in addition to sawdust and cement, paper is added to the general solution, this composite composition forms an excellent long-term thermal insulation of the walls. The only thing is that this insulating solution dries out for a rather long time, which is why the rooms where this plaster was used should be ventilated for 3-4 weeks until the moisture evaporates. Try to prevent dirt and dust from getting into the prepared solution, the solution should be spotless, otherwise fungus may appear on the dirty plaster. Sawdust and grass were often used earlier in construction and are often used to this day, from sawdust they make wall material such as sawdust concrete, arbolite and a number of others.

Heat-insulating special plaster is prepared so, one part of cement is taken, two parts of cardboard mass and three parts of sawdust are added, all this is painstakingly mixed at first and then water is added, after which the whole mass is again well mixed. And when the mixture reaches the state of an ordinary cement mortar, you can already throw it on the wall like a standard plaster, only if you need to plaster the wood surface, then fill it with shingles first.

Astringents and their proportions

To prepare the sawdust mixture, there is no need to experiment, all the recipes have been known for a long time, the proportions are selected.

Gypsum

To fill, do the following:

- sawdust is placed in the prepared container (no more than 1/5 of the container);

- in a ratio of 1:10 or 1: 5, gypsum grade 1 and gypsum grade 2, respectively, are added to the base and mixed;

- add water at the rate of 1 liter per 1.4 kg of gypsum and mix;

- the mixture does not need to stand, it is immediately poured into a prepared mold.

For plastering work, the preparation of the working solution differs only in the amount of water: 1 part of water for 2 parts of gypsum.

It is necessary to prepare the solution in small quantities, since it rises quickly, and the finished solution cannot be diluted. However, a retarder can be used; casein (carpentry) glue is used as the latter.

As an analogue of casein retarder, you can use scabbard glue with lime. Retarder recipe: 1 kg of glue is soaked for 24 hours, 2 kg of lime is added and boiled in a steam bath for 4-5 hours.The resulting retarder is added to the mixing water at a rate of 1 to 50. The setting time of the solution is increased by 20-30 minutes.

Super insulation video:

Cement

For novice plasterers, the preferred option is “mud” with Portland cement. The solution lives infinitely long up to 2-3 hours, - you can plaster slowly. It can also be reanimated, the main thing is not to let it dry completely or lie down. A small amount of water is added to the prepared mixture as it thickens and mixed. Sometimes the unused solution is left overnight, flooded with water, but that's how lucky.

To improve (preserve) the thermal insulation properties of the wood base, various plasticizers are added to the cement, which increase the plasticity of the composition. As the latter, use liquid soap, shampoo or an inexpensive dishwashing detergent. The addition of a soap additive can also reduce the amount of water used. The amount of additive is measured by eye: there will be enough cap for a bucket - after a couple of batches, even a child will figure out the amount of additive.

Warming with a solution with sawdust and cement, as well as soapy water, is not recommended, because after getting up, the mixture does not allow moisture to pass through - as a result, you will get damp walls, ceiling and floor.

For indoor work, it is better to use industrial additives such as polyplast, fort or superplast - they are more effective than soap or milk.

Milk is used in the same capacity as other plasticizers, but it should be remembered that, using it, the cement will lose strength.

Plastering walls with a solution with the addition of sawdust

Lime

A very necessary and useful substance in the household. Lime is an alkali that is a natural antiseptic. However, she can wash not only linen, but also disinfect shavings from various microorganisms and their larvae. In addition, the alkali will relieve the base for the solution from rot and protect it for a long time from the appearance of unnecessary organisms, including rodents (they are afraid of it like fire).

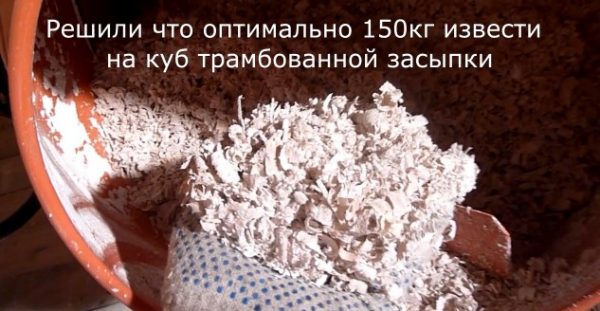

For use, you only need slaked lime (so as not to injure yourself). It is necessary to mix lime with sawdust in the following proportion: 1 part of lime to 10-15 parts of sawdust.

Important! Timber frame walls treated with lime mortar will be more durable. Neither bark beetles nor all kinds of aphids will start in them.

Any other astringent can be added after the sawdust has been treated with lime.

It is possible to use lime as an adhesive composition, but the indicators will be unimportant, and besides, it is better not to use it inside the dwelling.

Lime works too

Clay

Another folk material forever young. It has been used throughout the history of mankind. By mixing clay with straw, you can build a hut. Clay has unique properties and is also very affordable.

Clay as insulation for the walls of the house

For home insulation, the following proportions are recommended:

- For the ceiling and floor - 1 part of diluted clay and 10 parts of wood waste;

- For wall insulation, for filling internal cavities, - 1 to 5;

- For plastering walls, a more viscous mixture is needed - 1 to 2.

The readiness of the clay solution is determined by touch, it should be a little greasy and elastic. If the pieces stick strongly to the trowel, then the mortar must be combined with the shavings.

Clay compositions are the most suitable for human life. They are environmentally friendly, durable, the main thing is to protect products made of unbaked clay from direct exposure to water. Warming with clay with sawdust is a common phenomenon.

The life of the prepared composition is endless, if the clay is dry enough to add water, and it will be fine again.

You can buy clay at any hardware store, but you can get it yourself.You should know that the best clay is at a depth of at least 1.5 meters, since its upper layers may contain particles of plant roots, and this is not welcome.

To fill the walls with clay, the composition should not be liquid and even creamy, otherwise drying will last indefinitely. Clay lumps with sawdust should be moist and slightly crumbly so that they stick together when tamped.

PVA glue for walls

To prepare heat-insulating material, you need a universal or construction PVA, other brands of glue for thermal insulation will not work.

The wood raw material for the mixture needs to be dry and as fresh as possible. There are no clear proportions, the solution is prepared by eye, about 1 to 5-10. The less amount of glue is used, the lower the heat transfer will be. But you should not be greedy either, because poorly processed shavings will rot and rot.

The process of making sawdust mixtures

Thermal insulation of buildings with sawdust materials is associated with the preparation of appropriate mixtures. Each of them is associated with a specific recipe. However, their approximate composition is identical:

The binder is made of lime or cement mixed with water and an antiseptic.

- For 10 buckets filled with sawdust, take 1 bucket of lime and mix thoroughly.

- Add 8-10 liters of water diluted with boric acid or copper sulfate to the resulting mixture. These substances are known for their excellent antiseptic properties, which is especially important for the bath. The liquid should be infused smoothly.

- The prepared solution is infused for 5-10 minutes, after which it can be used. The surface of the walls must be vapor-tight. Glassine will serve as a good basis; roofing material is not recommended.

Dry prepared components must be thoroughly mixed, after which you can add water by pouring it in a thin stream from a watering can. The finished mixture looks like this: the composition is taken in hand and compressed, the resulting lump should be flexible and not fall apart, there should be no excess water.

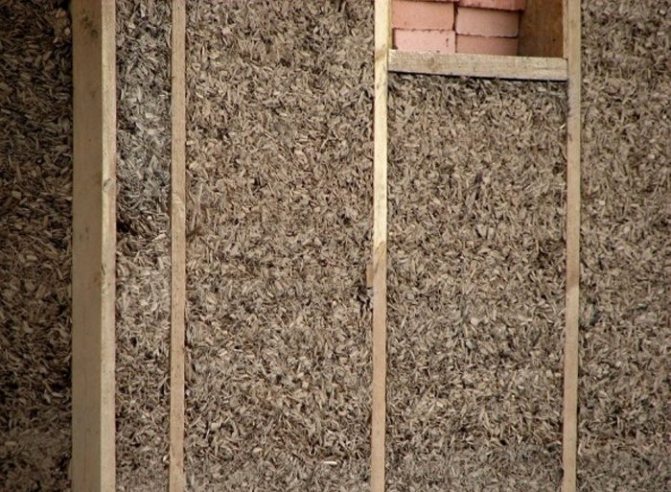

The finished sawdust mixture is laid in neat layers, which are small in size, only 25-30 cm.

Measured styling should be combined with good compaction. Then other layers fit in, and so on until the entire base is filled. In some variants, a diluted composition of sawdust and lime is used. Its cost will be slightly higher, but the moisture fill level reading will be lower. The mixture will not settle too much, which is very valuable for placing a bath, which means that it will not be necessary to periodically add material. It is worth noting that any work with wood chips is associated with a high degree of dustiness, and the process of preparing and pouring the base with a mixture will not be easy.

Advantages and disadvantages of sawdust

Sawdust, considered as a raw material for construction, has its own advantages and disadvantages.

Wall insulation with sawdust pros and cons:

- Cost. This is the first thing for which this multifunctional raw material is valued. For many, the price is zero at all, whether financial costs for delivery are necessary.

- An environmentally friendly material that, when used correctly, does not emit any harmful substances. Chemical contamination is generally excluded.

- Durability in use. This fact is proven by human history - many generations of our ancestors used it and did not complain.

- Installation. In order to perform any kind of manipulation with these materials, qualifications are not needed, the work can be performed even by a person of mental labor who is far from construction.

- Thermal conductivity. A very low indicator for this parameter. The wood structure itself has the smallest air cavities, which is already a universal insulator, plus the fine fractional component of the sawdust themselves.

House of waste from shavings and clay

Disadvantages of woodworking:

- Combustible.It is necessary to observe increased measures for fire safety.

- Rotting.

It should be noted that the existing drawbacks can be solved in various ways, including those discussed in this article.

Autoforum Rostov-on-Don

Help determine the choice of plaster

Jack61 12/18/2013

Omniscient autoforum tell me which plaster to choose for self-repair the first groove in life in a new building. Naturally, dry gypsum mixtures are of interest. On the Internet, they write well about rotband and volma, but they are expensive. A familiar plasterer says Turkish siva will do just fine. Dad generally recommends mixing gypsum with sawdust, as if cheap and cheerful. I would be glad to receive any information.

Nikolay 12/18/2013

Knowledgeable Armenians add milk to gypsum with sawdust.

For a beginner, I recommend Knauf. If you save on teachers, then at least take the material so as not to spit.

Astriх 12/18/2013

A zil of lime mixture costs about 3000 rubles. Enough for the neighbor's apartment. Slopes start knauf.

Jack61 12/18/2013

Knowledgeable Armenians add milk to gypsum with sawdust.

For a beginner, I recommend Knauf. If you save on teachers, then at least take the material so as not to spit.

There are teachers, just some say we like this plaster, others like this one. The choice comes down to how much money their clients have for material, but I want to hear a more objective comparison. Studying the characteristics on the packaging, I realized that they are all about the same, except for the graininess, on the knauf it is also written about environmental friendliness (I think this is pure marketing)

OLEG -161 RUS- 12/18/2013

A zil of lime mixture costs about 3000 rubles. Enough for the neighbor's apartment. Slopes start knauf.

For 3 thousand it will be just a cube of solution. And a full zil of 2.5 cubic meters was taken in the summer for 5000 (2000 per cubic meter of slaked lime mortar) + 1300 delivery. So for it you need to knock down the tray (about 2.5 meters wide). Well, for reference, 3.5 cubes were used for 140 square meters of walls.

sergey 12/18/2013

For a beginner, ABC Turkish is suitable, the mixture can work for more than an hour, go to bed very well, and the price is good, in Leroy it costs two hundred rubles with a penny.

Astriх 12/18/2013

For 3 thousand it will be just a cube of solution. And a full zil of 2.5 cubic meters was taken in the summer for 5000 (2000 per cubic meter of slaked lime mortar) + 1300 delivery. So for it you need to knock down the tray (about 2.5 meters wide). Well, for reference, 3.5 cubes were used for 140 square meters of walls.

If the Novocherkassk plant of synthetic materials is still alive, then this slaked lime was worth a penny for them, the worker drove zil at one time he brought it for plasterers, the price was generally ridiculous. As I understand it, they use acetylene and this mulka is a by-product. Druzhban alone took zilok, it was enough for a house of 70 square meters to plaster almost everything. I didn't knock anything down or any trays, I just covered it with a film and that's it, though I chopped pieces in the winter and brought it in gradually as it worked out. Well, if we compare with ready-made mixtures, then 3.5 cubes would come out at a serious pretty penny at a cost of 170 rubles per bag of 30 kg.

Changed: Pimenov Maxim, 18.12.2013 - 22:15

Alex_lok 12/18/2013

I would tell all about the wisdom of this matter, why the plasters are different and how they really differ and about specialists, how to distinguish a good specialist from a bad one according to his reviews about plaster mixes, BUT there is not a single piece of advice on this resource

If it boils, you can just walk by, next time there will be sanctions for the cryptomat

A zil of lime mixture costs about 3000 rubles. Enough for the neighbor's apartment. Slopes start knauf.

from whom, but from you I did not expect to hear this.

Or do you still want to do this?

Changed: tank166, 12/19/2013 - 14:34 cryptomat

Jack61 12/18/2013

I would tell all the intricacies of this case, why the plasters are different and how they really differ and about specialists, how to distinguish a good specialist from a bad one according to his reviews about plaster mixes, BUT there is not a single piece of advice on this resource

at least a few words in a personal write

Alex_lok 12/18/2013

at least a few words in a personal write

Yes, you better ask ASTORIA, she will tell, well, or don-a

and itb will tell you about an electrician with halogens in sockets

right there is a forum of aligarh craftsmen, EPT

andrew261 12/19/2013

Take Forman10 in Leroy 278 rubles for 30 kg. Lays down perfectly. Doesn't float. Like a good old rotbant 10 years ago. Turks are very weak in strength after drying out.

Ilja86 12/19/2013

I plastered myself with a volma, very satisfied, strong. It all depends on the square, if it is not much better to overpay a little, but it will turn out reliably, and if the square is large, then yes, you have to look for options. P.S. as an option, take small bags of different brands and check on small surfaces, and then decide.

Changed: Ilja86, 19 Dec 2013 - 06:55

Astriх 12/19/2013

from whom, but from you I did not expect to hear this.

Or do you still want to do this?

It all depends on the thickness of the layer, what you put on the wall under the wallpaper is not so important, but it’s not so important to putty and putty anyway, and I’ll tell you I saw a lot of houses and that and that was done, and so my belief is that there is no difference, with normal observance of the technology, it only looks the same the costs are not commensurately greater. In addition, lime plaster is less susceptible to various types of fungus. Yes, if the layer is not large, then dry mixtures are quite suitable, and when the walls are so crooked that the difference is at the level of 7-10 cm, it is too expensive to level them. Apartments plastered 30-40 years ago with lime plaster feel great. That is to say, the material is time-tested.

Changed: Pimenov Maxim, 19 Dec 2013 - 07:53

ASTORIA 12/19/2013

Yes, you better ask ASTORIA, she will tell you, well, or don-and itb will tell you about an electrician with halogens in sockets right there and then the forum of craftsmen-aligarh, EPT

Astoria's 1200-odd meters of walls plastered by Armenians have not given a single crack in 14 years, and with one and a half brick walls - they are warm in winter)) Armenian plaster: gypsum + sawdust + milk - while driving unusually. But. in Armenian hands

tank166 12/19/2013

On the Internet, they write well about rotband and volma, but they are expensive. A familiar plasterer says Turkish siva will do just fine. Dad generally recommends mixing gypsum with sawdust, as if cheap and cheerful. I would be glad to receive any information.

Rotband is really expensive. Turkish mixtures will be weaker in strength - this has already been noted here.

I'll tell you about Volma. For a long time we used plaster of a little-known Ural manufacturer and did not know grief - and the price was very good, and there were no questions about the quality. At the same time, we were persistently attacked by the Volma sellers, proving that their mixtures are more economical. It was hard to believe, given the almost 15 percent difference in price per bag. However, out of sporting interest, we decided to conduct tests - they gave the Volmians and our masters along exactly the same wall, and they themselves sat down to count how much material would go in both versions. After recalculating the consumption of plaster per square with the same layer, we got that Volma in money gives a gain of almost 6 percent. Small, but nice, especially on a large volume. What is noteworthy is that the resigned suppliers of the Ural mixture insisted on re-testing with their plasterers. As a result, Volma again won, even by a wide margin.

As for the Armenian plaster - for all its advantages, it has one feature - it dries much longer due to sawdust that retains water

andrew261 12/19/2013

As for the Armenian plaster - with all its advantages, it has one feature - it dries much longer due to sawdust that retains water

And if it gets wet, for example floods, you will get yellow-brown spots. Well, she assumes a thick layer. So if the drop is large, then I am also for lime. Cheap and cheerful.

ps I have limestone (from the developer) + forman + knauf finish.

Odin 12/19/2013

I started repairs with workers, now I'm finishing it myself. I put it on myself for the first time (a new building, probably a socket?). Fugen is good, but quickly hardens, you need to interfere with handles. Volma was praised by the workers (there were two teams, he did it in parts), Turkish putty too, but no plaster.

There is nothing terrible, success.

There are some good videos in the net.

Xoka 19.12.2013

Winchester_777 12/20/2013

extra-gypsum from shmakaturka and satin putty. This is for the Turks.Facade bark beetle

Another variant of the Weissbau shmakaturka putty, self-leveling floors and so on.

Kemikol tile adhesive.

MiD 12/20/2013

For me, plasterers work with Volma MN (for machine application), they say that it is better than for manual application. They immediately wash the plaster, the surface is smooth. No need to putty under the wallpaper.

Dmitrievich 12/21/2013

Volma is one of the last gypsum in the south of Russia, produced by cyclic technology (technology of cooking in boilers).

Plus hammer crushers.

Use it while this plant - the last of the gypsum plants built in the USSR (1986) - is still working.

Changed: Dmitrievich, 12/21/2013 - 00:11

Jack61 02/12/2014

In general, I decided to make a layer with a volma. It seems like nothing happens. Now the question of quality interests. By what criteria is it assessed?

When I started to do it, I thought that ideally flat walls would turn out, but in practice, if the rule of 2.5 m is applied to the plastered wall, then there are one two holes from 1 to 2 mm. depth, various lengths. Is this normal or not?

xlk 02/12/2014

In general, I decided to make a layer with a volma. It seems like nothing happens. Now the question of quality interests. By what criteria is it assessed?

When I started to do it, I thought that ideally flat walls would turn out, but in practice, if the rule of 2.5 m is applied to the plastered wall, then there are one two holes from 1 to 2 mm. depth, various lengths. Is this normal or not?

ok, this is called high quality plaster by building codes

Permissible deviations:

- surfaces from the vertical:

- for 1 m of length - 1 mm,

- for the entire height of the room - no more than 5 mm,

- uneven surfaces of smooth outline (by 4 m 2) - no more than 2 pcs. depth (height) up to 2 mm,

- window and door slopes, pilasters, pillars, husks, etc. from the vertical and horizontal (mm by 1 m) - should not exceed 1 mm,

- the radius of curved surfaces, checked by the piece, from the design value (for the entire element) - should not exceed 5 mm,

- surfaces from the horizontal by 1 m in length - 1 mm,

- the width of the slope from the design one - should not exceed 2 mm,

- rods from a straight line within the limits between the angles of intersection of rods and ripping - should not exceed 2 mm.

Jack61 02/12/2014

ok, this is called high quality plaster by building codes

It turns out that you can safely glue wallpaper on such a surface?

Additional filler for painting?

xlk 02/12/2014

I would putty anyway, but I'm paranoid. If light sources are planned on the walls, deviations from the plane may be visible, even under the wallpaper.

Modern technologies

Wall insulation technology

With regard to technology, the following should be noted:

- backfill method. The mixture is poured onto a solid base or placed inside two surfaces where it is rammed;

- filling. A relatively liquid solution is poured into a prepared form, where, as it dries, it acquires the property of a solid monolith;

- plastering. If the walls are plastered with a sawdust mixture, then they acquire thermal insulation properties.

Thermal insulation blocks

A proven method of floor insulation with sawdust

The floors were insulated long before there were special target materials that provide high-quality and reliable thermal insulation. Traditionally, all sorts of improvised materials were used for these purposes, for example, floor insulation with sawdust. True, this method may seem outdated, but due to its environmental friendliness and exceptional low cost, it is successfully used today.

A thick layer of sawdust is as effective as many heat insulators!

There is wood waste on almost any sawmill, but in order to properly insulate the floor with sawdust, the material must first be properly processed.

Preparation

Ordinary sawdust remaining after cutting the logs is pretreated with antiseptic agents and thoroughly dried.It should also be taken into account that a layer of such insulation is an excellent habitat for rodent pests. To protect the backfill, sawdust must be mixed in a certain ratio with slaked lime, fluff. Hydrated lime should constitute at least a tenth of the total mass. To make it easier to achieve Mass homogeneity can be achieved more easily if the components of the mixture are poured onto a metal or wooden board. The mixture is stirred by inverting with a shovel.

It is also important to eliminate the flowability of the material, otherwise, over time, you can face the problem of subsidence of the insulation layer, due to which the backfill will begin to transmit heat. What are they doing for this? To change the free-flowing structure of the backfill to solid, lime and gypsum are added, in a specific proportional ratio: 85% sawdust - 10% lime and 5% gypsum.

Insulation is prepared in small portions to prevent it from hardening ahead of time. The fact is that gypsum sets very quickly. As part of the additional components can be replaced with others:

- lime - for lime dough, but you need to take it twice as much,

- gypsum - for cement.

How is styling

The process of laying sawdust should be described using the example of insulation of an attic space in a residential or utility building. During warming with sawdust, you need to weigh all the pros and cons, then familiarize yourself with the technology of their installation.

First, the surface is prepared for the thermal insulation coating, the cracks are covered with clay or filled with polyurethane foam to improve the quality of thermal insulation. In the presence of a chimney, in order to protect against fire, the area around it is lined with non-combustible material, for example, slag.

Sawdust screed

The sawdust screed has several advantages. First, it is environmentally friendly and does not contain harmful ingredients. Secondly, it is cheap, 70% consisting of sawdust, which will be given away for nothing at any sawmill and will also say thank you. Thirdly, it is very warm, no additional insulation is needed. Finally, it is durable - not inferior to a standard screed, but warmer. The sawdust screed is made in two layers: the first is warmer, the second is more durable, resistant to abrasion. For the lower layer (warm), the solution is diluted in the following ratio:

- 1 part cement

- 2 parts of sand,

- 6 parts of sawdust.

For the top layer (durable), the solution is made in the following ratio:

- 1 part cement

- 2 parts of sand,

- 3 parts sawdust.

Cement freezes, but such a composition does not. With the same success, sawdust is added to the plaster to preserve heat.

How to prepare the solution?

Clay with sawdust works well as wall insulation only if the materials are selected, prepared and applied correctly. The process of home insulation begins with the preparation of the solution and the selection of materials. Both ingredients are available free of charge. But it is worth paying attention to their quality.

Clay

The material is readily available, inexpensive, and in some cases free to obtain. Attention should be paid to the quality of the material: the presence of foreign objects in the material is not allowed.

You can use the clay you just brought, but to get the perfect consistency of the mixture and the durability of the insulation, you need to prepare the clay. To do this, it is poured with water, mixed and left for the winter. During this time, the material undergoes several thawing and freezing cycles. Natural heaving forces the material to expand and contract again several times, the clay becomes homogeneous and plastic.

Clay can be "skinny" and "oily", plasticity depends on the fat content. When using "greasy" (plastic) clay, it is necessary to add a little sand to the insulation.

Clay for solution preparation

Before starting work, clay must be prepared: leave for the winter in a state saturated with water.

Sawdust

Sawdust is a waste from the woodworking industry.They can be specially purchased at a low price at any enterprise. For wall insulation, you can use different sawdust, which have their own useful properties:

- Oak almost does not change its size and density under the influence of moisture, almost does not rot, and is resistant to bacteria.

- Coniferous sawdust is less susceptible to mold formation than other types of wood due to the high content of essential oils.

When insulating walls, you can use a mixture of several types of sawdust.

Before starting work, sawdust must be prepared:

- First, sawdust is removed from impurities, sieved and washed.

- After that, the sawdust is thoroughly dried.

- Dry sawdust must be impregnated with compounds that protect the wood from decay, mold and fire.

Sawdust for mixing

Mixed sawdust can be used to obtain better thermal insulation properties.

Preparation of the solution

To properly prepare the mixture, you need a set of tools:

First, clay is soaked in one of the barrels. It is left for several hours and stirring occasionally, they are waiting for it to become homogeneous. After that, 1-2 buckets of clay are poured into a concrete mixer and sawdust is gradually added there in a ratio of 3: 2, respectively.

To achieve better thermal insulation properties, technical salt is added to the mixture, but in this case the proportion of clay and sawdust changes by 1: 1.

After a short stay in the concrete mixer, the mixture is ready for use, it is poured into a second barrel or immediately proceeds to installation.

Application

Formwork can be used to apply insulation to walls, but this method is very laborious, it is much easier to prepare insulation plates:

- To make slabs, you need to make several molds for them in advance. Their size will depend on the parameters of the wall. Molds can be prepared by yourself by collecting them from plywood and blocks using nails and a hammer. The thickness of the insulation plates will depend on the average winter temperature and the presence of technical salt in the mixture.

- The form is poured with the prepared solution in small portions and periodically leveled. It is advisable to minimize the amount of air bubbles and thicker the mixture.

- The installation of the plates is carried out after the material has hardened, you can use not completely dried plates, it is enough that they just keep their shape.

- Plates are installed close to each other, fixed.

- The joints, chipped corners and gaps are covered with the remnants of the clay mixture.

Installation of clay slabs with sawdust

For installation, wooden guides are used, plates are placed between them and after that the joints are rubbed with the remains of the clay mixture.

This home insulation technology ensures a clean room during installation. Raw clay is a very dirty and difficult to clean material. It is not recommended to use it in rooms where installation work has already been completed. The slabs can be prepared elsewhere, keeping the room clean.

It is very important to properly dry the insulation boards. When it dries quickly, a dense dry crust forms on the surface of the boards, which prevents the water inside from coming out, this leads to uneven drying, damage and loss of thermal insulation properties. To dry the boards evenly, they must be left in a room with sufficient humidity and protected from direct sunlight.