Perlite: a new word in the insulation market

Perlite is considered a versatile material used as insulation for walls and floors. This is volcanic sour glass. Raw materials can be obtained by sharp heating up to 1100 degrees, when it swells. Fractional composition is different. Various components are added to the raw materials that improve heat and sound insulation properties.

Today this insulation is considered one of the most effective in the world. Due to its special properties, the product is used not only in construction, but also in other areas. The largest producer of perlite is the United States.

Advantages and disadvantages

Perlite is a finely porous material, this is what ensures its lightness and the unique property of thermal insulation. Volcanic sand occupies a reliable position in construction, having many advantages:

- does not deform at high and low temperatures;

- hypoallergenic material;

- does not emit toxic compounds;

- has a high degree of sound insulation;

- when filling the frame with perlite, it is not required to strengthen the strength of the structure;

- ideal for indoor and outdoor insulation;

- relatively inexpensive price.

Disadvantages:

- it is not recommended to use perlite in rooms with stably high humidity of 12-15%;

- in the process of work, aluminosilicate dust is released from the material, therefore, open areas of the body and mucous membranes must be covered with clothing and a protective mask.

Scope of application of perlite as insulation

Since the insulation is available in different forms, it can be used in different areas. Perlite is used in:

- energy;

- construction of private and multi-storey buildings;

- metallurgical, food and oil refining industries;

- medicine.

Insulation can be used for external plastering of walls of buildings, when leveling and insulating internal surfaces. In this way, not only heat preservation is ensured, but also a change in the acoustic properties of the structure. Perlite is required to treat the roof. The material is also used when arranging a warm floor.

Perlite sand is used to make building mixtures. They are suitable for filling joints, cracks, cavities in walls, providing thermal insulation properties.

Pros and cons

Perlite has a rounded shape and characteristic luster, which makes it look quite pearl-like. The use of such material as insulation has many advantages:

- environmental friendliness of the material;

- fire safety;

- resistance to sudden changes in temperature, which is very important for outdoor insulation;

- lightness of the material;

- lack of odor and toxicity;

- relatively low cost;

- durability.

What does perlite look like?

The material is resistant to aggressive compounds, not subject to corrosion and decay. Loose insulation does not attract insects and rodents and is able to tightly fill voids, which makes it possible to achieve a sufficiently high level of sound insulation.

The disadvantage of using perlite as a heater is often considered the formation of dust during installation, which can be harmful to health. But this problem can be solved with protective equipment.

Insulation features

Insulation can be laid in different ways, it all depends on the type of material. If you need to fill it up, then you should do it right from the bag. In this case, a convenient interval must be observed. You need to check the material to make sure it is dry. If there are cracks or holes in the walls, then they need to be repaired so that the perlite does not spill out.

Cavities in the wall, which are located under windows and doorways, are subject to insulation.If necessary, the material is rammed. Insulation is also required between the exterior masonry and the interior trim.

Properties and advantages of perlite

Such insulation for walls as perlite has the following advantages and properties.

- light weight, which allows not to carry out additional strengthening of the walls' strength - the structures remain light, and the load on the foundation practically does not increase;

- resistance to temperature extremes, therefore, the material can be used to isolate internal and external surfaces (the material can withstand -220 - +900 degrees);

- environmental friendliness: the insulation does not emit toxins, regardless of the operating conditions;

- hypoallergenic;

- fire resistance - the insulation not only does not burn, but also protects structures from ignition;

- resistance to aggressive chemicals: it is not affected by alkalis and acids;

- inertness to corrosion;

- providing a high level of sound insulation;

- no deformation when exposed to heat in the room;

- the average cost in comparison with other materials, especially since its use pays off within a few years after the start of operation, since the cost of heating the house is reduced;

- ease of use, high efficiency;

- bulk density - 45-500 kg / m3;

- thermal conductivity - 0.043-0.053 W / mK;

- porosity - 70-90%.

But pearlite also has some disadvantages. You should not insulate the walls with this material if the rooms are constantly high humidity. During work, protective equipment and protective clothing should be used, as perlite emits aluminosilicate dust. It irritates the mucous membranes of the respiratory tract.

Comparison with vermiculite

Vermiculite is a stronger material than perlite

Among bulk insulation materials, the choice is usually made from two minerals - agroperlite or vermiculite. An unambiguous conclusion can be made by comparing their characteristics. Vermiculite is a layered dense material. In construction, it is used in expanded form. The mineral is heated to a temperature above 1000 ° C, during processing it increases in volume up to 20 times.

A significant advantage of vermiculite is its elasticity. Unlike perlite, it does not deform or crumble under its own weight. The insulation is heat-resistant and environmentally friendly. The high hygroscopicity of the filling requires a high-quality ventilation device on the roof.

The physical and technical properties of materials are similar to each other. Loose substances differ in appearance: light perlite, brown vermiculite. The thermal insulation properties of perlite insulation are slightly higher than that of vermiculite. But the main factor in favor of volcanic glass insulation is its cheapness. The material costs 2-3 times less vermiculite, therefore it is more popular in construction.

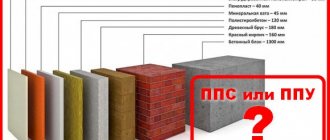

Varieties of perlite insulation

The specified wall insulation is produced in different forms and their characteristics are somewhat different.

Backfill insulation

Perlite sand for wall insulation is the lightest. Thanks to him, you can lighten any design. Material is used for arranging interlayers between floors, filling cracks and other voids. With this form of insulation, you can adjust the floor to the required level, plaster the walls. The material reduces heat loss by 40%.

Perlite in the form of slabs

The plate form of insulation is produced more often than others, since it is convenient to use, it makes it possible to quickly carry out installation work. The material is hygroscopic, so you should not use it for outdoor use. If such a need arose, then a waterproofing layer is required. The production of slabs involves hydraulic pressing of raw materials.The material contains other components that improve technical characteristics: cement, polymer substances, lime, liquid glass, bitumen.

Roofing models

Perlite as insulation is used to insulate roofing systems. The binder in the product is bitumen. Its characteristic feature is increased flexibility, as a result of which structures of any shape and type of complexity can be isolated. In addition to thermal insulation properties, the material provides reliable protection of the roofing system from fire.

To fix the product, it does not require preheating, as is the case with other bitumen-containing products. The low coefficient of thermal conductivity will allow the use of insulation in the northern regions.

Dry building mixtures based on perlite

There is a possibility not only of wall insulation with perlite, but also the use of material for the manufacture of building mixtures. In this case, fine-grained raw materials with the addition of cement are required. The mixture must be diluted with a sufficient amount of water. The mortar is intended for grouting cracks and joints. Raw materials are added to plasters to achieve a thermal insulation effect. Perlite is added not only to cement, but also to gypsum and lime compositions.

Perlite-based plaster is resistant to fire, does not weigh down walls, does not rot and is inert to the effects of negative temperatures. The product has good adhesion to the surface. Finishing provides high-quality sound insulation and helps to retain heat in the room.

Varieties of loose thermal insulation

Perlite slabs instead of plaster or embankment

Perlite insulation comes in various forms. It is recommended for the construction of residential buildings and industrial facilities, outbuildings. Depending on the type, the material is added to the composition of the plaster mortar, is backfilling the walls or laid like ordinary slabs. A decorative coated material is used as a cladding.

Pressed boards are the most convenient form of using mineral rock. They are used for thermal insulation and fire protection of buildings. It is easy to work with the plates, the appearance of dust, typical for sand, is excluded. In their manufacture, mineral raw materials are mixed with cement, liquid glass or bitumen. The resulting material has low thermal conductivity, heat-resistant and durable.

Perlite sand is used for backfilling the floor

This type of insulation is used as filling voids in walls, ceilings, floors. The most popular in construction is perlite sand of the M-75, M-100, M-150 grades. The material is lightweight and does not create excessive pressure on the base. Insulation is purchased in bags, from which it is filled into voids.

Dry mixes

Dry construction mixtures based on expanded perlite are distinguished by increased thermal insulation properties. In addition to sand from volcanic rock, the composition includes cement or gypsum. To prepare the plaster solution, it is enough to add water in the amount specified by the manufacturer. The mixture is used for facade insulation, interior work, and decorative coating.

Compared to ordinary plasters, perlite plasters, due to their high porosity, have 2-4 times less volumetric weight and 4-6 times less thermal conductivity. At the same time, the sound absorption coefficient of heat-insulating perlite plaster is 0.2-0.65, and that of ordinary sandy ones is 0.015 -0.2 (at a frequency of 1000 Hz). Mortar mixtures on fine perlite VPM * have high plasticity, workability and rubbing ability.

Perlite plaster mixes do not crack or shrink when dry.

Thermal conductivity λ - 0.15-0.2 W / (mK)

Water vapor permeability µ-0.22

Compressive strength -24 -34 kg / cm2

Sound absorption coefficient at 1000Hz - 0.5

8 (by volume - cement: lime: VPM perlite *).Mixtures of this composition have a fairly high plasticity and workability, and solutions have a relatively low bulk density and sufficient porosity. The surface of the plaster is well rubbed, it turns out smooth, without defects. Therefore, they are prepared with the addition of lime or clay to make the solutions more plastic and mash.

Thermal conductivity λ - 0.10-0.11 W / (mK))

Compressive strength -8 -9 kg / cm2

We suggest that you familiarize yourself with the Calculation of the cable cross-section of the wire by power current 220

-Average density - 650kg / m3.

- Tensile strength - more than 1.7N / m2.

-Compression strength - 60kg / m2.

- Thermal conductivity - 0.26 WmK.

An air-entraining additive is used in the form of (emulsion or liquid soap) ***. Such a solution is most interesting when building from lightweight bricks or foam concrete, the properties of which are close to their thermal parameters and characteristics of the solution. Masonry on such mortars does not have cold bridges.

Thermal conductivity λ - 0.26 W / (mK))

Water vapor permeability µ-0.16

Compressive strength -60kg / cm2

-The coefficient of heat assimilation - no more than 5kcalm2.h.C

- Ultimate compressive strength - not less than 45kgcm2.

These requirements are met by cement-sand perlite mortars, which include expanded perlite of the VPK ** grade with a bulk weight of 80-150 kgm2. To increase the mobility of the mixture, surface-active air-entraining additives can be added. The thickness of the filling on the interfloor floors is 30mm, above the unheated technical underground - no more than 100mm.

Such perlite solutions are especially popular during the installation of Warm Floor systems, since perlite is not prone to expansion when heated, does not shrink, and is absolutely not flammable.

Thermal conductivity λ - 0.10 W / (mK))

Water vapor permeability µ-0.15

Compressive strength -45-50kg / cm2

When mixing perlite solutions, initially the mixture turns out to be dry and crumbly, do not rush to add more water, let the batch stand for 10-15 minutes, during which time the perlite will give water. Stir the mixture thoroughly to obtain a plastic solution. Water is given in approximate quantities. The exact amount is selected depending on indicators such as air humidity and sand frequency.

Perlite backfills in wall structures are used to protect premises from overheating and hypothermia. As world practice shows, perlite is very successfully used in construction, as a fireproof bulk insulation. Possessing fluidity, when falling asleep, it fills voids of irregular shape.

VPK perlite ** can be filled up both during new construction and during the insulation of already built houses, which have air gaps in the walls. If necessary, perlite can be poured into the structure, tamped and refilled if possible. All openings that can be in the wall and through which the perlite insulation can pour out must be closed by the time the perlite is filled up. Filling is carried out both from bags and by means of special sandblasting machines.

For the installation of insulated monolithic floors, relative to the ground or basement and between floors, expanded perlite VPK ** is used. Perlite is poured out of the bags onto the base and spread with leveling strips so that the thickness of the perlite layer exceeds the desired thickness by 20%. The minimum installation thickness is 1cm.

Pipelines and other irregularities are buried in a layer of bulk material. The entire surface is covered with slabs, on top of which a monolithic coating is made. If such layers are not mounted on the basement floor, then, first of all, drainage pipes are laid to accumulate and remove moisture. An absorbent protective pad, such as kraft paper (but not foils), is placed under the layer. When installing wooden floors, the expanded perlite is laid without compaction.

Any cavities between beams and lumber are filled without difficulty, without loss of insulation for various cuttings. The non-combustibility of perlite increases the fire safety of the floor structure. If it is necessary to prevent dusting and strengthen the upper layer, the layer is sprinkled with cement, followed by light wetting. Perlite will allow you to quickly achieve evenness and at the same time create a high-quality sound insulation layer between floors.

One of the effective solutions to lighten the structure of a house, along with increasing its heat-conducting characteristics, is the use of filling insulation of the roof with expanded perlite VPK **. It is used in pitched roofs for attic insulation, for attic insulation, as well as for flat roof insulation. (See "Seamless bulk heat and sound insulation of floors")

A vapor-permeable membrane is used on top.

A vapor barrier is used below.

While the lower film layer prevents the penetration of water vapor from the room into the perlite insulation, the upper film layer releases vapors from the perlite insulation and does not allow external moisture to enter it, which is formed as a result of condensation on the inner surface of the roof or a roof leak.

We suggest that you familiarize yourself with Izospan B (32 photos): technical characteristics and instructions for use, which side to the insulation to lay

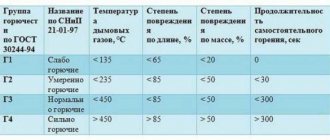

Comparative factors for building materials

| materials | Density kg / m3 | Coeffits. sound absorption at 1000Hz | Coeffits. thermal conductivity W / mK | Coeffits. vapor permeability mg / (m * h * Pa) | Flammability group According to the classification |

| Perlite | Up to 150 | 0,7-0,9 | 0,04-0,05 | 0,23-0,30 | ng |

| Vermiculite | Up to 150 | 0,7-0,9 | 0,04-0,06 | 0,23-0,30 | ng |

| Expanded clay | 800 | 0,15-0,28 | 0,12 | 0,21-0,26 | ng |

| Foam glass | 400 | 0,30-0,50 | 0,11 | 0,02-0,03 | ng |

| Basalt slabs | Before190 | 0,30-0,80 | 0,05-0,072 | 0,30-0,60 | Ng; D1 |

| Styrofoam | Up to 50 | 0,24-0,38 | 0,04-0,05 | 0,05-0,23 | G2; G3 |

| Penoplex | 25-35 | 0,15-0,35 | 0,15-0,35 | 0,15-0,23 | G3 |

Attention! When working with perlite, be sure to use personal protective equipment: glasses and a respirator!

Criterias of choice

The choice of insulation depends on the purpose of its application. Several types of material are used in construction: M75, M100, M150. The numbers are an indicator of the bulk density of raw materials. You also need to pay attention to the weight of the product. The smaller it is, the better the noise and heat insulation properties.

Perlite with a size of 0.16-1.25 mm is used for work. The larger the granule size, the worse the quality of the backfill. The fluidity of the material is thereby reduced. When choosing a heater, you need to pay attention to its shelf life and the integrity of the packaging - these parameters affect its technical properties. If the material has been in a humid environment for a long time, it will be useless.

A PEARL IN CONSTRUCTION!

Expanded perlite M75 GOST10832-2009 (construction)

Natural environmentally friendly material obtained as a result of heat treatment of volcanic rock. Due to its porous structure, perlite is a highly efficient heat and sound insulation material. Expanded perlite has excellent sorption properties, is fire-resistant, bio-resistant, chemically inert and has an unlimited shelf life and use. The use of perlite is possible in the temperature range from -200 C to +875 C. Perlite is absolutely safe for humans, does not cause allergic reactions and skin irritation, does not harm the climate of the room. Perlite is not flammable, when heated, perlite does not emit harmful substances, products made of expanded perlite increase the fire resistance of the structure several times. Depending on the grain size composition, perlite is subdivided into types:

- VPK (expanded perlite large) particle size from 1.25 to 5.0 mm.

- VPM (expanded perlite fine) particles from 0.16 to 1.25 mm.

Perlite insulation technology

The main advantage of perlite is its high level of fluidity, so it fills even the smallest cavities. The material is used to insulate walls and floors.

Wall insulation

The use of perlite for wall insulation is done in stages. The work is carried out as follows:

- Preparation of the base.It is carried out during the construction phase of the wall. For insulation, it is better to use a fine sand fraction of the material. For 1 cubic meter walls will require 60-100 kg of raw materials.

- Backfill. Insulation is laid in the space between the inner and outer parts of the wall. It is filled gradually, as the structure is being erected. The raw material should not be strongly rammed, but it must be compacted so that it does not shrink and the thermal insulation characteristics do not deteriorate.

As for the decoration of the walls with perlite plaster, preliminary surface preparation is also carried out here. The old decorative coating is removed from it. After the plaster has been applied and dried, a fine finish can be done. In this case, it will also perform its functions for a long time.

Floor insulation

Different types of floors can be insulated with perlite. It is often used when working with solid monolithic coatings. The sand fraction is 6 mm. The installation process is not difficult. The material is poured onto the prepared base directly from the bags. It must be distributed evenly, for which slats are used. If communications are laid on the floor, perlite sand should completely cover them. After that, you can mount the final monolithic coating.

When laying such floors, it is necessary to equip drainage branches so that it is possible to eliminate excess moisture. If the subfloor is made of wood, the perlite does not need to be compacted. Sand is poured into the gaps between the elements. Fiberglass is used to strengthen the insulation, but it can be replaced with fiberboard sheets.

Perlite is an innovative insulation material that is used to insulate walls, floors, and roofs. It has many advantages and provides reliable protection of the structure from unnecessary sound and cold. Subject to the technology of laying the material, it will last for more than a dozen years.

Perlite in building mixtures

Perlite (grade M75 or M100) is used as a component in dry mixes (cement and gypsum-perlite), significantly improving their properties. Application of ready-made dry perlite mixtures: for plastering works; for leveling surfaces, that is, arranging self-leveling floors.

The solution is prepared very simply: water is added to the finished dry mixture in the proportion indicated on the package. Perlite plaster, in comparison with the usual one, is distinguished by more effective thermal insulation (a layer of such plaster with a thickness of 3 cm in its thermal insulation properties can be equated with a brickwork of 15 cm), sound insulation, fire resistance (about 5 ÷ 10 times higher), high vapor permeability, frost resistance and not subject to decay. It is suitable for both interior and exterior work.