Now it has become very fashionable to have a pool on your suburban area. Why not? Why not equip a full-fledged place for taking water procedures? Moreover, if you do it yourself or with the assistance of some outside help. But remember: the waterproofing of the pool must be done on time. Otherwise, this "newfangled thing" will not please you for long. Do not delay with this process: waterproof the pool before using it.

Types of waterproofing

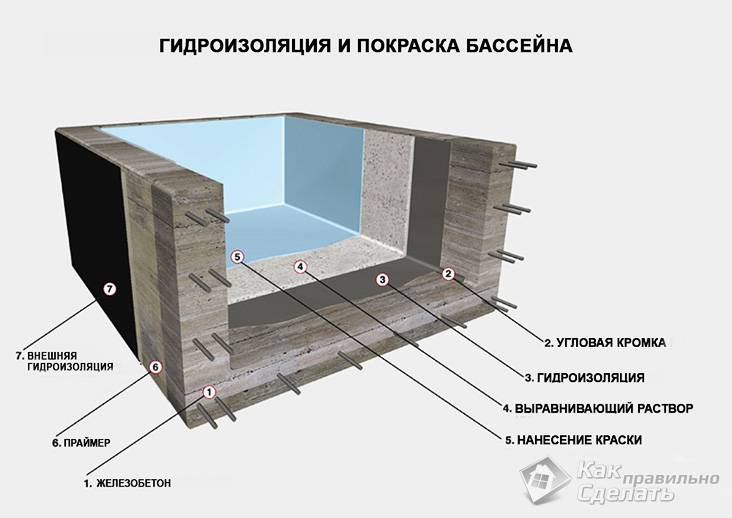

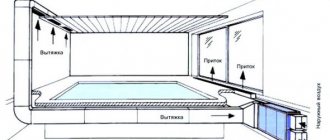

If the pool is located inside the structure, then only internal waterproofing is performed, which protects the surface of the font from the negative effects of water penetrating through (possibly) poor-quality materials or cracks. And, if the pool is outside, then in addition to the inside, it is necessary to perform external waterproofing, which protects the concrete pool bowl from groundwater and all aggressive elements contained in them.

That is, the purpose of waterproofing is to make the concrete waterproof. The strength and durability of the concrete pool as a whole depends on how well and correctly it is performed.

Important! If during the operation of the pool cracks of more than 4 mm appear, then it is unlikely that any waterproofing of the pool will solve this problem. In this case, you will have to take more "drastic" measures.

Waterproofing - why is it?

Why do you need waterproofing

Agree that not everyone is an expert in this area. It is often said about the importance of waterproofing, and its correct design. But why is she? What will be the benefits of using it?

As you know, waterproofing is a protective layer for any building structure (in this case, a pool), protecting it from the penetration and negative effects of water. Since the pool is directly connected to this liquid, it is important that it does not penetrate the material. Why? When moisture seeps into the concrete, it will lead to its destruction, as a result, your pool will not last long, and then it will have to be repaired or completely refurbished. This is one of the most important stages of work. It is important to note two types of pool waterproofing:

- Internal waterproofing.

- External waterproofing.

Internal waterproofing

It is the internal waterproofing that is carried out in the very bowl of the pool in order to protect the material from water penetration. There are many different ways to do this, which we'll talk about next.

External waterproofing

The essence of external or external waterproofing is to protect concrete from moisture penetration from the soil by adding plasticizing and mineral additives to its composition. This contributes to an increase in water permeability and mechanical strength of the structure. Another option is to install special expanding rubber profiles. It is worth noting the penetrating compounds that are applied to concrete for external waterproofing. These are special mastics that are easy to apply on your own.

Classification of materials for waterproofing

By application

All used waterproofing materials are divided into two main groups:

- bituminous;

- polymer.

Insulating bitumen is a material obtained by blowing hot air through tar. For your information: tar is obtained by heating the last fraction formed during oil refining in vacuum to a very high temperature (exceeding 400 degrees). The main feature of insulating bitumen (a resinous substance) is that it does not dissolve in water.After applying it to the surface, it forms a durable and waterproof coating that does not corrode.

Practice shows that the use of such waterproofing can significantly increase the service life of the pool and guarantee its long-term operation even in conditions of constant contact with groundwater. Roll and coating materials (mastics) are made from bitumen.

Polymer waterproofing compounds include polyurethane-based compounds. After this material is applied to the surface, it interacts with air and transforms into a polymer film that protects against moisture. Polymer waterproofing is a universal coating and has a number of advantages:

- good elasticity;

- durability (service life is more than 15 years);

- has excellent adhesion to materials such as ceramic tiles, concrete, glass and brick;

- resistant to temperature extremes;

- easy to apply (due to the fact that the composition is a liquid or semi-liquid substance).

Polymer insulation can be coated or sprayed. On the construction market, it is presented in the form of mastics and sealants. With the help of mastic it is possible to cover rather uneven and hard-to-reach surfaces with a protective layer. A sealant is a more viscous "representative" of polymer waterproofing, which can be easily applied to a surface of any geometric shape (for example, it can be used to isolate joints and seams). Liquid rubber also belongs to the category of polymer waterproofing.

By application method

According to the method of application, materials are divided into:

- coating;

- sprayed;

- roll.

Lubricants (penetrating impregnations, bitumen and polymer mastics) are used to create a seamless monolithic layer. Most often, one- or two-component cement-polymer waterproofing is made, using which you can carefully seal pores and small cracks formed in concrete. Lubricants, which have a relatively low cost, are able to provide high-quality protection of the font with minimal labor costs: after all, you can apply several layers of mastic with a brush or spatula on your own.

Roll materials (roofing material, film membrane, PVC film) are used to equip the protection of the pool both from the outside and from the inside. True, using such materials, you will not be able to avoid the presence of seams in the insulation.

Advice! We lay the roll materials in two layers in order to overlap the seams.

Materials for waterproofing works

The good news is that the range of materials for such work is quite wide, and you will have something to work with. The choice of such materials depends on many factors, including your desire, the price of the product, etc., however, it is important to take into account the terrain and climate in your region, as well as the type of the finished pool.

PVC film for swimming pools

The main and most common materials for waterproofing are:

- PVC film;

- penetrating waterproofing;

- liquid glass;

- coating waterproofing;

- liquid rubber;

- various materials on a bituminous basis (the option was effective earlier, when the above materials were not yet available, but now they are used extremely rarely).

External waterproofing technology

Before proceeding with the arrangement of the protection of the bowl of the font from the inside, the external waterproofing of the pool is made:

- if the groundwater level is higher than the bottom plate, then we construct a drainage system around the font;

- we carry out a concrete screed for the base of the pool;

- lay out the prepared roll material on the ground (according to previously performed measurements);

- we connect the seams by welding;

- we carry out the laying of external waterproofing, performing it with a large margin at the edges, so that later it can be brought onto the walls of the pool and connected to the inner insulating layer of the bowl.

Important! Instead of roll material, penetrating compounds can be used as external waterproofing, for example, mastics, with which we fill the smallest pores and cracks.

Advantages and disadvantages

The advantages of PVC membranes over other finishing options include:

- combination of decorative properties and waterproofing;

- wide range of colors;

- ease of installation;

- low cost;

- resistance to both low and high temperatures;

- resistance to microorganisms and algae;

- tear resistance.

With its advantages, the material also has a number of disadvantages:

- relative fragility (service life, depending on the intensity, 6-10 years);

- inability to hide butt seams;

- the impossibility of using in the case of a passage of groundwater close to the surface of the earth.

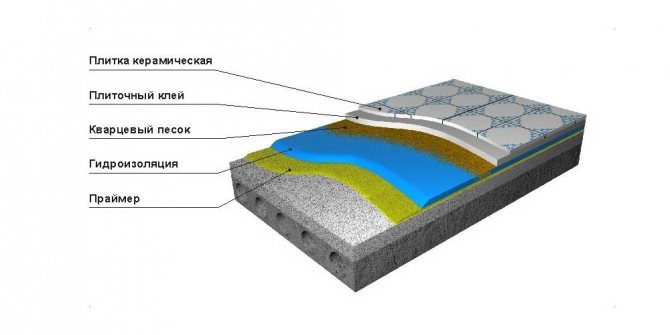

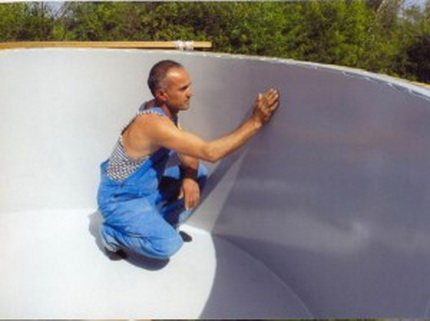

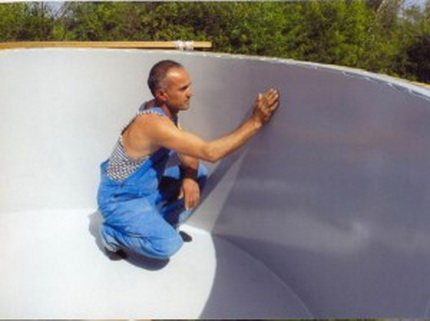

Internal waterproofing technology

Internal waterproofing of the pool is an important step in the construction of the entire facility. The technology for applying all kinds of coating materials is quite simple:

- after pouring the bowl (by the way, in order to increase the waterproofing properties of concrete, we add plasticizers and special additives to it), we leave it for final drying;

- small cracks and other defects are sealed with resin or sealant;

- we equip the screed of the base of the font with the help of a self-leveling solution;

- we make plastering works;

- we clean the surface of the bowl to make it rough (this is necessary for better adhesion of the protective coating to the concrete);

- we remove dust and debris; degrease the surface;

- we prime the inner surface of the pool bowl with a special compound;

- let the primer dry (the drying time is indicated on the package);

- prepare the coating composition according to the instructions;

- we apply waterproofing in two or three layers, profusely brushing the seams, small cracks, gaps and junctions of the surfaces of the pool surface with a brush (each subsequent layer is applied only after the previous one has dried);

- after the waterproofing layer has completely dried, we check the pool for leaks;

- we carry out facing work.

On a note! Remember: "the cheapskate pays twice," so you better buy expensive coating materials (they are more effective), and in combination with a fiberglass mesh, they become more durable and elastic.

Types of pool waterproofing

Protection of the structure from water is carried out from the outside and inside, in connection with which the waterproofing materials used are divided into two groups.

External moisture protection of the bowl

External waterproofing is used to protect the structure from flood and groundwater. It is relevant for street structures buried in the ground. Requirements for external waterproofing are similar to those for moisture protection of foundations.

The main difference lies in the shrinkage indicators and in the changes in the geometry of the bowl structure, which occur under the influence of a significant mass of water on it. Before building the bowl, it is necessary to carefully study the structure of the soil in the selected area, find out the level of soil freezing, as well as the depth of the groundwater.

It is very important that the level of the bottom plate of the bowl is not lowered below the depth of the groundwater. If so, waterproofing alone will not be enough. In this case, the groundwater must be diverted from the structure using a drainage system.

Internal waterproofing of the bowl protects the structure not only from moisture, but also from the destructive effects of chemicals, therefore, it must be resistant to them

The most proven and affordable method of arranging external waterproofing is considered to be a clay castle, which is mounted directly during the construction period. After the soil is taken out of the pit prepared for the pool, clay is poured into it and carefully tamped.

This is a clay castle. The best results are obtained when it is used in combination with other insulating materials: gluing, coating or penetrating materials.

It is necessary to choose the option of an external hydro-barrier for the bowl at the design stage. After the construction of the pool, it is more expensive and more difficult to eliminate imperfections and apply material to the walls. And it will be impossible to protect the bottom at all.

Internal waterproofing of the pool

Internal insulation of the bowl is a must for any type of pool. The insulating layer protects the material from which the structure is made from the damaging effects of moisture and chemical compounds.

Most often, the composition includes protection against disinfectants, which will necessarily be present in the water. The latter are relatively safe for humans, but they are an aggressive environment for building materials.

Waterproofing not only protects the pool from moisture, but also from possible leaks and corrosion. Internal insulation will be considered good quality if it is resistant to opening holes and cracks up to 3 mm wide.

It is desirable that the waterproofing layer is low, but elastic. The material should have good adhesion to the substrate and maximum water resistance.

In addition, the insulating coating must resist hydrostatic and dynamic loads and fully comply with environmental standards. It would be nice if the waterproofing inhibits the activity of microorganisms. Another important nuance is full compliance with the type of finish chosen, otherwise it will be impossible to carry out a full-fledged lining of the bowl.

Internal waterproofing of the bowl is applied at the final stages of the pool construction. You can choose the material for it after all the work on the construction of the bowl has been completed, but always before the lining.

Most popular waterproofing materials

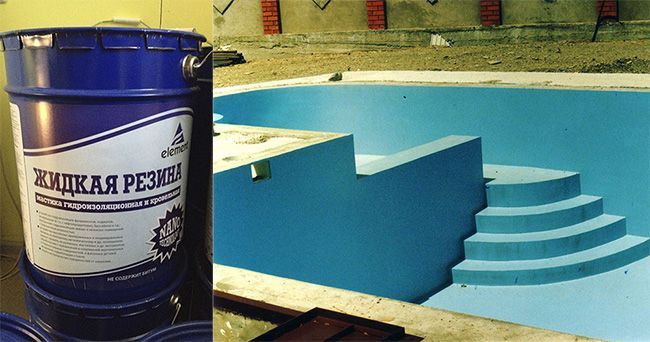

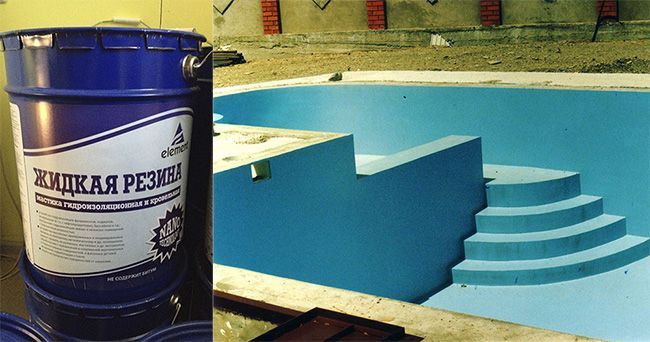

Liquid rubber

Liquid rubber is a bitumen-polymer mastic that has good waterproofing properties and combines the advantages of coating materials and roll materials. It is applied in several layers: as a result, we get a pleasant to the touch, dense and durable seamless coating.

Liquid rubber is a versatile material in the sense that it can act both as a topcoat, that is, without further decoration (just buy a colored material), and as a base for tiles or mosaics.

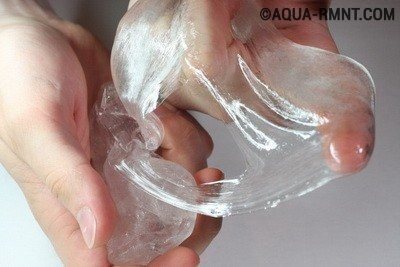

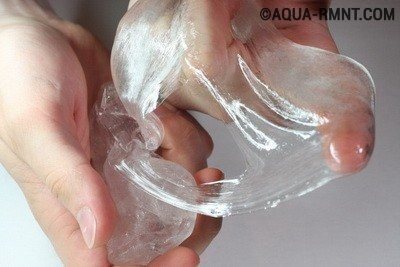

Liquid glass

An aqueous alkaline solution of sodium or potassium silicates is nothing more than water glass, which is also known in the trade as silicate glue. Liquid glass in combination with a cement-sand mortar creates a durable waterproofing coating. The advantages of silicate glue include the fact that it is relatively inexpensive, and the disadvantages that this material quickly hardens after mixing (within 5 minutes) and is short-lived.

Liquid glass: a modern way of fast and effective insulation

If it is important for the owner of the site that the process of waterproofing the pools is simple and does not take much time, then he should buy liquid glass. This modern insulating material has collected positive reviews from developers, who appreciated the convenience of its use, the high-quality result of the insulation and the low capital costs required for its implementation.

Liquid glass

In a jar with liquid glass, there is a composition based on sodium and potassium silicates. It has a thick consistency and a fairly high density.The main feature of the composition is that the developer can use it to isolate the hydraulic structure even at the stage of constructing the concrete bowl. The specificity of using the material is that it is added to the concrete solution, and then work is performed to pour the base, bottom and sides of the bowl. Concrete with liquid glass in the composition acquires the following features:

- reduced porosity and ability to absorb moisture;

- improvement of strength characteristics;

- increased resistance to stress and mechanical damage.

To achieve a more reliable result upon completion of the construction of the bowl, liquid glass is applied in another layer over its walls and bottom. To evenly distribute the composition over the surface of the bowl, use a roller or brush. The work is carried out as follows:

- preparation of the surface of the pool tank, cleaning it from litter and dust;

- removal of grease stains from concrete pouring, its cleaning in order to improve the adhesion properties of the surface;

- preparation of liquid glass for work in accordance with the manufacturer's recommendations specified in the instructions;

- accurate application of the first layer, drying it, even application of the second layer.

Application of liquid glass

After that, the work is completed, and the developer will have access to all the bonuses that the liquid glass insulation has. This protects the walls of the pool from leaks, chemical reactions, UV rays.

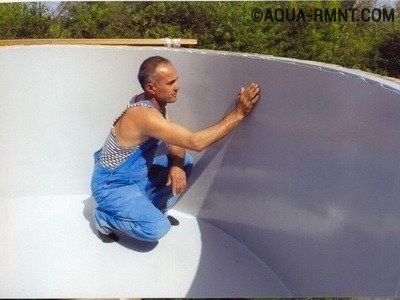

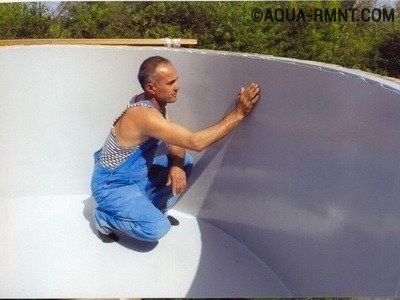

PVC film as a material for waterproofing swimming pools: an overview of the advantages and disadvantages

Colorless thermoplastic PVC film, which is resistant to chemicals, is a fairly common material in private and corporate construction. It is used for various purposes, including for DIY isolation of hydraulic structures. Correctly applied membrane waterproofing protects the concrete pool, preventing leaks and breaking the integrity of the bowl.

The material has many advantages:

- is durable;

- meets modern quality standards;

- has decent performance characteristics - durability, light weight, tear resistance.

An additional advantage is the loyal cost of this flooring. However, the disadvantages should not be forgotten either. In order for the film to perform its function as an insulation material, it is necessary to select it correctly in terms of density and carefully observe the laying technology. This will take a lot of time and effort. However, the end result is worth it - the pool will be reliably protected from leaks, and the owner will not have unforeseen hassles for major or current repairs of the bowl.

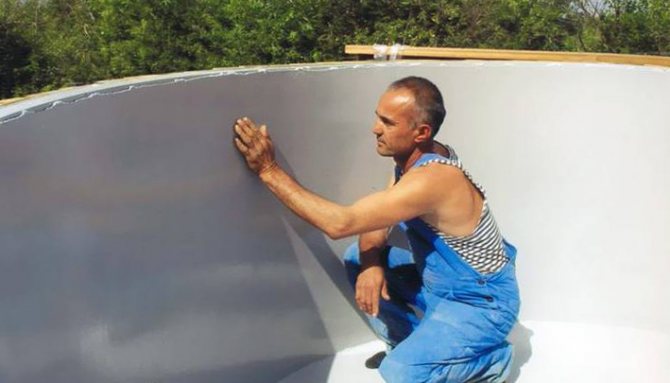

The work technology has the following sequence:

- calculation of the required amount of film in accordance with the shape and configuration of the bowl, its purchase in the construction center;

- preparation of the bowl - cleaning the pool from debris, dust and other contaminants;

- fixing special brackets on the concrete walls and the bottom of the pool - tapes, corners, hooks, on which the PVC film will be fixed;

- flooring of geotextiles (the task of this layer is to prevent violation of the integrity of the film due to abrasion on the edges of the concrete bowl);

- the film is spread over the bowl and its parts are welded with a special soldering iron.

After the owner is convinced that all seams are reliable and airtight, the insulation work using PVC film is considered complete. Now you can proceed to the next steps.

Popular insulation materials

High-quality waterproofing of the pool can be done in several ways. They all have certain advantages and disadvantages. To choose the best option, you need to get acquainted with each of them.

Option # 1 - cement based materials

Materials based on a cement-sand mixture are used as insulation. Most often these are two-component film polymer-cement compositions based on vinyl acetate and synthetic resin. The advantages of isolation include:

- High strength and reliability, allowing the material to withstand dynamic and static loads.

- Good adhesion to various surfaces.

- Long service life and maintainability.

- Good vapor permeability, which solves the problem of the formation of unwanted bubbles and blisters on the surface.

- Environmental friendliness of the material.

- Possibility of applying to a damp surface.

The biggest drawback of the material is considered to be low elasticity, which makes the compositions ineffective in areas of stress concentration. Therefore, they are used in combination with more elastic sealants, which insulate and embroider abutments, seams and similar areas. They become additional unloading belts. An important feature of cement-based insulating compounds is the ability to combine the function of waterproofing and tile adhesive.

Low elasticity and insufficient resistance to dynamic and hydrostatic loads are the main disadvantages of cement-based waterproofing

Option # 2 - Penetrating Insulation for Concrete Bowls

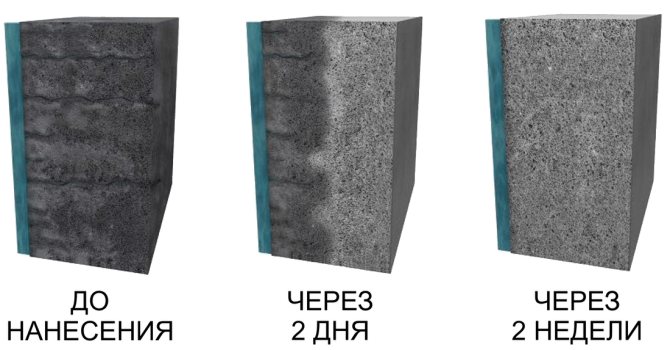

The composition of the materials includes chemically active compounds, including modifiers, which, when they hit the concrete surface, begin to spread very quickly through the pores. After solidification, water-insoluble crystals are formed that completely fill the pores, microscopic cracks and other cavities.

The advantages of penetrating materials are:

- Water vapor permeability allowing concrete to "breathe".

- Good adhesion to the substrate.

- Continuous, seamless insulation layer.

- Resistance to aggressive environments.

- The ability to apply the composition to surfaces of any shape, even very complex ones.

- Long service life.

- Prevention of mold and mildew.

- Possibility of applying on a damp base.

The insulation forms a good plastering base. The disadvantages of the material include the lack of the possibility of applying the composition to the areas of connection of concrete and elements of water supply equipment.

The active composition penetrates deeply into the pores of the base and, after hardening, forms crystals that tightly clog all cavities

Option # 3 - PVC insulating film

There are three types of insulation material. The most budgetary option is unreinforced film. Has the lowest strength and is most often used for prefabricated pools. The reinforced material is more durable because it is reinforced with polyester threads. It is able to withstand rather heavy loads without deformation. On sale you can also find an anti-slip film that prevents the pool surface from slipping. The best option is an acrylic coated material that prevents the growth of microorganisms and prevents fading.

PVC film acts as a waterproofing and at the same time finishing the bowl. You can choose a single color material or find a coating that imitates a stone, mosaic, etc.

The advantages of film insulation are:

- The ability to simultaneously act as a decorative coating and waterproofing.

- High frost resistance and resistance to aggressive environments.

- Low cost.

- Hygienic coating.

- Possibility of using both in the construction and reconstruction of swimming pools. The material can be laid over old finishes such as tiles.

- Variety of colors and finishes. You can choose a plain film or a material that imitates a mosaic, stone, etc.

The main drawback of the material is its relatively short service life. It is only 5-10 years old. Over time, the surface of the film is covered with scratches and color intensity is lost.Another drawback is the rather laborious installation. Most often it is carried out by professionals, since it involves the use of complex technologies, for example, hot air welding of joints. The slightest mistake will lead to moisture getting under the waterproofing carpet.

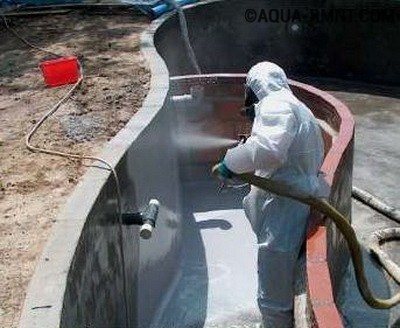

Option # 4 - liquid rubber

The material is a bitumen-polymer aqueous elastomeric emulsion. The solution is applied by spraying using a catalyst, which allows you to start a fast reaction of the emulsion decomposition. As a result, water is pushed out of the composition, and the dry residue forms a waterproofing membrane.

The advantages of liquid rubber include:

- Resistance to the effects of various aggressive environments.

- Forms a seamless, continuous membrane, the thickness of which can be adjusted during the spraying process.

- High strength and reliability, long service life.

- Possibility of applying to any surface configuration.

- Complete waterproofing.

- The material does not emit toxic substances. It is safe for humans.

- The ability to add the desired pigment to the solution, which allows you to obtain a coating of the desired shade.

A serious drawback of liquid rubber is its instability to UV radiation. The material must be covered with special means to protect it from ultraviolet radiation. For coating, special equipment is used, with which only specialists can work. In addition, thorough preparation of the substrate is required before applying liquid rubber.

Liquid rubber is applied by spraying using special equipment. The procedure is performed only by a specialist

Option # 5 - liquid glass

It is an aqueous solution with sodium silicate, which fills well all the pores and microcracks in the base. The material is considered an excellent sealant, its crystal structure provides reliable protection against moisture. It can also be used in the form of additives, impregnations and additives. The advantages of the coating include:

- Formation of a waterproof barrier.

- Easy to use.

- Antiseptic properties to prevent the growth of microorganisms.

- High level of fire resistance.

- Reliable adhesion to the base.

- Frost resistance.

- Low cost.

The disadvantage of liquid glass is rapid crystallization. The prepared working solution must be applied in a very short time. That is why it is best to entrust waterproofing work to a specialist. In addition, liquid glass breaks down quickly. Without protection, its service life will be only 5 years. To prevent this, it is recommended to cover the waterproofing with a protective paint layer.

Liquid glass crystallizes very quickly, so it should be applied to the base almost immediately after preparation of the working solution

Option # 6 - latex membrane

It is a latex-based, ready-to-use liquid. It comes with a special reinforcing fabric. The mortar is applied to the abutment lines and corners, which are glued with strips of fabric. Then the floor and walls of the pool are covered with a compound, on top of which the canvas is laid. Finally, everything is again covered with a layer of solution. After complete drying, a protective membrane forms on the surface of the bowl. Advantages of latex waterproofing:

- Forms a thin, waterproof, elastic, crack-suppressing coating.

- Suppresses the growth of microorganisms.

- The material easily bridges plastic inserts and cold seams.

- Possesses high strength and long service life.

The disadvantages of the coating are the high cost and complexity of application. Do not lay the membrane on a damp surface.

The latex membrane is a liquid solution complete with a special reinforced fabric.The material provides an elastic, strong and durable insulating coating