One of the simplest roof structures is a pitched roof, its construction is within the power of even slightly experienced builders. With the right approach, a do-it-yourself shed roof can significantly reduce the cost of building a building, this option will be the most optimal when building a small country house or utility structures.

Advantages and disadvantages of shed structures

In addition to significant savings, a pitched roof has a number of other advantages:

- A roof of this design is exposed to significantly lower wind loads due to the reduction in windage.

- As roofing coverings, it is possible to use various materials depending on the angle of inclination of the slope.

- The simplicity of the design can significantly reduce the construction period

- Installation does not require the use of powerful lifting equipment, most of the elements are installed manually due to their relatively low weight.

But there are several negative points that may prevent you from building a shed roof, despite the simplicity of the process:

- At small slope angles of the slopes, such a roof is exposed

significant snow loads, therefore, the cross-sections of the rafter system must be calculated and selected with a maximum margin. - The impossibility of arranging the attic space, even if you make a separate overlap, the useful area of the attic will be minimal.

- Compared to other types of roofing, a pitched roof loses significantly in beauty, although this can be corrected by using modern roofing materials.

Roof insulation

It is necessary to start dealing with the insulation of pitched roofs with heat-insulating materials. They are presented on the market with a fairly wide range, but only four are used for roofs:

- mineral wool slabs are mineral wool pressed into mats;

- expanded polystyrene plates;

- polyurethane foam;

- ecowool.

What insulation to choose

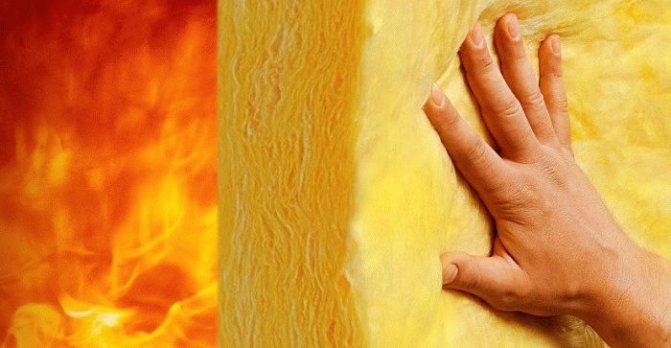

Mineral wool slabs

It is a rock material that is heated, melted and pulled into threads. The latter are in a chaotic state in the material itself.

As for the technical characteristics:

- thermal conductivity - 0.042 W / m K;

- density - from 50 to 200 kg / m3;

- 100% environmental friendliness;

- ease of installation by hand;

- service life is 50 years;

- flammability class - NG (non-flammable).

Mineral wool mats

Expanded polystyrene plates

It is expanded polystyrene with a structure of closed balls filled with air. At the same time, air occupies 90% of the volume, which reduces the weight of the insulation and its thermal conductivity.

Specifications:

- thermal conductivity - 0.034-0.044 W / m K;

- density - 25-45 kg / m3;

- flammability class - G3 (burns and supports combustion);

- environmental friendliness is high;

- installation method - manual;

- service life - 20 years.

It should be noted that the higher the density of the insulation, the higher its thermal conductivity.

Expanded polystyrene boards

Polyurethane foam

It is a foamed mass that hardens in air, turning into a durable, seamless coating. In fact, this is polyurethane foam, only modified. The insulation itself of this type is a two-component material. Its ingredients are mixed in a special container and supplied under pressure through a hose and a nozzle to insulated surfaces.

Specifications:

- thermal conductivity - 0.019-0.028 W / m K;

- density - 55 kg / m3;

- flammability class - G2;

- service life - 80 years;

- environmental friendliness is high;

- installation method - special equipment is required.

Polyurethane foam is applied to the attic roof

Ecowool

This insulation is pure cellulose made from wood. It looks like cotton wool. Here are its characteristics:

- thermal conductivity - 0.038 W / m K;

- density - 40-45 kg / m3;

- flammability class - G1 (low flammability);

- service life - 100 years;

- laying method - with the help of equipment;

- environmental friendliness - 100%.

Ecowool - one hundred percent natural insulation

Comparative analysis

It is incorrect to make such an analysis of insulation materials for roofs (different pitched roofs). Each material has its own pros and cons. In addition, the price is different, and the installation method varies greatly. For example, polyurethane foam is better than others in terms of its heat engineering characteristics. But it cannot be applied to the roof without special equipment. And this increases its already high price.

In this regard, mineral wool and polystyrene foam boards are the best option. They are easier to install and inexpensive. But their service life is short.

Price comparison:

| Tinsulation type | Mineral wool | Expanded polystyrene plates | Polyurethane foam | Ecowool |

| price, rub. | 50-100 per 1 m2 | 250-300 per 1 m2 | RUB 1,500 per 1 m2 50 mm thick | RUB 2200-2700 for 1 m3 |

And one more criterion by which insulation materials can be compared is the thickness of the layer to be laid. Here are the positions:

- mineral wool - 214 mm;

- foamed polystyrene - 120-150 mm;

- foamed polyurethane - 50-100 mm;

- ecowool - 150-200 mm.

Comparison of building materials in terms of thickness and heat engineering characteristics

Basic material requirements

High-quality insulation material must have some necessary qualities:

- 1. It should be lightweight so as not to exert significant stress on the roofing base. To determine the weight of the material when choosing it, first of all, you should pay attention to the density.

2. The insulation must be moisture resistant. If it allows moisture to pass through, it will become saturated with it over time, and the entire structure may collapse. In addition, when exposed to moisture, the material loses more than half of its technical characteristics and simply becomes ineffective.

3. It is necessary to take into account the coefficient of thermal conductivity: the indicator should be low - about about, about5 W per sq. meter.

4. You should choose environmentally friendly materials, especially when insulating the roof of residential buildings.

5. It is necessary to take into account such qualities as fire safety, flammability, self-extinguishing.

6. Insulation must be completed in such a way that it fits snugly to the surface.

7. A very important quality is resistance to temperature changes and sharp temperature fluctuations. The duration of the operational period largely depends on it.

8. The service life is determined by several factors, including the quality of the installation and the specific type of material.

- Fiberglass, mineral wool, polyurethane foam, extruded polystyrene foam, basalt wool are suitable for insulating a pitched roof.

They meet all the basic requirements for the quality of insulation.

- Sometimes natural materials are used: straw, linen insulation, seaweed, etc.

However, they do not differ in durability, in addition, some varieties are very expensive.

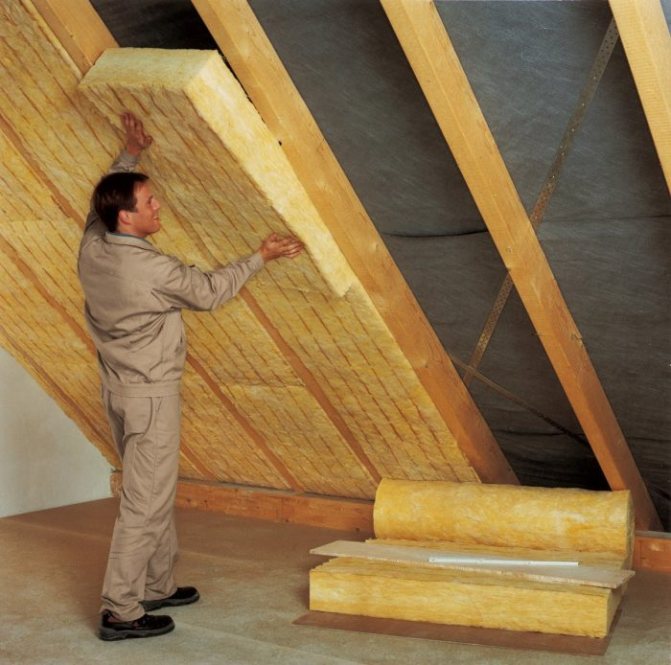

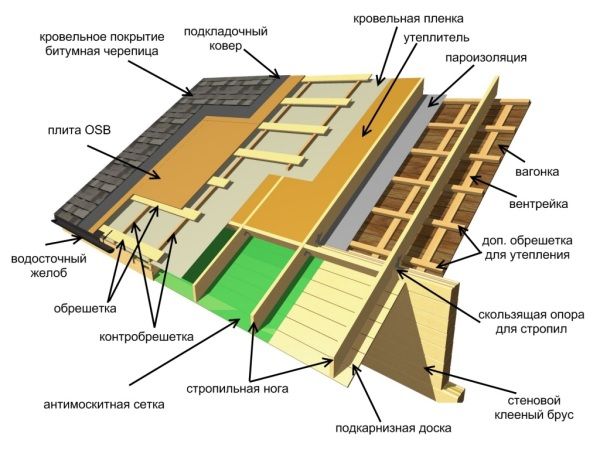

Pitched roof thermal insulation technology

Insulation of mansard gable roofs is very different from the thermal insulation of single-pitched roofs. Because the latter have a small attic space, hence the difficulties of carrying out work from the inside. They are carried to the outside from the side of the roof covering. In this case, we immediately denote that polyurethane foam is not used in a single-pitched structure.

Thermal insulation of a pitched roof

So, how to properly insulate a pitched roof:

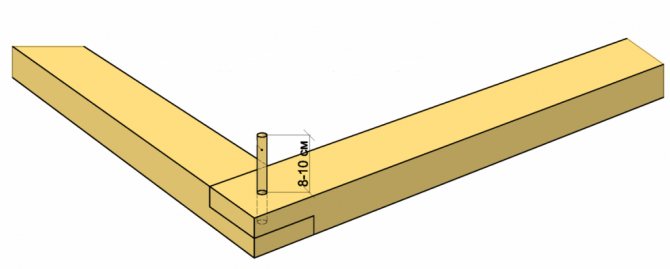

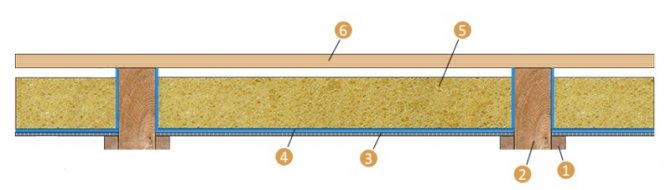

- Along the rafters, at the ends, at the lower edges, the so-called cranial slats are stuffed along.

- Between the rafter legs, boards or any durable plate or sheet material are laid on the rails: plywood, chipboard, OSB, and so on. The feet are fastened with self-tapping screws. Niches are formed.

- A vapor barrier membrane is laid along the rafter system. Installation is carried out in strips with an overlap of 10-15 cm, after which the joint is closed with self-adhesive tape. Laying should be carried out so that the film covers the niches, emphasizing their shape.

- Insulation is being installed in niches.

- On top of the rafters, a waterproofing film is laid in the same way as a vapor barrier, only tightly without sagging. Fastening to the rafter legs with staples from a stapler.

- Installation of the lathing.

- Installation of roofing material.

As you can see, insulating a pitched roof is not the most difficult process, so even a person who is far from the construction industry can do it with his own hands.

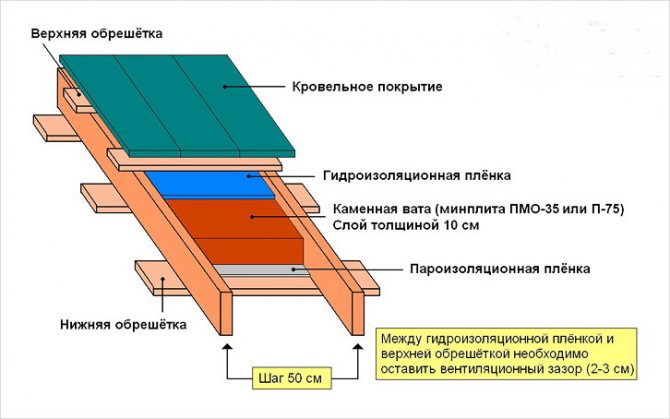

Shed roof construction with insulation

The order of work

The sequence of laying the layers depends on the method of insulation: external or internal.

Due to the low slope of the single-pitched roof, it is advisable to insulate it from the outside, in this case, to lay the heat-insulating material from the underside of the rafters, a crate is attached to which the vapor barrier is laid in a continuous layer (inside the room).

After installing the insulation, it must be protected from moisture, roll-up waterproofing or membrane films are used.

If the work is carried out indoors, first the waterproofing material is nailed, then the insulation is laid, the last layer is vapor protection.

Installation of each layer has its own nuances and requirements.

Waterproofing

Protection of the insulation from external moisture is a prerequisite, otherwise it will lose its insulating properties. A gap of 3-5 cm is provided between the roof and the waterproofing.

A moisture-proof membrane sheet or film is laid with a slight deflection. For fasteners, a construction stapler is used, the places of fasteners and joints are glued with tape.

With internal insulation, the rafters remain unprotected from moisture, it is recommended to treat these structures with antiseptics. For protection of wooden structures, see the link.

Insulation

Before installation, fibrous materials such as glass wool or basalt wool are opened in advance to restore their shape. The space between the rafters is filled with insulation. It is impossible to knock down and specially seal soft types of insulation, this worsens its thermal insulation properties.

Rigid plates of extruded polystyrene foam are laid according to the same principle - in the rafter gaps, at least in two layers, for sealing all the cracks are filled with polyurethane foam.

If the roof is already covered with roofing material

Here, the technology of thermal insulation differs little from the previous one. The peculiarity lies in the fact that all work is carried out from inside the attic space. And the main distinguishing feature is waterproofing, which is applied in strips along the rafter legs with the recessed film into the formed niches. To make it clear what is at stake, look at the photo, which shows how the waterproofing should be laid and fixed.

Waterproofing membrane installed from the inside of the attic on the roof slope

All other operations are carried out according to the technology described above. I.e:

- The laying of the slab insulation is in progress.

- Installation of vapor barrier film.

- Interior decoration of the attic.

If polyurethane foam is used, then it is simply applied to the rafter legs covered with a film. If ecowool is used, then a vapor barrier layer is laid, and the space between the two protective layers is filled with insulation.

Calculation of the required amount of materials

When all the materials have already been selected, you need to take care of buying exactly as much as you need.

If you make a mistake in the calculations, then a situation may arise when you have to reapply for a purchase. This will require additional costs not only finances, but also time. And when the construction time is limited, it is very important.

But at the same time, you should not buy too much, otherwise the leftovers will have to be stored somewhere or, in general, thrown away. But building materials are not cheap.

Therefore, the main thing is to calculate the area of the future roof and the angle of the slope. Based on this, you can use ready-made construction tables that are in every hardware store. The sellers will be happy to provide all the assistance you need.

Thermal insulation technology for a four-pitched roof

The process of insulating a hipped roof or hip roof is no different from the thermal insulation of a gable roof. These are all the same slopes, only there are not two, but four of them. The amount of work being done is simply increasing.

The only negative point regarding plate heat insulators is a large amount of their waste. It's all about the shape of the stingrays. It is trapezoidal and triangular at the hip roof, only triangular at the hip roof. This means that in places where the structure is narrowed, the thermal insulation materials will have to be cut.

This does not apply to polyurethane foam and ecowool. Here, the consumption does not change, and it corresponds to the area of the insulated pitched areas.

Pros and cons

If you are going to carry out a single-pitched roof with your own hands, then you should study its advantages and disadvantages. The positive aspects include the following:

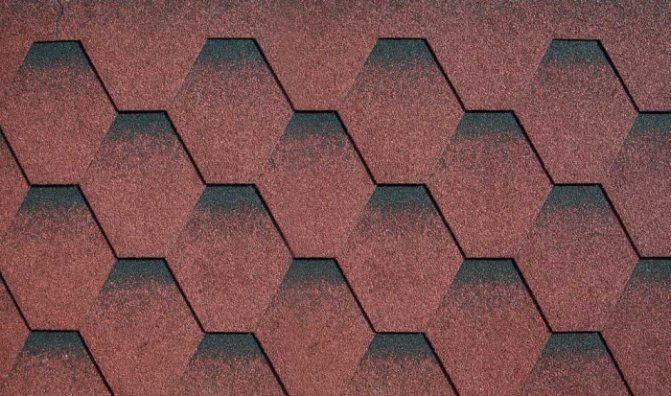

- The possibility of choosing any roofing material is ensured by the fact that you can make the minimum angle of inclination of the pitched structure.

- Gentle pitched roof systems have minimal windage, so they can be equipped even where strong winds prevail.

- Do-it-yourself installation of a shed roof can be done quickly and easily. Moreover, such a roof is easy to maintain and operate.

- Compared to other roof systems, single-pitched structures are lightweight.

- If you want to achieve aesthetic appeal and originality of the building, then you can equip several pitched roofs over different levels of the house.

- An opportunity to save not only your time, but also your finances.

- One of the sides of the house can be completely secured against dripping water during rain.

Among the disadvantages are the following:

- Less attractive appearance compared to gable and multi-slope systems. Although, with imagination and design developments, this drawback can be leveled.

- Under a very shallow pitched roof, it will not work to equip an attic or attic.

What points should you pay attention to

Despite the seeming simplicity of the operations carried out, there are many nuances in them, on which the quality of the final result depends. And for those who decide to carry out the insulation on their own, it is recommended not to miss these important points:

- Before starting work, all wooden units and parts must be treated with an antiseptic and fire retardant. First, the first is applied, after drying the second. The antiseptic composition is protection against biological effects (microorganisms: mold, fungi). Fire retardant composition - protection against fire. That is, if a fire starts, the wood will not immediately catch fire, it will take several minutes.

Antiseptic treatment of rafters

- Waterproofing is installed at the roofing material. Its purpose is to prevent leaks, if such leaks suddenly arise, to penetrate the insulating cake. The second purpose is not to let through the moisture that has formed in the layer of heat-insulating material.

- A vapor barrier membrane is the same film, similar to a waterproofing membrane. But it is denser and does not allow steam (humid air vapor) to pass through. Therefore, its main task is to close the insulation layer with itself so that moisture, emanating from the interior of the building and passing through the ceiling, cannot penetrate into it. But even with very careful installation, small gaps remain in the vapor barrier layer through which steam enters the insulation. So that he does not stay there, they lay on top of the waterproofing. It is important not to confuse the two materials with each other.Otherwise, the thermal insulation cake will quickly lose its properties. This mainly applies to ecowool and some models of mineral wool.

- If it is decided to use polyurethane foam as insulation and do the whole process with your own hands, then it is recommended to purchase a mini-installation consisting of two cylinders into which the components are pumped under pressure. They are mixed when leaving the containers in a special mixer of small dimensions. And already through the hose with a nozzle, the foam is supplied to the outside. Manufacturers today offer installations with different volumes of cylinders, with different speeds of work. This equipment is reusable, just after the ingredients are used up, they are poured into containers. And you can continue to work.

- If foamed polystyrene plates were used as insulation, then they can not be covered with a vapor barrier film. This insulation is not afraid of even a large amount of water.

- Ideally, fill the space between the rafter legs completely, both in width and depth.

If a decision is made to insulate the roof of your own house, then this process should not be postponed indefinitely. The main thing is to decide on the choice of thermal insulation. And the operation itself is simple. Strictly follow the steps and the high quality of the final result will be guaranteed.

Design features

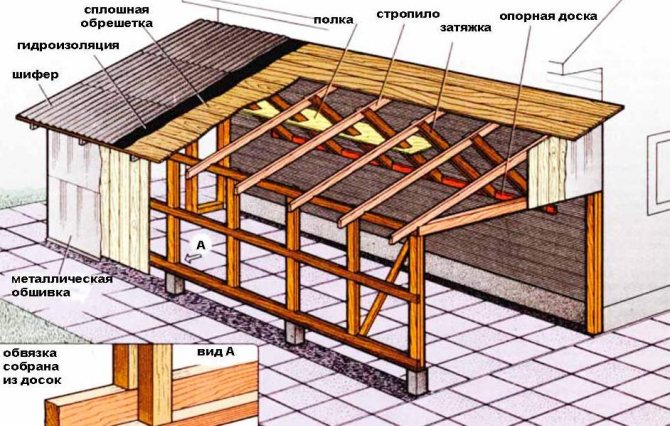

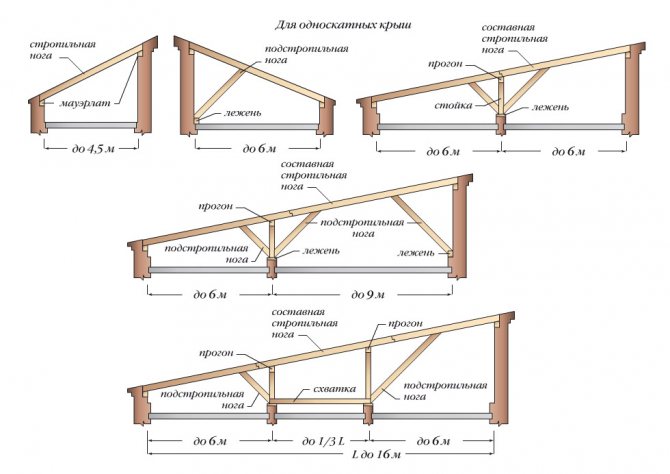

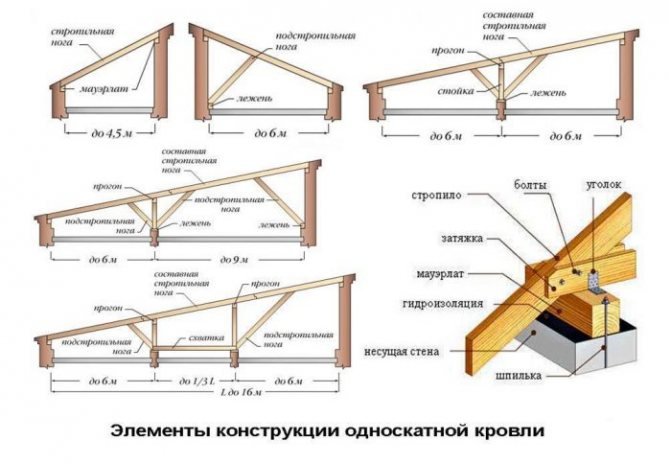

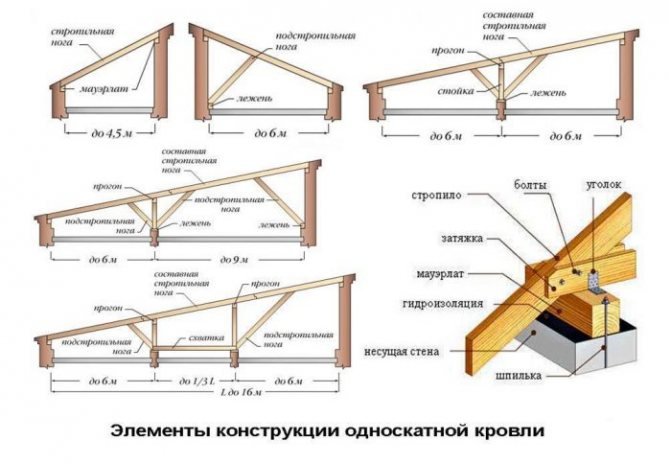

Before you build a gable roof with your own hands, you should understand its design features. This roof consists of only one slope. The supporting frame is a layered rafter system, which rests on two opposite walls of the house of different heights.

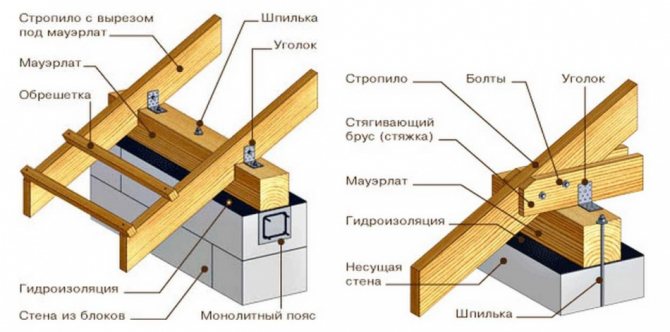

The rafter legs are placed on the Mauerlat. Often, a higher lying Mauerlat is called a ridge element, although in fact it does not form a ridge fracture of the slopes and serves as a support.

Important: concrete, brick or wooden walls, as well as pillars and supports, which will subsequently be sewn up with finishing, can act as supporting elements when installing a single-slope roof system.

If you look at the drawings and photos of pitched roofs on the network, you can understand that such structures are cold and insulated, with and without an attic. It is worth noting that a single-pitched roof with an attic is quite rare, since the construction of an attic room with a height below 1.6 m is prohibited by fire regulations. And when studying the drawings of such structures, you can see that the pitched roof is rather flat, since its slope is more often within 5-15 °.

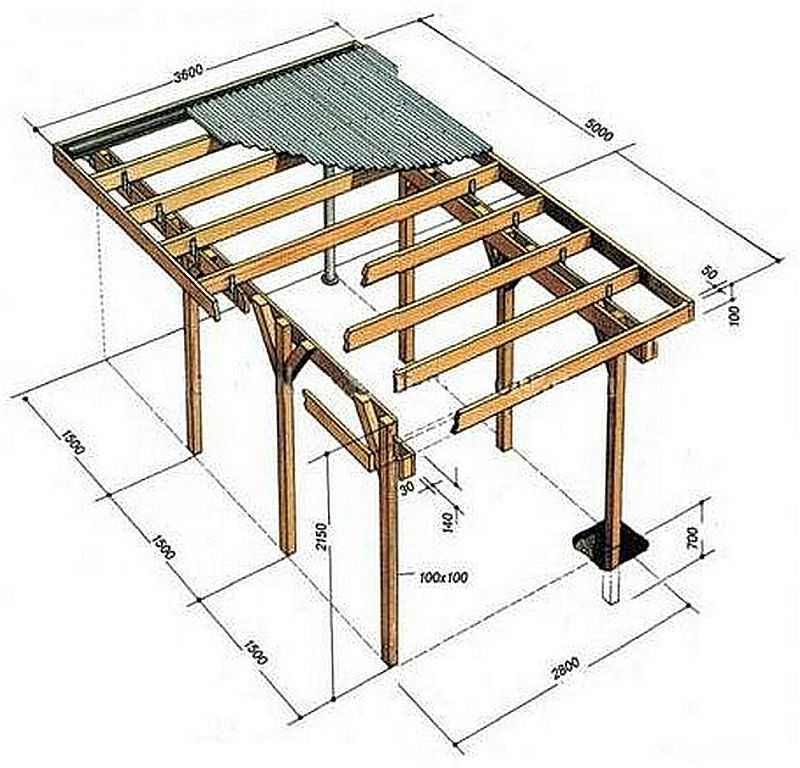

The device of a pitched roof is justified when building a small country house, a bathhouse, a garage. In addition, the installation of such a roof structure is often carried out over the entrance groups (porch), terraces. Installation of single-slope systems is often performed during the construction of a temporary building (shed, trailer, utility building).

As a roof of a single-pitched system, metal tiles, soft roll materials, profiled sheets, and galvanized roofing steel are used. The roof of pitched roofs is not made of straw, shingles, and reeds because of their rapid decay on a gentle slope.

First of all, you need to make a scheme with a shed roof, on which you can decide how the required slope can be provided:

Do-it-yourself installation of a frame shed roof on a shed

- This can be done due to the walls of the house of different heights or rows of support pillars.

- The device of the required slope can be provided using half-frame trusses of own hand or factory production. They are mounted on walls of the same height or rows of posts.

- Support structures can be attached to one of the walls to achieve the required height difference.

Shed roof device

Roofing Pie - The inner layers of the roof covering that ensure the reliability of the roof itself, warmth in the building, dryness and comfort... The defining factors for arranging the roofing cake are the purpose of the structure and the outer covering material of the roof.

You can read more about the calculation of roofing here.

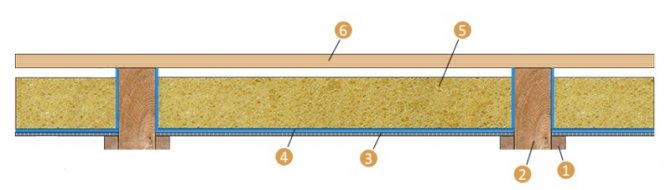

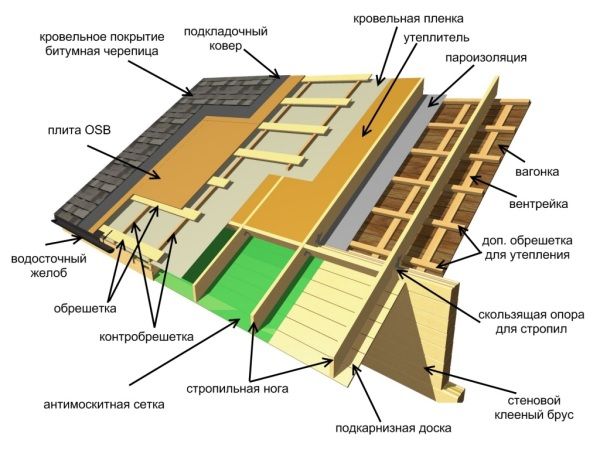

For a classic cold pitched roof the roofing cake consists of the following layers:

- Rafter system;

- Waterproofing;

- Counter grill;

- Finish coating.

If the project provides for a warm room, then the diagram of the roofing pie looks like this:

- Rafter system;

- Waterproofing layer;

- Insulation;

- Vapor barrier;

- Finishing roofing.

Depending on what the roof will be covered with, a counter-lattice is laid on a vapor barrier layer.

Roofing cake device

Advantages of a pitched roof

In addition to the unpretentious installation process available even to a non-professional, this type of roof has a lot of additional advantages that make it in demand in construction. The advantages of such a roof are:

- relatively small mass;

- acceptable costs for the arrangement;

- the available possibility of using various types of building materials;

- the ability to easily mount chimneys, drainage systems, etc.

Despite the fact that the pitched roof is simple and straightforward, it can be interesting to beat it with the help of design solutions, thereby decorating your site.

Sources used:

- https://expert-dacha.pro/stroitelstvo/krysha/vidy-krysh/odnoskatnaja/odnoskatnaya-montazh.html

- https://krysha-expert.ru/kak-sdelat-kryshu-odnoskatnuyu-svoimi

- https://kakpostroit.su/odnoskatnaya-kryisha-svoimi-rukami-poshagovo/

- https://stroypomochnik.ru/vidy-krysh-po-konstruktsii-01/

- https://krovlya-mp.ru/kak-uteplit-odnoskatnuyu-kryshu.html

- https://planken.guru/vse-dlya-kryshi-i-krovli/ustroystvo-kryshi/odnoskatnaya-krysha-svoimi-rukami-kak-sdelat-poshagovo.html

- https://mojdominfo.ru/odnoskatnaya-krysha/