- Advantages of single-layer walls

- Warm plastering system

Due to its cellular structure, aerated concrete perfectly resists heat transfer, therefore, with a density not exceeding 400 kg / cm², it can itself act as a heater. Given the low coefficient of thermal conductivity, gas-block walls do not need insulation, but it is almost always produced in heated buildings - to protect the masonry from temperature extremes and blowing by the wind. However, an incorrectly selected insulation in terms of properties and thickness can not so much solve the problem as aggravate it. How to prevent this from happening, and is it possible to insulate aerated concrete with foam outside?

Is it possible to insulate walls made of aerated concrete with foam plastic outside and inside

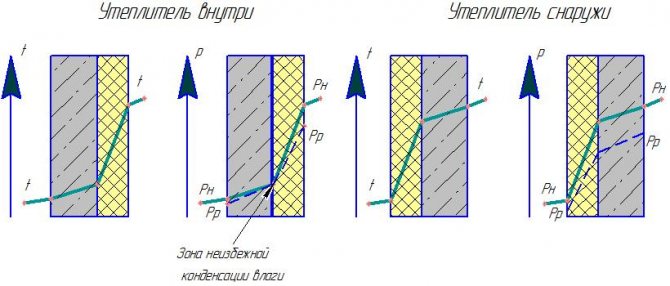

To understand in which cases it is possible to insulate aerated concrete with expanded polystyrene, it is necessary to familiarize yourself with the regulatory requirements for external insulation of aerated block masonry as a whole. Why exactly to the outside, and not to the inside? Yes, because protection from temperature extremes is required precisely from the outside, and if the insulation is placed inside, the wall will still freeze through. Inside, you can only make additional insulation, if the external, for some reason, was not enough.

- The thermal insulation layer in the wall cake is closely related to its final finish. There are basically two options: cladding and wet finishing. And this is where problem number one lies. It is associated with the use of polymeric plate heaters, including foam.

- The fact is that the lined enclosing structure made of aerated block must dry to the calculated moisture content. For aerated concrete, it is 4-5% and is achieved 3-6 months after the start of the building's operation. Due to its low vapor permeability, the foam simply will not allow the masonry to dry out qualitatively. Not to mention, the adhesive used to mount the boards is itself a source of moisture.

- Installing thermal insulation boards on the outer surface of the walls slows down the rate of moisture removal from the masonry. Its movement is carried out under the influence of various physical factors: thermocapillary flow, diffusion of water vapor, capillary thermoosmosis.

- Their mechanisms are triggered due to the temperature difference arising from the inner and outer sides of the wall. Moisture is directed from warmer layers to colder ones, asymmetrically distributed in the thickness of the wall. Having reached the cold layer, it begins to condense, which contributes to waterlogging of the masonry.

- If you immediately insulate aerated concrete with foam, this moisture will be trapped in the outer layer of the masonry, which, especially when the thickness of the insulation is insufficient, turns out to be in a zone of constant negative temperature.

Expert opinion Vitaly Kudryashov builder, novice author

Ask a Question

On a note: Unlike expanded polystyrene, mineral wool, due to its higher moisture capacity, is able to dry aerated concrete, taking moisture onto itself.

If the external finish is made according to the ventilated facade system, the amount of water in it, although it will not drop to zero, will decrease significantly. After a year or two, the moisture content of the masonry will be balanced and the residual moisture will be distributed more evenly over the thickness of the wall. Accordingly, the condensation zones will also decrease.

Expert opinion Vitaly Kudryashov builder, novice author

Ask a Question

Note: The moisture content of the walls made of aerated concrete directly depends on the vapor permeability of the insulation and its thickness. In the first heating season, the initial moisture contained in the masonry becomes the source of moisture for the insulation. Insulation of the gas block with polystyrene foam of insufficient thickness contributes to the secondary moistening of the enclosing structures - now due to condensate. Moisture, which has not found a way out, partially returns back, moistening also the middle layers of the masonry.

Advantages and disadvantages of foam insulation with surface plastering

The wrong choice of the external insulation system leads to an increase in heat loss, a decrease in the service life of the enclosing structures. Errors occur when a person does not have an understanding of the technology that dictates a certain sequence of materials installation, their characteristics are not taken into account. Consider, for example, the insulation of a house made of aerated concrete with penoplex with plaster applied to its surface:

- Board materials made of foamed polymers have a very low vapor permeability. For non-pressed expanded polystyrene, this indicator is only 0.018 mg / (m * h * Pa), for extruded it is even less. Aerated concrete D500 has a vapor permeability of 0.20 mg / (m * h * Pa) - that is, 11 times more.

- Between the masonry and the polymer insulation, the density of the steam flow decreases sharply, and when the temperature drops, it begins to condense directly in the thickness of the aerated concrete. If a house is insulated with aerated concrete outside with a thin layer of foam, ice formation also begins on the border of the two materials.

- That is, in this case, the foam does not work as a heater, but as a moisturizing lotion that promotes an increase in the thermal conductivity of the wall. To prevent moisture-saturated masonry from freezing, it is necessary to correctly calculate the thickness of the thermal insulation.

- If it is thick enough to ensure a positive temperature on the surface of the masonry, there will be no stable steam condensation in this place. To ensure the temperature under the insulation is above +8 degrees, at which condensation appears, at an average winter air temperature of -8 degrees. The minimum insulation thickness should be 80 mm.

Expert opinion Vitaly Kudryashov builder, novice author

Ask a Question

Note: When performing a heat engineering calculation of a wall, take into account the properties of all layers of the cake. Their total value is the final characteristic of the building envelope as a whole. If the aerated block is insulated with foam, the latter must provide at least half of the total resistance to heat transfer of the entire wall as a whole - only then such a measure will make sense.

But on the inner surface of the masonry, polymer insulation works very well. Provided that the density of the foam is not less than 25 kg / m³, and the joints of the slabs are sealed with a vapor-reflective tape, steam will practically not be able to penetrate into the thickness of the masonry. It turns out the effect of a thermos, but with well-organized ventilation, the microclimate in the premises will not spoil it.

Characteristics of polystyrene in systems with a ventilation gap

The ventilated gap can be provided both in curtain facades, in which the finishing material is mounted with an indent along the lathing, and in the case of external facing with bricks. A distinctive feature of such systems is the presence of free space under the cladding with air access, which ensures the removal of excess moisture.

Insulation of walls made of aerated concrete with penoplex with such a wall structure is not recommended, since this material has the same flammability, smoke-generating ability and toxicity as wood. Oxygen entering the air vents feeds the combustion, therefore, flammable heaters are undesirable for this design in principle.

Expert opinion Vitaly Kudryashov builder, novice author

Ask a Question

Note: For such systems, mineral-based heaters are recommended, selected in terms of density so that their vapor permeability is higher than that of the material of the main wall.

Brick cladding option

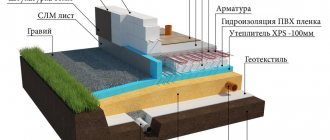

Aerated concrete wall with brick cladding and internal insulation is considered three-layer.

- Such designs are classified by the type of insulation, which can be:

- slab;

- jellied (the same polystyrene, only in the form of foam);

- filling (PPS in the form of granules).

- Thermal insulation of aerated concrete with foam plastic for brick cladding is not the best solution, and it is even prohibited in a number of regions for budget construction. The reason for this is the impossibility of carrying out repairs and quality control of hidden works, more frequent cases of collapse of brick lining.

- The blame is the poor fit of the slabs to each other, the joints between which become channels for the intense passage of warm air currents. Mineral wool, due to its lower rigidity, fills cavities better, but due to moisture and settling, the problem ultimately arises the same.

- So it is better not to use slab insulation as such as a middle layer in masonry at all. If you use polystyrene, then in addition to fixing the plates with glue, it is imperative to fix them with disc dowels.

- The ideal option for filling the sinus of a three-layer construction is a jellied insulation. In this capacity, lightweight and cellular concrete, penoizol, polyurethane foam are used. The problem with this solution is that such materials have a high initial moisture content, and the brickwork will not allow the pouring to dry normally.

- Therefore, in this case, it is very important that the facing brick has the lowest possible density, and is mounted on a porous masonry mortar, which will allow moisture to freely escape to the outside. Fumes alone will not be enough for this.

Expert opinion Vitaly Kudryashov builder, novice author

Ask a Question

Note: Naturally, other materials can be used, but the foam can take all three forms.

In the case of using a backfill insulation (this is not only foam granules, but also perlite, vermiculite, expanded clay, sawdust, ecowool), there is at least initial moisture. But the general problem remains the same as with plate heaters: compaction under its own weight and subsidence, which over time worsens the thermal insulation qualities of the structure.

We tried to tell in detail whether it is possible to insulate walls made of aerated concrete with penoplex. Now let's clarify why thermal insulation is generally needed, if aerated concrete itself has excellent thermal technical data.

How is mineral wool made, its properties

Mineral wool is formed by melting rocks and passing them through the thinnest dies. The resulting fibers are immediately cooled at the exit from the furnace and wound onto spools. Electrical insulating woven materials are produced from stone fibers, but a certain part of them (usually rejection) is cut off the spools and ends up in beater machines, where cotton wool is produced.

Then the resulting wool is fed under the presses, where canvases are formed, rolled into rolls (low density) and slabs (medium and high density mineral wool).

In its essence and chemical composition, fibrous wool remains the same stone (mining material), which is not afraid of dampness, mold, or any other fungi. This is a chemically neutral insulation that behaves calmly when the acid-base environment changes, does not react in any way to the appearance of, for example, rust. Mineral wool is not afraid of temperature changes, it is not prone to fires, it does not conduct electric current.

Why you need to insulate

With a thickness of 375 mm, the wall erected from the D400 gas block fully meets the requirements of the rules for thermal protection of buildings. Why then insulate the aerated concrete with EPS?

The characteristics of masonry made of aerated concrete blocks may be unequal due to their density, different wall thicknesses and its design features, the mode of operation of the building and, of course, the quality of the materials used. In modern conditions, the main task of the insulation is not even to get thermal comfort, but to reduce heating costs by reducing heat loss by structures during the heating season.

According to the norms, it is possible to make single-layer walls from aerated concrete. But this is provided that the house is both designed and built without mistakes, the material is used autoclaved and mounted on glue with thin seams. In reality, everything is far from being so cloudless, as evidenced by numerous reviews of private developers.

Advantages of single-layer walls

Anyone understands that if the walls are erected in a single layer, without insulation and other layers, it will be beneficial from a financial point of view. This solution has other advantages as well:

- You can hire bricklayers with lower qualifications or do the wall erection yourself, while multi-layer structures should be erected by people with the appropriate experience.

- "Naked" masonry is surveyed from all sides, you can see the error and eliminate it in time. For example, to close the gap. Under the insulation, this will not be visible and it is unlikely that it will be possible to establish exactly what is the reason for blowing the wall.

- Time is saved that does not need to be spent on insulating the house from gas blocks. And when using a vapor-proof heat-insulating material, which is expanded polystyrene, you will have to wait 2-6 months before proceeding with its installation at all (this depends on the climatic conditions of construction, and on the thickness of the wall and the density of the stone). If the industrial moisture is not allowed to come out of the walls, it will remain in the masonry and create problems during the operation of the house.

- The service life of the insulation is also in question. It is definitely less than that of aerated concrete masonry, sooner or later it will need to be replaced.

- The use of hinged structures of the ventilation facade system forces the use of blocks of higher density for masonry. It is much easier to simply plaster aerated concrete walls without any insulation. In this case, you do not have to "perforate" the walls with disc dowels, with the help of which the expanded polystyrene is attached to the aerated concrete.

But there are situations when one cannot do without insulation, and first of all this applies to regions with frosty winters. Or, if there are no D 400 blocks on sale in the area, and you have to take material with a higher density. Their thermal conductivity coefficient is higher, and in order not to increase the thickness of the wall, it is easier to insulate outside.

Expert opinion Vitaly Kudryashov builder, novice author

Ask a Question

Note: The lower the density of the foam for insulating aerated concrete from the outside, the more effective it will be. The minimum is 15 kg / m³.

It is also necessary to insulate the walls in the case when the blocks were laid not with glue, but with a solution of cement and sand. Firstly, such seams are thicker than glue seams, and secondly, they make the wall heat-engineering heterogeneous due to different thermal conductivity coefficients.

In general, the meaning of using insulation for aerated concrete masonry is to level out the flaws in its performance, preventing cold air from entering the premises from the outside.

The service life of foam as insulation

Another commonly used insulation material is polystyrene foam. It is generally accepted that the shelf life of expanded polystyrene reaches several decades. Manufacturers give a guarantee for material durability for 50 years. However, with the correct insulation procedure, this period can be doubled. This is one of the main reasons why it is so popular.

It should be borne in mind that there are several types of insulation made of foam:

- Polystyrene... A material that is made in the form of foam rubber. Suitable for protecting a room from the inside. It has very high performance characteristics.

- Polyvinyl chloride substances are very flexible. They have a very high resistance rate.

- Polyurethane foam... It is considered to be a hardy thermal insulation that will last quite a long time, quickly hardens, forming a very strong protection that can withstand many external influences.

Based on the above materials, we can conclude that the service life of the foam is very long and fully meets expectations.

Technology for performing the installation of house insulation with penoplex

To insulate or not to insulate - and even more so with foam, everyone decides for himself - we just tried to explain in as much detail as possible all the pros and cons of such a decision. Now let's just look at the technology of mounting this material.

The preparation of all materials and tools required for the installation of foam board may differ depending on the proposed insulation system - plaster or ventilated facade. We will talk about plastering, since it is more complex, most often it is performed on foam. In the course of the story, we will pay attention to the improvised inventory.

Warm plastering system

The classic insulation system with a finishing plaster layer consists of six layers:

- Adhesive layer.

- Thermal insulation boards (it can be not only expanded polystyrene, but also hard mineral wool).

- Base reinforced layer (cement-based adhesive + fiberglass mesh).

- Primer.

- Plasters.

- Finish staining.

[expert

Note:

When such a system is installed on aerated concrete walls, another layer is added: an adhesive primer, which is applied directly to the base. Its task is to prevent the aerated concrete masonry from absorbing moisture from the glue on which the foam plastic slabs will be mounted.]

Surface marking

As part of the preparatory work, first of all, it is necessary to evaluate the geometry of the facade with the help of a bubble level. You will also need a water level - so that you can correctly draw the starting line. A basement profile will be mounted along it, supporting the first row of insulation.

- The profile is a galvanized steel groove with mounting holes and a drip, through which condensate will be removed from the system during operation.

- For fastening in the corner zone of the building, a triangular fragment must be cut on the profile corresponding to the degree of the right angle. It is cut so that the profile with an intact drip can bend around the corner of the house.

- The presence of the basement profile increases the accuracy of the installation of the thermal insulation plates many times over. To ensure an even fit, despite the unevenness of the masonry, it is necessary to use pads for fasteners in the form of plastic leveling plates.

- If the window blocks are installed in the plane of the facade, a profile with a fiberglass mesh is installed along their perimeter. This profile is self-adhesive, so for installation it is enough to remove the protective paper cover.

Styrofoam installation

Before installing the foam plate on the aerated concrete facade, its surface must be treated with a deep penetration primer. There are compounds on sale that are specially designed for aerated concrete.

- Aerated concrete-contact (as such compositions are often called) differs from conventional primers by a higher vapor permeability with a simultaneous water-repellent effect. The number of applied layers is determined by the primer manufacturer, so read carefully the instructions on the package. Before you start gluing EPSP on aerated concrete, the impregnation must be allowed to dry completely.

Expert opinion Vitaly Kudryashov builder, novice authorAsk a Question

On a note: Materials for all other layers of the system, including expanded polystyrene, are sold in a set from the manufacturer.So it doesn't make sense to go shopping and pick everything up separately.

- Adhesive for expanded polystyrene is usually offered in dry form, it must be mixed with water before use. Some manufacturers offer glue foam, but it will definitely cost more. When mixing dry glue, water is first poured into the container, then the mixture is poured into it and mixed with a construction mixer until smooth. Letting the mass stand for 5-7 minutes, mix it again and start working.

- A straight and notched trowel is required to glue the foam board to the wall. The glue is applied in a continuous strip 5 cm wide along the perimeter of the sheet and in bumps in the center. Many craftsmen limit themselves to this, some spread the glue over the entire area of the plate with a notched trowel.

- This is not so important, in both cases the connection will be strong, since subsequently the foam is still necessarily fixed by fungi - dowels with a wide plastic cap. Normally, 5 such fasteners should be performed per 1 m² of insulation.

- At the corners, the slabs are installed so that the end of one slab is hidden by the frontal plane of the other. The excess foam is simply cut off with a hacksaw. Places of cuts are trimmed with a foam trowel and dust removed with a brush.

- In the area of the window opening in the sheets, L-shaped notches are made with the same tool. To make them even and exactly in size, preliminary pencil markings are made on the plates, using a level as a ruler. When gluing the foam around the opening, you need to carefully tuck the fiberglass mesh of the profile adjacent to the window under it.

Expert opinion Vitaly Kudryashov builder, novice author

Ask a Question

Note: The density of polystyrene foam, mounted under plaster, must be at least 25 kg / cm³ (marked with PSB-25).

Reinforcement and sealing

Installation of disc dowels is carried out after 3 days, when the glue is completely dry. But before that, the joints between the boards, which should not be more than 2 mm, must be filled with polyurethane foam. After it dries, the excess is cut off with a clerical knife. If there are irregularities (when the plane of one sheet slightly extends beyond the plane of another), they are removed with an abrasive float.

- The dowels are installed in pre-drilled holes. For drilling in aerated concrete, a hammer drill is used, set to shock-free mode. The depth of the holes must exceed the length of the dowel by at least 10 cm, the length of which, in turn, depends on the thickness of the foam. It is important that the caps of the installed "fungi" do not protrude beyond the plane of the insulation, as this will interfere with further work.

- To bypass the openings, now corner plaster profiles with fiberglass mesh are mounted on top of the foam. At the intersection of the horizontal and vertical profiles, an overlap of the mesh is made and, in addition, mesh rectangles with a size of 200 * 300 mm are glued. This strengthens the corners of the opening, preventing them from cracking the plaster. The mesh is embedded in a pre-applied strip of glue, and is sealed with it from above.

- Similarly, all external and internal corners of the building are reinforced with a profile. After that, you can start plastering over the entire surface. For this work, a plaster-adhesive mixture for expanded polystyrene boards and a fiberglass mesh with a density of at least 160 g / m² are used.

- Mixes specially designed for application to insulation are distinguished by high adhesion, elasticity, crack resistance and impact resistance, since they contain reinforcing fibers. They are applied in a continuous layer, in strips with a width corresponding to the size of the mesh.

- While the glue mixture retains its plasticity, the mesh unfolds, is applied over the layer and sunk into it with a scraper. They begin to smooth it from the middle, gradually moving towards the edges. The next sheet is glued in the same way, with a mandatory overlap with the previous one by at least 100 mm.

At the end of the installation of the fiberglass mesh, a break is made in the work for another 3 days - for the glue mixture to completely harden. After this time, an adhesive primer is applied to the dried surface, which will ensure the best adhesion of this layer to the plaster. The primer is usually ready to use, applied in favorable weather conditions and dries for about 3-5 hours. It can be tinted in the color of the plaster so that the gray base does not shine through.

Where is mineral wool used?

In general, mineral wool is an ideal insulation that is used for thermal insulation of pipelines of heating mains, water pipes, industrial boilers at thermal power plants.

In recent decades, mineral wool is increasingly used to insulate walls in housing construction. With the correct implementation of all work on heat and vapor insulation, mineral wool insulation will retain heat for as many years as the walls stand. The manufacturer calls the service life of mineral wool insulation - 50 years. But in fact, with proper installation work, it will last much longer.

Myth number 2: mineral wool is a reliable insulation

Minvata is the absolute leader in the transmission of warm air to the outside; it does not create any barrier to warm air. The thermal conductivity of mineral wool drops several times when it is moistened, once it accumulates moisture, the mineral wool does not heat and is deformed forever.

Although manufacturers of mineral wool insulation indicate a service life of up to 50 years, the practice of using the material shows that in the event of a deviation from the technology of installing mineral wool, it will last for a few years. Under ideal conditions, subject to all installation requirements, the service life does not exceed 8 - 10 years. It is known that already a year after the installation of mineral wool, thermal conductivity indicators deteriorate to 40%.

The table below is compiled from the characteristics of thermal insulation materials. Unfortunately, not only in theory, but also in practice, mineral wool cannot cope with the function of insulation. This happens not so much because the material itself is outdated, but, as mentioned above, due to non-observance of the method and technique of the complex installation of mineral wool insulation.

Influence of vapor permeability on other characteristics

It is worth noting that if no insulation was installed during construction, in case of severe frost in windy weather, the heat from the rooms will go away quickly enough. That is why it is necessary to competently insulate the walls.

At the same time, the durability of walls with high permeability is lower. This is due to the fact that when steam enters the building material, moisture begins to freeze under the influence of low temperature. This leads to the gradual destruction of the walls. That is why, when choosing a building material with a high degree of permeability, it is necessary to correctly install a vapor barrier and heat insulation layer. To find out the vapor permeability of materials, you should use the table, which contains all the values.

Manufacturing of medical devices

Another area of pharmaceutical technology is drug technology. This science covers the processing of raw materials, as well as the chemical synthesis of compounds for the creation of biologically active substances, enzymes, etc. for the manufacture of medical and veterinary drugs.

Intersection of straight line coordinate planes

Now let's solve this problem. A straight line is given, which is given as follows:

(x; y; z) = (1; 0; 0) + λ * (2; 0; -1)

It is necessary to find the angles of its intersection with three coordinate planes.

First, you should write down the expressions for the specified planes mathematically. They look like:

x = 0 (yz plane);

y = 0 (xz plane);

z = 0 (xy plane)

For each of them, we write down the coordinates of the normal vector:

n¯ (1; 0; 0) for x = 0;

n¯ (0; 1; 0) for y = 0;

n¯ (0; 0; 1) for z = 0

It is seen that the lengths of all normal vectors are equal to one. Find the dot products for each of them with the directing vector of the straight line:

for x = 0: ((2; 0; -1) * (1; 0; 0)) = 2;

for y = 0: ((2; 0; -1) * (0; 1; 0)) = 0;

for z = 0: ((2; 0; -1) * (0; 0; 1)) = -1

The modulus of the direct vector is:

|(2; 0; -1)| = √5

We substitute the calculated values into the formula, we get the intersection angles:

with x = 0: α = arcsin (| 2 | / √5) ≈ 63.4o;

with y = 0: α = arcsin (| 0 | / √5) = 0o;

with z = 0: α = arcsin (| -1 | / √5) ≈ 26.6o

Thus, the given line intersects only the yz and xy planes, and it is parallel to the xz plane.

Direction biopharmacy

In the middle of the last century, when assessing the quality of drugs, the main attention was paid only to such factors as its color, smell, weight, volume. However, it was later noticed that drugs of the same composition, released by different manufacturers, can vary significantly in effectiveness. As a result, a new area of pharmaceutical technology has emerged that studies the dependence of the effectiveness of finished drugs on various factors - biopharmacy. At the moment, it is this industry that is the scientific basis for the search for ways to create and manufacture new drugs. Biopharmacy studies the dependence of the effectiveness of drugs on:

- the chemical nature of the active substance and its concentration;

- the physical state of the medicinal substance (the shape of the crystals, the presence / absence of charge on the surface of the particles, etc.);

- chemical nature and concentration of excipients, route of administration, dosage form;

- manufacturing techniques and equipment used.

Plane and line and the value of the angle of their intersection

It is necessary to find the angle between the straight line and the plane, given by the expressions:

(x; y; z) = (1; 1; 0) + λ * (2; -1; 3);

x + y - 2z + 1 = 0

It is convenient to use the above formula for α if the moduli of the vectors and their scalar product are calculated beforehand. Let's do it:

n¯ (1; 1; -2);

v¯ (2; -1; 3);

(n¯ * v¯) = ((1; 1; -2) * (2; -1; 3)) = -5;

| n¯ | = √ (1 + 1 + 4) = √6;

| v¯ | = √ (4 + 1 + 9) = √14

Now the found values can be substituted into the formula for α:

α = arcsin (| -5 | / (√6 * √14)) = 33.06o

Thus, we have shown that the plane and the line really intersect, and the angle between them is approximately equal to 33o.

Pharmacy in the XIX-XX centuries

In subsequent years, medical chemistry developed by leaps and bounds. In the 19th century, for example:

- first started producing pills;

- invented hard gelatin capsules;

- developed preparations for subcutaneous injection;

- designed a syringe;

- developed methods of sterilization by filtration and steam;

- began to use sodium chloride 0.9% as a saline solution.

In the XX century. antibiotics were discovered and the production of drugs using biotechnology methods began. Later, even more advanced medicines and methods of their manufacture were invented.