Roof insulation with mineral wool

Varieties of mineral wool and options for mounting material on various types of roofs, pros and cons of fiber-based coating, rules for choosing components, installation technology.

- Features of work

- Advantages and disadvantages

- Insulation technology

- Choice of mineral wool

- Sloping roof

- Flat roof

Roof insulation with mineral wool is the creation of a shell for comprehensive protection of the house from cold, overheating, precipitation. The composition of the thermal insulation coating includes, in addition to the main element, steam and waterproofing materials, a screed to protect against mechanical stress. You can learn about the rules for forming a warming "pie" from this article.

Insulation of the attic floor

Of course, it will be easiest to install thermal insulation during the construction of a building - this will simplify the design and some of the nuances of work. In most cases, following this advice will not work - a lack of finances or time may well interfere, so the overlap remains without insulation. As a rule, this state of affairs persists until the first frost, and the owners have to hastily install thermal insulation.

Before insulating the attic floor, you need to carry out a number of preparatory work, which is especially important when using bulk insulation materials. There are two insulation technologies - traditional and modern.

The traditional method of floor insulation is implemented as follows:

- The first step is to process the boards attached to the ceiling with a clay or lime mortar - such processing will ensure the structure is tight while maintaining normal ventilation;

- When the mixture hardens, you can proceed directly to the insulation work - filling bulk materials into the space between the floor beams on pre-processed boards.

Today, a more modern method of floor insulation is used much more often:

- First of all, a vapor barrier membrane is laid with a 20-cm overlap on the floor and beams, which not only protects the insulation material, but also complements its thermal insulation properties, reducing the amount of heat leaving the building through the ceiling;

- For tightness, the membrane in the overlap areas must be sealed using construction tape;

- The next step is to install the selected insulation (mineral wool, ecowool, expanded clay or one of the bulk materials) using the appropriate technology;

- So that the floor beams do not have cold bridges, it is necessary to ensure that the insulation passes over them;

- Above the insulation, in compliance with the already known rules, another layer of vapor barrier film is laid, which is attached to the beams with counter-rails;

- It remains to lay a covering of boards or sufficiently strong plywood over the finished thermal insulation structure.

Sometimes, instead of insulating the ceiling from the attic side, the thermal insulation is placed inside the building itself. This design is also quite effective in insulating, but requires additional finishing.

Floor insulation

Interfloor and attic floors are made of load-bearing beams or reinforced concrete. In the first case, the heat insulator is placed in the space between the floor beams, and in the second - on the surface of the slabs.

Insulation of the attic floor

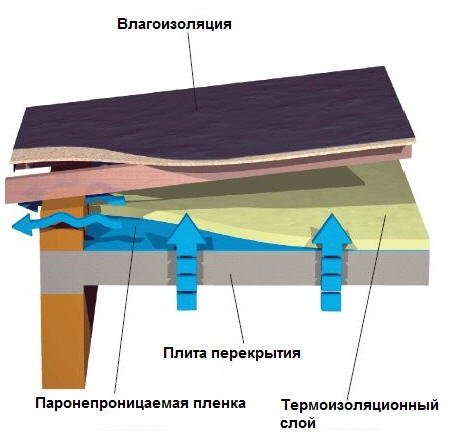

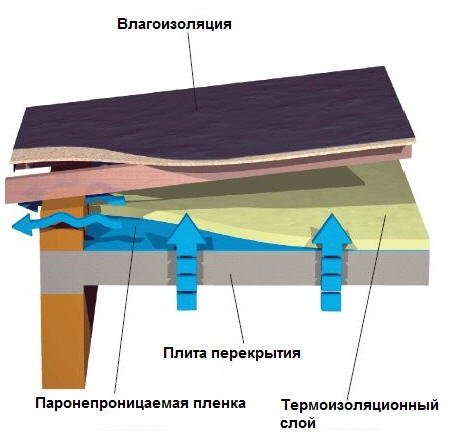

First of all, it is necessary to install a vapor barrier. It will protect the insulation from moisture and steam. Before laying the vapor barrier film, it is necessary to study the instructions for its use.If the vapor barrier is installed incorrectly, then it will not perform its tasks.

Flat roofs are usually insulated with rigid slabs of mineral wool, the density of which is more than 150 kg / m3. A layer of waterproofing is laid on top of it. It is necessary to lay the slabs very tightly to each other. In this case, the seams should not be located on the same line. The optimum thickness of the mineral wool layer is 25 centimeters.

You can also insulate interfloor and attic floors with sawdust. They are used together with sand, clay, lime and cement. The composition provides good thermal insulation.

Expanded clay is also often used to insulate the attic. This material contains a large number of pores, due to which the function of thermal insulation is provided.

When using these materials, financial costs will be less, and the quality of thermal insulation is not worse than in the case of mineral wool insulation. When choosing a heater, one should take into account the height and area of the building, the materials from which it is built and other parameters.

Video on thermal insulation of the attic floor:

Vapor barrier materials

The most popular vapor barrier material is a special film that protects wood and insulation from the effects of steam, which turns into condensation as a result of temperature changes. The negative impact of moisture on the elements of the roofing structure can not be mentioned once again - suffice it to say that it significantly reduces the service life of the roof and the efficiency of the heat-insulating material.

The vapor barrier membrane is attached to the roof or slab before the thermal insulation materials are installed. In rooms where heating has been carried out, the vapor barrier must be installed only under the finishing layer. To protect structures that are constantly in temperature contrast conditions, a vapor barrier layer must be placed on both sides. The exception is concrete floors, which do not require such protection.

For arranging the vapor barrier layer, a film with different characteristics can be used. The simplest option is a nonwoven film, but a foil membrane is a much more efficient option. The last option, as its name implies, has a thin foil layer on one side, which prevents heat from escaping outside the structure. The roof vapor barrier installed from the inside of the house is connected with special tape, which ensures a tight connection.

Requirements for attic insulation

So, what is the best insulation for a mansard roof? It all depends on what exactly you expect from him, because for thermal insulation of the attic of baths and saunas, where fire-safe chimneys pass, it is difficult to come up with something better than basalt insulation that can withstand up to 1000 ° C, but for insulation of an ordinary summer attic the house is a losing option: everyone will be eaten by mice. But what do you need?

Each material has its own valuable properties and its disadvantages. When choosing a material for insulating an attic, most people are interested in such aspects as:

- Thermal insulation qualities.

- Profitability.

- Durability.

- Ease of installation.

- Water repellent properties.

- Noise isolation

- Versatility

But let's approach this issue from a professional perspective. Of course, the most valuable quality is still the ability of the insulation to retain heat:

The second important point: is it possible to insulate the sloping walls of the attic and the floors with the same insulation. Therefore, pay attention: if the name of any insulation contains the word "universal", then it can be used both for insulation of the roof and for walls, floors and ceilings.For finishing the attic - this is the best option: we buy the material we like and immediately finish the walls, gables, and the floor. Quickly, and less problematic - now all insulation will have the same properties and will serve the same long time.

And now about the absorption of sounds. But why should the roof have soundproofing, because there are no neighbors behind it, no stomping of feet? Let's just say: those in whose house a metal roofing (profile, metal tile), and it rained at least once, do not have such questions. It is clear that a non-residential attic can still be left without sound insulation, but when arranging a residential attic, it is important to understand that comfort is, first of all, silence.

Also, the choice of insulation for the attic directly depends on what its supporting structure is made of: reinforced concrete, metal or wood. And the more combustible the material of the same rafters, the less combustible the insulation should be, so that later the "bohemian" space does not flare up like a match.

And, finally, for an attic insulation, due to the presence of constant water vapor in the room, the most valuable quality is still hydrophobicity:

And now about what kind of insulation is most suitable for the attic roof of your particular house.

The choice of material for insulation

Today, the choice of heat-insulating materials is so great, and their characteristics are so different, that making the right choice for a particular case can be very difficult.

Most often, developers prefer the following materials as insulation:

- glass wool;

- mineral wool;

- basalt (stone) slabs (there are ready-made sandwich panels with basalt insulation);

- polystyrene (expanded polystyrene);

- polyurethane foam (liquid sprayed insulation).

Recently, Izover, a fiberglass material with a high level of heat and sound insulation, has been especially popular in the insulation of pitched roofs. Due to the content of air in the structure of this material, its low thermal conductivity is ensured, not exceeding 0.044 W / mK. In addition, this material has tremendous durability (at least fifty years), excellent vapor permeability and high fire resistance (flammability class - G1).

Considering other types of roof insulation, you should pay attention to expanded clay. It is also characterized by excellent heat and sound insulation, environmental friendliness and fire safety.

Since clay is used for its manufacture, it does not lose its properties under the influence of temperature, does not deform and does not emit any substances harmful to humans, which is possible in the case of using synthetic thermal insulation materials.

Insulation technology

Installation of thermal insulation material begins with the preparatory stage. If you skip it, critical errors are inevitable. Unplanned expenses will arise, the expenditure of physical forces will increase, the nervous system will suffer. We will tell you about the errors of self-installation of the announced isolator, but later. Now let's get back to the main technology.

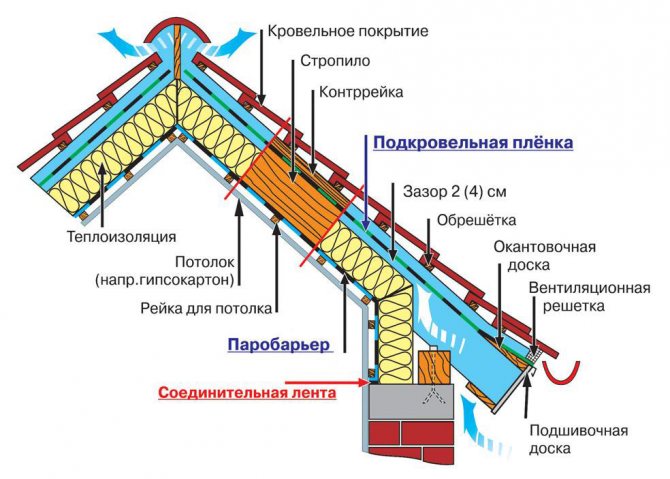

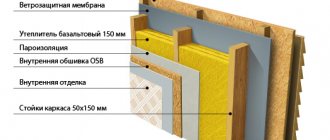

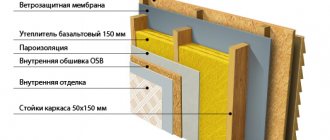

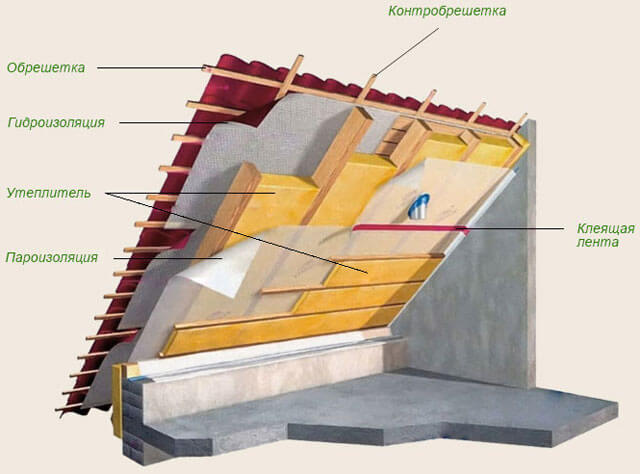

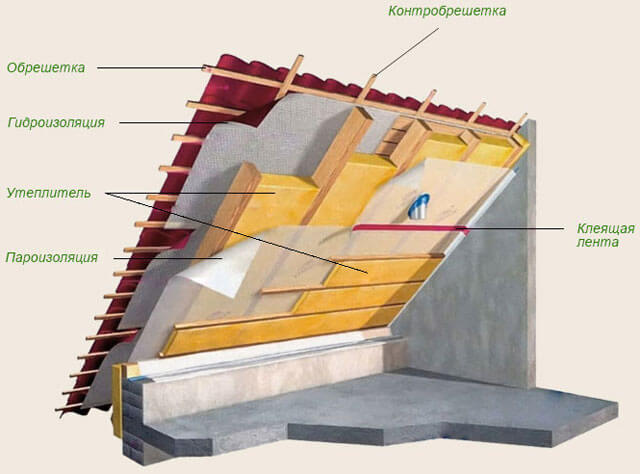

You should start with the installation of the supporting structure elements. They are perfectly replaced by wooden rafters. The second stage involves laying a waterproofing sheet or film. The third stage is the direct installation of mineral insulator plates. The lathing is installed at the end of the installation work. Finishing with plasterboard, wallpaper or other decorative components is the final part of the event.

Instructions for insulating a pitched roof

Laying mineral wool

The entire installation process can be divided into several stages of work:

Stuffing on the rafter legs on the inner side of the lathing boards with a step of 20 to 30 cm - they are needed to fasten the insulation.Mineral wool is laid on the outside of the rafter legs. Subject to the installation of insulation for cold regions, it is better to increase the number of layers to two or three. The main condition for work is tight pressing of the joints of the slabs to the rafter legs

It is important to ensure that there are no through holes in the mineral wool layer. If, after installation, you still notice holes, then they must be eliminated with polyurethane foam. When the mineral wool installation is finished, it is necessary to install a waterproofing membrane.

To do this, it is simply nailed onto the rafter legs, leaving a slight sagging. Interference mounting is not desirable. The waterproofing membrane must be correctly positioned. The fact is that such material has a front and back side. The first is designed to prevent the passage of moisture, but the lower one, on the contrary, allows moisture and vapors to pass upward. The waterproofing material is laid in strips, leaving a slight overlap. It is also necessary to create a 5 cm gap between the membrane and the mineral wool.

When the waterproofing material is attached in place, go to the additional ventilation device. For this, bars of wood with a section of 25x50 or 50x50 cm are stuffed onto the rafter legs. They can be trimmed bars. The length can vary from one to two meters. When the bars are in place, it is necessary to fill the crate, placing the boards across the rafter legs. This will create a gap that will facilitate the evaporation of condensation and moisture that will collect on the waterproofing membrane. The roofing material is laid on the crate. Do not forget to treat wood with antiseptic solutions. This will help extend the life of the roofing pie structure. The creation of a vapor barrier is an important stage in roof insulation. It will prevent water vapor from entering the mineral wool. The vapor barrier film is stretched over the inside of the rafter system. To be able to decorate the room, it is necessary to lay the sheathing boards on top of the vapor barrier material. For this, slats are used, on which the inner lining in the form of lining, drywall, plywood, etc. will later be attached.

Scope of use of mineral wool for thermal insulation

ui

Due to its high technical characteristics, mineral wool is used to insulate various surfaces:

- when insulating the floor in the house;

- when insulating walls inside the premises;

- when insulating the roof;

- when insulating balconies and attics.

Depending on the raw materials from which the insulation is made, mineral wool can be: slag, glass wool and stone wool. Mineral wool can last over 45 years. More resistant to deformation is stone wool, which is produced from molten stone fibers. Phenol-formaldehyde resins are used to connect them. In the future, they will be neutralized. Therefore, stone wool is environmentally friendly. It is used for insulating elements with a high load.

Features of roof insulation from the inside with mineral wool, and the cost of work

Mineral wool is the collective name for three types of insulation, which have one thing in common - their fibrous structure.

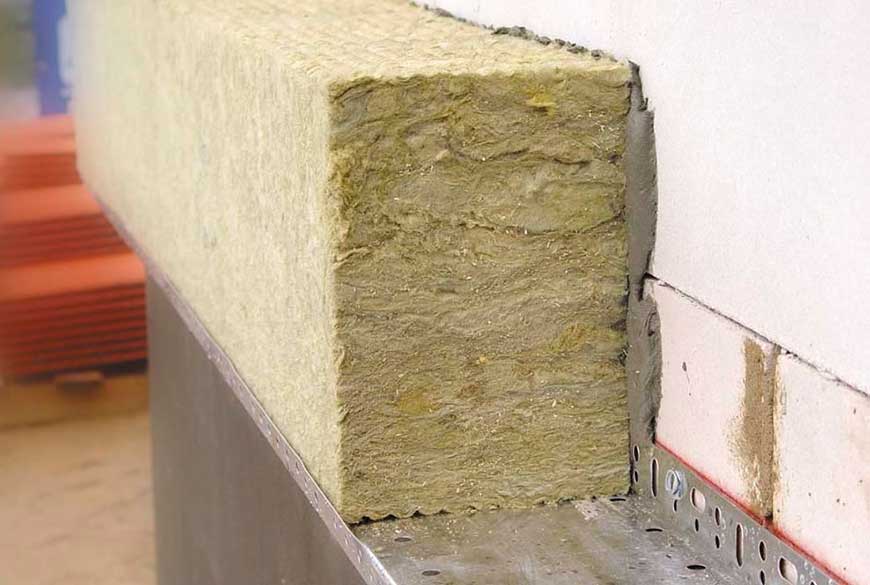

Basalt or stone wool is made from rock. It serves for a very long time, therefore it is used for capital construction. The most expensive type of mineral wool.

Glass wool made from the same components as regular glass. Cheaper than basalt, but its service life is much shorter. It is used in places where it can be replaced quickly and cheaply.

Slag wool, for the manufacture of which wastes from blast furnaces are used. Price and properties are similar to glass wool.

These materials come in a variety of forms. It can be slabs, rolls, mats, and cylinders.

Insulating the roof with glass wool from the inside is the most effective and affordable way to keep heat in the attic.

In order to insulate the roof from the inside, especially when it comes to a structure made of wooden structures, materials that meet serious requirements should be used. They should be:

- Non-flammable (fire safety class from G3 and higher).

- Long lasting.

- Eco-friendly.

- Resistant to decay.

- Possessing not only insulating, but also soundproofing properties.

- Not suffering from temperature extremes.

- Resistant to damage from insects and rodents.

Mineral wool meets these requirements most of all. To insulate the roof from the inside, mineral wool is used in the form of a roll or mattress. The last option is the most convenient for installation.

Prices for mineral wool allow you to use it for the purpose of roof insulation for almost every owner of a cottage, bath or garden house.

The only drawback of this material is its ability to absorb water, while losing up to 40% of its thermal insulation properties. However, the insulation of the roof from the inside with mineral wool, carried out in strict accordance with the technology, helps to prevent liquid from entering the insulation.

Well, the quality of roof insulation can be seen with the help of a thermal imager, which can instantly show the places through which heat loss occurs.

What set of tools and consumables will be needed to insulate the roof from the inside?

When carrying out roof insulation on your own, you should prepare everything you need to carry out the work:

- Minvatu.

- Wooden bars with a cross section of 40 mm.

- A vapor barrier (for example, any waterproofing film).

- Drill.

- Glue.

- Antiseptic solution for wood.

- Nails or screws.

- A hammer.

- Mineral wool dust mask.

Features of mineral wool

Mineral wool

Minvata is not for nothing that it is very popular as a heater. This material is easy to work with and has a number of advantages, including:

- low thermal conductivity;

- combustion resistance;

- environmental friendliness;

- resistance to aggressive environments;

- high level of heat saving;

- good noise absorption;

- hydrophobicity. This property manifests itself as resistance to wetting; You can not rely only on the hydrophobic qualities of mineral wool. It is imperative to carry out measures to protect the under-roof space from moisture. When wet, any insulation will reduce its effectiveness a couple of times.

- high resistance to deformation;

- ease of installation;

- the duration of the operational period.

Unlike Styrofoam, careless handling of the material will not damage it. And thanks to the softness of mineral wool, it is easy to install.

Despite similar insulation procedures, mineral wool differs from ecowool, which appeared not so long ago on the construction market, which is an insulator characterized by looseness and light weight. Ecowool contains cellulose, antiseptics and boric acid.

Insulation of a flat roof

Quite often, flat roofs of houses are used to equip terraces, winter gardens, sports or playgrounds. Therefore, such a structure should be as reliable as possible and capable of withstanding significant loads, and the thickness of the insulation for the roof should also be quite significant (also read: "House Roof Scheme - Features").

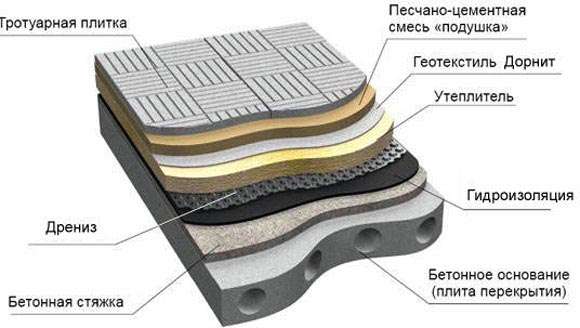

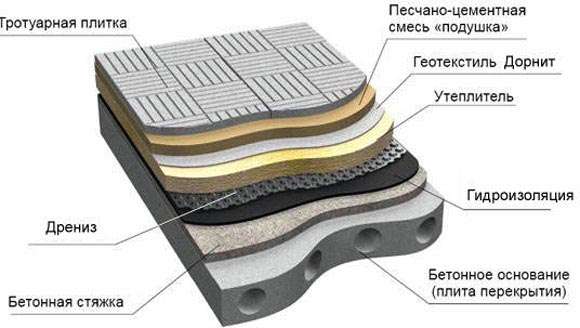

Insulation of such a roof is performed as follows:

- first, a cement screed is arranged along the reinforced concrete floor slab, which forms a slope. Then a layer of waterproofing is laid;

- after that, a layer of extruded polystyrene foam with a density of at least 35 kg per square meter is laid;

- then, to create filtration, everything is covered with fiberglass, covered with a layer of gravel or pebbles, and at the end paving slabs or paving stones are laid.

Foam can also be used for roof insulation or foam concrete applied to the vapor barrier layer and covered with a foam fiber concrete screed. After that, a welded or membrane coating made of polyvinyl chloride is equipped.

In cases where flat roofs are used under the attic, and a soft roof with insulation is supposed to be installed, a vapor barrier and insulation layer is laid in the attic, and a waterproofing layer is laid under the roofing material. It is also possible to insulate the attic floor with expanded clay. If the operation of a flat roof is not foreseen, then it can be insulated both from the outside and from the inside (in more detail: "Insulation of a flat roof and its features").

Flat roof insulation instructions

All flat roofs are divided into ventilated and non-ventilated. Let's consider both types.

Ventilated flat roof

Ventilated flat roof structure

The process of insulating it is similar to the scheme for working with a non-residential attic. Such a roof structure provides a minimum distance between the slope and the ceiling, which makes it difficult to move in the under-roof space and reduces the functions of the room to only technical ones.

For work, mineral wool slabs with a thickness of 20 cm are suitable. The material is laid on the floor of the attic. Dowels are used as fasteners. In addition to the mechanical installation method, it is allowed to use glue or hot mastic, but the latter method has not gained much popularity. For the insulation to work properly, it is necessary to place the construction film under it in one layer.

Stages of work

- To begin with, the condition of the entire roofing cake is checked. Damaged elements must be replaced.

- For additional insulation of the attic, it is possible to lay a layer of mineral wool on an existing one.

- Before starting the installation of mineral wool boards, you should clean the surface of the floor, which will be insulated. When using reinforced concrete floor slabs, a vapor barrier is not necessary, because concrete does not allow moisture to pass through.

- The beams must also be insulated or covered with insulating materials, or mats (roll insulation can be used) between the beams. But before that, it is necessary to mount a vapor barrier layer.

- When using foil-clad material, laying is carried out with the plates facing down with the foil.

- Leave a ventilation gap near the eaves.

Unventilated flat roof

Unventilated flat roof structure

Concrete slabs or wood are used as the base, depending on the material from which the house was built. The peculiarity of this type of roof is in the absence of any gap between the roof and the ceiling. Therefore, it is necessary to install mineral wool directly on the base.

Stages of work

- The vapor barrier foil is applied to the base of the roof.

- After that, you can start laying the mineral wool boards. It is recommended to do this with a staggered arrangement of the material so that the joints are not located along the same line. Fitting the slabs must be done with a tight abutment. The most suitable thickness of the thermal insulation layer is 25 cm.

- Then the roofing material is laid on top of the mineral wool slabs.

An unventilated flat roof can have various types of thermal insulation:

- Single layer. For this, hard mineral wool slabs are used, which have increased strength. But their thermal insulation qualities are not great.

- Two-layer system. For this, elastic plates are suitable to form the first row, and for the second, harder plates are used.Thus, a structure is obtained in which the lower layer exhibits excellent thermal insulation qualities, and the upper one helps to compensate for the sensitivity of the first row to various mechanical damage. Basalt mineral wool is used as a material.

- Mixed system of two layers. This option is similar in design to the previous one, but differs in the use of two types of mineral wool boards. Glass wool is used for the lower layer, and basalt wool for the upper layer.

Thermal insulation methods

Depending on which element of the building structure is insulated, 2 methods can be distinguished.

Floor insulation

The first option is floor insulation. The method is inexpensive, very simple to implement. It consists in laying cotton wool on concrete base slabs or, in the case of a wooden floor, between structural elements. Any kind of mineral wool will do, even soft and granular. Installation is simple, you do not need to bypass the rafters, as when insulating roof slopes, you can easily fill in all the gaps and cracks.

Heat protection of skates

The second option is to insulate the roof slopes. If the premises in the attic are not used, then this option is economically unprofitable. The consumption of materials increases significantly, it takes more time due to the bypass of the rafters and additional fastening of the mineral wool.

Thermal insulation of slopes can be done in two ways: over open rafters or between them. In the first version, wooden beams remain visible inside the room and have an additional decorative function.

Advantages and disadvantages of mineral wool

When compared with other thermal insulation materials, mineral wool has the following advantages:

- a wide selection - in the form of rolls, plates, that is, you can choose what is most suitable;

- high moisture resistance, which is important when installing material in the attic;

- high level of thermal insulation due to the low thermal conductivity of the material;

- soundproofing;

- fire safety, since mineral wool is not subject to combustion and melting up to 900 degrees Celsius;

- mineral wool does not shrink and does not deform;

- suitable for both indoor and outdoor use;

- the material is resistant to mold and mildew;

- is not used as food by rodents and insects;

- environmentally safe and non-toxic, it is allowed to carry out insulation with mineral wool for children's and medical institutions.

Along with the advantages, the material has some disadvantages. These include low strength. Mineral wool provides good thermal insulation results only when used simultaneously with a vapor barrier membrane or waterproofing film.

Insulation of a pitched roof

The technology for insulating a pitched roof depends on its structural features, as well as on the purpose of the attic space. So, if the attic is uninhabited, then the insulation is laid on the ceiling (attic floor), and not between the rafters. If mineral wool is used, then the following roof insulation scheme is recommended, a photo of which can be seen on the pages of many specialized publications or sites: walkways are made along the lags of the attic, and a special membrane is laid on the wool layer, which ensures steam removal and fiber filtration. After that, the floor is sewn up with OSB plates, and any floor covering is laid on top of them (useful article: "Types of pitched roofs").

How to properly insulate a pitched roof, see the video:

https://youtube.com/watch?v=C4QOujBaYVQ

In the event that a residential attic is planned, then they resort to a different insulation technology:

Outcomes

For roof insulation with mineral wool, soft glass wool and dense stone wool with a soft end are suitable. Materials are stacked between the rafters. The density of thermal insulation must be at least 55 kg / m.cube, while you should not take too heavy cotton wool, after all, there is an additional load on the rafter system. For flat concrete roofs, heavy and dense rock wool is suitable. It is important to calculate the thickness of the insulation, for this you can use an online calculator, it's easier. In tandem with mineral wool, vapor and waterproofing are used, which prevent moisture from entering and retaining in the heat-insulating cake.

We will send the material by mail

A warm roof is a requirement for modern construction of private, public and industrial buildings. Saving energy resources, the price of which is growing from year to year, is an important component of government programs that form a social package. Therefore, in this article we will talk about roof insulation from the inside with mineral wool. We will tell you how to do this, what additional materials are used besides mineral wool. We will also draw your attention to the important nuances of the installation process.

Insulation of a pitched roof with mineral wool from the inside of the attic

How to make roof insulation with mineral wool from the inside

Roof slopes can be equipped using different technologies, but their design always includes a heat, hydro and vapor barrier layer, as well as a counter lattice that creates a ventilation gap and is used for additional fastening of materials.

Roof mounting technology involves the following actions:

- Waterproofing is laid on the assembled and installed truss system. Most often, high-density polyethylene is used as a waterproofing material, which can protect the roof from both moisture and gusty winds. The waterproofing of the roof is laid from the inside of the house with an overlap of about 20 cm and is attached to the rafters with a construction stapler.

- A counter-rail is installed above the film along each rafter. This element forms a small gap between the film and the roof covering, due to which the structure is constantly ventilated.

- For laying a soft roof, sheets of moisture-resistant plywood are attached above the counter-batten. Before insulating a metal roof, or a roof made of other solid roofing materials, you will need to create an ordinary crate with a well-calculated distance between its elements.

- After the lathing is assembled, you can start installing the roofing.

Mineral wool for the roof of a private house

Choosing how to insulate the roof from the inside of a private house, many prefer mineral wool. It is used when arranging the insulation of flat and pitched roofs. This fibrous material is produced from rock melts. In the building materials market, mineral wool is sold in the form of mats (plates) and roll products. When making a choice, one should take into account its thickness and density.

Among the advantages of mineral wool:

- high degree of thermal insulation;

- incombustibility;

- ecological cleanliness;

- stability of parameters;

- easy installation;

- affordable price;

- soundproofing;

- absence of rodents and microorganisms.

Rigid mineral fiber slabs are used for external insulation of a flat roof structure. Mineral wool with a lower thickness and density is used to insulate pitched roofs.

Insulation using this material requires the arrangement of hydro, vapor barrier and ventilation gaps. These layers prevent moisture from collecting in the insulation. Otherwise, the heat-insulating qualities of the mineral wool are reduced, and decay processes begin in the rafter system.