Process of creation

As a raw material in the manufacture of such material as mineral wool slabs, a melt of volcanic rocks, glass and blast furnace slag is used. This hot, viscous substance is fed into a special centrifuge, in which (as a result of blowing with air) it is converted into pulp. Further, binders are introduced into it. Usually phenol-formaldehyde resins play their role. Further, the sticky "cotton wool" goes under the rollers, forming an even layer of it. At the final stage, the material is cut into slabs of the desired size.

View gallery

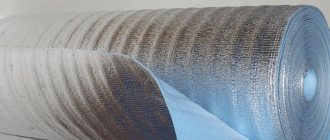

Mineral wool fibers can be arranged both in a chaotic manner and perpendicular to each other. The last version of the material is called laminated, has a high density and degree of thermal conductivity, and is characterized by increased strength. Sometimes mineral wool slabs are glued on one side with thick aluminum foil.

Technical parameters and types

Mats made from mineral fibers differ in technical characteristics that depend on the density of the product, the location of the fiber raw materials and the quality of the raw materials involved.

Experts advise, when choosing a heater, to take into account the specifics of the scope of application, to compare it with the properties of the required product.

Experts advise, when choosing a heater, to take into account the specifics of the scope of application, to compare it with the properties of the required product

As for the variety of slabs for the floor, ceiling and walls, it is represented by slag, glass wool and stone wool. It is worth dwelling on each option in more detail:

- Glass wool is the most affordable insulation in this series. The initial raw material is limestone, dolomite, soda, sand, borax. From all this, fiber is produced in 5-15 microns, reaching 15-50 mm in thickness. The permissible temperature range at which the material is allowed to be used varies from -60 to + 450 ° C. Over time, glass wool can cake, which leads to a decrease in its heat-shielding function. In the process of work, this fragile material breaks down, so it is imperative to use protective equipment. Prevention of glass dust entering the room is ensured by a special vapor barrier.

- Slag wool is distinguished by a low indicator of environmental safety, since it is produced from blast-furnace slag. Due to this feature, the insulation is not recommended for installation inside residential premises. The fiber reaches 4-12 microns in thickness, its length is 16 mm.

- The safest and most effective is the basalt version of mineral wool as a heat insulator. The material does not crumble, does not penetrate into the air inside the room, has high wear rates, is durable and fire-resistant. If phenol-formaldehyde resins are not involved in the production process, basalt slabs can be called completely environmentally friendly. Their significant drawback is their high price.

If we consider the structural feature of the miniplates, then they are distinguished by a chaotic or lamellar arrangement of fibers.

Fire resistance

The main advantage of mineral wool in comparison with other insulators is its incombustibility. It is allowed to use this material for warming surfaces, the temperature of which reaches +400 degrees Celsius. That is why mineral wool slabs are an ideal insulator for boilers and furnaces of various types. Basalt fibers begin to melt only after a two-hour exposure to a temperature of 1000 degrees. This is a very impressive figure.As for the ambient temperature, this material can withstand 750 degrees without harm to itself. The flammability group of mineral plates is KM0. The foil variety has KM1.

View gallery

Slabs

It is convenient to attach stone wool slabs to walls and ceilings. They are often denser, which makes it comfortable to work with - cutting, fixing, plastering. With it, the joints are of better quality. Due to the increased density, the slabs are more resistant to stress, they absorb less moisture. The dimensions of the plates (sheets, mats) are very diverse, therefore, before buying, you need to carefully measure the dimensions of the insulated area. You should also pay attention not only to the dimensions of the slabs, but also to the structural features - some of them have a groove-comb system, which greatly facilitates the installation process. In this version, the heat insulator can be used for insulation:

- Ventilated facades.

- Paul.

- Sten.

- Frame structures.

- As a sound insulator in any room.

Since the plates are packed in a sealed tightening film, you should not be guided only by the volume of the package, you should pay attention to the dimensions of a separate mat. On average, width / length is 1 / 2m. If necessary, sometimes manufacturers take orders for the manufacture of non-standard sizes, but not all.

Minvata in rolls

Minvata in a roll

Such dense stone wool lends itself to cutting and cutting to the desired parameters. Some dimensional characteristics of well-known mineral wool manufacturers:

- Knauf - plate is 1.25 m long, 60 cm wide, 5 cm thick.

- Izover - 1.17 m / 56.5 cm / 5-10 cm.

- Technicol - 1.2m / 60cm / 10cm.

- Rockwool and Ursa have standard lengths of 1 and 1.25 m, and the width and thickness are different.