The protection of the insulation layer in the roofing cake is performed by two types of insulating materials that are different in structure and purpose. Their illiterate use, incorrect selection according to technical indicators, incorrect installation leads to wetting of the thermal insulation and to the loss of the qualities laid down by the manufacturer. As a result, instead of reducing heat loss, wet insulation will increase leaks, in rooms equipped in this way it will be excessively damp and cold.

To avoid the described negative, we will find out how vapor barrier differs from waterproofing, how a roof insulation system is constructed using these protective films.

The subtleties of building a roofing pie

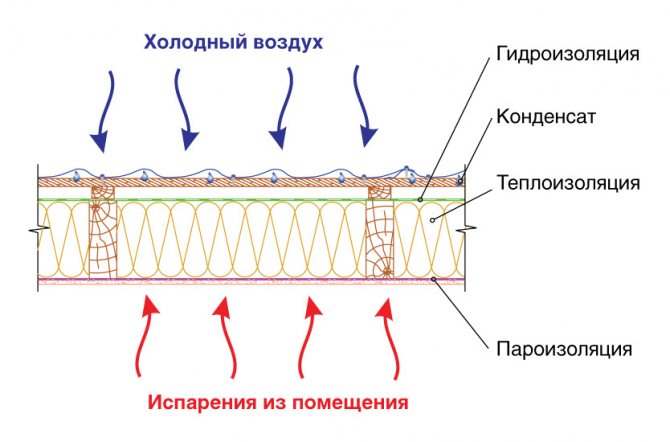

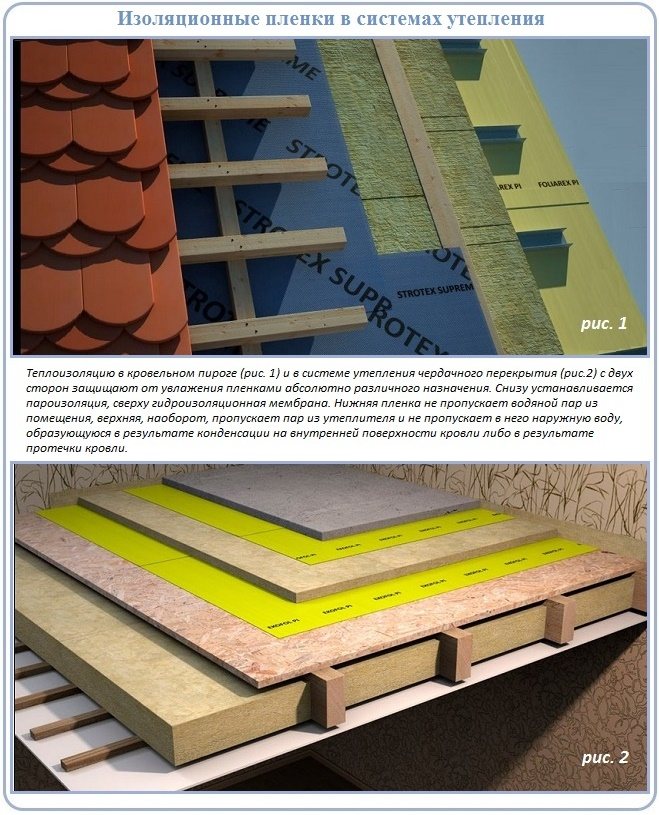

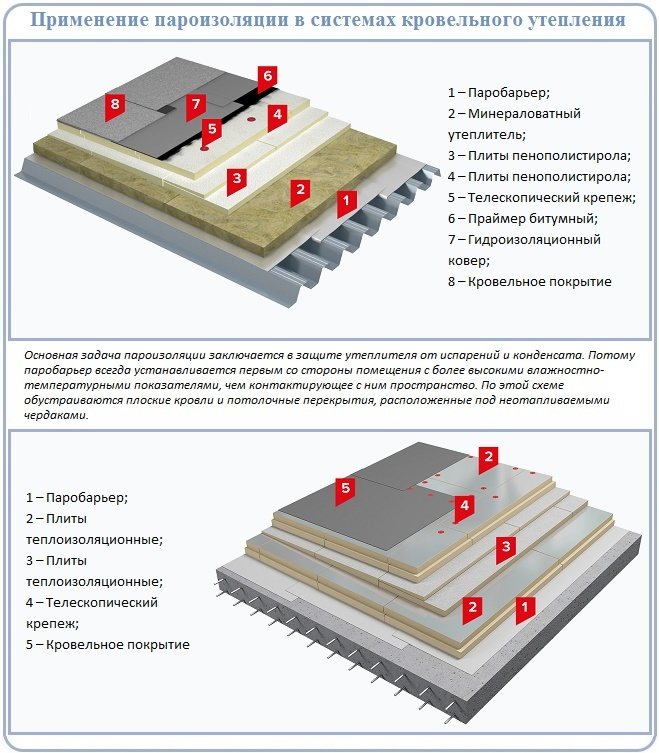

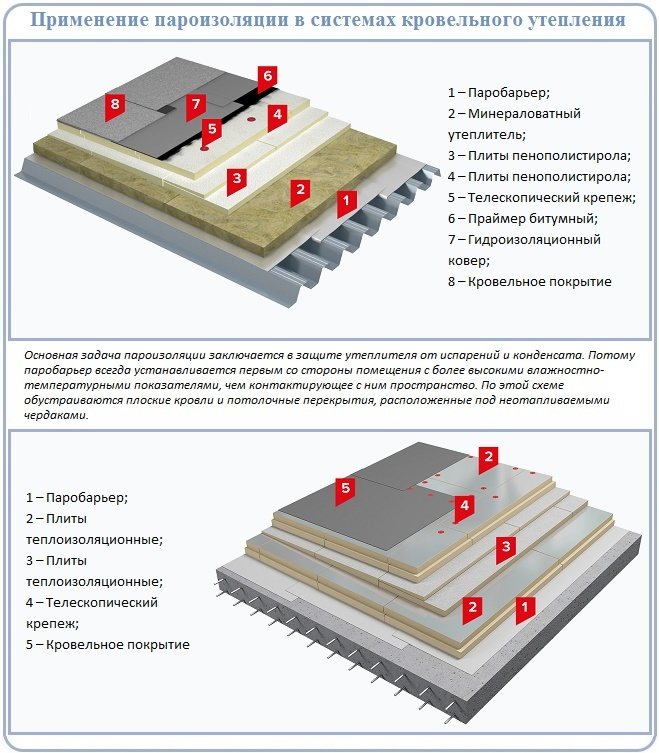

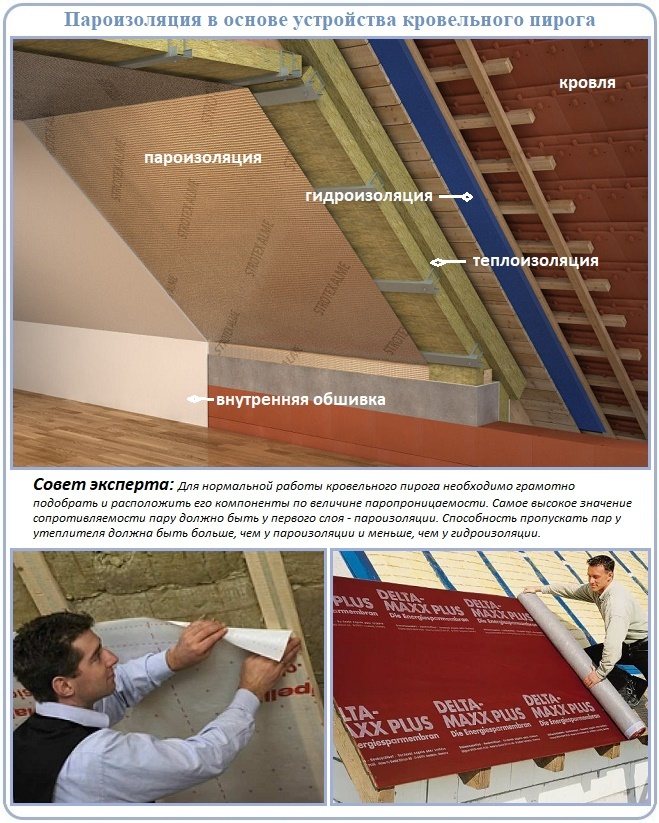

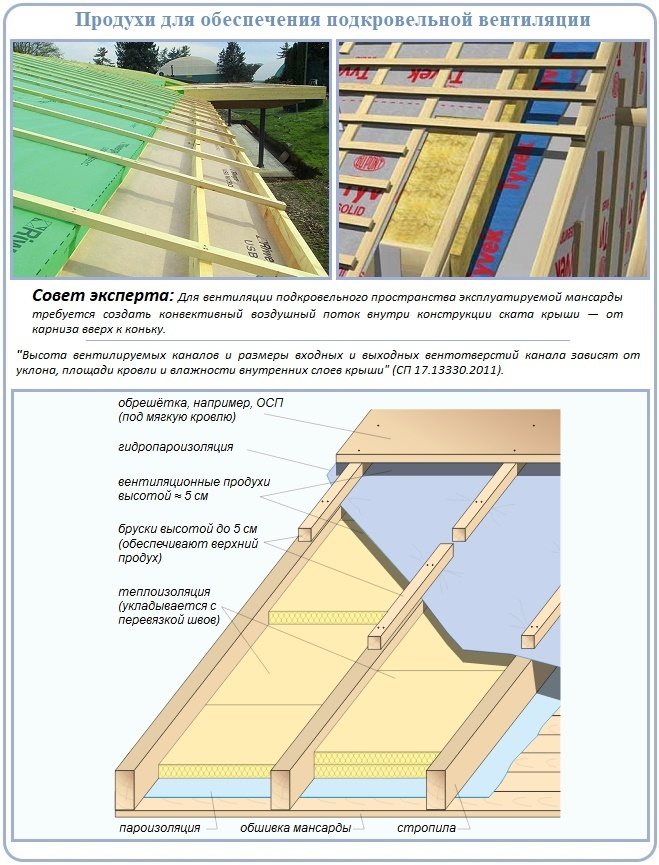

The cake of the insulated roofing system is a multi-layer structure, each component of which is obliged to flawlessly perform the work entrusted to it. Its main component is represented by insulation, to protect it from getting wet from above and below, insulating films are installed, ventilation ducts are arranged.

The upper and lower protective layer of roofing insulation perform different types of work:

- The barrier laid on top protects the thermal insulation from atmospheric water that falls in the form of liquid precipitation and forms when snow deposits melt. This layer is called waterproofing, it prevents moisture from penetrating from the outside of the insulation system, but does not prevent moisture that has adhered from the inside to freely leave the insulation.

- The insulation installed at the bottom protects the insulation from household fumes generated during the operation of premises, during cooking, taking hygiene procedures, etc. This is a vapor barrier designed to prevent steam from entering the thermal insulation layer.

The vapor barrier does not let in at all or allows a minimum of vapor to pass through. The functional purpose of the waterproofing is to conduct the vaporous water coming from below. Hence the difference in structure, and differences in the work performed by the materials.

How to protect the roof from piercing winds?

Now you know what is the main difference between vapor barrier and waterproofing. It is worth mentioning about the materials for wind protection, which will help to eliminate another problem of roof insulation - a strong wind blowing out warm vapors. That is why it is advisable to use windproof films or plates, the main purpose of which is to protect against strong side winds. At the same time, the properties of the windproof material are such that it allows moisture and steam to pass outward, so that you can not be afraid that the insulation will get wet.

The most famous plates are Izoplat, they are very durable, environmentally friendly, reliable. In addition to protection from wind, such material saves walls from freezing, which can also be attributed to the advantages of using wind protection in the house. At the same time, remember that you need to choose what to install - wind protection or vapor barrier, since the combination of these products will lead to the fact that the roof will stop "breathing", and condensate will begin to settle on the insulation.

Naturally, this will negatively affect its characteristics. Therefore, on the side, for example, from where usually strong winds blow, you can install a windscreen, and finish all other parts with a vapor barrier.

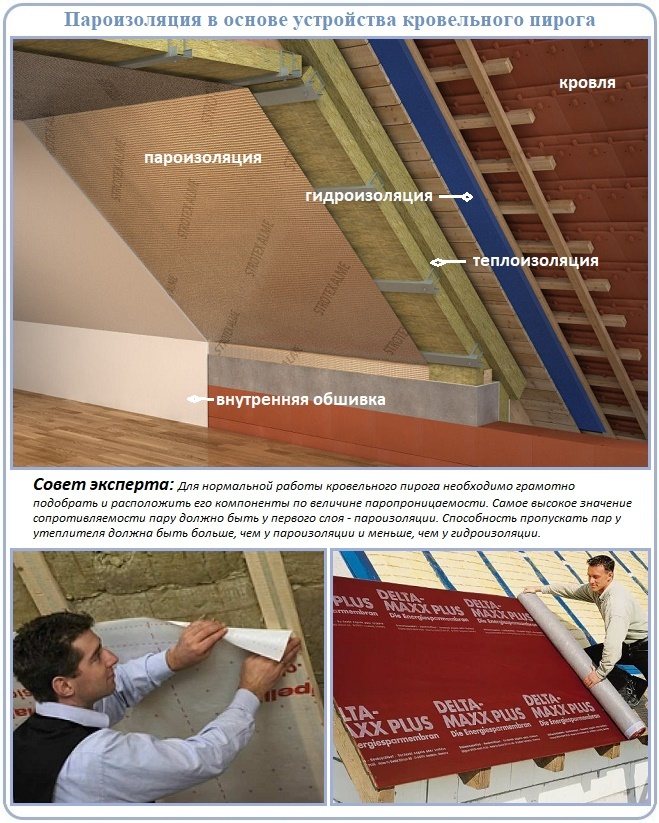

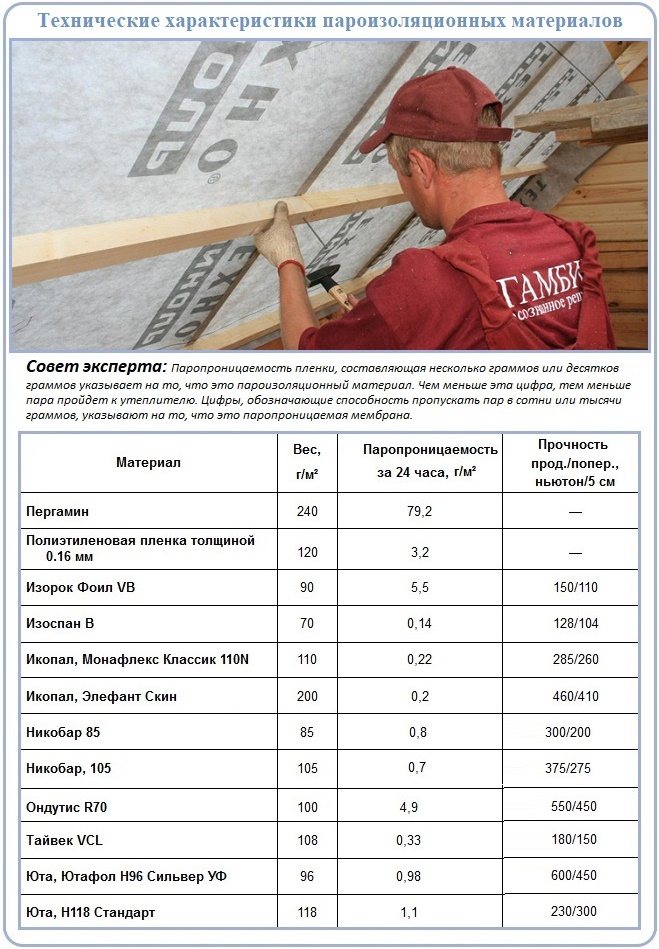

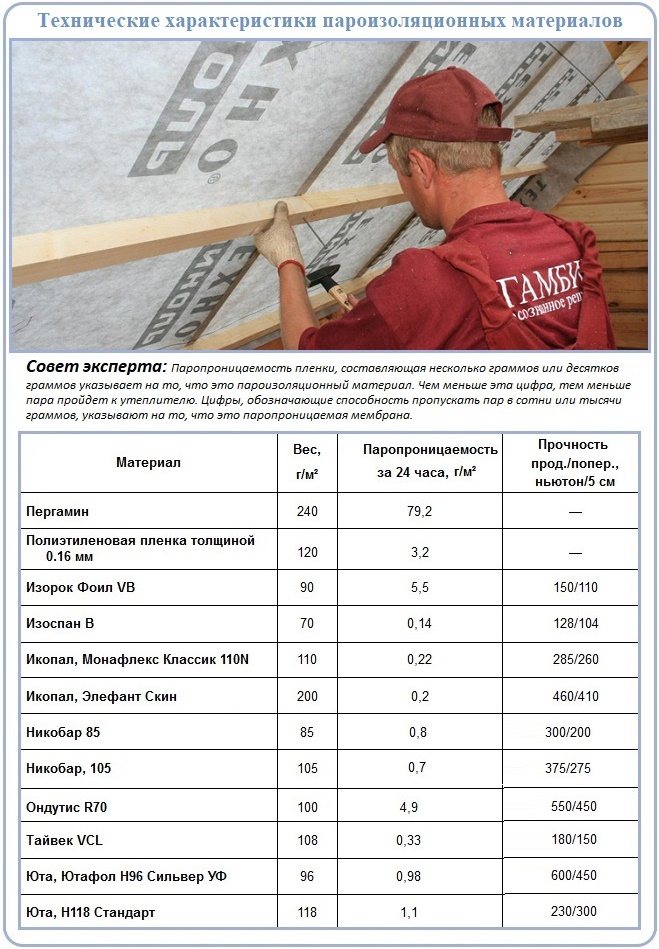

Water vapor permeability as the main indicator

Water vapor permeability is one of the main characteristics of insulating roofing films, influencing the choice and determination of the place for their installation.It is indicated by the manufacturers of materials in the technical documentation, it is indicated in grams or fractions of a gram, which 1 m2 of roll insulation can carry out per day (mg / m² per day).

Based on the ability of protective materials to pass steam, they are divided into two main classes:

- Vapor permeable. Includes all types of waterproofing membranes. The ability to conduct steam is calculated in hundreds and even thousands of milligrams.

- Vapor tight. Includes polypropylene and polyethylene films, anti-condensation membranes. Their ability to pass steam is equal to fractions of a milligram, several units or tens of milligrams.

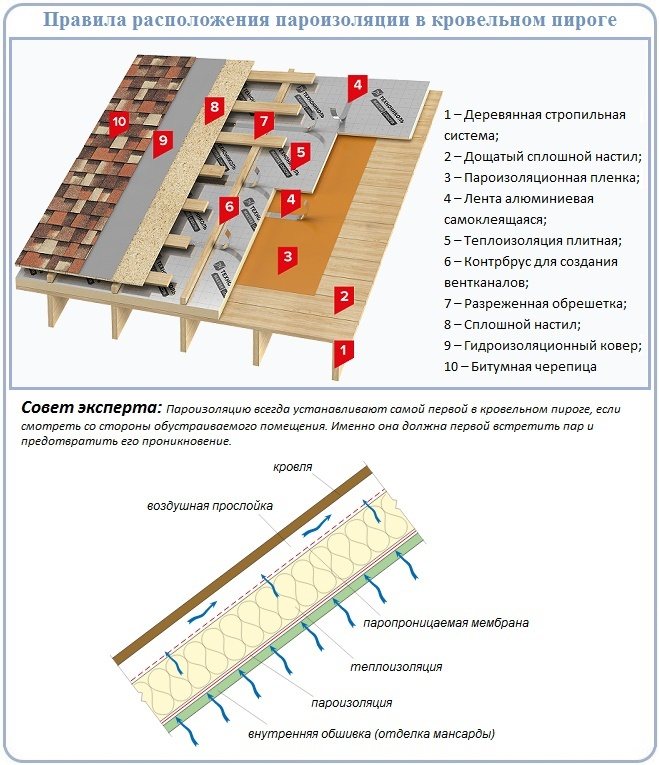

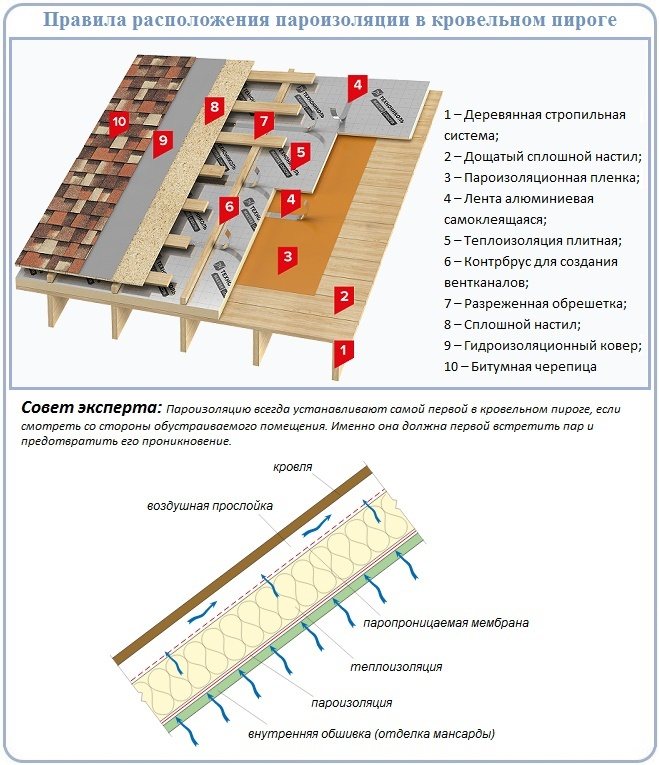

According to building regulations, the components of the roofing cake are selected so that their vapor permeability increases from the inside to the outside. Those. the lowest vapor permeability indicators should be possessed by the lower film.

The insulation should be endowed with more steam permeability than the vapor barrier, but they should be less than the waterproofing. The described structure of the roofing cake is necessary so that all moisture that may be in the thickness of the thermal insulation does not linger there and is freely removed outside the roofing system.

In a well-arranged pie, everything that managed to break through the vapor barrier rushed through the insulation to the waterproofing, which freely passes steam outside the structure, but excludes the penetration of rain drops and melt water into the thermal insulation.

A similar principle is observed when arranging partitions and ceilings installed between rooms with different operating conditions. Simply put, between the heated rooms and the cold attic, a thermal insulation system should be arranged, deployed with a vapor barrier to the dwelling.

If, within one floor, a room with standard operating conditions is adjacent, for example, to a steam room of a Russian bath, then a partition is insulated between them by installing a vapor barrier film first from the steam room.

However, for the flawless organization of the roofing system, it is not enough to divide the materials into classes according to their ability to block or easily part with steam. It is imperative to find out what materials are used as undercoat films, what is the difference between the methods of vapor barrier and waterproofing, how the technology of their laying is implemented.

Types of modern vapor barrier materials

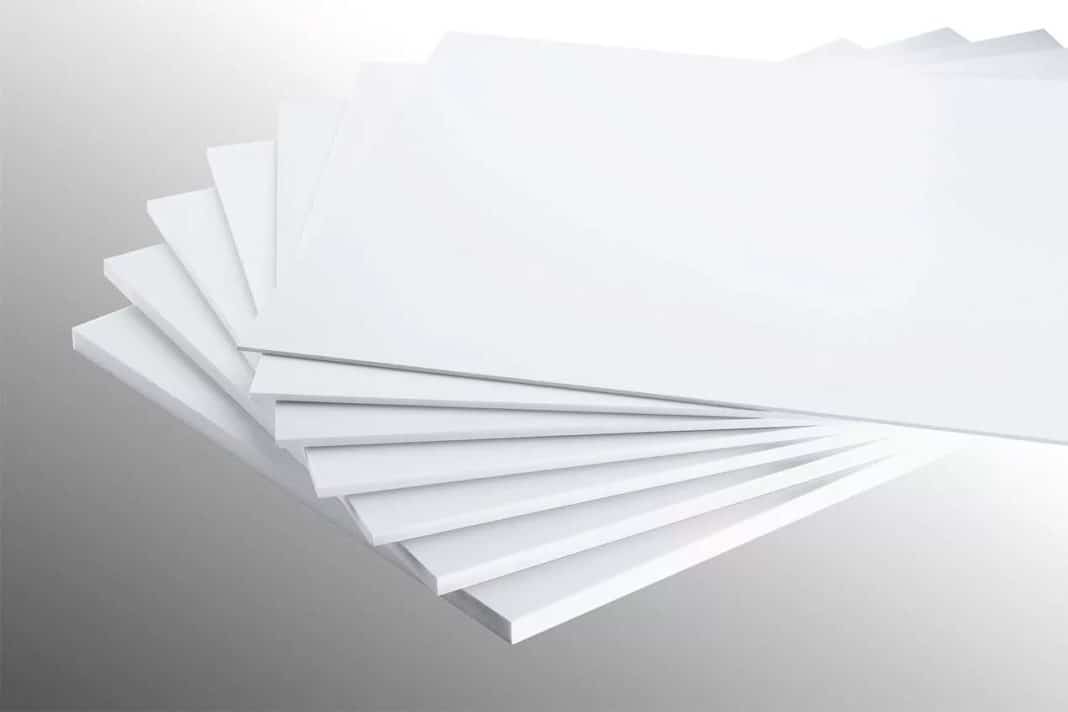

The modern vapor barrier film for roofing is a multilayer material with limited or practically zero diffusion properties.

Note: You can of course use regular HDPE. But given the low resistance to mechanical damage, it is not even recommended to use it when arranging the vapor barrier of the floor. And at the roof, the degree of "responsibility" of this layer of the roofing cake is even higher.

The simplest version of the film contains two layers, one of which has an anti-condensation surface.

The anti-condensation surface has a "rough" appearance and is turned into the attic

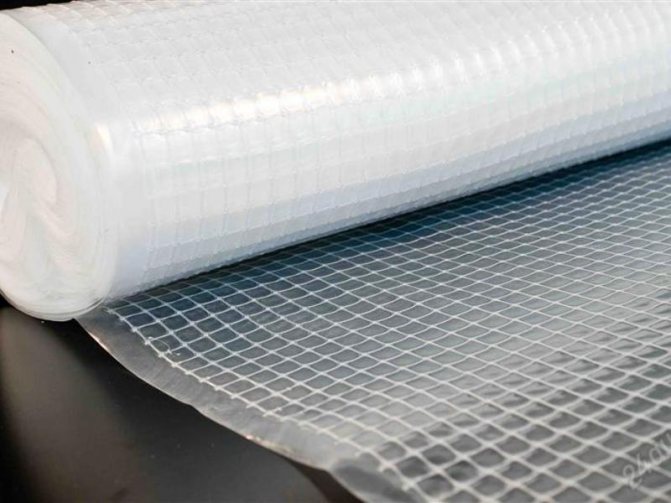

Reinforced films in their structure also have a reinforcing layer - a mesh of durable polypropylene threads. This type of vapor barrier belongs to the Standard category. And for example, the Utah company offers a special type of Yutafol Special vapor barrier with improved fireproof properties, which in its composition, as a third layer, does not have a reinforcing mesh, but a self-extinguishing reagent.

And the last option is three- and four-layer films with a heat-reflecting surface. In this case, the vapor barrier gets one more additional function - energy saving.

Types of vapor-tight options and their characteristics

Previously, the only vapor barrier option was glassine, which passes on average about a hundred mg / m² per day. For the construction of a vapor barrier from it, the roofer had to show miracles of dexterity, because the material was easily damaged during installation. There was a problem when connecting strips of glassine into a single canvas and when wrapping structures of an uneasy shape.

Glassine was replaced by polyethylene, later polypropylene, more precisely, a film made of it, was introduced into the vapor barrier sphere. It was they who became the basis for the development of an extensive line of polymer membranes used in vapor and waterproofing. The new generation of insulating materials is ahead of its predecessors in terms of strength, UV resistance and unstable temperatures.

The list of polymer vapor barrier types includes:

- Foil membranes... Materials with a metal sheath arranged on the working side. They are used in the arrangement of hygienic premises requiring the preservation of the temperature obtained during heating: saunas, steam rooms. The foil surface can serve as a reflector of heat waves if a gap is left between it and the skin without ventilation.

- Anti-condensation films... Roll materials, one side of which has a rough texture, the other is smooth. A rough surface excludes the formation of dew on the vapor barrier, a smooth surface prevents the return flow of moisture that has penetrated or formed in the insulation.

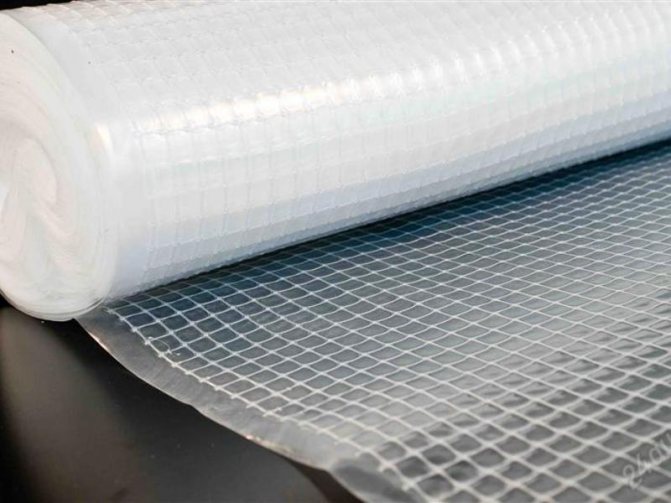

- Films made of polypropylene and polyethylene... Most often, these are reinforced analogs of outdated polyethylene and polypropylene options. They are used in budget construction, although at a price per 1 m2 they do not differ too much from new polymer vapor barrier materials.

Vapor barrier materials with a vapor permeability of several tens of mg per 1 m2 per day are still used in thermal insulation systems for cold attics, insulated with backfill material, for example, expanded clay. If there are real restrictions in the construction budget, then this type can be used in the arrangement of heated attics.

However, the difference between the cost of polyethylene with propylene and membrane barriers is such that there is little sense in such savings. In addition, new types of vapor barrier protection are much stronger, they are difficult to damage if carelessly moved during installation. Anti-condensation membranes serve almost as long as roofing, i.e. during the entire operation of the roof, it will not be necessary to carry out major repairs.

The structure of vapor barrier films

Vapor barrier differs from waterproofing mainly in that both sides of it are completely waterproof. Vapor barrier should not allow steam or water to pass either outside (into the house) or inside the insulation.

The cheap version of such a film can be attributed to ordinary polyethylene. However, it is not recommended to use it as a vapor barrier for the roofing "pie" due to the fact that under the roof, especially in summer, the film will be very hot, which will lead to its stretching and possibly damage. And since we cover the roof for more than one year, it is optimal to use a film of several layers with a polymer reinforcing frame, which prevents the film from stretching.

Sheathing the inner surface of the attic roof with a foil-covered film on one side will cost a little more than using various types of vapor barrier materials, however, in addition to creating a reliable vapor barrier, it will also be possible to retain heat in the house. The installation of this film is carried out with a foil surface inside the room, which contributes to the reflection of infrared radiation from it, with which the bulk of the heat from the dwelling evaporates.Thus, the use of such a vapor barrier allows you to kill two birds with one stone, reducing heat loss through the roof of the house to a minimum, which in turn will allow you to save quite good money on heating.

Before buying any film, be sure to make sure that it is vapor barrier, as evidenced by the inscription on the package.

Properties and types of vapor-permeable membranes

The main difference between polymer membranes for waterproofing and materials for vapor barrier is that they freely let out steam and condensate formed in the thickness of the insulation due to the difference in temperature indicators under and above the insulation system. A material has not yet been invented that can prevent the appearance of moisture in thermal insulation. However, there are technologies that allow you to get rid of water in the roofing cake, and materials for the implementation of such schemes.

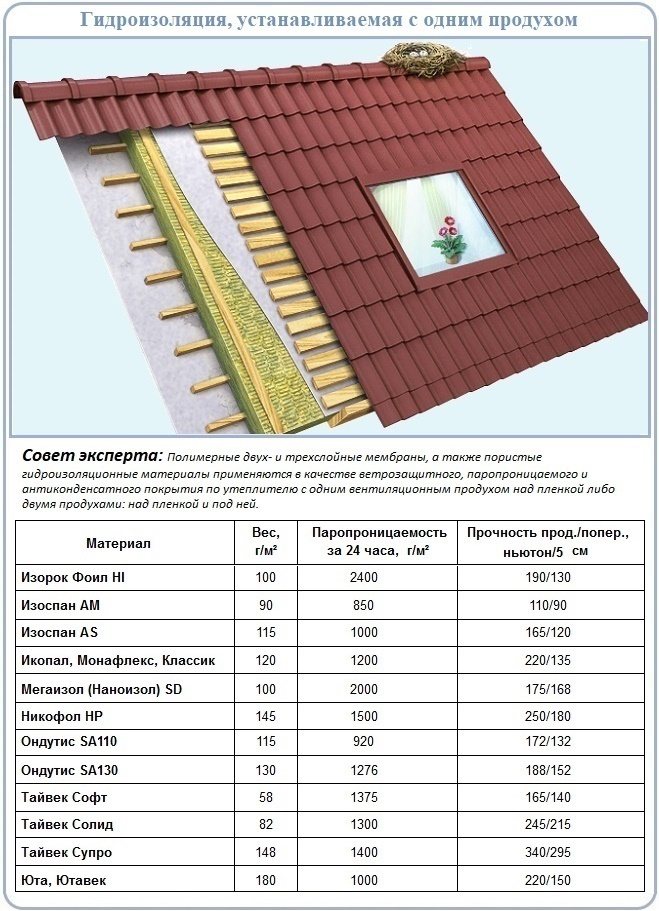

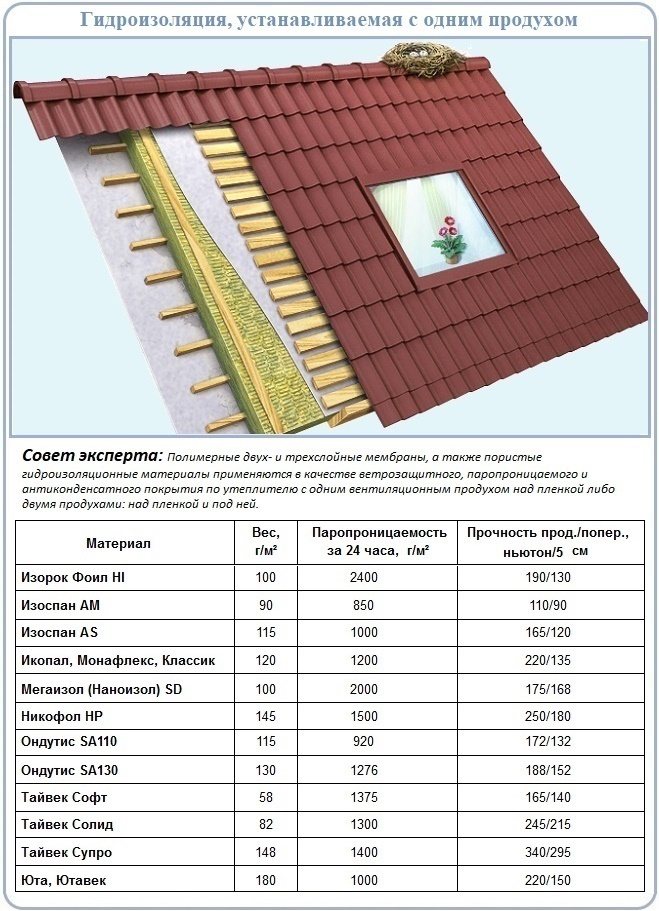

As already mentioned, waterproofing is placed on top of the insulation. Place it under the roof. Between it and the heat-insulating layer, a ventilation gap is arranged or not, depending on the material used in the organization of the system.

The types of vapor-permeable, otherwise called vapor-transparent materials that are in demand in construction include:

- Perforated Films... Roll materials with specially shaped holes that allow steam to escape, but do not let water through from the outside. They serve mainly as insulation of ramps above cold attics, because cannot fully perform waterproofing and windproof functions.

- Porous membranes... Materials with a fibrous structure, similar in structure to a filter. The vapor permeability indicators of this type depend on the pore diameter and the ability of the fibrous tissue to transmit vapor. This type of waterproofing is not used where there is a possibility of clogging of pores from excessive dust content.

- Superdiffusion membranes... The thinnest multilayer membrane systems, each layer of which does a specific job. There are no holes in their structure that can be clogged with dust, therefore the materials of this group have the highest resistance to all kinds of pollution.

Super diffuse membrane insulation is available in two or three layers. Two-layer varieties are inferior to three-layer brothers in terms of strength, because one of the reinforcing substrates has been removed from their structure. In terms of cost aspects, both options are not very different, therefore, if possible, it is better to choose a three-layer material.

Porous and super diffusion materials, together with waterproof duties, play the role of wind protection. They prevent the winds from "washing away" the heat from light fibrous wadding insulation. Perforated films do not do this work, therefore, when using mineral wool for insulating slopes, they require an additional windproof carpet, which sometimes nullifies the initial savings.

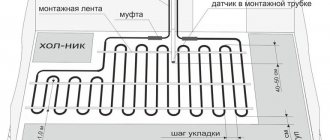

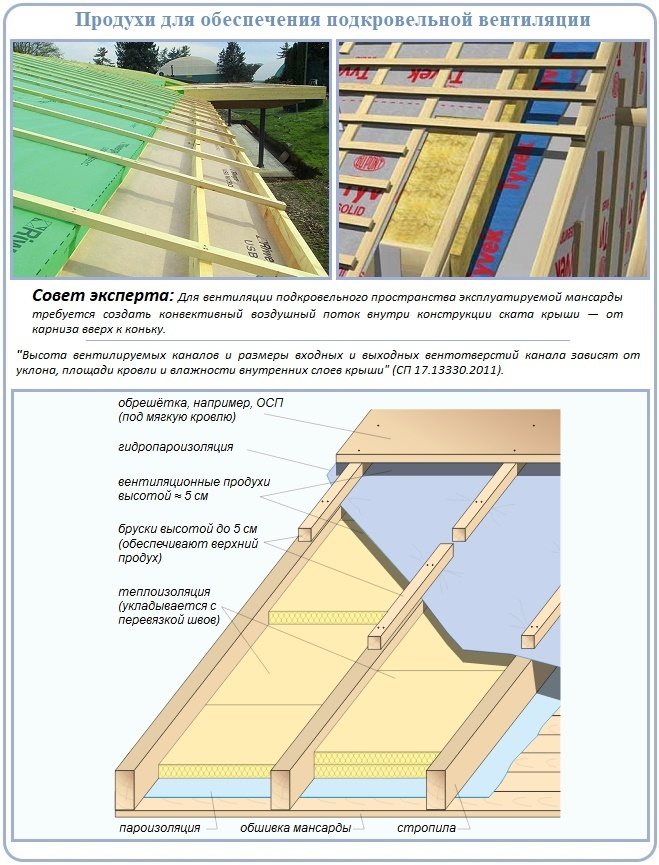

The installation of under-roof waterproofing must be accompanied by the device of a ventilation system, which is:

- Sibling... Predetermining the organization of ventilation ducts, air vents, between the waterproofing barrier and the roof covering. It is arranged using superdiffusion and porous membranes, which are not forbidden to come into close contact with any type of insulation.

- Two-tier... Assuming the organization of two levels of vent. channels located between the thermal insulation and the hydro-barrier, then between it and the coating. the scheme is typical when using perforated films

Air - ventilation ducts located parallel to the pitched roof are arranged by installing a wooden slat with a wall height of at least 4 cm. For a two-level system, the river is fixed in two tiers: above the insulation and above the waterproofing. The lathing formed with its help at the same time fixes the roll insulation, and also serves as the basis for laying the roof or solid flooring for soft types of coatings.

Purpose of waterproofing

The main task of the waterproofing layer is not to let water inside the enclosing structure (from the street, groundwater, water leakage in the room). Consider application examples:

- The enclosing structure is a roofing pie. In this case, the main waterproofing layer that provides protection against direct rainfall is roofing material (slate, metal, and others). This is followed by additional protection against moisture. For example, a layer of waterproofing film or membrane.

- Basement, ground floor. To maintain an optimal microclimate and protect against moisture ingress, it is necessary to create a barrier between the structure and the soil in contact with it. By treating the outer surface with special waterproofing compounds or fused materials, you can protect yourself from the effects of groundwater.

- Indoor areas in contact with water. These include the kitchen, bathroom, toilet. Unlike basements, where they struggle with moisture from the outside, in this case, using waterproofing materials, they try to prevent unwanted water from entering other rooms.

The nuances of laying under-roofing films

We found that waterproofing materials covering the cake from atmospheric negativity can be installed with one or two ventilation gaps. They are needed so that moisture does not accumulate in the multilayer roofing system, but is freely removed by the air flow through the vents formed by the slats.

An equal function is performed by ventilation gaps accompanying the installation of vapor barrier films. Regardless of the structure and composition of the material, they are installed with two tiers of ventilation located on both sides of the vapor barrier. Due to its low vapor permeability, this layer requires enhanced ventilation.

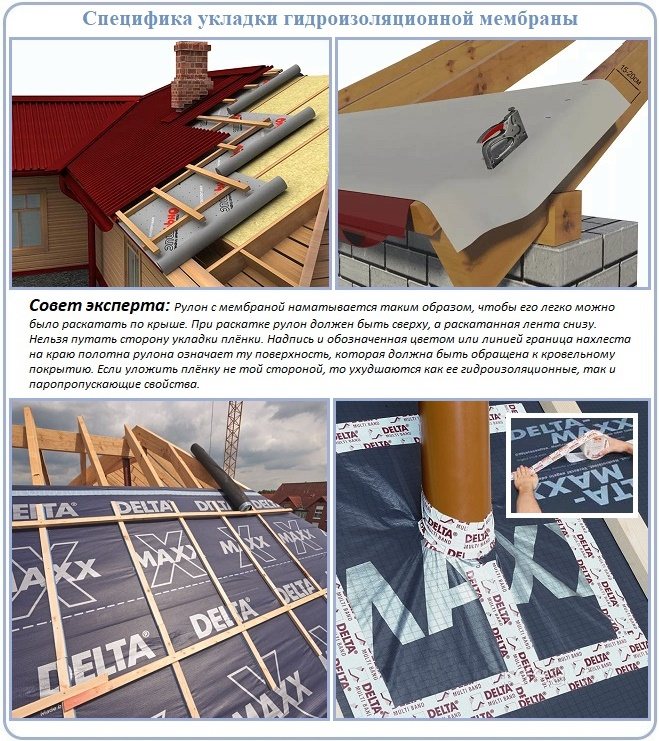

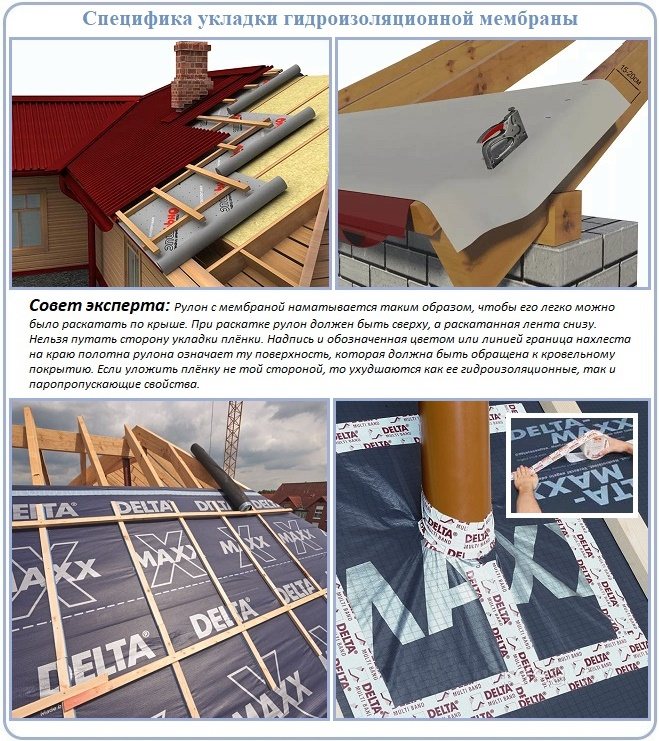

Most roofing films do not stretch under tension. Therefore, they are laid on the rafter frame so that the roll insulation sags somewhat in the space between the rafters. The slack is necessary to prevent the material from cracking under tension during the standard movement of wood systems.

The sheets of waterproofing are spread depending on the steepness of the structure. On steep roofs, the material is laid along the rafter legs; on flat roofs, it is placed parallel to the ridge run. The vapor barrier strips are installed exclusively parallel to the ridge.

The strips are laid with an overlap, the size of which is indicated by the manufacturer of the insulation product. On the rolls, the side according to which the strips are to be installed must be indicated. It is strictly forbidden to change sides, because as a result, the steam and water insulation properties will change.

When installing a water protection, laid parallel to the ridge rib, they start from the line of the cornice. For proper arrangement, the edge of the starting waterproofing strip should protrude from the edge of the cornice by 10 cm at a minimum. It is then taken out under a drip or cornice bar. The strips are laid so that the overlap of the upper panel overlaps the edge of the lower one.

The construction of a vapor barrier begins from the ridge rib. Each next panel must overlap the edge of the previous one. If you follow the described technique in the device of both types of insulation, a minimum of water gets into the insulation.

Installation features

After installing the rafter system, waterproofing is attached, then the roof sheathing and the roof itself. Insulation is placed between the rafters, and laying the vapor barrier on the roof is the penultimate stage of its arrangement. The next is the lining (finishing) of the attic space.

To create a continuous sealed vapor barrier, the film is installed from the bottom up with an overlap of adjacent panels by at least 15 cm.The same principle is followed if it is necessary to increase the length of the canvas. Fasten the film to the rafters (or crate) with a stapler or nails with a wide head.

Joints and mating points with adjoining surfaces are additionally glued with a sealed vapor barrier tape. To do this, use a tape 10-25 mm wide with a butyl rubber or acrylate double-sided self-adhesive layer.

The Ondulin company produces a vapor barrier film, which already has a self-adhesive layer located from the edge of the panel at an overlap distance

First, the release paper is removed from one of the sides and applied to the lower strip of the vapor barrier. Then, with an overlap, the upper strip of the vapor-proof film is attached to the lower one, the release paper is removed from the other side of the tape, and the strips are pressed against each other. When gluing the roof vapor barrier to adjoining fences and structures (concrete, brick, metal or plastic), their surfaces must be free of dust and dirt.

The final fixation of the vapor barrier to the rafters or to the lathing of the inner sheathing is carried out using wooden slats or a metal profile.

For the anti-condensation or reflective surface to function properly, a gap is required between the vapor barrier film and the finishing cladding. If the finishing is carried out with wall panels, then a rail with a section height of 4-5 cm is used for the lathing.

A slat or board on top of a vapor barrier also serves as a batten for the inner lining of a residential attic

When sheathing an insulated attic with plasterboard, the gap is set using a direct suspension (the height of the side of the CD ceiling profile is insufficient - only 28 mm).

From the video you can learn about the installation of a vapor barrier:

It may be interesting! In the article at the following link, read about the modern "House of the Earth".

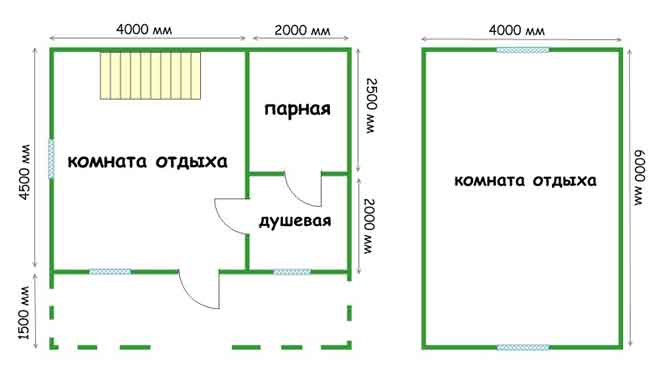

Important requirements for the premises of the bath

In order for the bath to become a favorite vacation spot, you need to take into account a number of certain nuances during its construction.

Steam room

- The size of the steam room should not be large, otherwise it will be difficult to heat it up and maintain the required temperature in it for a long time. In this case, it is important to take into account the length of the bench - it should be convenient for each member of the family. Often the length of the bench is made about 2 meters, and the size of the steam room is from 2.5 by 2.5 meters to 3.5 by 3.5 meters.

- The ceiling height in the bath should not be lower than 2.5 meters so that you can raise your hands in the steam room, as well as to maintain the correct volume of the steam layer - otherwise the steam layer will be unstable.

- The entrance door to the steam room should have a threshold 25–30 cm from the threshold of the entrance door to the bath. Or the floor height in the steam room should be 25–30 cm higher than other rooms in the bath. What for? So that cold air from the dressing room does not "flow" into the steam room. And the width of the door to the steam room to preserve heat is best done no more than 60 cm.

- Flow ventilation must be provided. This can be a window in a steam room, an exhaust vent, or a view in a chimney. The window in the steam room should be no higher than 1 meter from the floor and 40 by 50 cm

Banya broom.

If heating is planned in the bath only from one stove, then all rooms should touch it, or, in other words, adjoin the stove.

It is desirable that the firebox of the stove goes into the vestibule. This will allow you not to carry dirt, bringing in firewood and taking out combustion products, and will also give an additional flow of oxygen to the stove, the firewood will burn better.

Restroom

There must be at least two doors to the recreation room from the steam room. Otherwise, it will be damp, the steam from the steam room will cool and settle in this particular room.

The presence of a washing room in the bath is not necessary. However, if it is provided for by the project, there must necessarily be a window for ventilation. The recommended window size is 60 by 60 cm.

Many bathhouse owners believe that if the relaxation room is furnished with upholstered furniture, then it is worth adding a dressing room with a bench and a hanger.Or you can equip a dressing room in the washing room, and dry yourself in it is a matter of taste. If you abandon the changing room, then you can increase the area of the rest room.

Tambour and toilet

Tambour is one of the most controversial places in the bathhouse. Someone does not need it, but someone considers two doors and a microtambour between them sufficient. Often its presence is dictated by the habit of taking a steam bath in winter. To use the bath in the cold season, it is better to include the vestibule in the plan.

There is also no consensus on how much a toilet is needed in the bath. Again, a lot depends on whether the bathhouse will be used in winter or not, whether it is a separate building or combined with the main house, on the wishes of the homeowners, and also on whether the bathhouse will also serve as a guest house in the winter season.

Comfortable rest is the main goal of building a bath.

Warmth warm, but in the bath you also need to breathe with something! To ensure the flow of fresh air, it is necessary to arrange supply and exhaust ventilation in the steam room. To control the conditions in the steam room, a thermometer is installed (at the level of the head of a standing person, strictly not mercury) and a hygrometer that measures the humidity of the air. It is useful to have an hourglass in the steam room.

The washing room is usually equipped with a sink and shower, and, if desired, a bath or a hot tub with cold water. Well, further modernization is limited only by your imagination!

Differences in the installation of hydro and vapor barrier

Given the difference in the structure and properties of these materials, they should be fixed in different ways. To avoid mistakes, it is recommended to watch the video: insulation, waterproofing, vapor barrier - these are 3 layers of a properly equipped thermal insulation "pie". All mounting options should be considered:

- Roof. First of all, moisture protection is attached to the rafters. The waterproofing strips are overlapped. This increases the reliability of the coating. In addition, the waterproofing is fixed with construction tape. The vapor barrier is installed last. The principle of its fastening is similar to waterproofing: the strips are overlapped, fixed with tape.

- External insulation. The waterproofing is installed from the street side after the thermal insulation has been installed. In this case, the vapor barrier is not always laid.

- Internal insulation. Waterproofing is applied to thermal insulation in rooms such as bathrooms, kitchens. For example, if a heater is installed on a concrete floor, first the moisture protection is attached to the ceiling, then the thermal insulation is fixed, and from the side of the room it is closed with a vapor barrier.

When installing the foundation, it is not necessary to use both materials. Enough moisture protection. It must be remembered that the heat-insulating "pie" will suffer first of all if the vapor- or waterproofing membrane is laid on the wrong side. In rooms where the roof or ceiling is protected by a vapor barrier, it is recommended to equip a ventilation system, since a significant part of the steam will remain in the room in the form of moisture.

Create door and window openings

There are two fundamentally different schemes used to create doors and windows in a wooden bath:

- Windows and doors are created after the construction of the bath. In this case, at the stage of laying the crowns, it is necessary to leave gaps that correspond in size to the products to be installed (for more details: “Which windows for the bath are better to choose - the pros and cons of the options”). When the bath is built, using a chainsaw, suitable openings are cut in the right places.

- Windows and doors are prepared in advance. This method is much more complicated, since its implementation will require special grooves and beams with end cuts.

How to choose a stove?

One of the most optimal ways to acquire a bath is its turnkey construction. You can choose a developer using the advice of friends and acquaintances. Reviews about the company on the Internet are also important.But do not forget that the presence of only positive reviews is alarming, because negative ones can be removed by the company itself.

Another way to choose a developer company is to see and touch the bathhouse built by him in real volume. This opportunity is provided by the exhibition "Low-rise country". Arriving here, you can evaluate the quality of the construction of a bathhouse and even consult on lending with banks - partners of the exhibition.

Examples of baths in real size can suggest new ideas, make a general impression and deal with their own requirements for a bath. And then arranging soulful bath evenings with friends, you will relax and have fun, and not regret the shortcomings of the bath.

Read later

We will send the material by mail

The author of the article

Designer-architect, landscape designer and blogger

Alexey Kondratyev

The heater stove should take up little space, quickly warm up the steam room, and keep the accumulated heat for a long time. For a small family bath, brick-lined metal stoves are usually used. The base of such a stove should rest on a metal sheet 2-3 mm thick, under which asbestos cardboard is laid to protect the floor from high temperatures.

Hot heart of the house: which stove to choose for a summer residence? Read the article {amp} gt; {amp} gt;

The choice of films for vapor barrier

- The surface of the film has a double-sided waterproof surface. The most inexpensive option for this material is regular plastic wrap. It is often used in home gardens to cover garden beds.

- It is highly undesirable to use it to create a vapor barrier layer, only in extreme cases. It expands and collapses under the influence of heat.

- Therefore, a more optimal option for creating protection against steam and moisture is a multilayer film with a frame. It performs the function of reinforcement, preventing the film from deforming and sagging. The multi-layer design ensures a long service life.

- The best option for creating a vapor barrier would be to use a foil film. During installation, the foil layer should be directed towards the roof.

Vapor barrier materials are based on a film

Wall insulation

Whatever fence thick walls using expensive materials, it is quite advisable to use insulation for their construction. Fortunately, the choice is great. This is where the rule of breathing walls is important. When the accumulated moisture from the room will be easily discharged outside, thereby not causing damage to the main structure, and from the outside will not penetrate inside. In addition to the permeability, the walls must protect from the wind and keep warm. Very often, saunas and baths are built into houses, in order to protect the walls from destruction by dampness, vapor-proof materials are used; for such cases, anti-condensation membranes with a foil side are better suited. This protection will keep the warmth inside the room and keep moisture out. Glassine was widely used for walls earlier, but due to its fragility, it is not convenient to install. Today, polyethylene, polypropylene, and anti-condensation films are increasingly used as vapor insulators. They are more resistant to UV rays and unstable temperature conditions. Anti-condensation films are produced with a double texture, on the one hand it is smooth, protects from external moisture, and on the other, rough - absorbs moisture. After using such films, it is enough to decorate the walls with decorative plasters or other building materials to acquire an aesthetically finished look.

Roof and wall vapor barrier. Where is it installed and why is it needed?

To understand this, you need to add a little theory.

Let me remind you that the task of this article is to explain "on the fingers" what is happening, without going into physical processes, partial pressure, molecular physics, etc. So I apologize in advance to those who had five in physics.