Heated rooms are characterized by a partial vapor pressure, the values of which exceed atmospheric pressure. According to the laws of physics, steam seeks to escape through the holes. Wall structures and ceilings become steam escape routes. This process stops when the thermal insulation layer is installed. Any thermal insulation will contribute to the formation of condensation. But in the cold period of the year, a “dew point” is formed in the steam outlet zone - a place where condensation and settling of drops in the form of moisture occurs. This phenomenon becomes the reason for the moisturizing of the structure itself and the insulation during the entire autumn-winter period. To protect all the building envelopes, including the upper floor, a competent device of effective vapor barrier is required.

House ceiling vapor barrier: is it necessary?

For such premises as a bathroom, a bathhouse, a sauna, the problem of the correct vapor barrier device is one of the main tasks of forming the correct microclimate. You can read more about the rules for the vapor barrier of the bath ceiling here.

Partial pressure is the pressure that the gas would have in the absence of other components of the mixture.

The vapor barrier of the ceiling of a wooden house helps to solve several important problems:

- increase the service life of roofing materials;

- protect the structural elements of the house from the formation of mold and mildew;

- prevent heat leakage through cracks;

- do not sustain combustion.

A properly installed vapor barrier made of modern membrane materials does not require additional maintenance during its entire service life.

Insulation of the attic floor on wooden beams: materials and stage-by-stage installation

Interfloor and attic floors on wooden beams are much cheaper than reinforced concrete slabs, so they are installed more often. If the attic is cold, then the ceiling must be insulated.

Insulation of attic floors using wooden beams does not require high qualifications and can be done by hand

Next, we will figure out how and how to insulate the attic floor, and most importantly, I will tell you about gross mistakes when choosing a material and carrying out work.

How to put a vapor barrier on the ceiling

The presence of a vapor barrier in a wooden house is an indispensable condition for the long-term preservation of floors. With an ideal assembly of a log house without gaps, condensation accumulates much faster than in a panel house. The vapor barrier layer can be installed both during the construction phase of the building and during the renovation period.

Preparatory work for the vapor barrier device:

- cleaning the surface from debris and dust;

- putty of existing gaps using special compounds;

- primer;

- drying.

Vapor barrier installation steps:

- The vapor barrier material is laid on the ceiling surface with an overlap with a wall vapor barrier (the overlap is 200 mm) and fixed to the ceiling with a stapler.

Ideally, thin slats are laid at the joints of the canvases.

- To obtain strong joints, a special waterproof tape is used.

It is important that the vapor barrier material covers the ceiling in a continuous layer without gaps.

- The layers on the ceiling are joined with an overlap of 100 mm. The material should lie freely, without tension. Experts advise to do even some slack so that the vapor barrier does not break through with sudden temperature changes.

- When laying insulation on the ceiling, it must be remembered that it is not allowed to pierce the vapor barrier with nails. Therefore, a frame system for laying heat-insulating material is used, which makes it possible to avoid damage to the vapor barrier.

And also you can watch an informative video about the vapor barrier of the ceiling:

Ceiling vapor barrier materials

The modern building materials market offers high-quality, environmentally friendly samples of vapor barriers with high fire resistance rates.

- The cheapest, but also the most primitive option is polyethylene and glassine, which create an uncomfortable indoor climate due to the lack of air circulation. In addition, these materials are subject to rapid wear.

- One of the most common methods for constructing a vapor barrier is to use a paint vapor barrier. For this purpose, cold asphalt, bitumen-kukersolny, bitumen-lingo-sulfonate mastics, hot bitumen mastics, rubber and polyvinyl chloride varnishes are used.

When the treated layer is adjacent to the vertical surface, it is also coated with mastic by 100-200 mm.

- Membrane films with limited vapor permeability are designed for controlled removal of excess moisture from the room. The moisture removal limit is set by the membrane itself.

- Membrane film with variable vapor permeability for dry and humid air. With increasing humidity, the throughput of this material increases.

- Membrane films fitted with aluminum foil. These materials have a reflective function and enhanced vapor barrier properties. In addition, this film also performs an additional function - it reflects and returns part of the thermal radiation to the room. Such membrane vapor barrier is widely used in baths, swimming pools, saunas, bathrooms.

Are you building a bathhouse? The vapor barrier of the ceiling in the bath is an important process that you can carry out yourself. In our article, we have collected all the information necessary for this.

The vapor barrier of walls is a complex process, the implementation of which must be carried out according to certain rules. Read here instructions on vapor barrier walls and which materials are preferable.

What to choose for do-it-yourself ceiling vapor barrier

Modern manufacturers offer a wide range of vapor barrier materials, which are often capable of performing several functions at once:

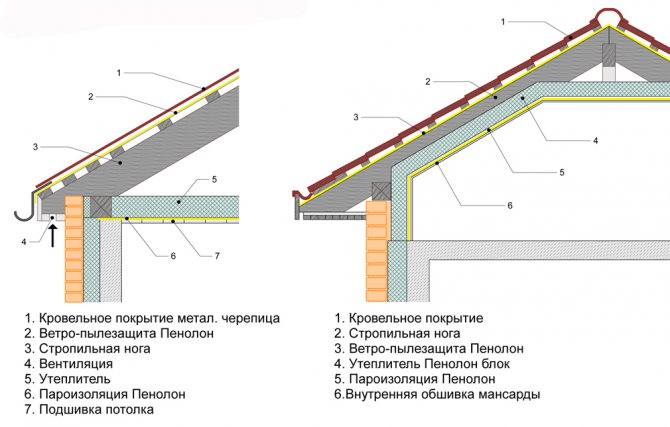

- "Penofol" is a material that can be used for heat, hydro and vapor insulation. It is a multilayer composite consisting of foamed polyethylene, covered with aluminum foil on one or both sides. "Penofol A" is equipped with a foil film on one side, "Penofol B" - foil on both sides, "Penofol S" on one side has a foil surface, and on the other self-adhesive. Such a variety of modifications allows you to choose the material that is most suitable for a particular case. When joining, the layers can be stacked on top of each other or joined using a special self-adhesive aluminum tape. If it is necessary to obtain exclusively heat-insulating properties, with the possibility of increased steam permeability, perforated "Penofol" is used.

- "Armofol" is a material foiled on one or both sides, made on the basis of a glass mesh. On the one hand, some modifications of "Armofol" can have a self-adhesive layer. This multifunctional material, like Penofol, is used for heat, hydro and vapor insulation of ceilings, mansard rooms, baths, saunas, and bathrooms.

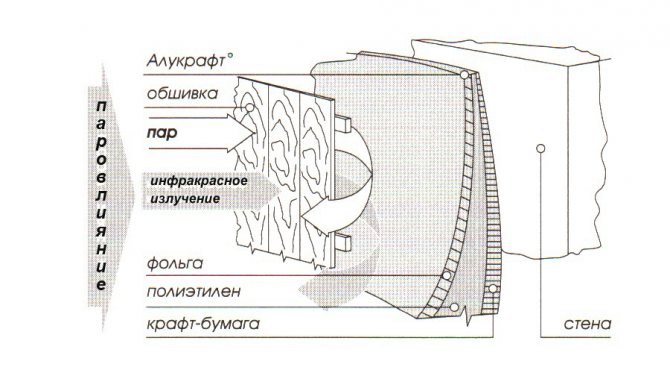

- "Alukraft" is a three-layer material consisting of foil, polyethylene and kraft paper, and is intended for the device of a vapor barrier on the inner side of the thermal insulation of ceilings and walls. It is mainly used for rooms such as saunas and baths. Installed "Alukraft" indoors under the clapboard or panels. Fasten it using a stapler and aluminum tape.

Prices for materials for ceiling vapor barrier:

| Name | units rev. | price, rub. |

| Penofol 2000, type A03 | 1 roll (36 m2) | 1270-1410 |

| Armofol type A | m2 | 39-53 |

| Alucraft | 1 roll (18 m2) | 360-540 |

| Alukraft reflective insulation 1.2mh15pm | 1 PC. | 415 |

The side facing the steam influence must be foil-coated. To maintain the high reflectivity of the foil, a gap of 20-30 mm is left between its surface and the facing coating.

- "Izospan V" is a vapor barrier used to protect insulation and structures of a building from saturation with water vapor from inside the room. It is mounted on the inner side of the insulation of insulated roof structures and interfloor ceilings. The material has a two-layer structure. One side is smooth, and the other has a rough surface, which serves to retain condensate and its subsequent evaporation.

The use of modern reliable and convenient materials for vapor barrier ceilings will make it possible to maximally protect the upper floor from damage and extend the maintenance-free period of the entire room. However, in order to improve the performance of the vapor barrier and get rid of condensation, it is necessary to establish good ventilation.

An equally important factor in protecting the curtain from steam is the correct installation of the vapor barrier. How to put a vapor barrier on the ceiling - look at the photo:

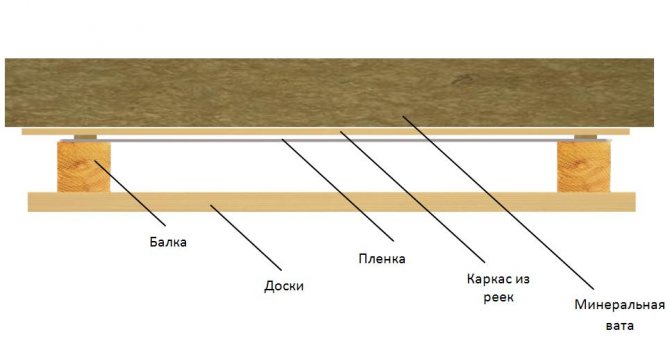

The third mistake is the rejection of moisture and windproof film in the overlap of a cold attic

Having read the article up to this point, you have already figured out the basic principles of vapor insulation of wooden structures and ceilings. Let's move on to the nuances. Another "stumbling block" is the correct pie of a cold attic, for example, the second floor of a country house.

I am finishing making the ceiling of the cold attic. The overlap is insulated. I know that first they install a vapor barrier and only then, between the beams, they put mineral wool. And how to close the insulation on top? The manufacturer's brochure says that a waterproofing vapor-permeable membrane must be installed. Why is she needed there? Maybe just spread the cheap hydro or wind protection?

In my opinion, insulation in a cold attic does not need to be covered with any films at all. Otherwise, you will disable it due to the formation of condensation. Let it lie to itself and lie.

First, let's answer the Bolt41 question.

The manufacturer correctly recommends closing the insulation on top with a waterproofing material - a membrane that allows water vapor to pass through, but does not allow moisture to get into the insulation. Remember that membranes have their own characteristics. First of all, pay attention to vapor permeability. It varies up or down.

Then the next question. Membranes are usually mounted on pitched insulated roofs close to the insulation. Those. water flows down them and does not stay on the surface. And if you lay the membrane horizontally, it will not leak?

If you are concerned that a horizontally laid superdiffusion membrane will leak or leak water due to roof leaks, choose a material with a higher water resistance. The simplest and cheapest vapor-permeable membranes have low water resistance. Therefore, they are laid obliquely, because stagnant water through them will sooner or later seep into the ceiling.

Now let's return to the words of alligator135, that the insulation on top does not need to be covered with films. Is this approach justified?

The stone wool is dusty. Therefore, the insulation should be covered with films on both sides. On the heat side with a vapor barrier, and on the cold side - with a membrane with a high vapor permeability. Over the years, the insulation becomes more and more dusty. Think about your health! In addition, the wind that walks in the attic, and this is necessary for airing the under-roof space, blows heat out of the fibers of the mineral wool. If the insulation is closed, then it, like a heat barrier, works more efficiently than uncovered with a film.

I ended up with the following cold attic pie, bottom-up:

Important! In a cold attic, cover the top of the insulation with a vapor-permeable moisture-proof membrane, which additionally protects the insulation from wind and moisture, and you from inhaling stone wool particles.