The roof is the final element in the construction of any building. To ensure its protection from atmospheric precipitation and winter freezing, it is necessary to perform a high-quality "roofing pie". It includes a covering (roof), insulation, hydro and vapor barrier.

Roof waterproofing and vapor barrier are designed to prevent moisture and steam from penetrating into the insulation layer. These elements of the "roofing pie" must be placed in the correct sequence in order to exclude high humidity in the room and the need for repairs during operation.

Floor protection

In the case when the floor is installed directly on the ground, use a special anti-condensation film or sheets.

If there is a basement under the floor with high humidity, as well as in cases of possible sudden temperature changes, an aluminum-sprayed vapor barrier with special reflective membranes would be the best option.

Rules for laying vapor barrier material

The installation of a vapor barrier film is a serious task carried out in stages:

- A decision is made regarding the method of stacking the material. Installing the foil horizontally starts from the top of the roof. There are no special requirements for vertical stacking of material.

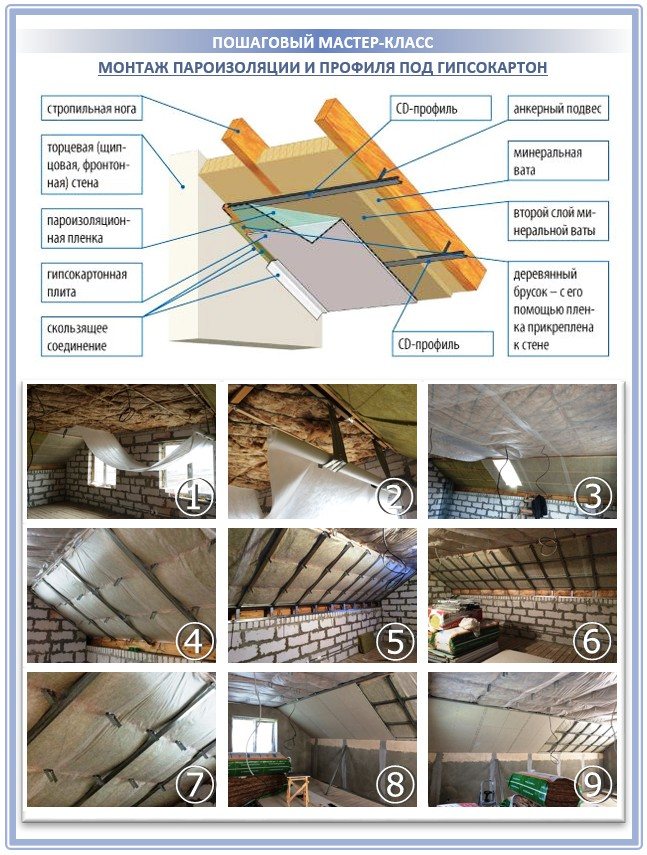

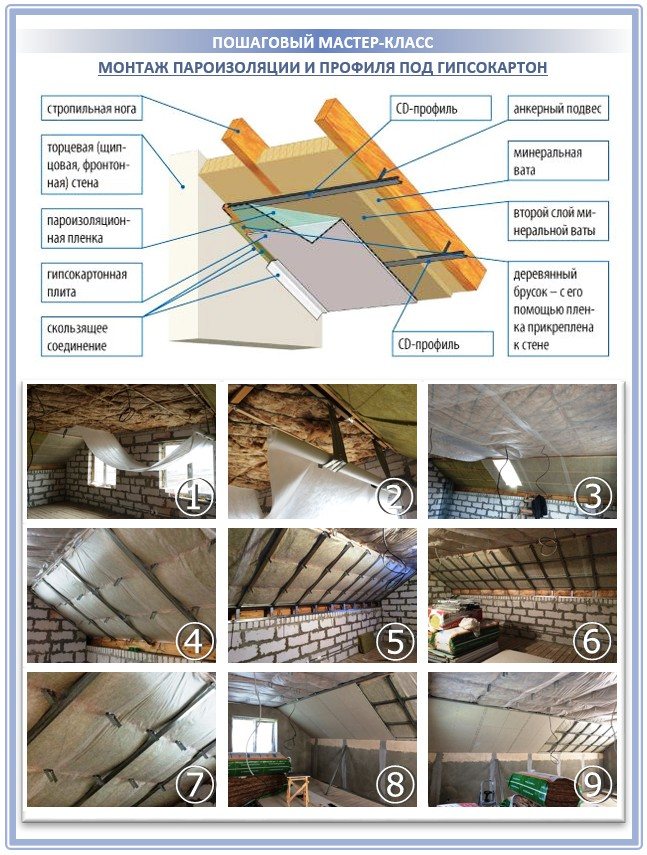

- A piece of vapor barrier sheet with a smooth surface is applied to the rafter beams from the attic side. Nails with large heads are driven into wooden elements through a vapor-proof material. If you want to speed up and simplify the process of fixing the film, they use not nails, but staple staples.

A construction stapler is used instead of nails. - The second piece of material is applied to the rafter legs so that its edge is in contact with 10 cm of the first piece. The seams formed by joining two pieces of film are sealed with adhesive tape. When installing a vapor barrier material along the rafter beams, in the absence of a rough lining of the insulation, the pieces of film are superimposed on each other only in the place where the rafters are located.

- The bonding zones of the material are fixed with clamping strips. These fasteners are especially needed in a situation where the installation of the film is carried out under a roof with a slope of up to 30 degrees, and the installed insulation is not very dense. In areas where the vapor barrier material is located near dormers, hatches and other openings to the outside, a vapor barrier apron is used, which is always included in their kit.

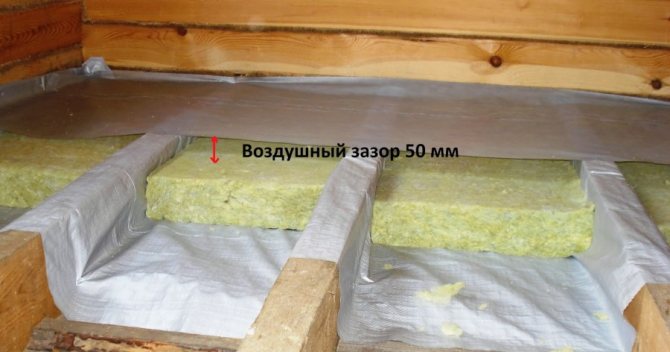

- On top of the film material, thin slats made of wood treated with an antiseptic are attached every 50 cm, from which a crate will be obtained for fixing finishing materials. As a result of this, a gap of 2 to 5 cm will appear between the vapor barrier and the interior trim of the roof. This is necessary to create natural ventilation.

When laying a vapor barrier under drywall, proceed according to the standard scheme

According to SNiP III-B. 12–69, during the installation of the vapor barrier, the insulation must not be moistened.

Roof protection

When choosing a vapor barrier for a roof, it is necessary to build on the type of roof. In this case, the thermal conductivity of the roofing material is of paramount importance.

Distinguish floorings with low thermal conductivity, in particular, they include:

- Roof tiles;

- Slate;

- Onduline and onduville coating;

- Bitumen compound coating.

For such a roof, a vapor barrier with diffusion membranes is used, while it is supplemented with a ventilation gap.

For roofs made of metal, profile iron and other types with heat-conducting coatings, vapor barrier is made on the basis of anti-condensate waterproofing. To screen condensate from the inside of the metal roof, use a film.

Important points when choosing a vapor barrier

The choice of vapor barrier for a flat structure should be made by the designer. The following points are taken into account:

- temperature zone of the location of the building;

- roofing cake construction;

- type of roof operation.

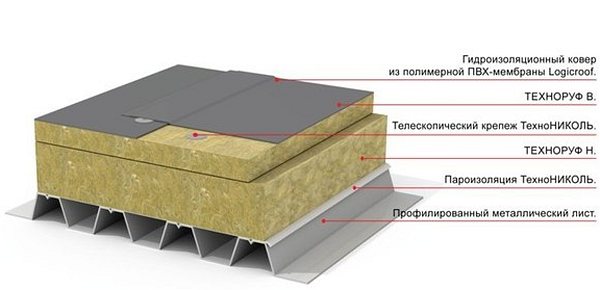

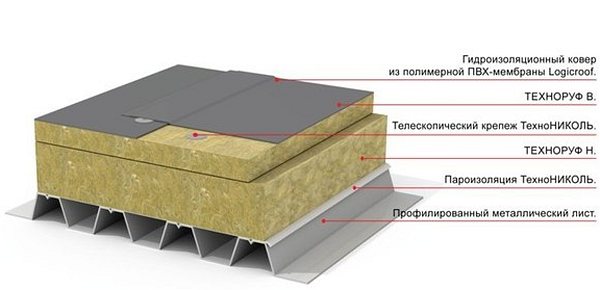

In the case of installing a new roof on an insufficiently dried base or directly on top of an old coating, the base does not belong to a vapor barrier. Steel profile cannot serve as a vapor barrier either. Despite its integrity, moisture can penetrate through the cracks in the areas of fasteners and joints.

Requirements for vapor barrier of flat structures and rules for its construction

- The main requirement for a vapor barrier system is absolute tightness. The material used for this purpose must be firmly sewn or welded.

- In modern construction, the roofing base is increasingly being created on the basis of steel profiled sheets to increase the level of fire safety at home. In order to achieve the highest resistance of the roof to the effects of fire, vapor barrier (in particular, bituminous) materials are located between the insulation layer and the profiled sheet.

- For the device of a vapor barrier, materials with a degree of incombustibility G2 should be used. To create the bottom layer, completely non-combustible materials can be used. In this case, the vapor barrier layer should pass in the middle, between the heaters. It can be arranged on the basis of bitumen-polymer materials. To increase the fire resistance, only mechanical fastening of the insulation layer should be used.

In areas of contact between the roof and the wall, the vapor barrier is wrapped on the wall so that it goes beyond the boundaries of the insulation. The vapor barrier material is glued to the wall and clamped from above using galvanized strips. This is done to increase the reliability of the fastening. In all areas of the connection, the vapor barrier must firmly adhere to all protrusions, irregularities, and component parts of the flat roof structure.

Vapor barrier parameters

In addition to knowing the types and materials of vapor and condensate protection systems, it is important to know and understand what vapor barrier characteristics exist and how they affect the choice. Let's list the main ones:

The most important parameter is vapor permeability. In general, this indicator determines the overall ability of the protection to effectively shield the space from steam. The vapor permeability index is measured in grams per square meter per day. The lower this coefficient is, the higher the quality of the barrier will be.

Durability. It would be unnecessary to explain the meaning of this parameter. Note that it is from the mechanical strength of the material, heat resistance, the ability to stretch and resistance to tearing.

The highest durability is possessed by a vapor barrier made of artificial materials with a protective coating.

Cost. This parameter depends on the quality of the vapor barrier material and its mechanical properties, as well as on the geometric dimensions, and therefore it is necessary to correctly approach the assessment of the area and analyze how and how much material is required.

It is important to remember that a well-planned system of protection of building structures from various mechanical, weather and other conditions will guarantee its durability, and therefore it is necessary to approach these issues with due attention.

What is a roof vapor barrier for and what functions does it perform?

The vapor barrier material is a special sheet that must be included in any roofing pie. Of course, if the construction is temporary, then you can do without this material, but in other cases you will have to acquire them.

As you know from the school physics curriculum: warm air rises, and cold air sinks to the floor. This can be clearly seen if in the winter season you open a window in the kitchen. Cold air will "flow" down the windowsill and spread across the floor. As for the warm mass, it will tend upward, towards the interfloor overlap.

Each of you was present in the kitchen when cooking, and you know that a large amount of steam is emitted from the stove during the cooking process. The humidified air has a high temperature, therefore, it will constantly be in the upper part of the room. This is an ordinary routine of life, and only some of the residents throw their heads back, look at the ceiling and ask themselves the question: "Will moisture really be here forever?"

According to the laws of the same physics, moisture has a unique ability to condense, i.e. settle on the warmer side of any element. Misted windows are an example. Now, let's go back to our floor slab. Here, droplets accumulated on the ceiling will perform a similar trick with condensation. This is how moisture will get into the attic and, alas, it is impossible to get rid of it. If you cannot get rid of something, then only the struggle remains, namely: to arrange a vapor barrier layer.

The vapor barrier material performs the following functions:

- Does not allow moisture to affect the thermal insulation layer. Almost all modern coatings have high thermal conductivity. This suggests that a large amount of heat will leave the living quarters through the roof. Of course, if you put insulation in a roofing cake, this problem will disappear, but a new one will arise. The overwhelming majority of thermal insulation products are afraid of water and when it gets into this layer, they simply lose their properties.

- Due to the fact that the blocking of water will be carried out below the coating, it will remain on the roof longer. This fact is especially important for metallic materials, for which moisture is the very first enemy.

- In addition to metal elements, there is a large amount of lumber on the roof, and wood tends to rot. Installing a vapor barrier will help reduce humidity in the attic and reduce its impact on surrounding materials.

When purchasing roofing materials, carefully read the recommendations for its use. It may turn out that the selected product is simply not suitable for use in your area. Often, such errors lead to accelerated formation of condensation and, as a consequence: the destruction of the roofing part of the building.

Composition of vapor barrier coatings

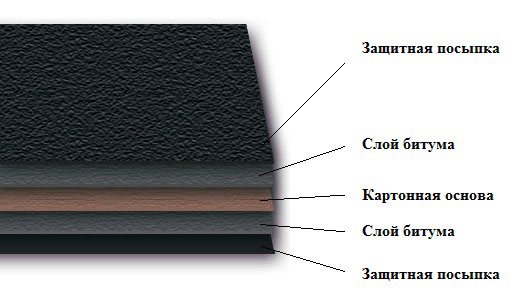

More recently, vapor barrier, like waterproofing a flat roof, was carried out exclusively with roofing material and glassine. Some builders and homeowners still use these materials to save money. However, such savings are costly: in just a few years, there may be a need for repairs.

In principle, roofing felt vapor barrier can be used, but when installing roofs of structures that do not need a high level of reliability: utility buildings, garages, etc. It is recommended to use it as an auxiliary material rather than the main one. In many cases, roofing material is quite suitable for flat roofing.

Vapor barrier membranes and films

Today, a fairly wide selection of modern vapor barrier materials is provided for roofing. These include new vapor barrier membranes and films.

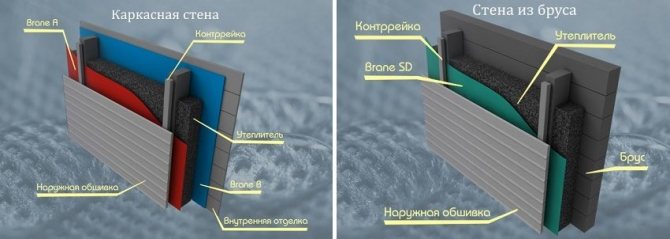

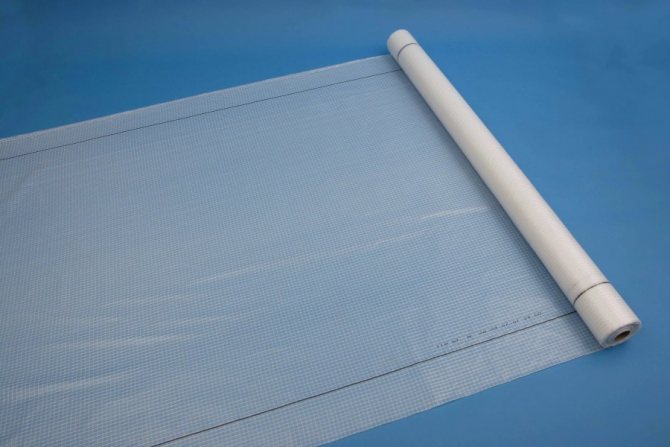

The latest generation of polymer membranes is a multi-layer material that is characterized by increased strength and excellent performance. Vapor barrier materials based on polypropylene or polyethylene are reinforced in almost all cases.

When installing membranes, builders use a fairly advanced technology for joining seams to each other using a stream of hot air. The advantages of this method are speed, increased safety, and excellent results.

Bitumen membranes are an excellent choice for vapor barrier concrete-based flat roofs. They are fused onto a concrete base. The material is flexible and capable of self-healing in areas of fracture or deflection. When used, even the attachment areas become impermeable due to the fact that the bitumen completely envelops them.

They are not susceptible to damage due to unevenness of the concrete base. High quality material is offered by Bikroelast, TechnoNICOL, Linokrom, Bikrost. A significant disadvantage of bituminous material is its significant specific gravity.

Recently, non-perforated vapor barrier films have become very popular, which are widely used in the creation of both flat and pitched structures with various coatings:

- reinforced polymer-based fabric;

- reinforced films with double-sided lamination and a screen based on aluminum foil, the function of which is to reflect heat into the interior of the living space.

Laminated membranes are attached directly to the insulation layer from the inside of the room. At the same time, a 4-6 cm distance from the inner lining is maintained: it is necessary for ventilation, since condensation can occur directly on the film due to the effect of vapors rising from the room.

Films come in various densities, differ in the level of flammability and resistance to the effects of ultraviolet radiation. The material used in them is completely safe for health, resistant to the development of mold and does not rot.

To remove excess moisture from the insulation layer, the latest generation anti-condensation material is used - anti-condensation films. They are made on the basis of a fleecy fabric, on the inner side of which a special absorbent layer is applied, which retains the accumulated moisture and contributes to its rapid weathering. The film should be in contact mainly with air, and not with a hard surface - otherwise, it loses its performance.

When choosing a vapor barrier, you should pay attention to the highest quality material - super diffusion breathable membranes... The distinctive properties of this ultra-thin material (layer thickness is from 0.2 mm) are lightness, strength, long service life of 30-50 years.

A super diffusion vapor barrier can have two or three layers.

The two-layer material consists of a polypropylene fabric and one layer of a polyethylene laminate.

The basis of the three-layer vapor barrier is mesh polypropylene laminated on both sides with polyethylene film.

Today's construction market also offers modified versions of membranes with an additional effect, designed for specific operating conditions.

Vapor barrier for flat roofs with metal sheathing. This design is subject to significant surface overheating. For this reason, for seam roofs, as well as roofs with a coating based on metal tiles, profiles, films are used that do not lose their quality characteristics under the influence of high temperatures.

Applying reflective vapor barrier it is advisable in the case of the presence of powerful convection flows and if it is necessary to keep the maximum possible amount of heat in the room. The matallized type coating perfectly reflects the heat rays, which are characterized by increased intensity. These materials are the ideal choice for a sauna or steam bath.

High strength films are used when constructing roofs of the exploited type. They are an excellent alternative to roofing material, moreover, they are less thick.

Vapor barrier material Izospan

This material of the latest generation creates a reliable vapor barrier and serves as an excellent protection of the insulation layer and supporting building structures from damage due to condensation.

The installation of the vapor barrier is carried out on the inner side of the thermal insulation coating. The two-layer structure of the material provides reliable protection of the insulation and retains thermal energy in the building structure.

One surface of Izospan is distinguished by a smooth texture, and the other has a roughness, due to which condensate drops are held on it with subsequent evaporation.

The material prevents the development of mold, fungi that can cause significant damage to the wooden elements of the roofing structure, and serves as an excellent protection of metal parts from corrosion.

Installation of Izospan is carried out on the supporting parts of the frame on the inner side of the heat-insulating layer. Fastening can also be carried out on the rough sheathing using a simple stapler. The work takes little time, and the result is excellent during the operation of the roof.

The use of Izospan minimizes the probability of penetration of particles of thermal insulation with a fibrous structure into the interior of the room.

Why are green roofed houses good? Answers on our website.

Read about the seam roofing device, price and materials here.

Useful information about brick gables can be found in the article.

Roof waterproofing: device, installation, films

As mentioned above, waterproofing is essential to the comfort of living in a home. DWaterproofing acts both as a barrier against the ingress of atmospheric moisture to the insulation, and acts as an obstacle against condensation, which is formed as a result of warm air entering the cold surface of the roofing. Without a waterproofing coating, moisture forms even in the most sealed roofs. This water will collect in the insulation, reducing its thermal insulation properties to a minimum. The waterproofing material is laid over the insulation so that a gap remains between it and the outer roofing material.

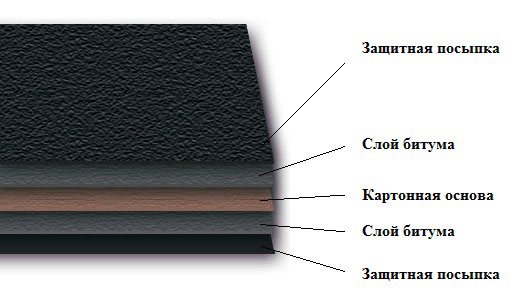

Roofing material structure.

Roofing material was previously recommended as a waterproofing layer. The disadvantage of roofing material is its fragility. Under the influence of natural factors, the bitumen contained in this material begins to deteriorate, losing its protective properties. Now, as a result of innovative technologies, new modified materials are being produced - analogues of roofing material. Also, the newest roofing membranes began to enter the market, which gained great popularity among consumers. Film membranes are based on glass or synthetic fibers ("polyester") in the form of fabrics or non-woven fabrics.

Membranes are panels 1000 mm wide, 1.0 - 6.6 mm thick. These materials are rolled into rolls, and their length is 7 - 20 m. Film materials based on "polyester" have high elasticity and high elongation at break - 45 - 50%. The name "membrane" came to our country from Western countries that widely use insulating panels in construction technologies.

The range of waterproofing materials is quite wide.They are classified according to the basis of the material, structure and component of the coating composition. The structure of the membrane can be single-layer or multi-layer, the base of the fibers can consist of one component or be combined. In roofing technologies, a film based on polyvinyl chloride has proven itself well.

Non-woven membranes are called "breathable" because they have the property of simultaneously not allowing atmospheric moisture to pass through and allowing steam to escape from the insulation. "Breathing" membranes are diffusion and superdiffusion.

Superdiffusion membranes perform a very important function for the roof: they allow vapors to pass through themselves, but do not allow water from the upper layer of the roof to pass through. This material is so vapor-permeable that it is installed close to the insulation, without a gap, thus reducing the thickness of the "roofing cake". Their vapor permeability is 1200 g / kV.m per day.

For mineral wool insulation, such a membrane is also a wind protection, therefore, this waterproofing material prevents heat loss of the dwelling through the roof. Superdiffusion membranes are available for single-sided and double-sided applications. Installation of single-sided films occurs when they are laid on the rafters with a certain side outward. Double-sided films can be installed on both sides.

Diffusion breathable membranes are reinforced polyethylene or polypropylene films with perforations in the form of the smallest holes. Steam passes through the holes in the membrane, but external moisture does not penetrate into the "roofing cake". The vapor transmission capacity of diffusion membranes is much lower than that of superdiffusion membranes, therefore it is incorrect to lay them directly on the insulation itself. Installation of these membranes requires the required air gap between the insulation and the waterproofing and the gap between the waterproofing and the roofing.

All insulating films must be flame retardant, resistant to sunlight and tear resistant. Experts say that the waterproofing is done correctly if it is located under the entire roof covering completely, including under the gable and eaves.